Patents

Literature

31 results about "Capacitor discharge ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capacitor discharge ignition (CDI) or thyristor ignition is a type of automotive electronic ignition system which is widely used in outboard motors, motorcycles, lawn mowers, chainsaws, small engines, turbine-powered aircraft, and some cars. It was originally developed to overcome the long charging times associated with high inductance coils used in inductive discharge ignition (IDI) systems, making the ignition system more suitable for high engine speeds (for small engines, racing engines and rotary engines). The capacitive-discharge ignition uses capacitor discharge current to the coil to fire the spark plugs.

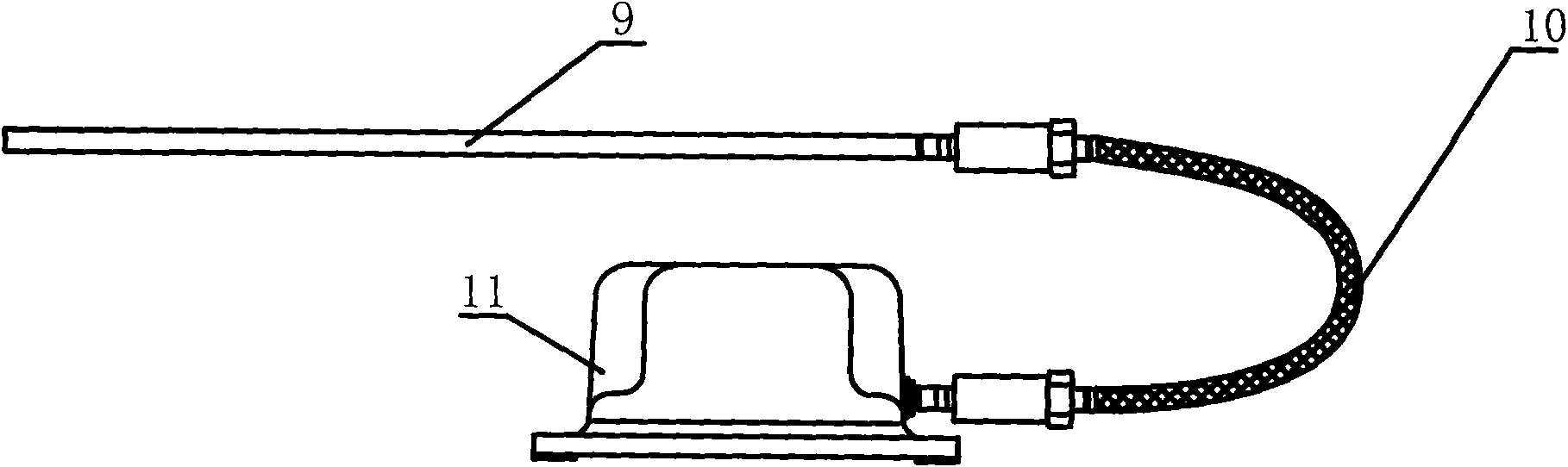

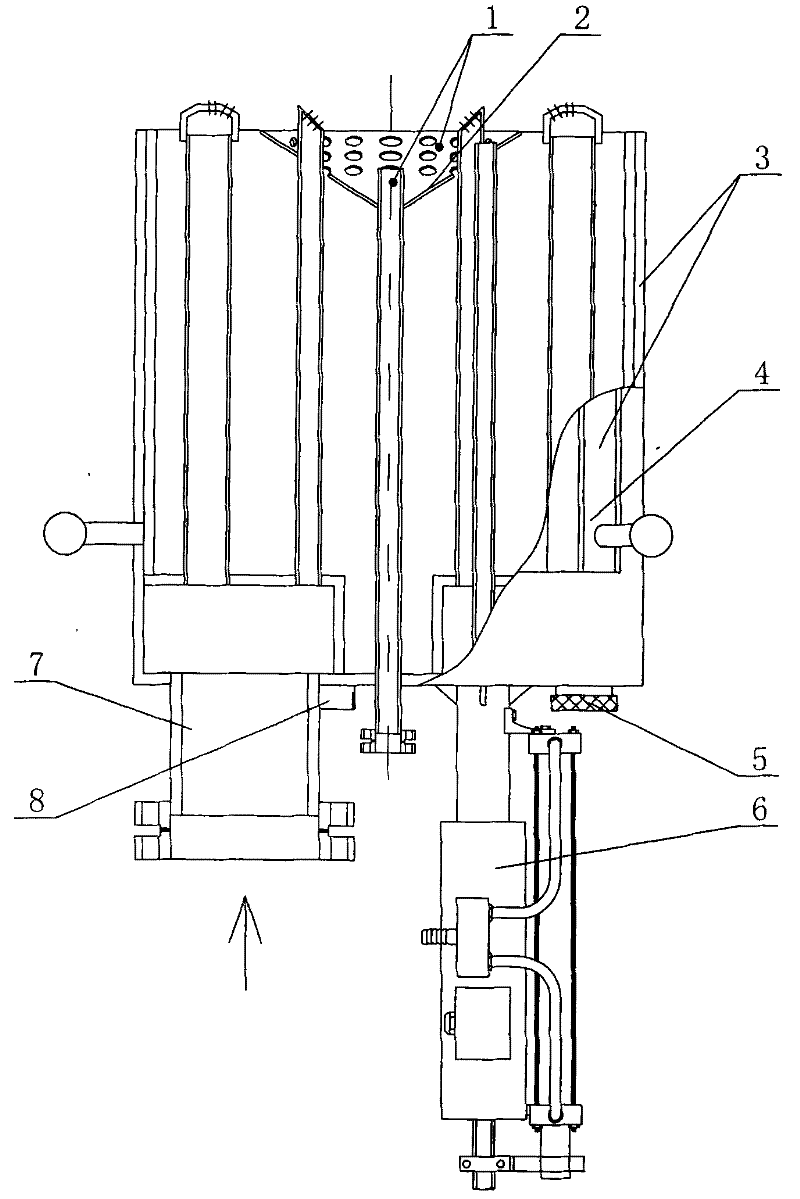

Ignition control system of tube furnace

ActiveCN101576314AEnsure reliabilityMake sure to installFuel supply regulationElectric spark ignitersCapacitanceHigh energy

The invention relates to an ignition control system of a tube furnace. The system comprises a high-energy ignition device, a burner, an automatic ignition control system and a burning control system, wherein the high-energy ignition device adopts a capacitive discharge type igniter capable of providing the safe and reliable ignition performance; the burner is provided with a flame detection device and can realize the regulation of burning-supporting air and fuel in certain proportion; and the automatic ignition control system has the functions of flame detection, safety protection of the furnace and self diagnosis. The invention has the advantages of high heat efficiency, safety and reliability, stable and controllable burning, energy saving and emission reduction.

