Cleaning machine for waste floating on water surface

A water surface floating and cleaning machine technology, applied in the field of sanitation machinery, can solve the problems of affecting the normal operation of the waterway operation generator set, breaking the regional ecological balance, unsatisfactory cleaning effect, etc., achieving the scope of environmental protection and energy saving, improving the scope of salvage, and having a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

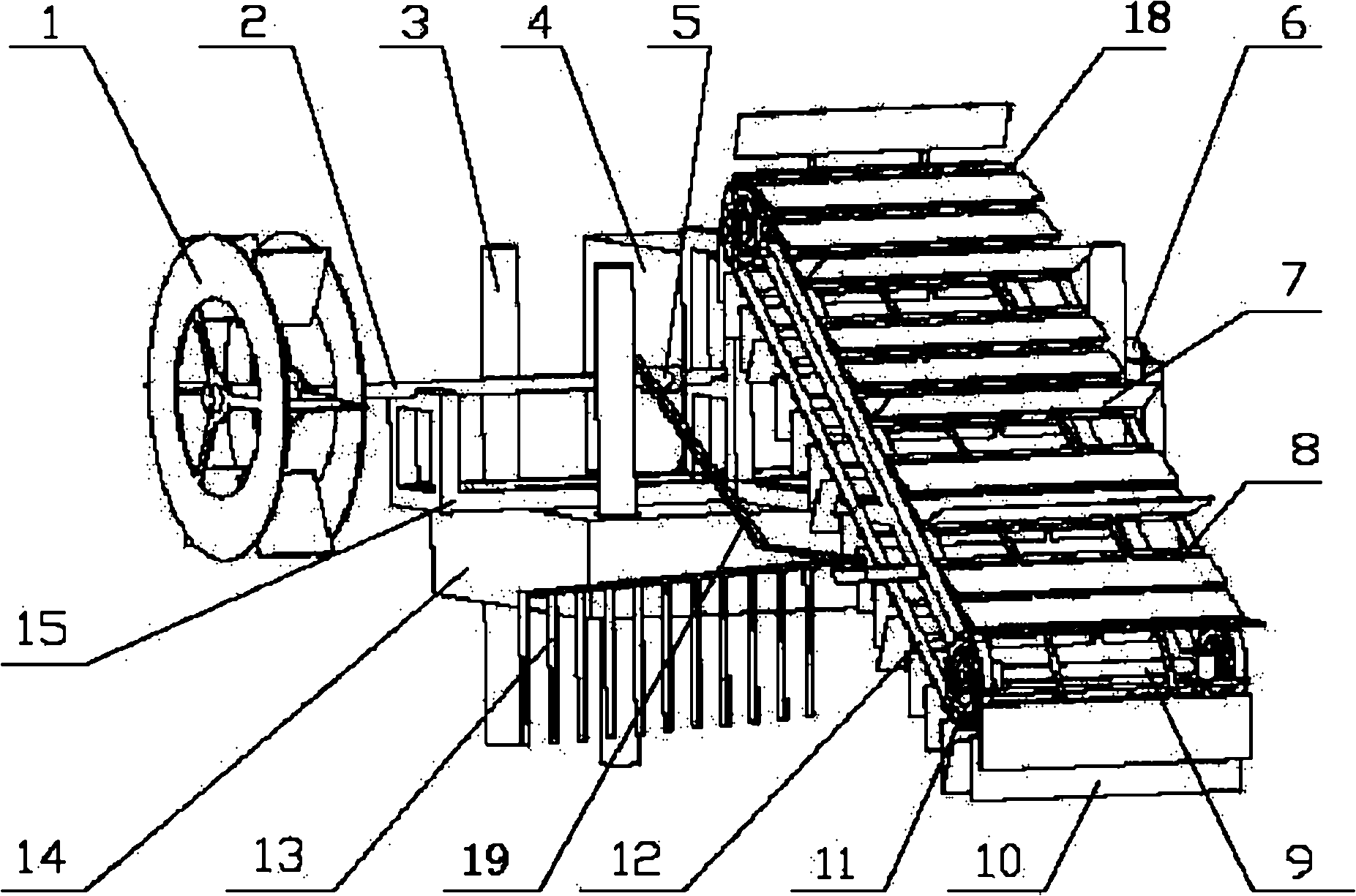

