Method for fabricating PVC (polyvinyl chloride) color painted floor

A production method and floor technology, applied in chemical instruments and methods, coatings, building elements, etc., can solve the problems of insufficient adhesion between PVC wear-resistant layers and PVC foamed layers, pattern deformation, and impact on aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

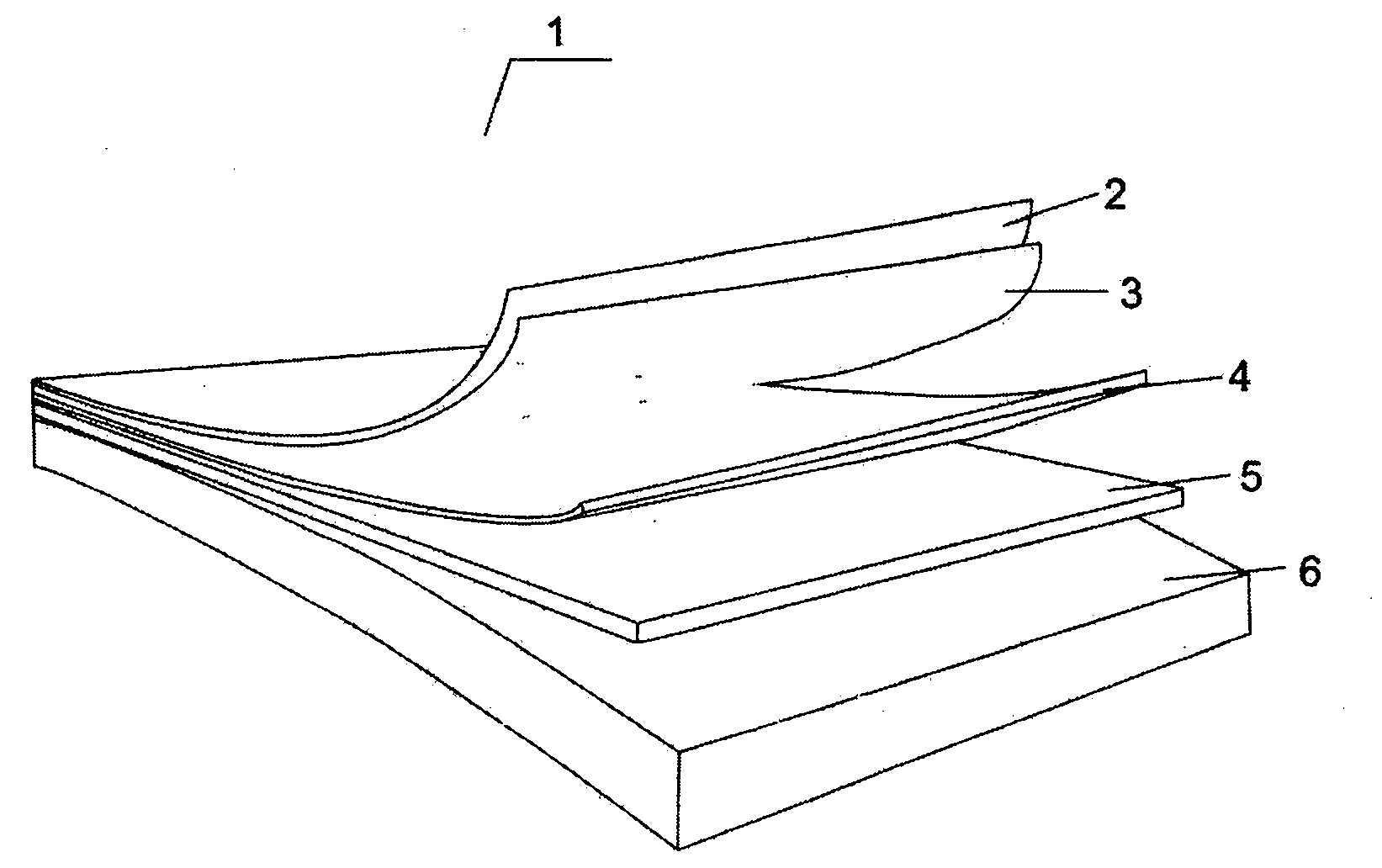

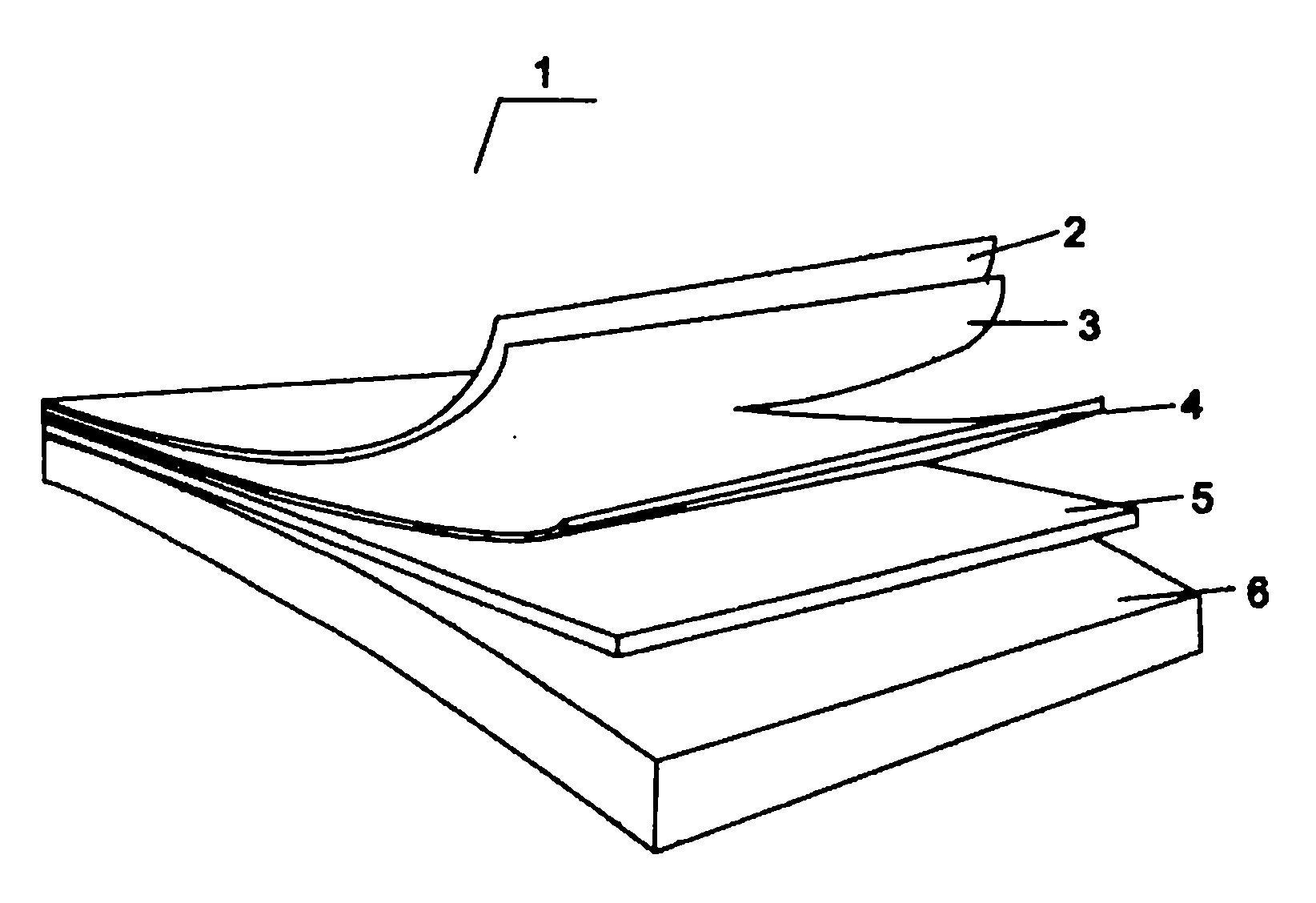

[0008] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0009] Preferably, a method for making a PVC painted floor, the steps comprising: (1) sending the painted PVC plastic transparent layer into a light curing machine for surface treatment to generate a PVC plastic transparent UV wear-resistant layer; (2) The back of PVC plastic transparent UV wear-resistant layer is coated with activating agent for activation treatment, and then sent to a special spray painting machine for special pigment spraying to generate various colorful patterns; (3) Coating activator activation treatment for PVC plastic foam layer, Send the spray-painted PVC plastic wear-resistant transparent layer and PVC plastic foam layer into a laminating machine with a high temperature of 130°C to 160°C for bonding.

[0010] The PVC painted floor made by the above-mentioned production method is sprayed on the surface of the PVC plastic foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com