Owner:ACRE AUTOMATION CO LTD MCC

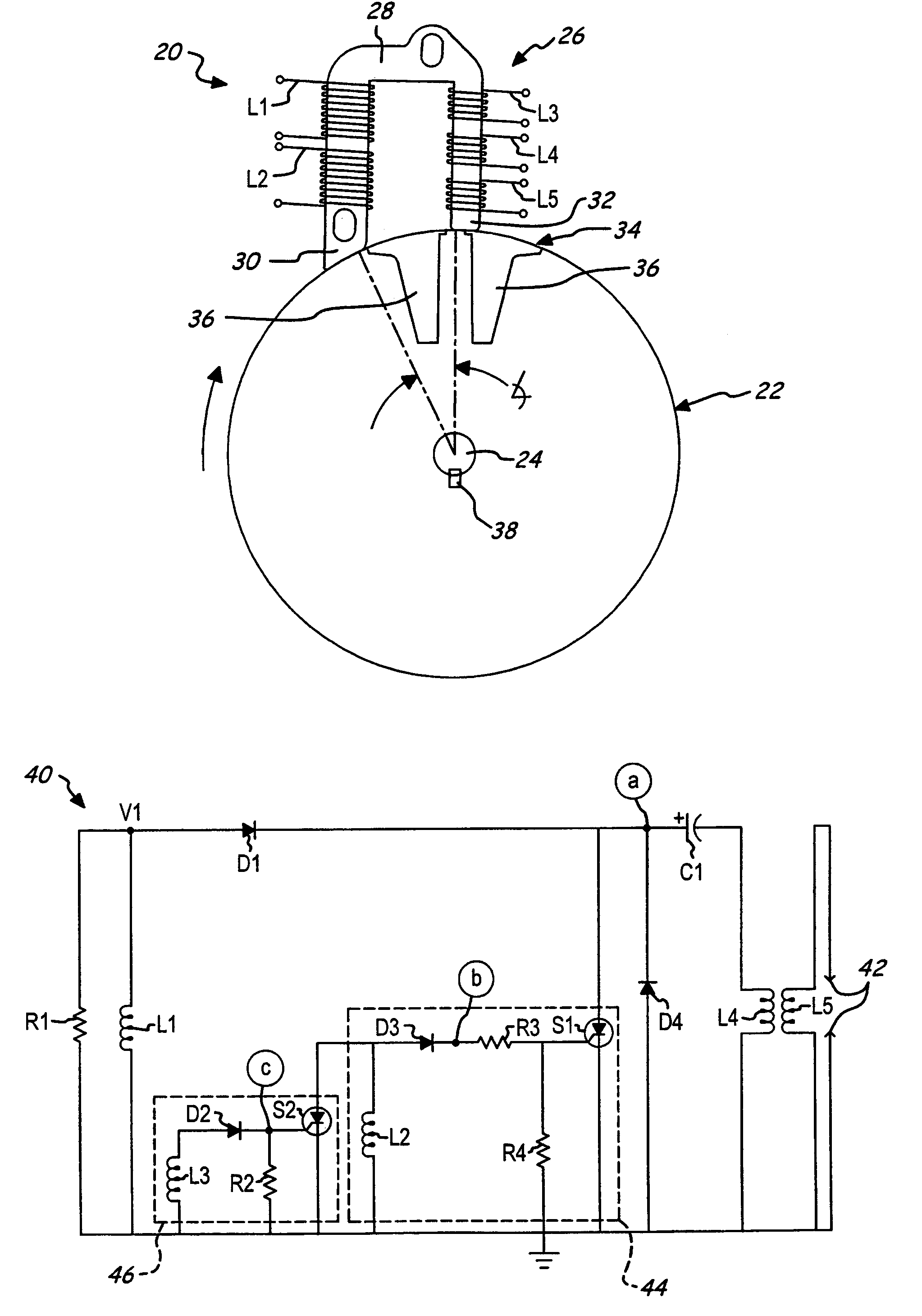

Capacitor discharge ignition

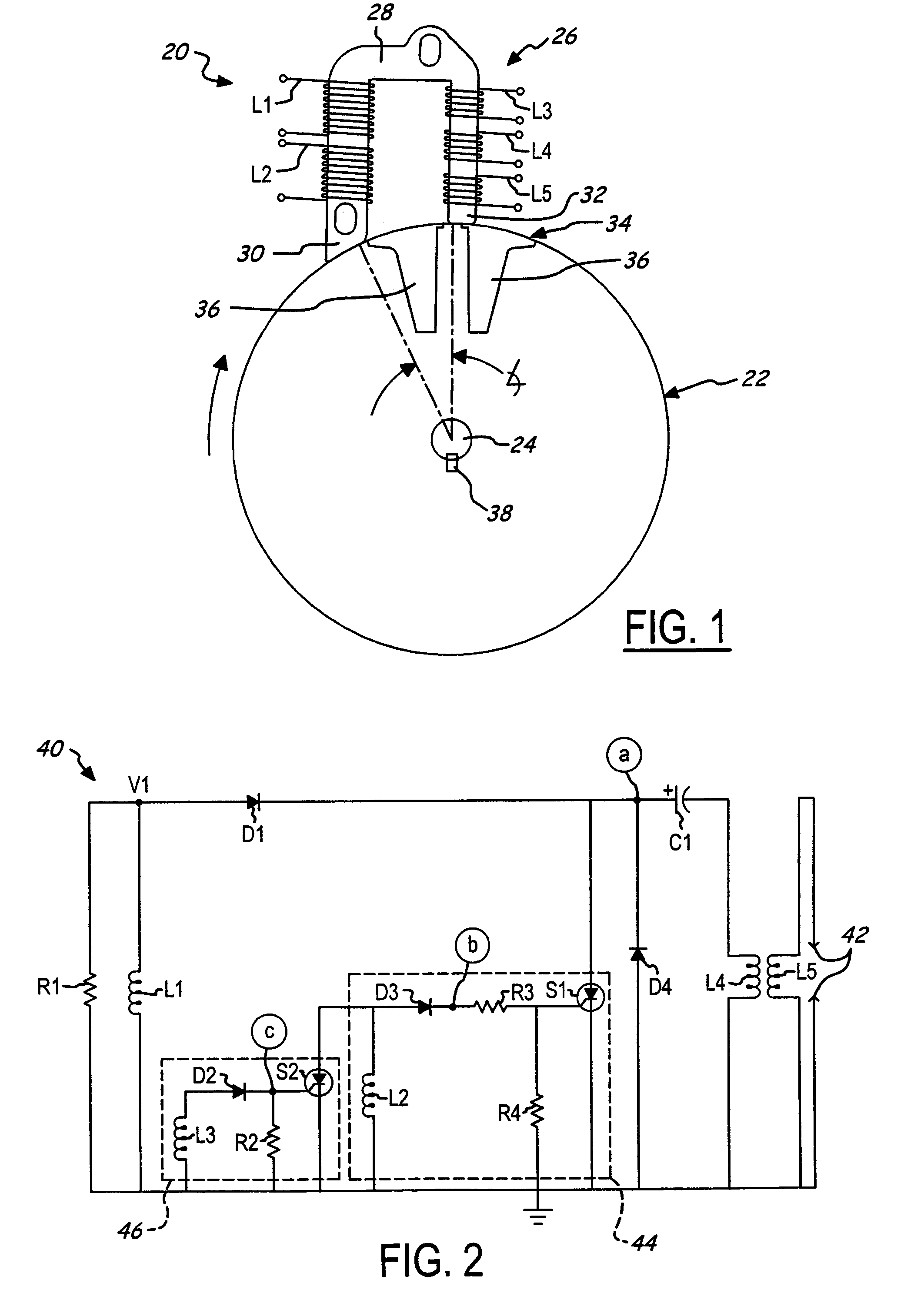

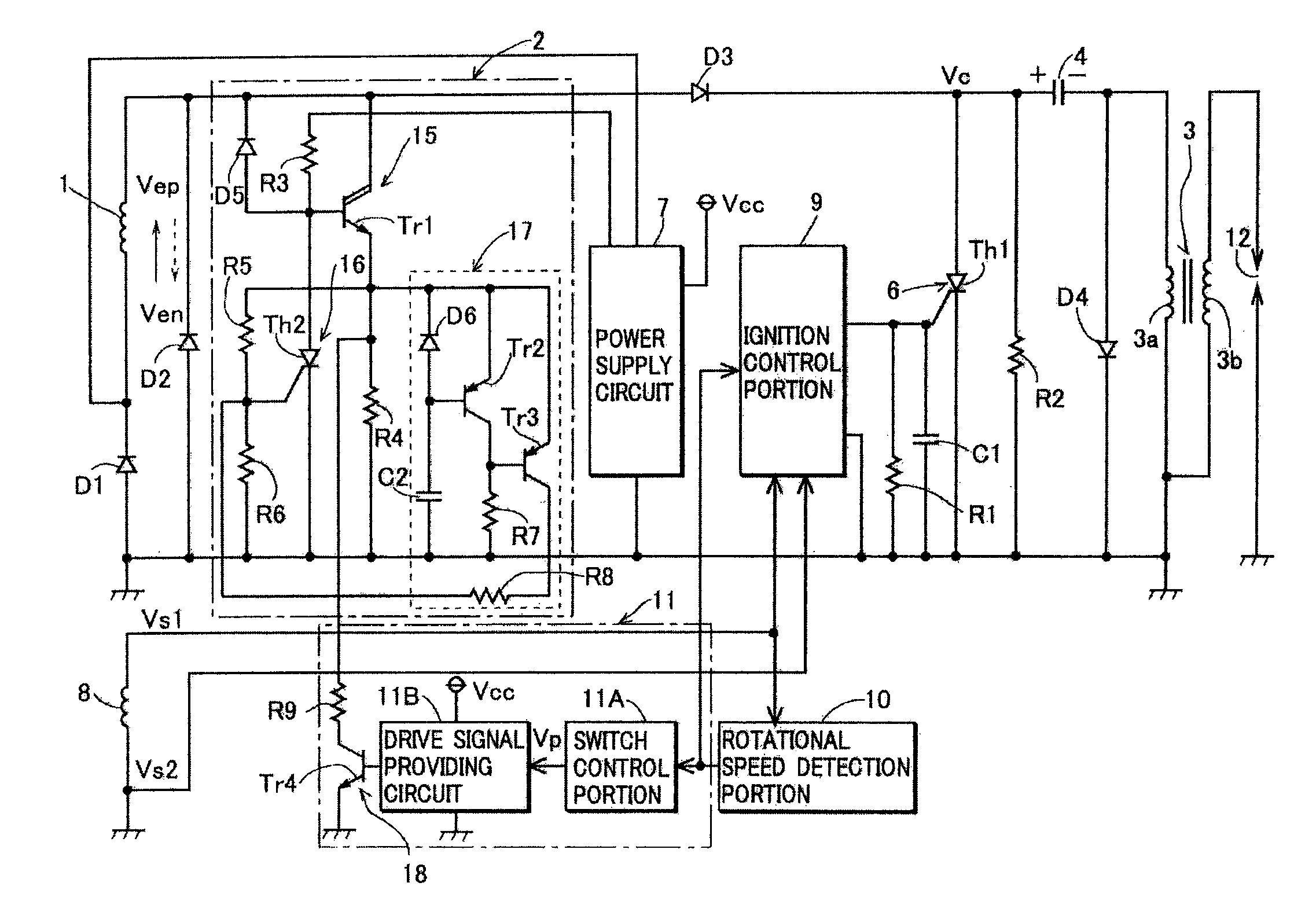

InactiveUS6932064B1Prevent reversalReduce stepsMachines/enginesIgnition circuit layoutsLow speedCapacitor discharge ignition

A capacitor discharge ignition (CDI) system includes a trigger circuit that generates a trigger signal in synchronism with operation of an engine for discharging an ignition capacitor. A timing circuit is connected to the trigger circuit for controlling the timing of the trigger signal and includes a timing coil for generating a timing signal in synchronism with operation of the engine. The timing circuit further includes a switch that has primary electrodes connected to the trigger circuit and a control electrode coupled to the timing coil for shorting the trigger circuit as a function of engine speed. The CDI system is thus capable of advancing engine timing to enable low-speed startup. The timing circuit is further adaptable to provide skip-spark speed-governing, timing retard speed-governing, and anti-reverse rotation of the engine.

Owner:WALBRO ENGINE MANAGEMENT

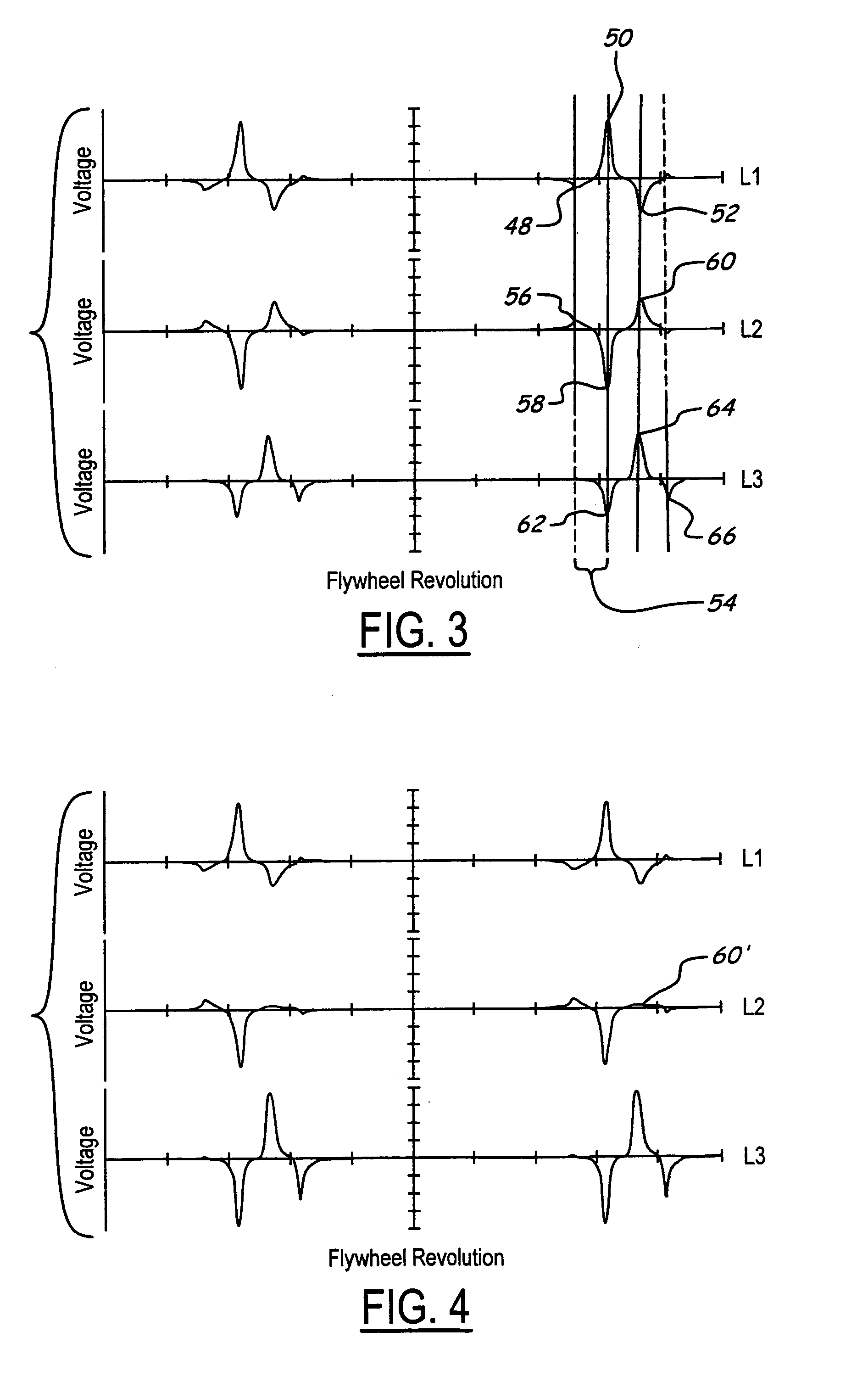

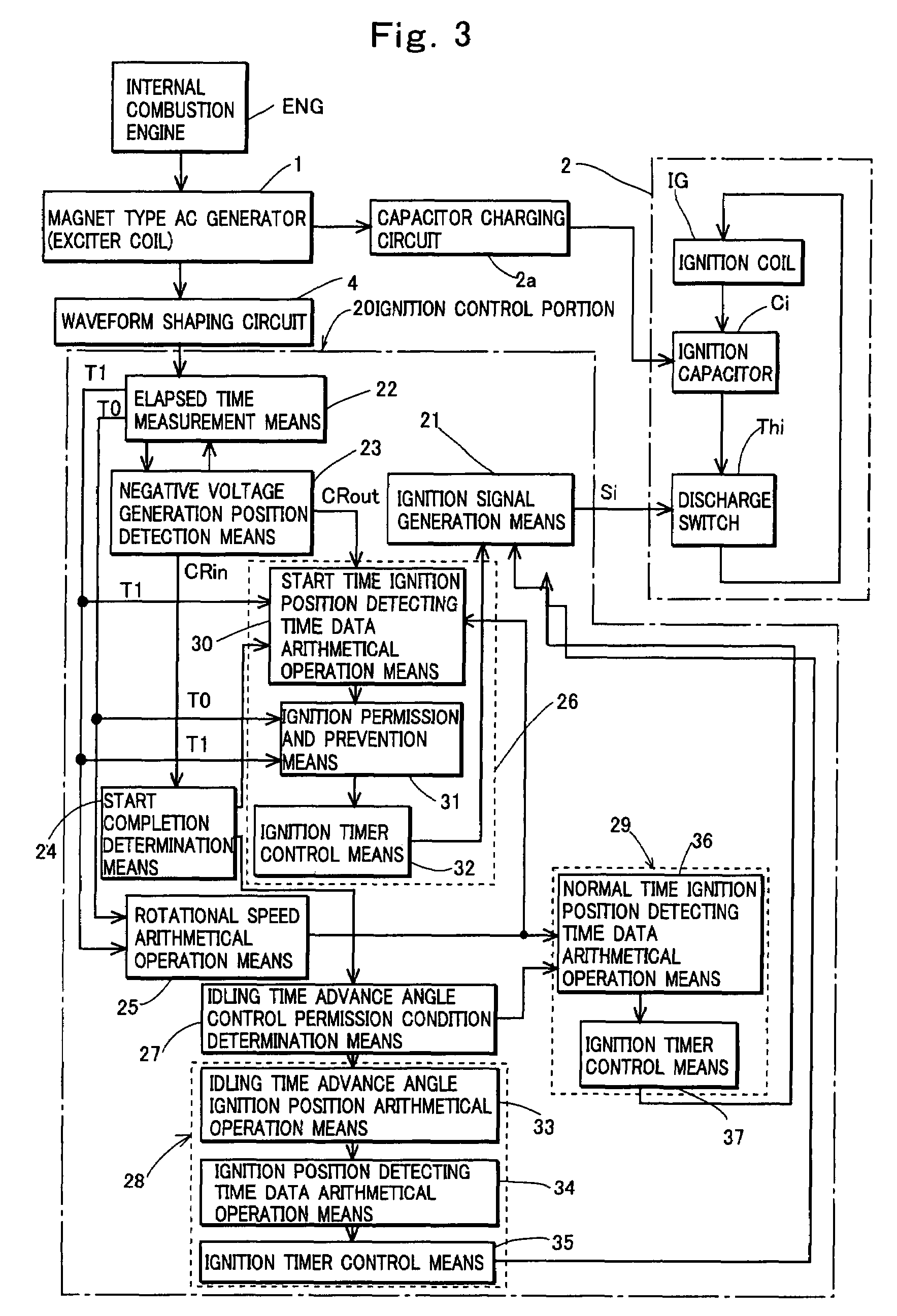

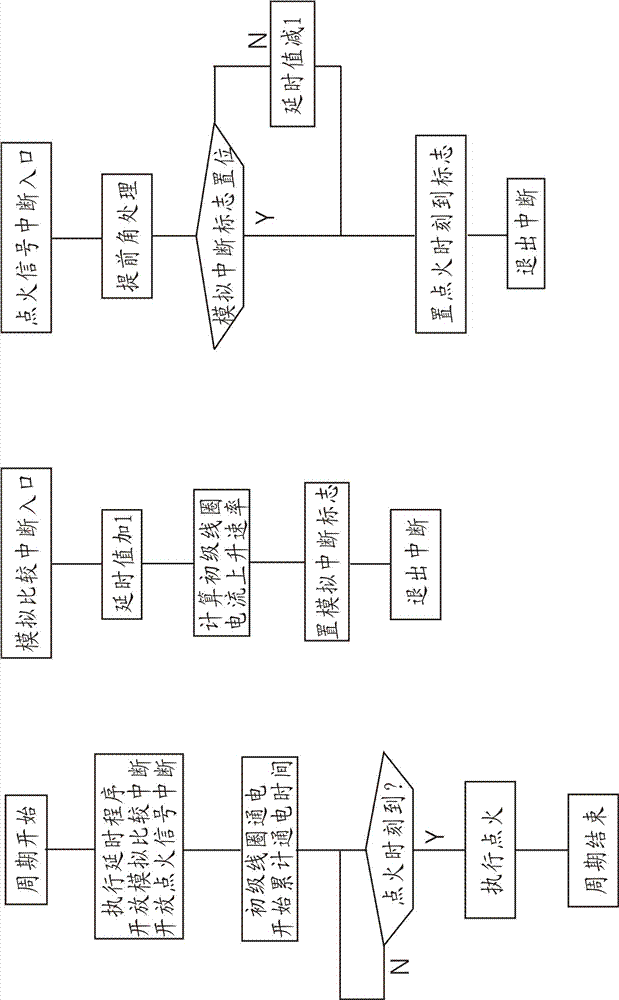

Ignition device for internal combustion engine

ActiveUS7472688B2Startability is improvedElectrical controlInternal combustion piston enginesIdle timeCapacitor discharge ignition

A capacitor discharge ignition device for an internal combustion engine including: idling time advance angle control permission condition determination means for determining whether an idling time advance angle control permission condition is met that is a condition for permitting control to advance an ignition position during idling immediately after completion of the start of the engine in order to stabilize idling immediately after completion of the start of the internal combustion engine; and idling time advance angle control means for advancing the ignition position during idling immediately after completion of the start of the internal combustion engine when it is determined that the idling time advance angle control permission condition is met.

