Gasoline engine igniter controlled by single-chip microprocessor (SCM)

A single-chip microcomputer control and igniter technology, applied in the direction of automatic control, automatic control, electrical automatic control, etc., can solve the problems of unstable current and low ignition current, and achieve the effect of improving stability and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

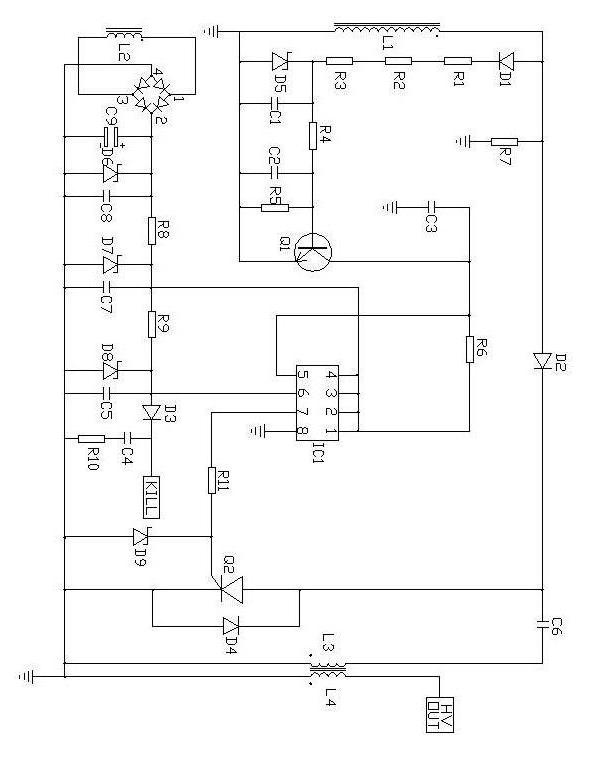

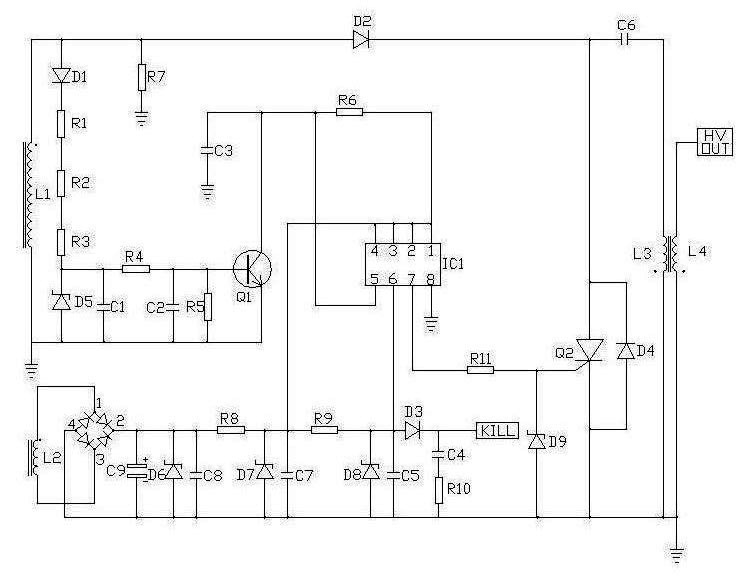

[0019] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, in this embodiment, the gasoline engine igniter circuit includes a single-chip microcomputer chip power supply circuit, a signal trigger circuit, a capacitor discharge ignition circuit and an igniter flameout function circuit, and the single-chip microcomputer chip power supply circuit provides the necessary working voltage for the single-chip microcomputer chip to work. The signal trigger circuit uses another inductor and its back-end circuit to realize the generation of the trigger signal, which does not interfere with the power supply circuit. Then, when the single-chip microcomputer chip is working normally, after receiving the trigger signal, the single-chip microcomputer chip outputs the trigger level. Make the igniter work and ignite.

[0021] In the signal tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com