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

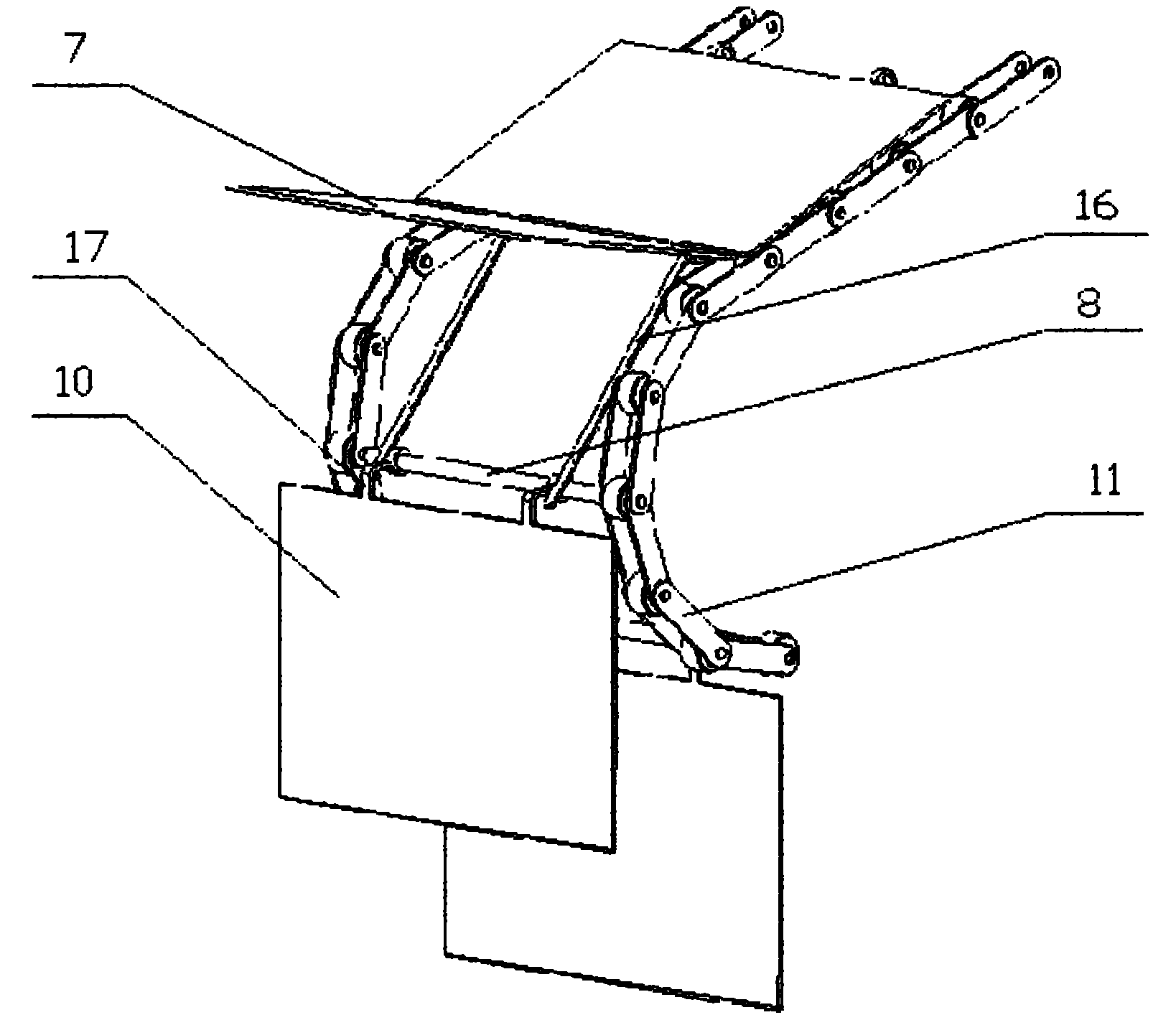

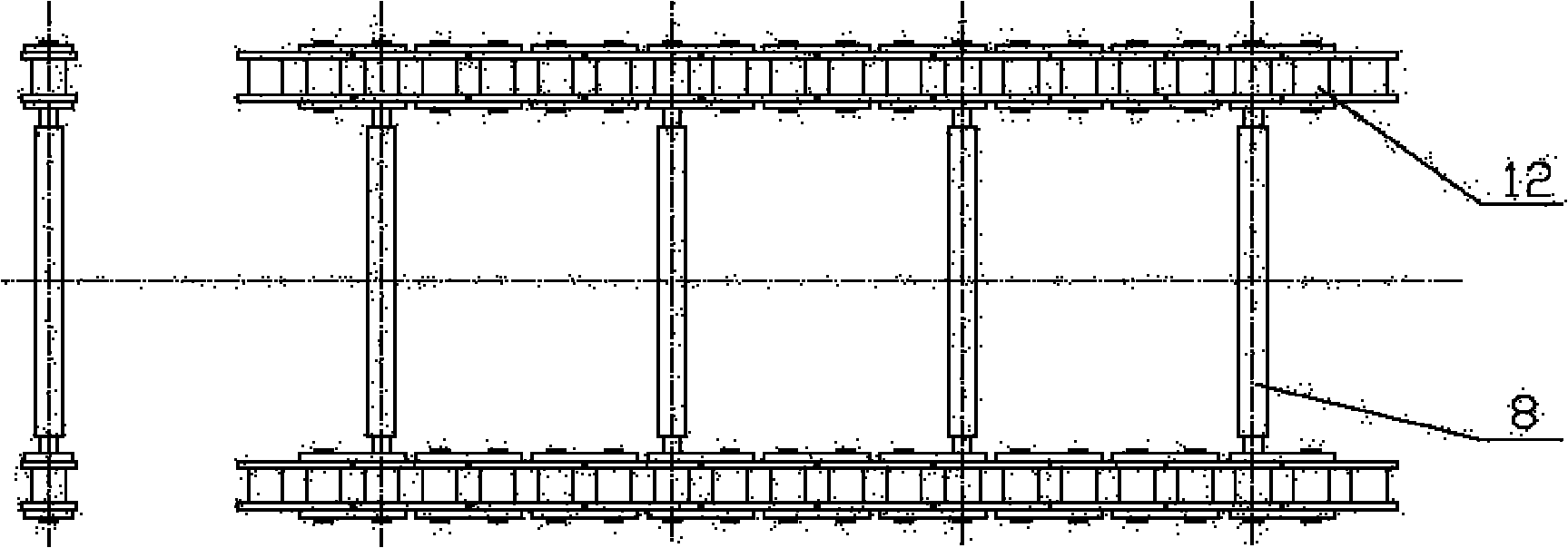

[0023] see figure 1 , figure 2 and image 3 , the floating platform 14 movable sleeves are interspersed in the four columns 3, the frame 15 is fixed on the floating platform 14, the floating platform 14 is provided with a dustbin 4, the floating platform 14 is provided with a transport frame 18, and on the transport frame 18 A connecting shaft 9 and a sprocket 11 are provided, and two parallel synchronous conveyor chains 12 are arranged on the sprocket 11. The parallel synchronous conveyor chains 12 are connected to the two parallel synchronous conveyor chains with a long axis 8 every certain number of links. Between 12, on the parallel synchronous conveying chain 12, there are mesh conveying boards 10 and mesh lifting boards 7 alternately, one side of the mesh conveying board 10 is hinged to the parallel synchronous conveying chain 12 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com