Owner:MAHLE INT GMBH

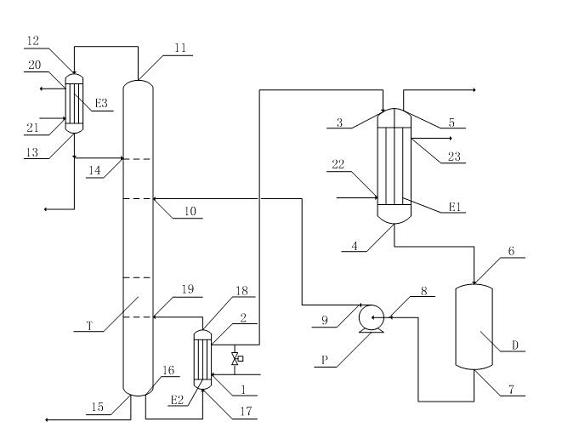

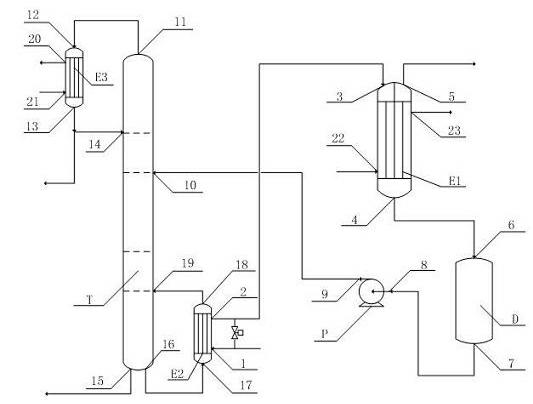

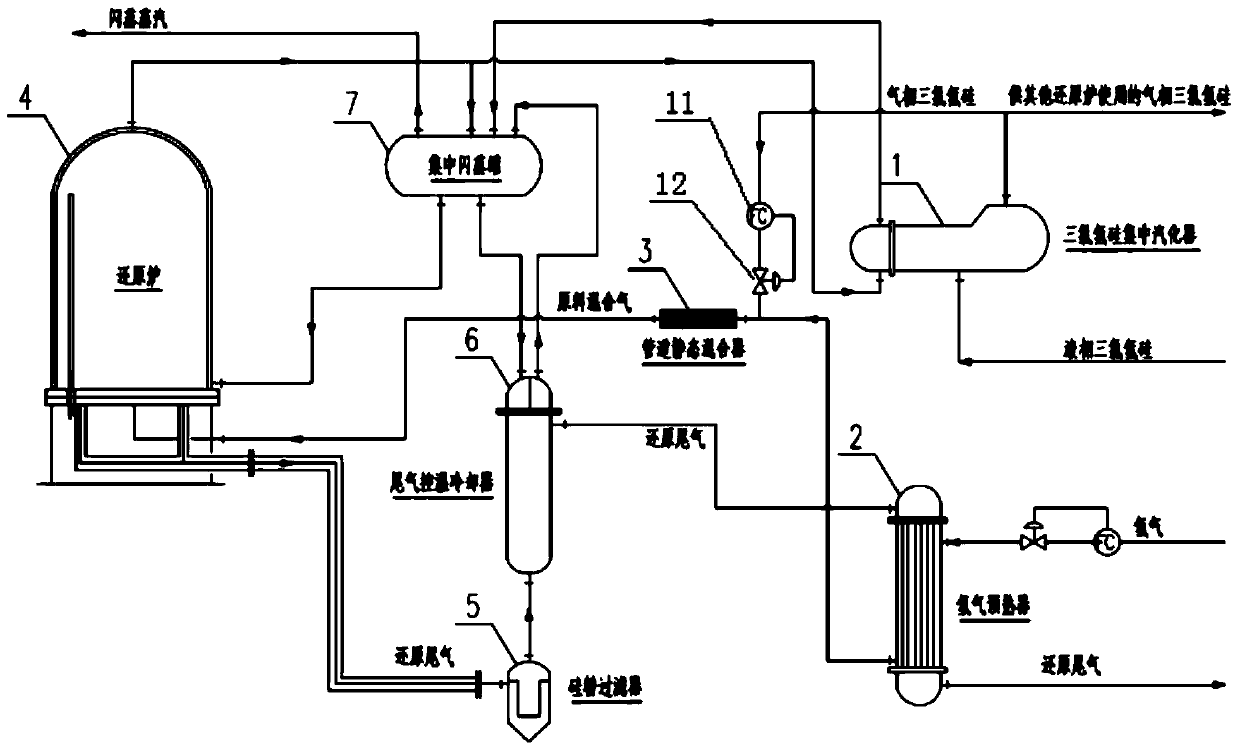

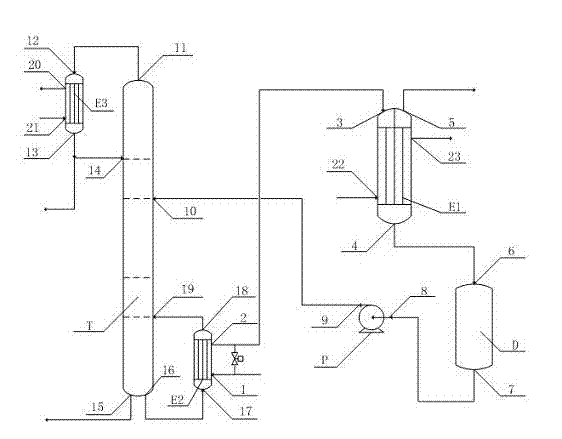

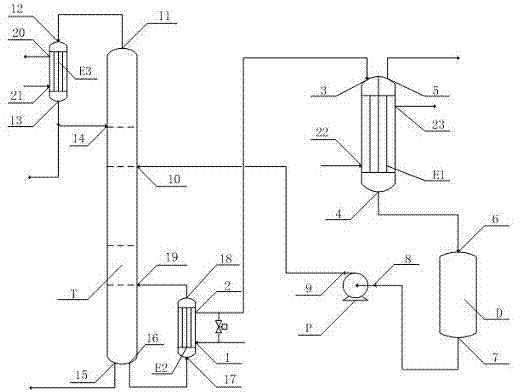

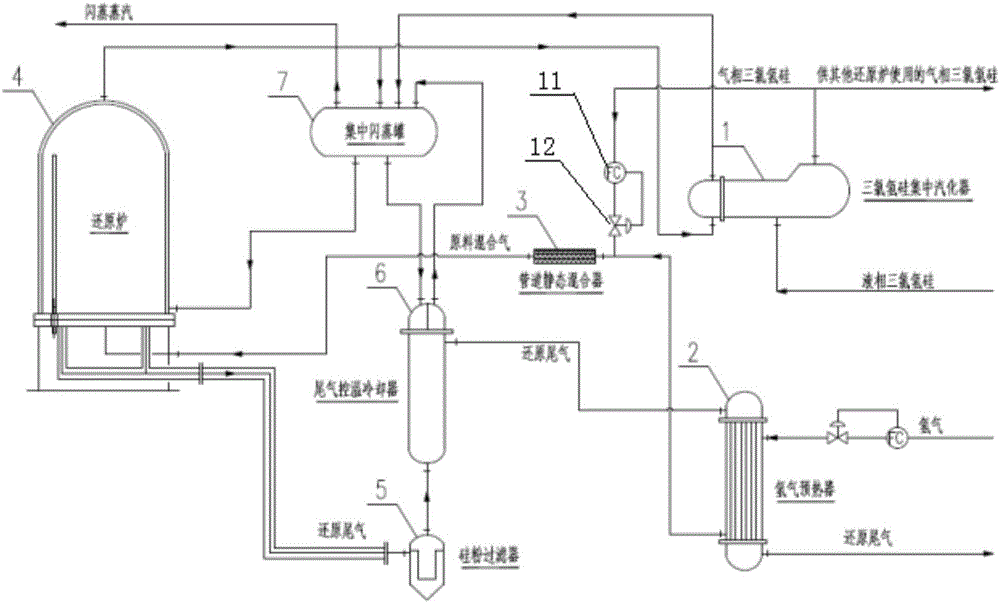

Method and device for recycling heat energy in reduction exhaust in polysilicon production process

ActiveCN102070145AReduce consumptionReduce loadSiliconIncreasing energy efficiencyBuffer tankReboiler

The invention discloses a method and device for recycling heat energy in reduction exhaust in a polysilicon production process. The method comprises the following steps: reduction exhaust and chlorsilane are subjected to primary heat exchange in a tower bottom reboiler; and after heat exchange, part of the chlorsilane is vaporized and delivered into a chlorsilane purification tower to serve as a heat source for the chlorsilane purification tower, the reduction exhaust subjected to heat exchange is delivered into a condenser, and the chlorsilane in the reduction exhaust is condensed into liquid to be delivered into the chlorsilane purification tower. The device for recycling the heat energy in reduction exhaust in the polysilicon production process comprises a tower top condenser, a purification tower, a tower bottom reboiler, an exhaust condenser, a chlorsilane buffer tank and a chlorsilane delivery pump which are sequentially connected, wherein the outlet of the chlorsilane delivery pump is connected with the purification tower. By means of the technical improvement provided by the invention, the steam consumption of the reduction rectification system can be reduced by 40%, the load of the refrigerator of a CDI (capacitor discharge ignition) system can be reduced by 7% simultaneously, and the circulating water consumption is reduced by about 52.44%, thereby achieving the purposes of favorable energy conservation and consumption reduction.

Owner:XINTE ENERGY

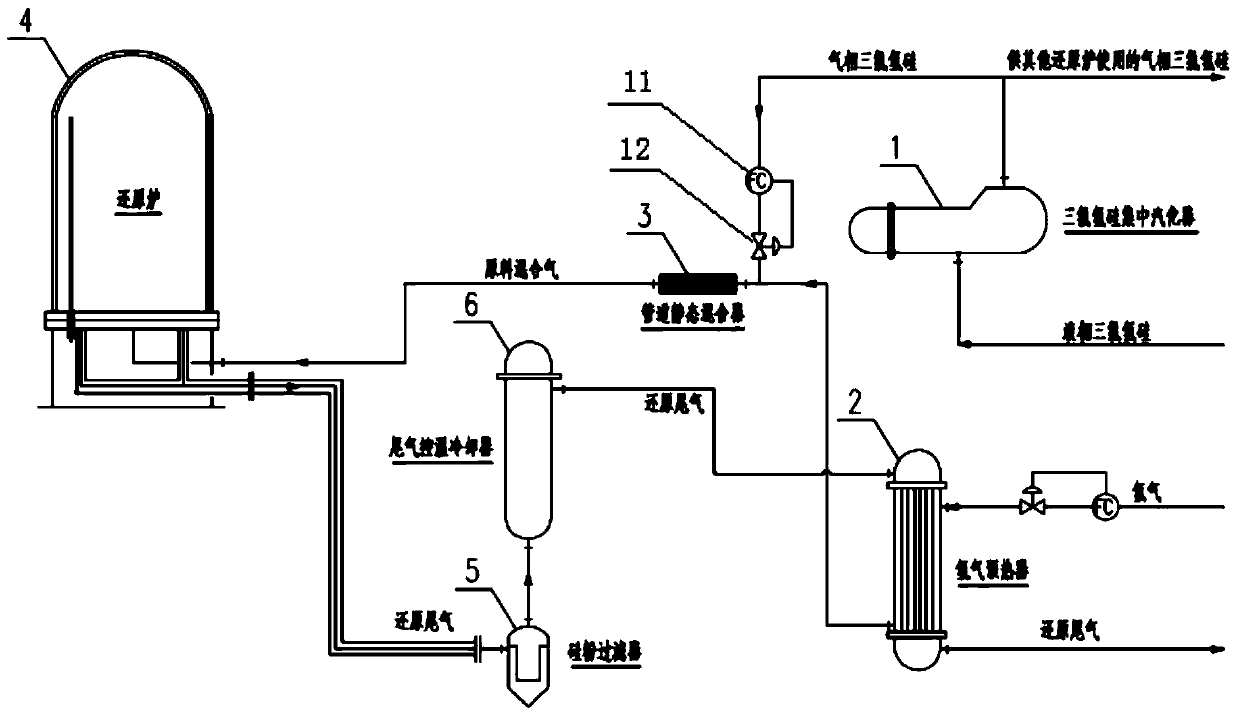

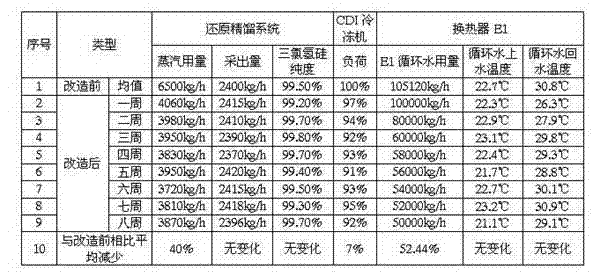

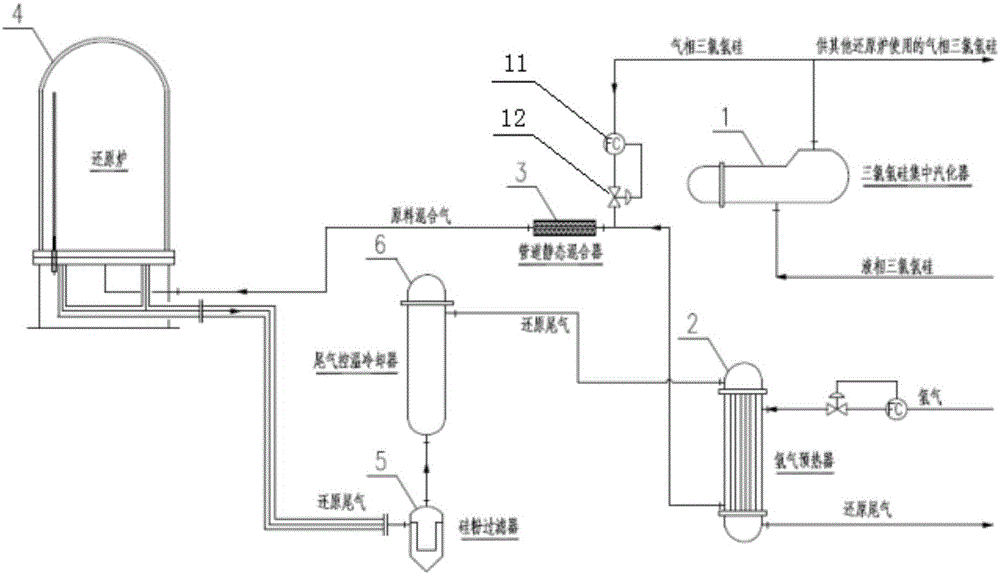

Temperature control and energy saving system and process for polycrystalline silicon reduction furnaces

ActiveCN103466629ATake advantage ofReduce energy consumptionChemical industrySilicon compoundsGas phaseCarburetor

The invention discloses a temperature control and energy saving system and process for polycrystalline silicon reduction furnaces. The system is characterized by comprising a trichlorosilane concentrated carburetor, a hydrogen preheater, a pipeline static mixer, a reduction furnace, a silicon powder filter and a tail gas temperature-control cooler, wherein the hydrogen preheater 2 is connected to the pipeline static mixer 3, and the trichlorosilane concentrated carburetor is connected to a tube pass of the hydrogen preheater; the pipeline static mixer is connected to the reduction furnace; the tail gas outlet of the reduction furnace 4 is connected to the shell-pass high-temperature gas phase inlet of the tail gas temperature-control cooler, and the shell-pass low-temperature gas phase outlet of the tail gas temperature-control cooler is connected to the shell-pass gas phase inlet of the hydrogen preheater. According to the system and application method disclosed by the invention, feed compositions are uniform, the feed temperature is stable and controllable, the heat energy is used fully, the power consumption of the reduction furnace and the system is reasonably reduced, and the growth quality of polycrystalline silicon is controlled better; silicon powder of a tail gas pipeline is effectively removed, thereby protecting valves of the tail gas pipeline and facilities of a CDI (Capacitor Discharge Ignition) system.

Owner:MORIMATSU (JIANGSU) HEAVY IND CO LTD

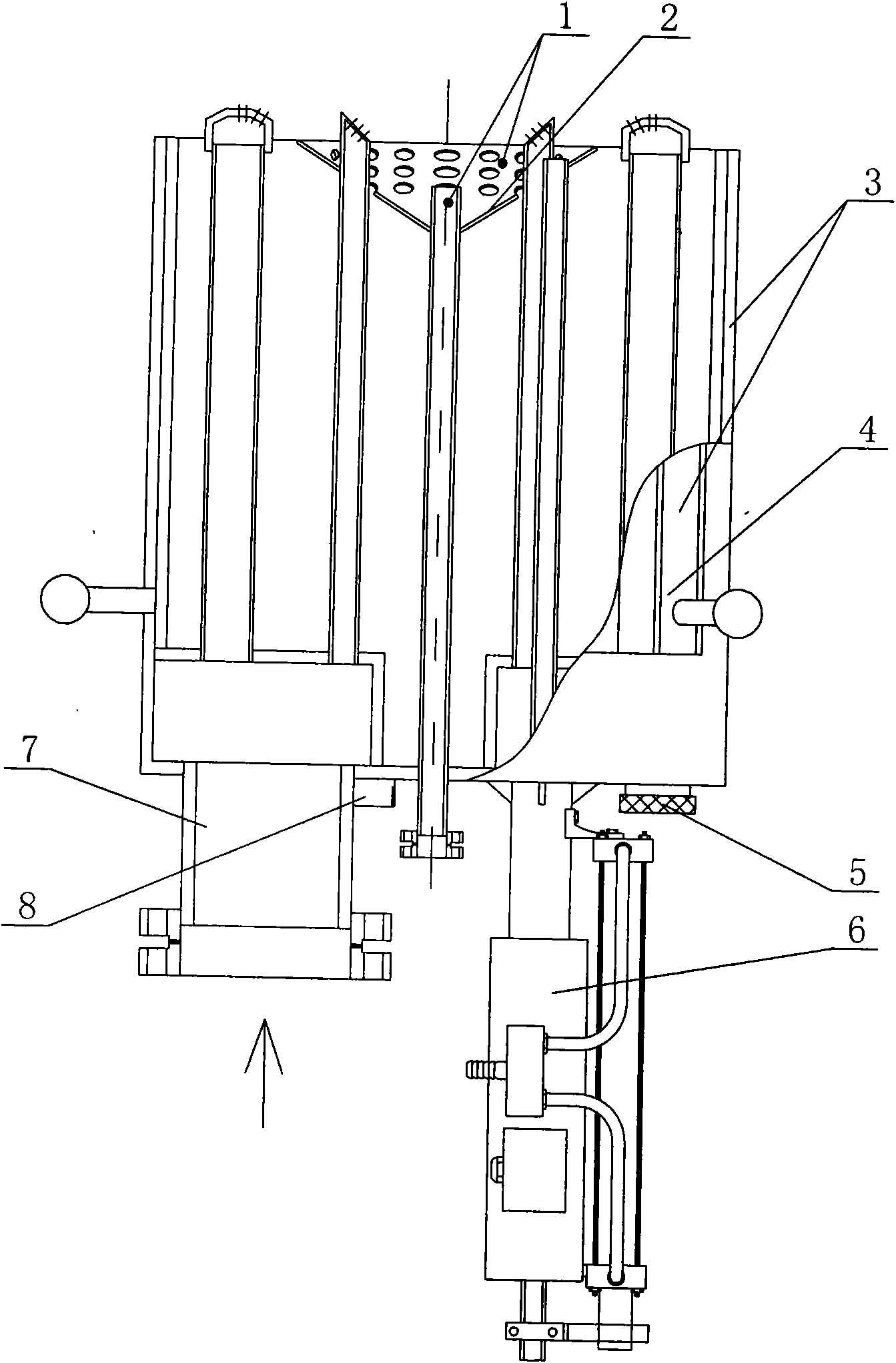

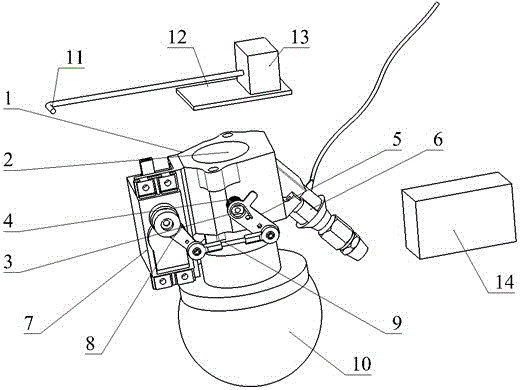

Integrated electronic injection/ignition system for aviation fuel engine

PendingCN106555690AStrong sparkSecondary current rises fastElectrical controlMachines/enginesCapacitanceAviation

The invention provides an integrated electronic injection / ignition system for an aviation fuel engine. The system structurally comprises a throttle valve assembly, an electric nozzle, a steering engine assembly, an air filter, a spark plug, a DD integrated circuit board and an oil supply system, wherein the throttle valve assembly comprises a throttle valve body, a throttle valve, a throttle valve shaft, a throttle valve return spring and a throttle pull bar, and the steering engine assembly comprises a steering engine, a steering engine rocking arm and a bulb pull bar; and the DD integrated circuit comprises an electronic control unit (ECU) and a capacitor discharge igniter (CDI). According to the invention, a miniaturized piston engine oil injection system is designed, the two major problems of mechanical spindle adjustment and low oil injection precision are avoided, a conventionally independent ignition system and an injection system are also integrated together, the structure is simplified, the space is saved, and redundancy design and self-check design also help to improve the flight safety and the maintenance efficiency.

Owner:辽宁大壮无人机科技有限公司

Fuel injection device for internal combustion engine

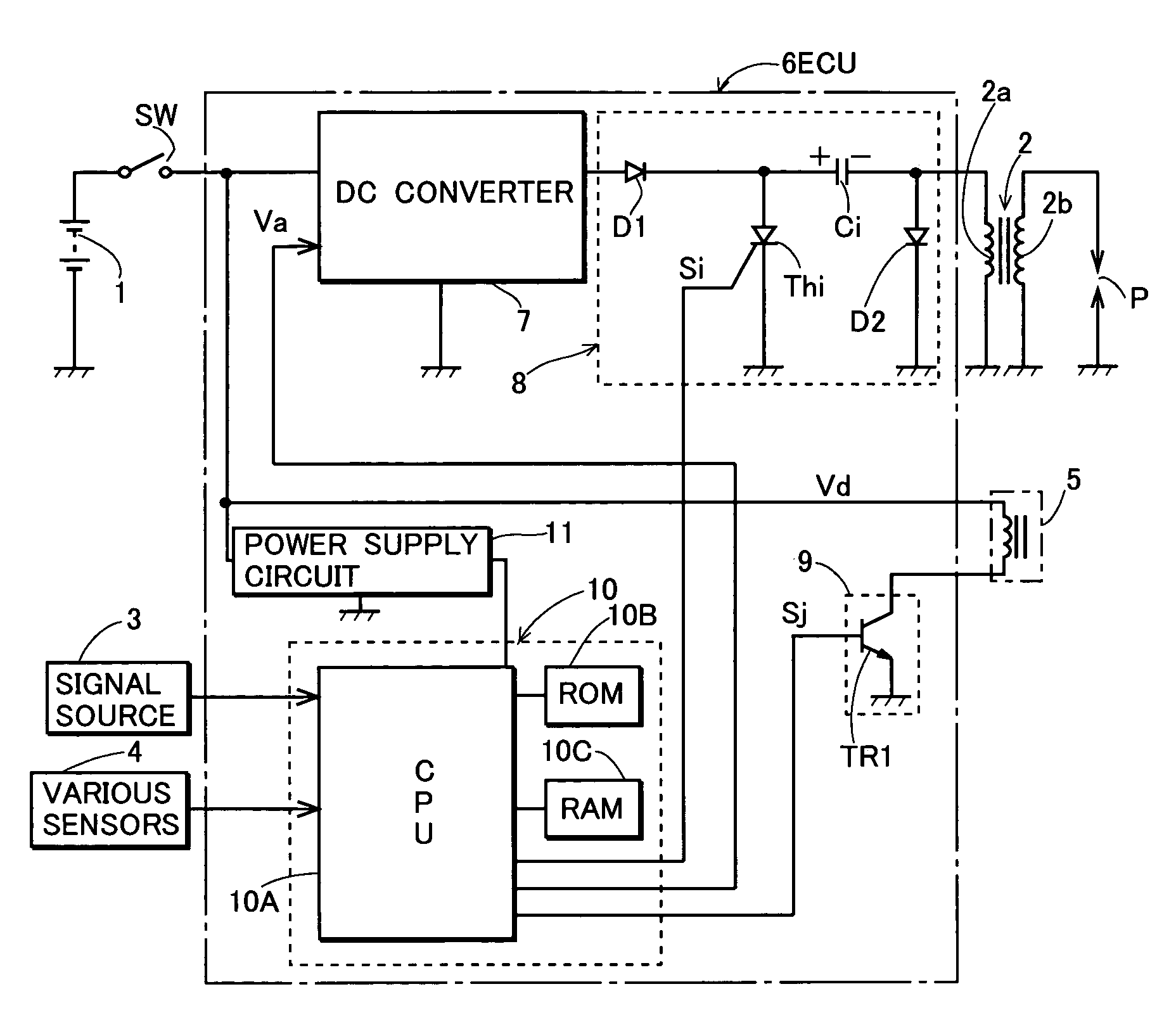

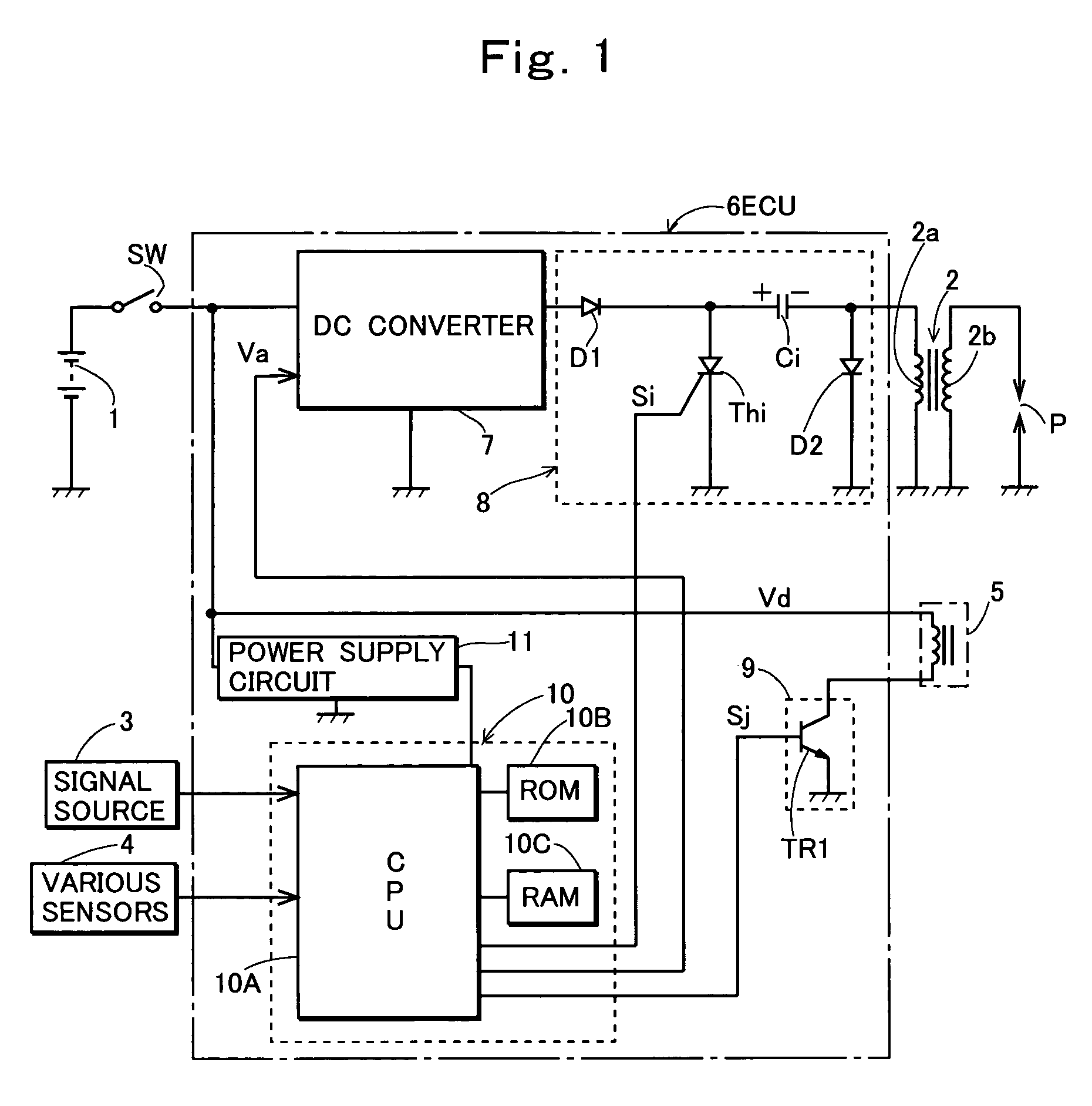

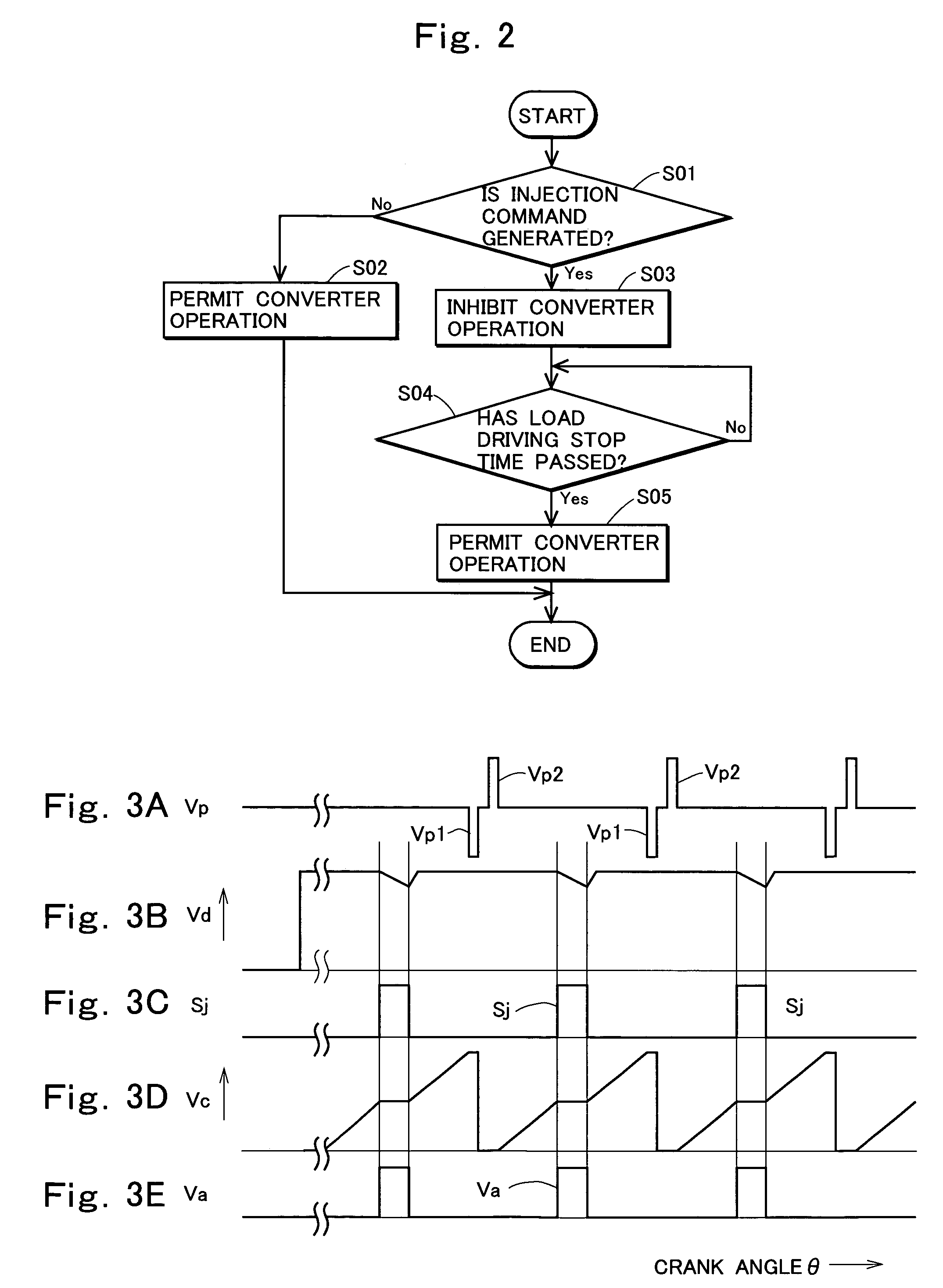

InactiveUS7401595B2Reduce voltageAvoid fuel injectionElectrical controlFuel injection apparatusDriver circuitElectrical battery

A fuel injection device for an internal combustion engine including: an injector that injects fuel to be supplied to the internal combustion engine; a battery to which a DC converter that charges a capacitor of a capacitor discharge ignition circuit is connected as a load; a control portion that is provided to operate when a power supply voltage is provided from the battery through a power supply circuit, and generates an injection command signal when fuel injection timing is detected; and an injector drive circuit that applies a driving voltage from the battery to the injector while receiving the injection command signal, wherein the device further comprises converter operation stopping portion for stopping an operation of the DC converter during set load driving stop time when the injection command signal is generated.

Owner:KOKUSAN DENKI CO LTD

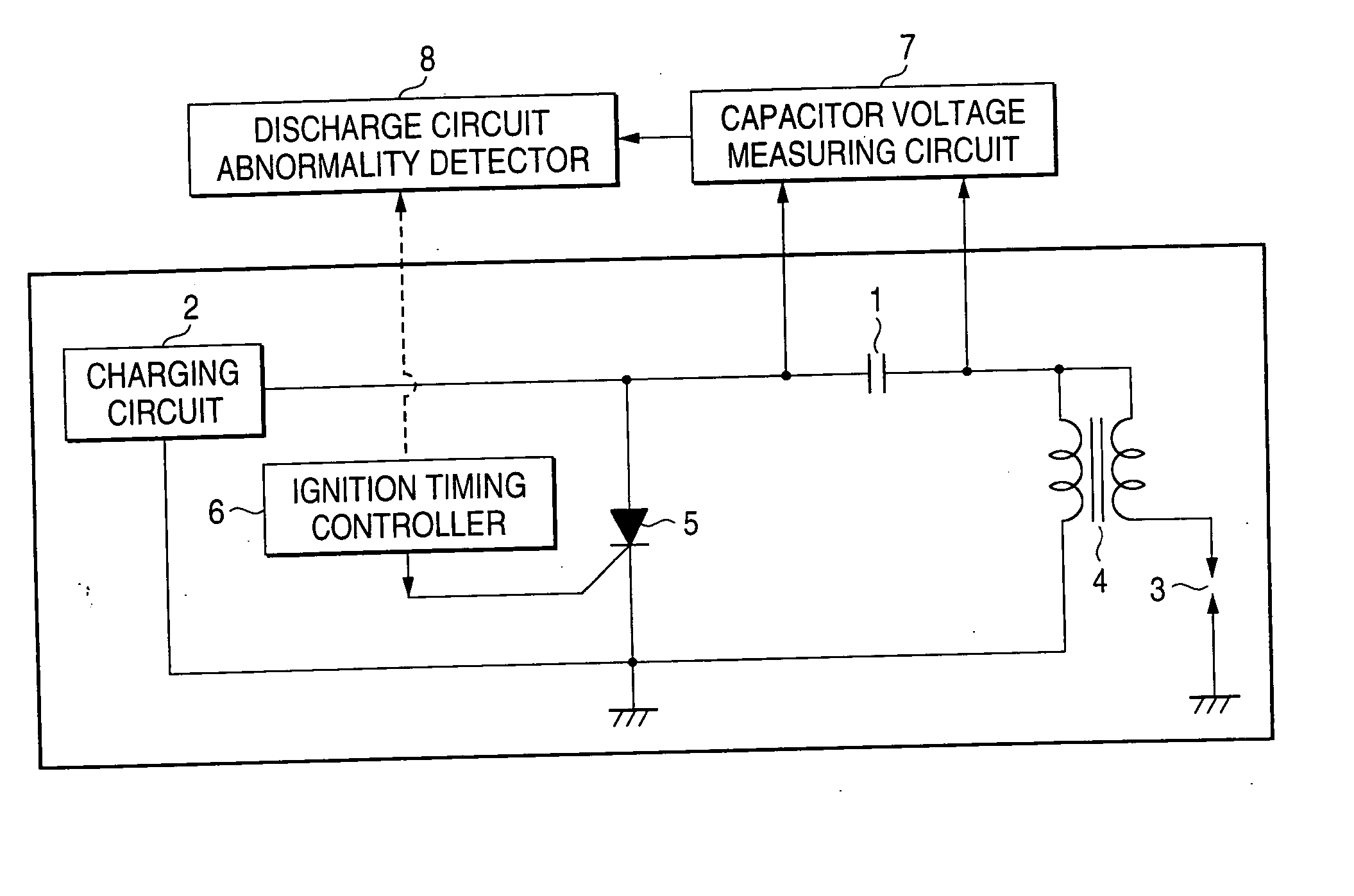

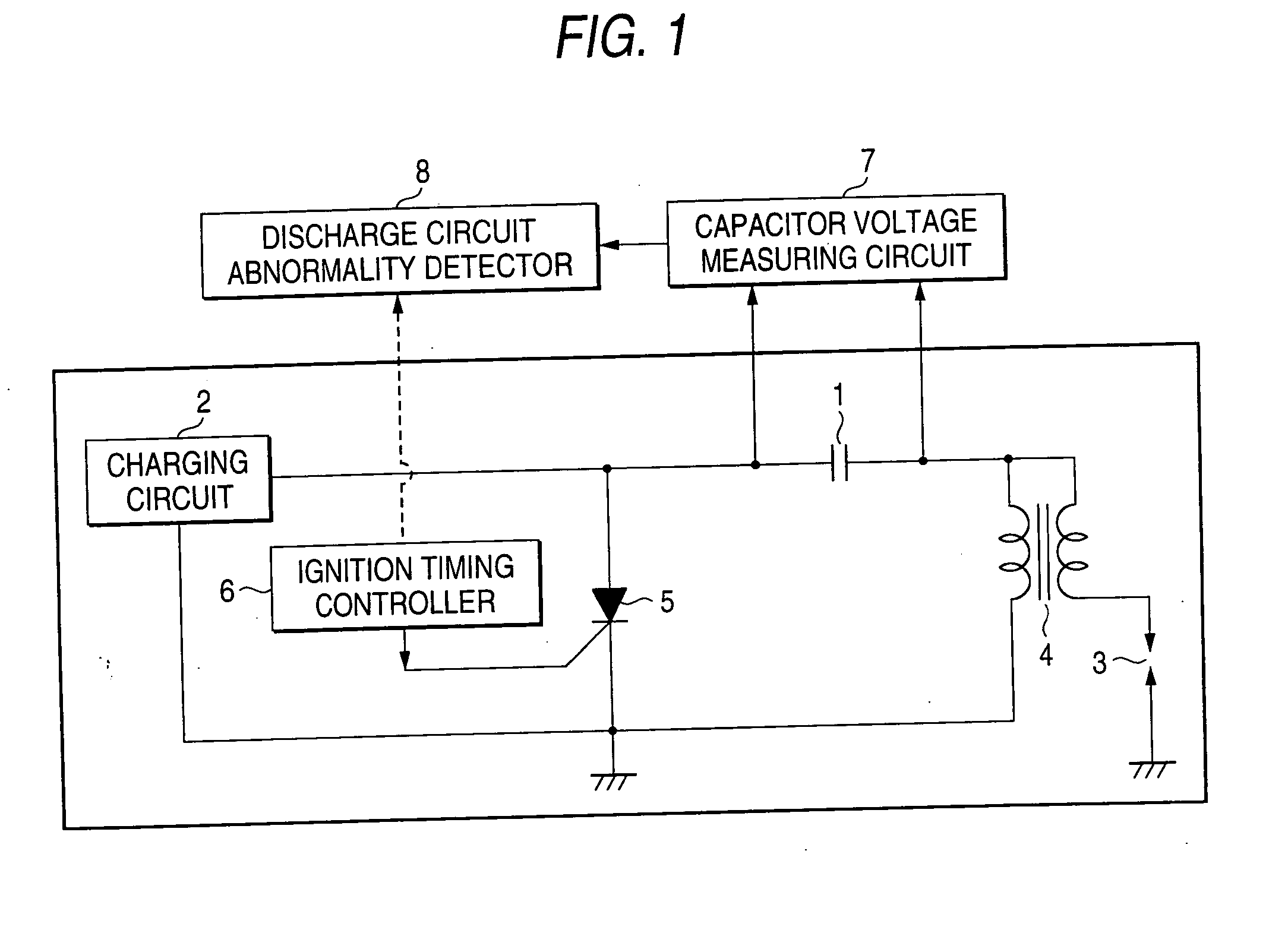

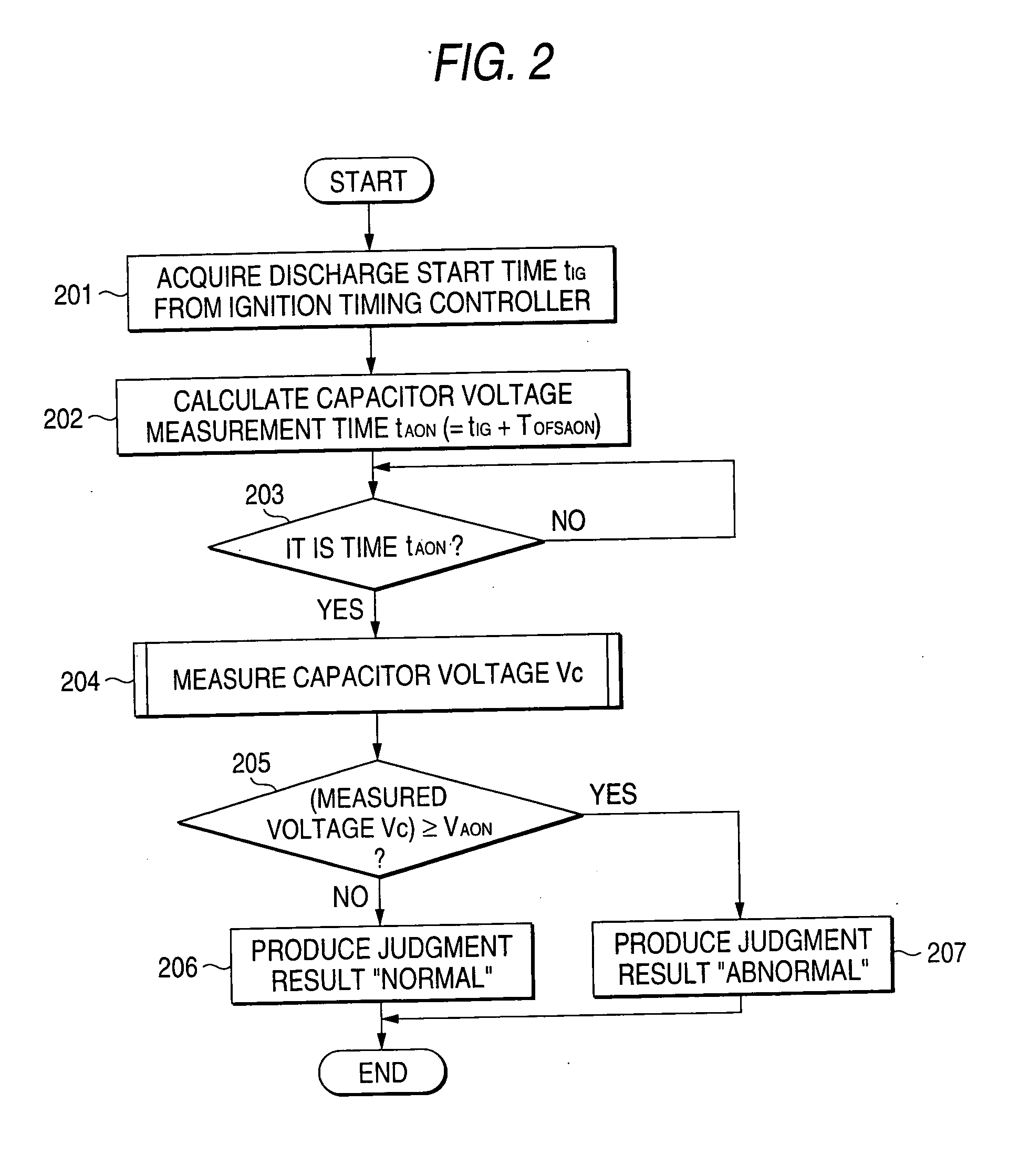

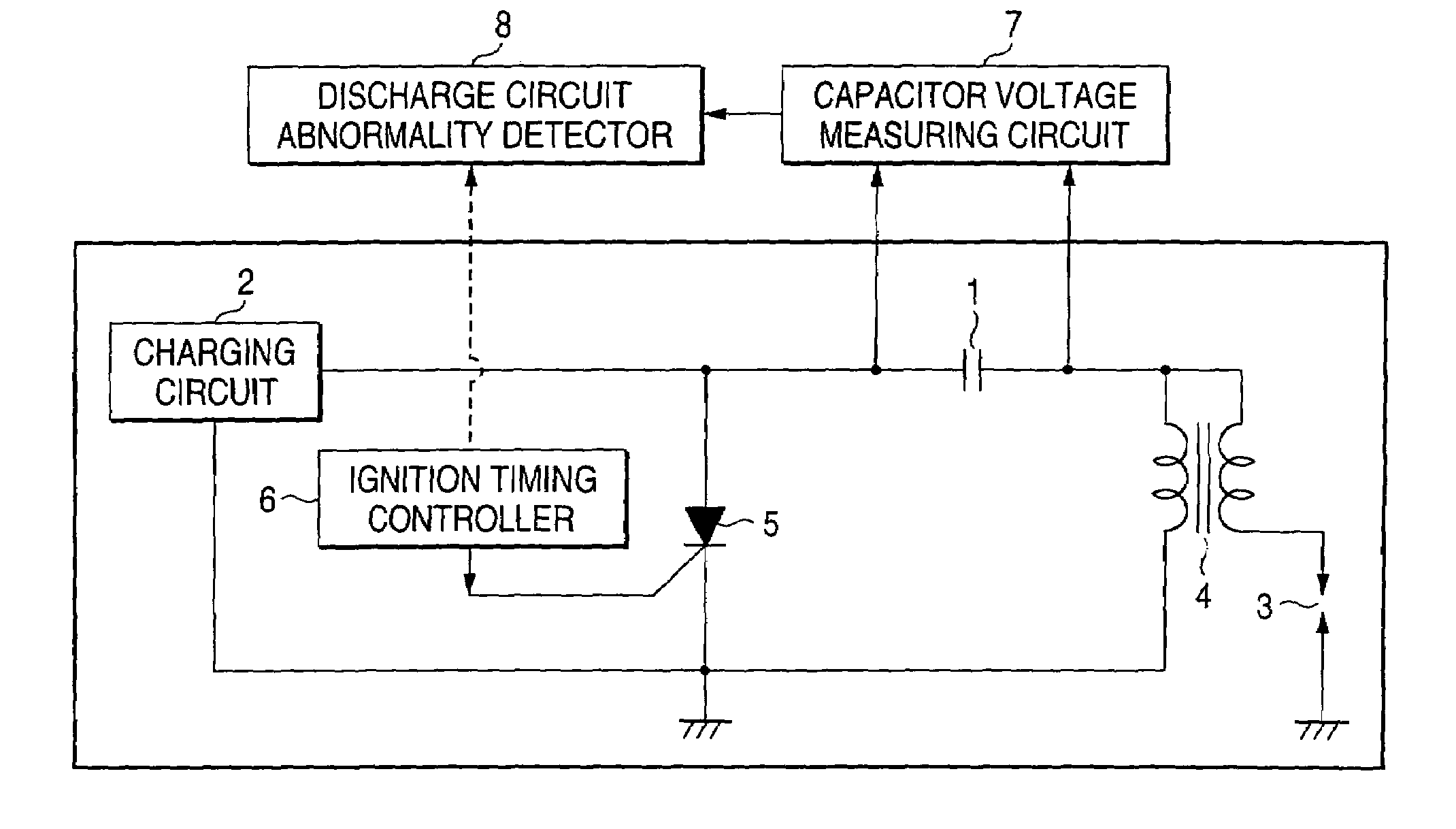

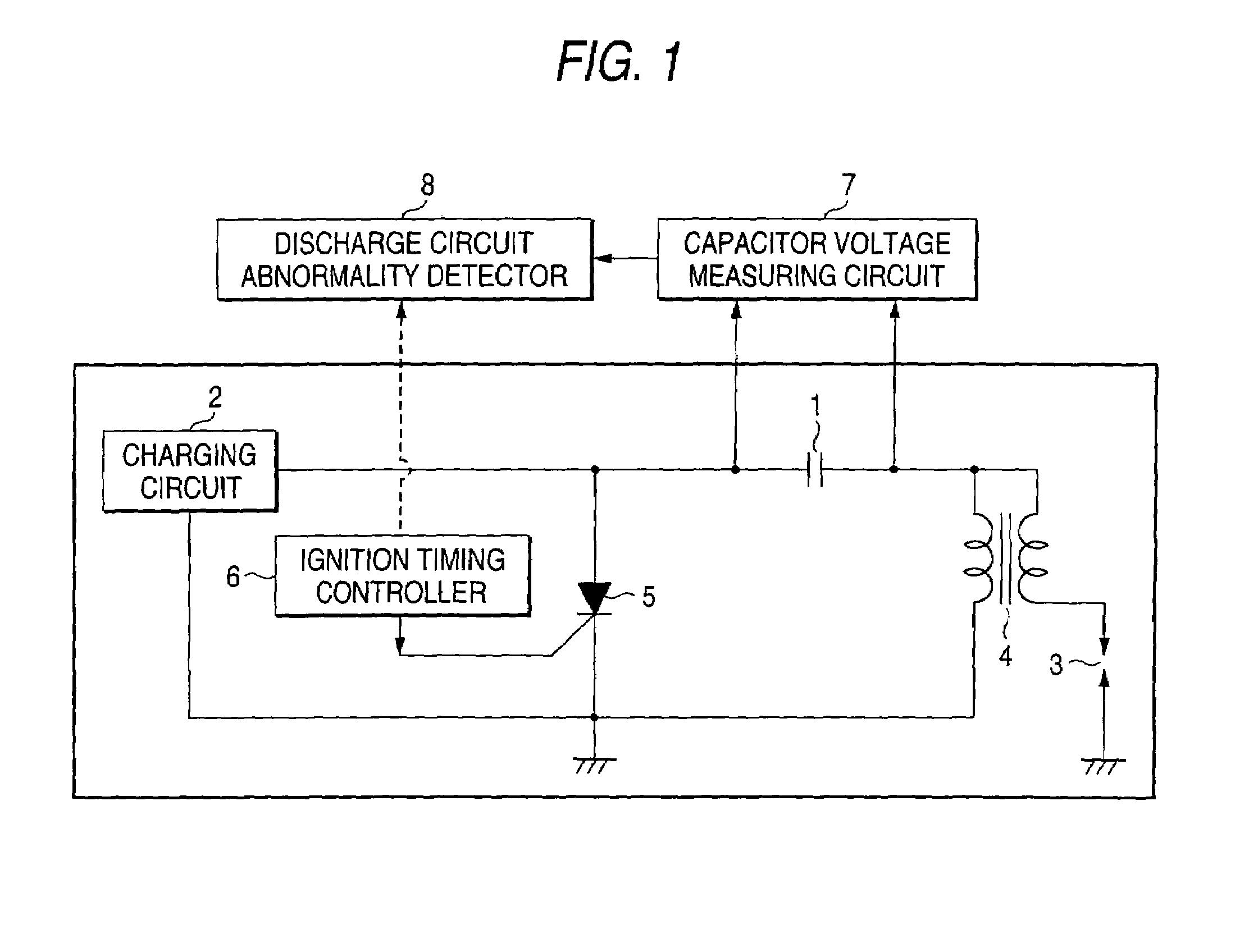

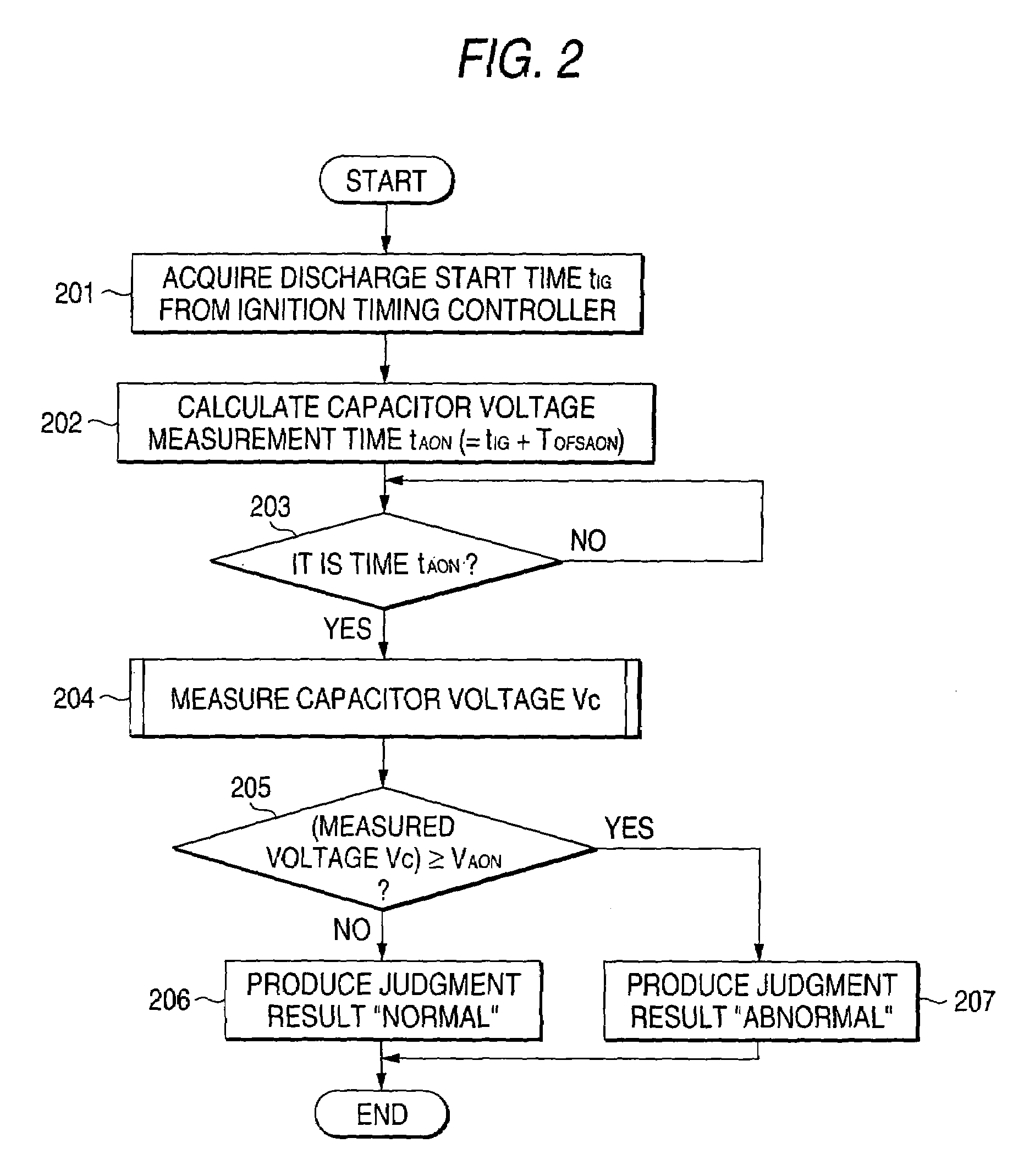

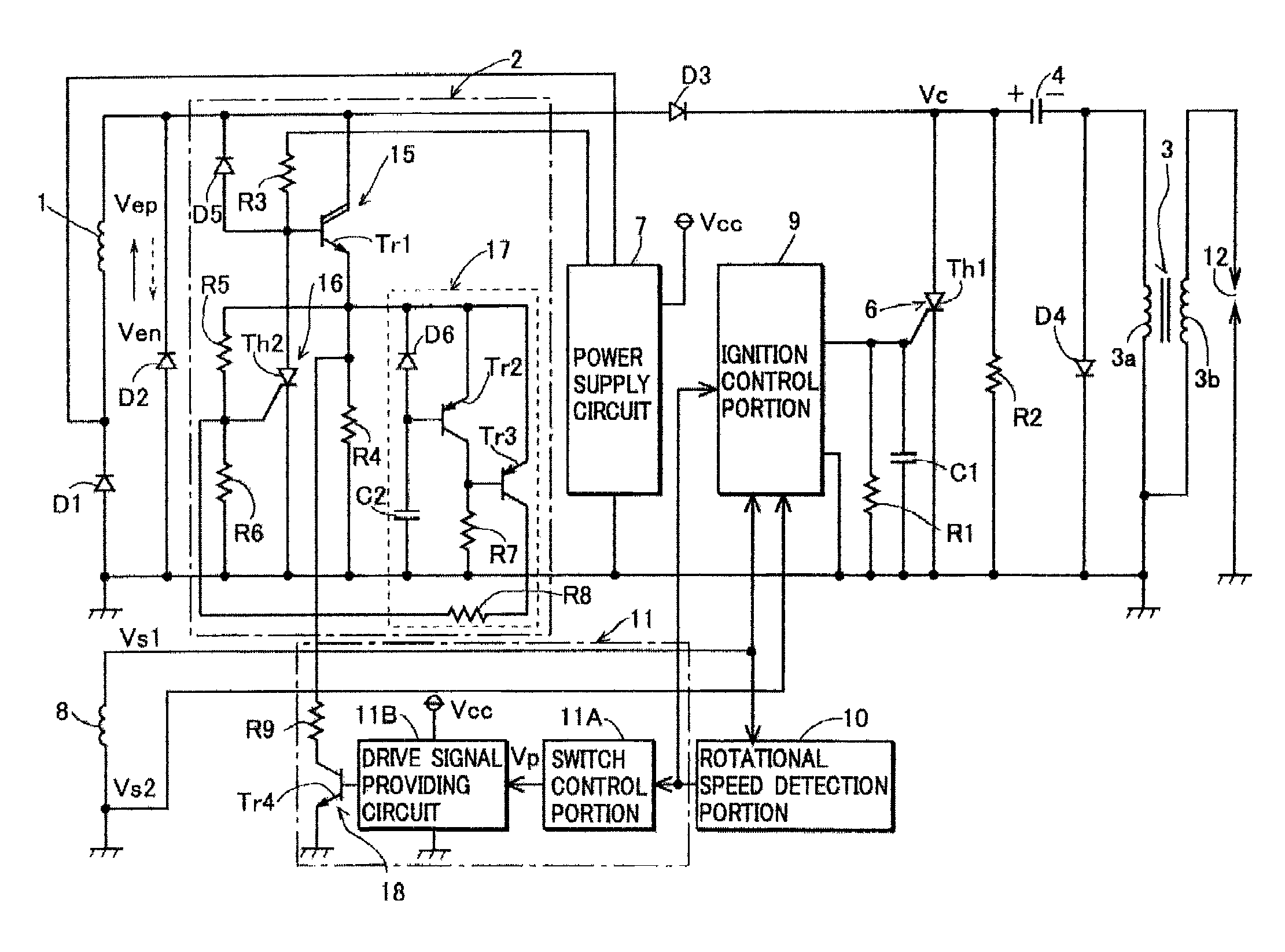

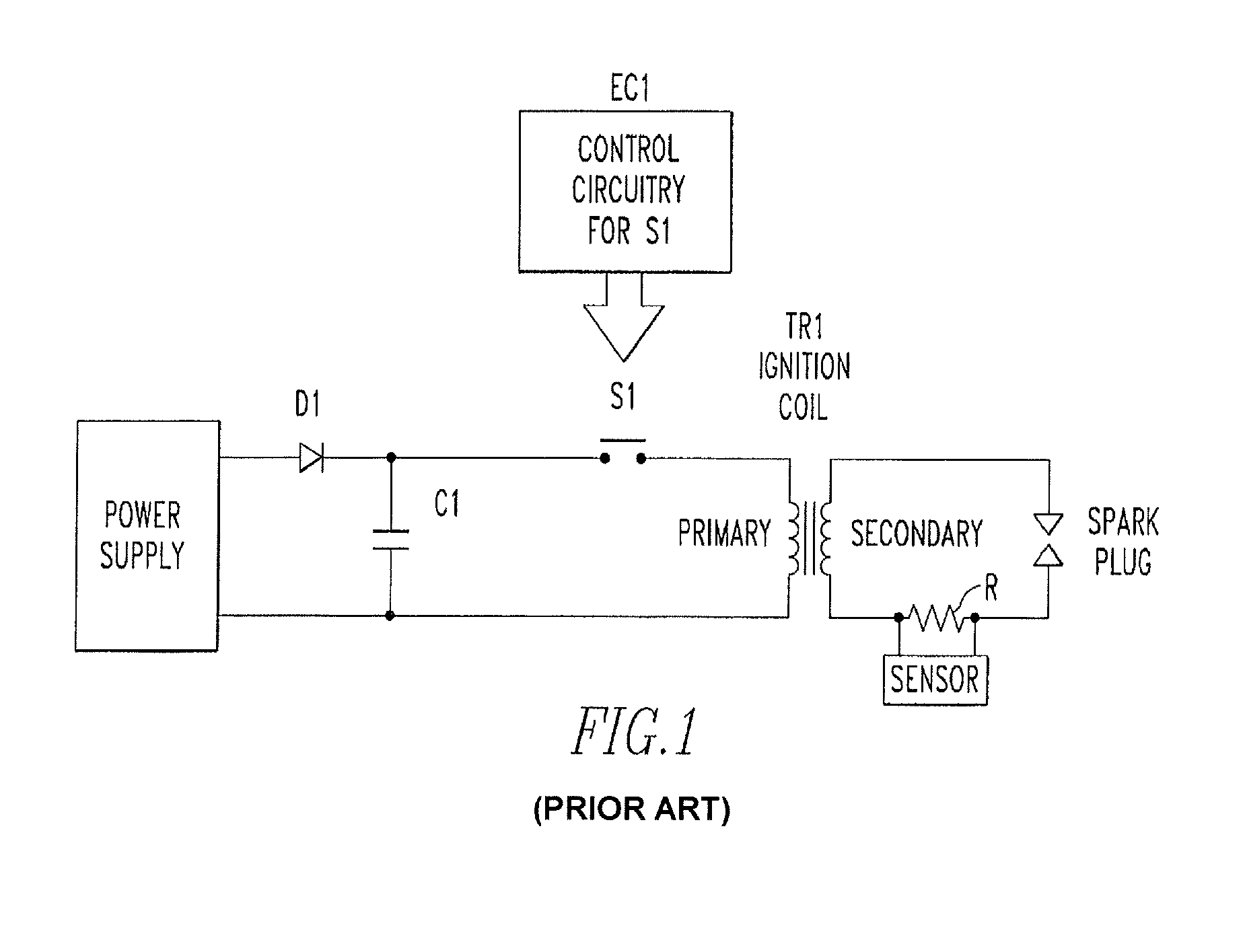

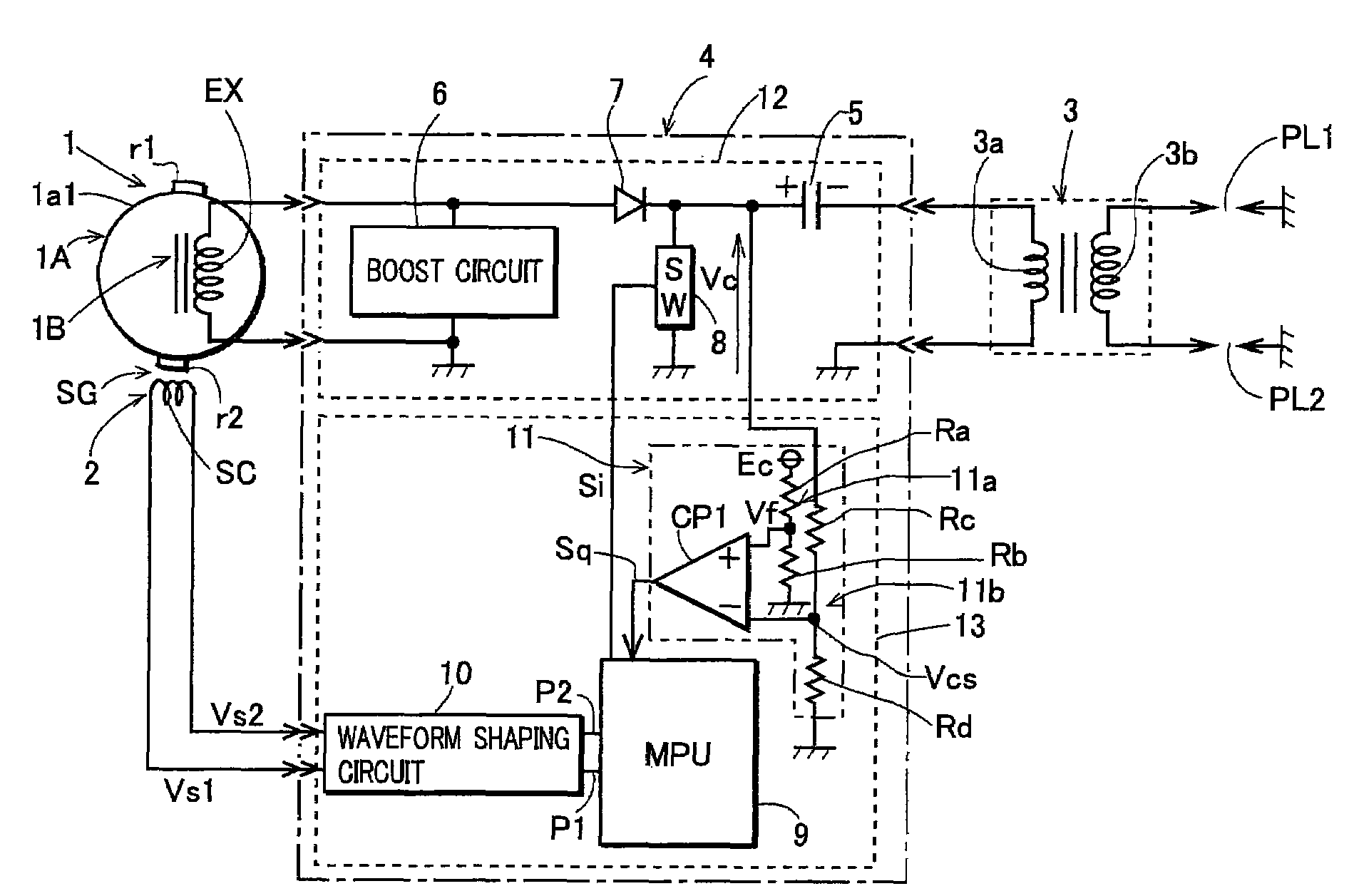

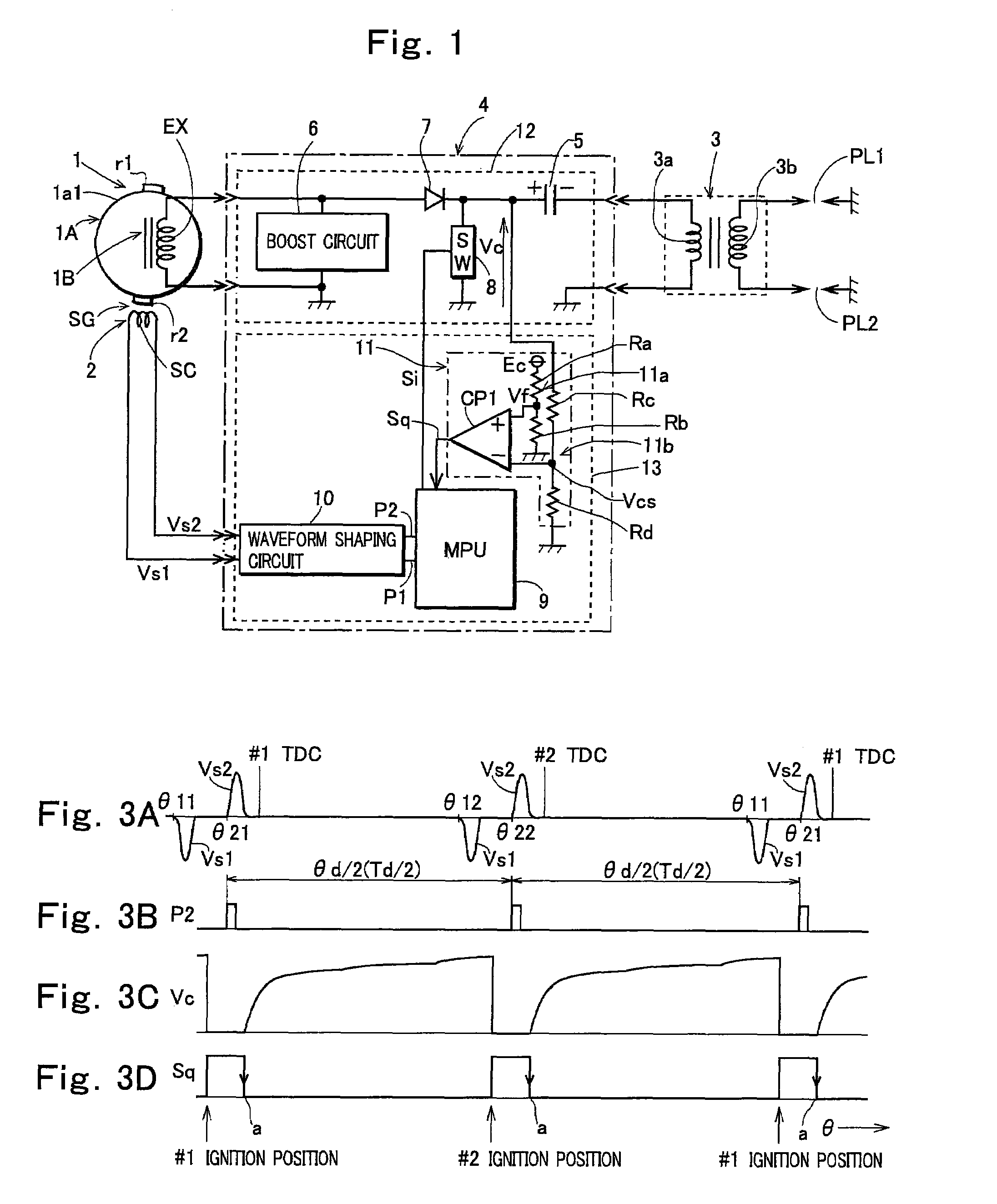

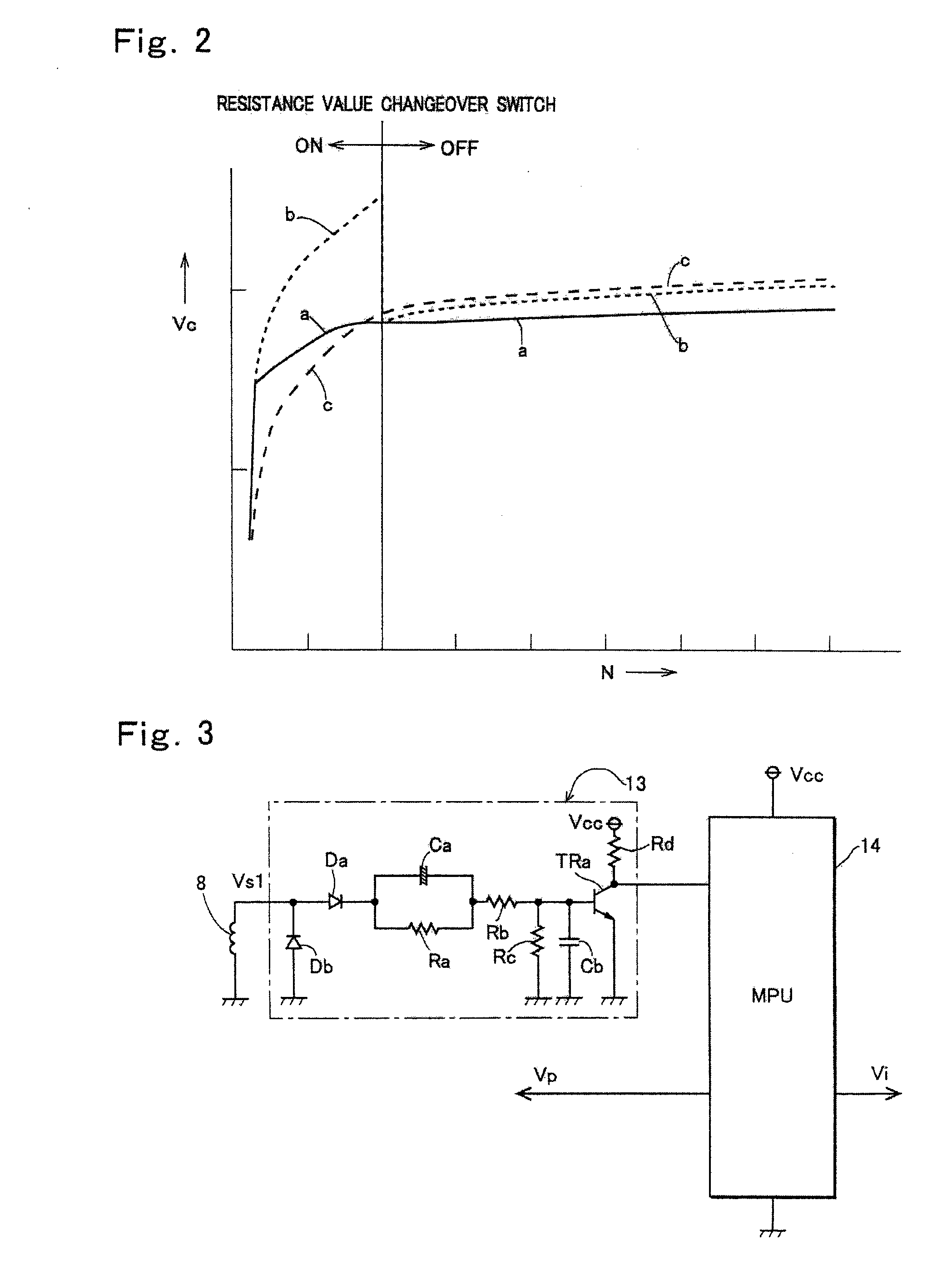

Capacitor discharge ignition device

ActiveUS20050066948A1Easy to detectSimple circuit configurationElectrical controlMachines/enginesCapacitanceCapacitor voltage

A capacitor discharge ignition device is provided with a capacitor for storing charge to produce ignition energy; ignition coils that receive charge released from the capacitor on the primary side and generate a high voltage on the secondary side; a switching element for causing the capacitor to release the charge stored therein to the ignition coils; ignition timing control means that receives a signal corresponding to a crank angle of an internal combustion engine and supplies an ignition signal to the switching element; and circuit abnormality detecting means that receives a signal from the ignition timing control means, sets a capacitor voltage measurement time, and judges for a circuit abnormality on the basis of a voltage of the capacitor measured at the capacitor voltage measurement time.

Owner:MITSUBISHI ELECTRIC CORP

Capacitor discharge ignition device

ActiveUS6948484B2Easy to detectSimple circuit configurationElectrical controlMachines/enginesCapacitor voltageCapacitor discharge ignition

A capacitor discharge ignition device is provided with a capacitor for storing charge to produce ignition energy; ignition coils that receive charge released from the capacitor on the primary side and generate a high voltage on the secondary side; a switching element for causing the capacitor to release the charge stored therein to the ignition coils; ignition timing control means that receives a signal corresponding to a crank angle of an internal combustion engine and supplies an ignition signal to the switching element; and circuit abnormality detecting means that receives a signal from the ignition timing control means, sets a capacitor voltage measurement time, and judges for a circuit abnormality on the basis of a voltage of the capacitor measured at the capacitor voltage measurement time.

Owner:MITSUBISHI ELECTRIC CORP

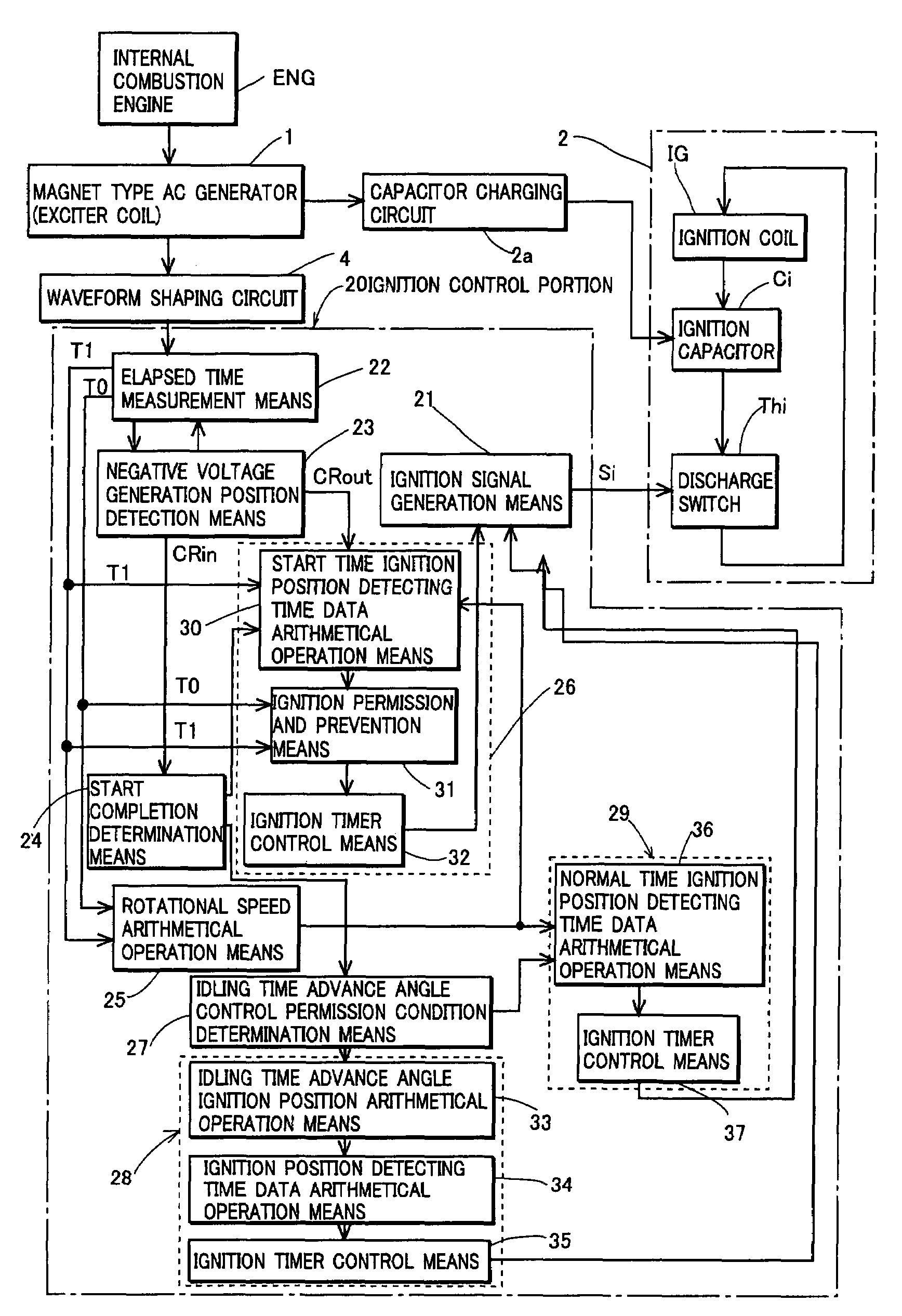

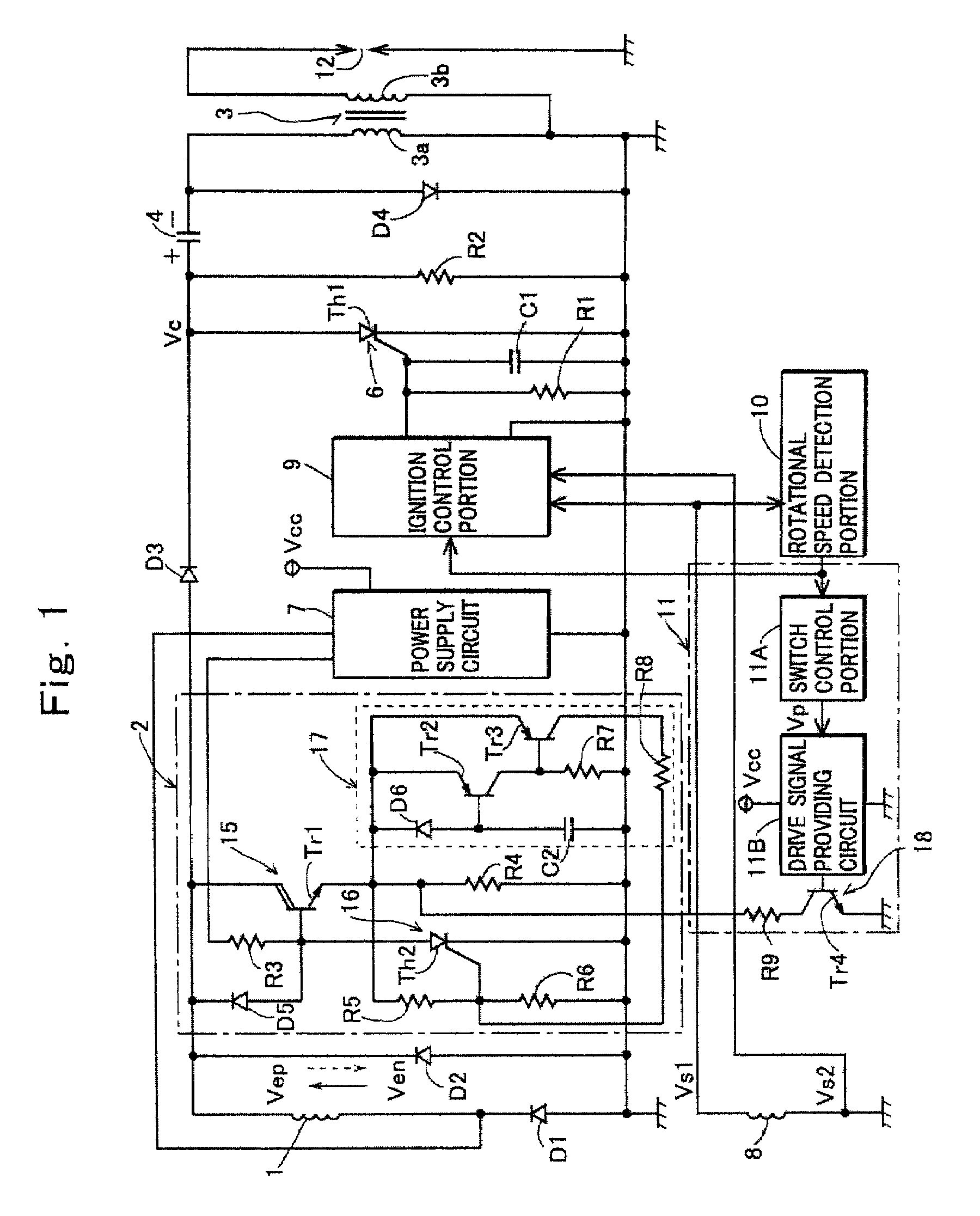

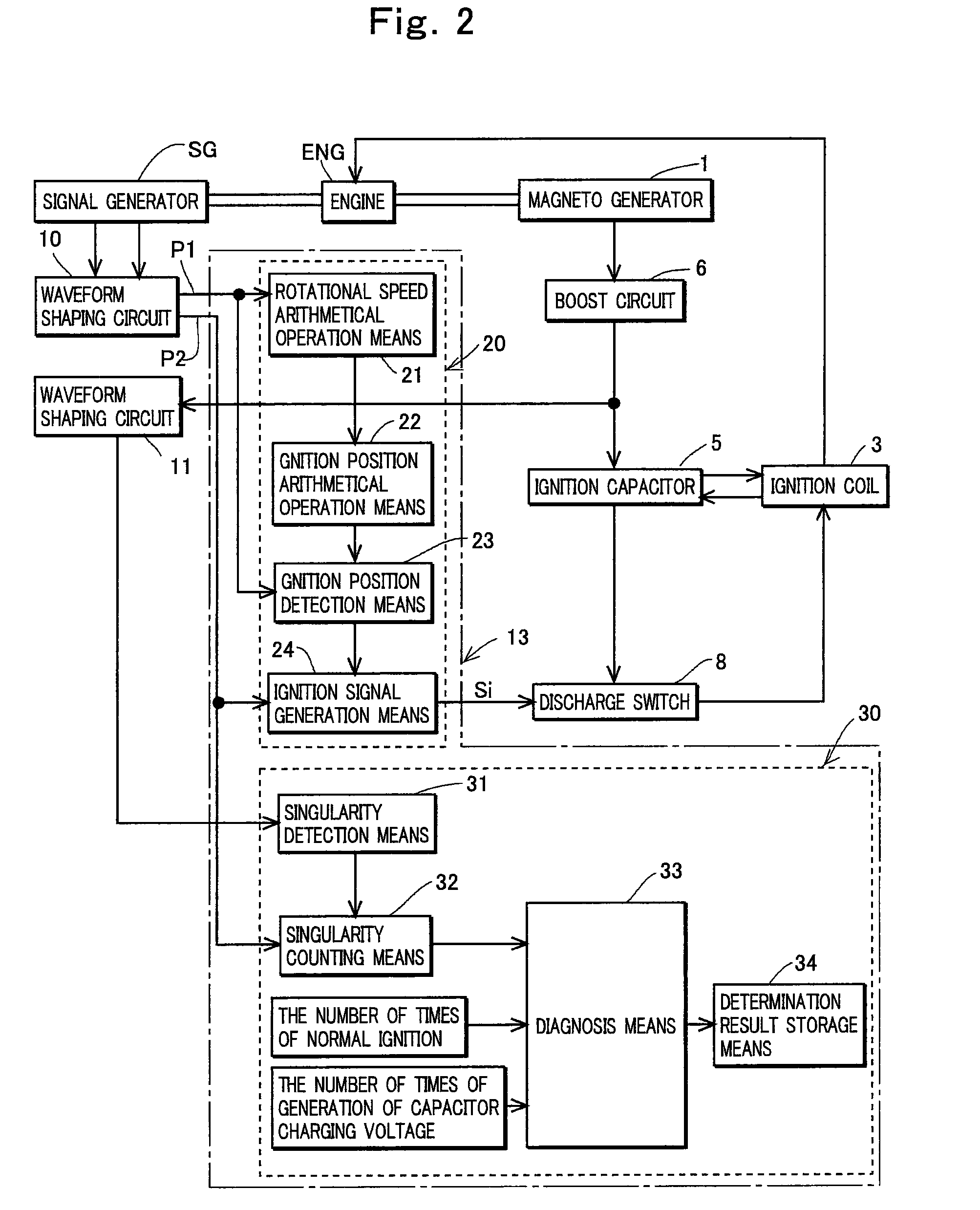

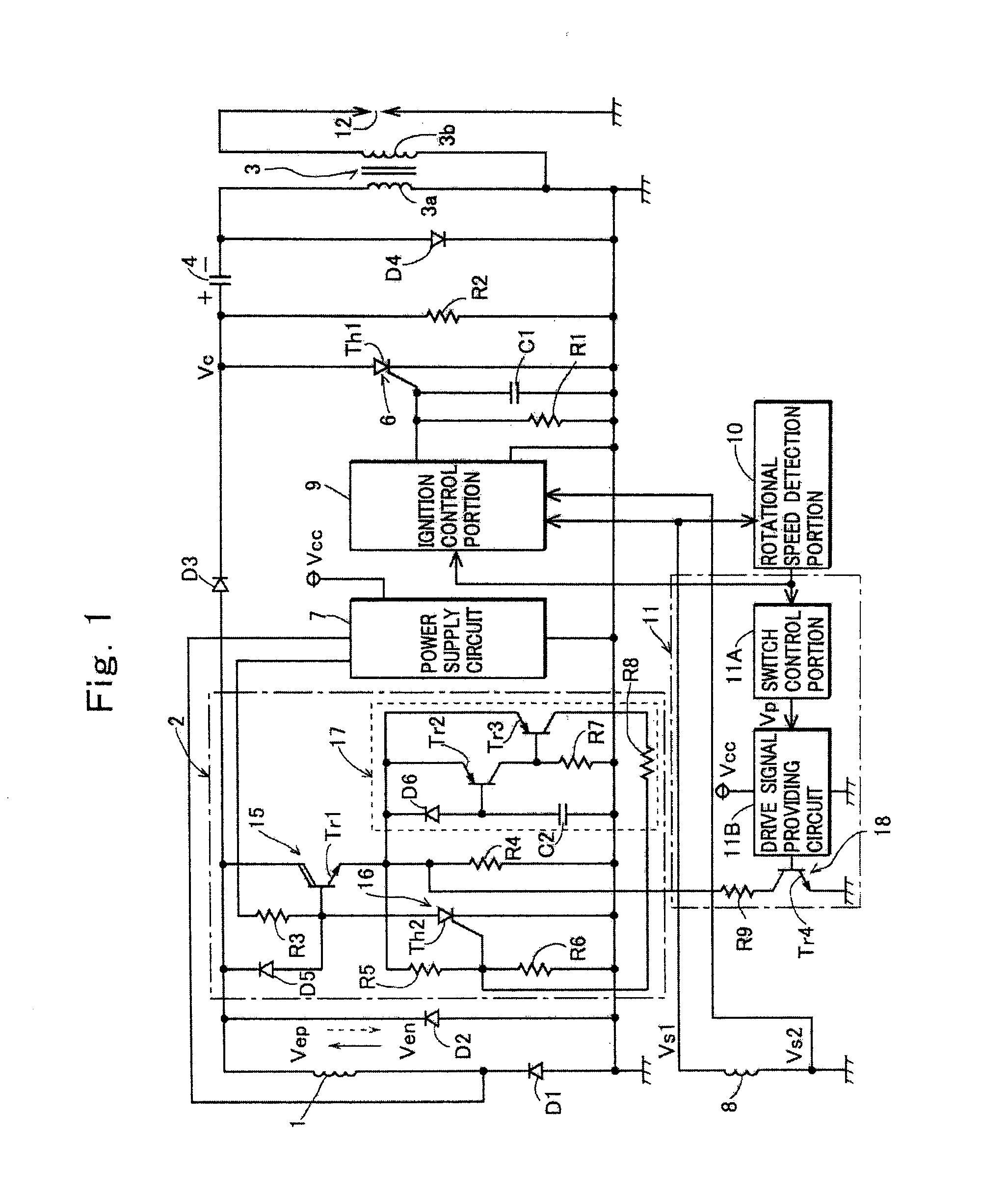

Capacitor discharge ignition device for engine

InactiveUS7631633B2Constant output voltageAvoid chargingElectric spark ignitersGenerator generated ignition energyCapacitanceCapacitor discharge ignition

A capacitor discharge ignition device for an engine including: an exciter coil provided in a magneto generator driven by the engine; a voltage increasing circuit that increases an induced voltage of the exciter coil; a capacitor charged by an output voltage of the voltage increasing circuit; and a discharge switch that is turned on at ignition timing of the engine and discharges charges in the capacitor through a primary coil of the ignition coil, wherein the ignition device further includes a voltage increasing control portion that controls the voltage increasing circuit so as to increase an output voltage of the voltage increasing circuit when a rotational speed of the engine is a set value or less, and limit the output voltage of the voltage increasing circuit when the rotational speed of the engine exceeds the set value.

Owner:KOKUSAN DENKI CO LTD

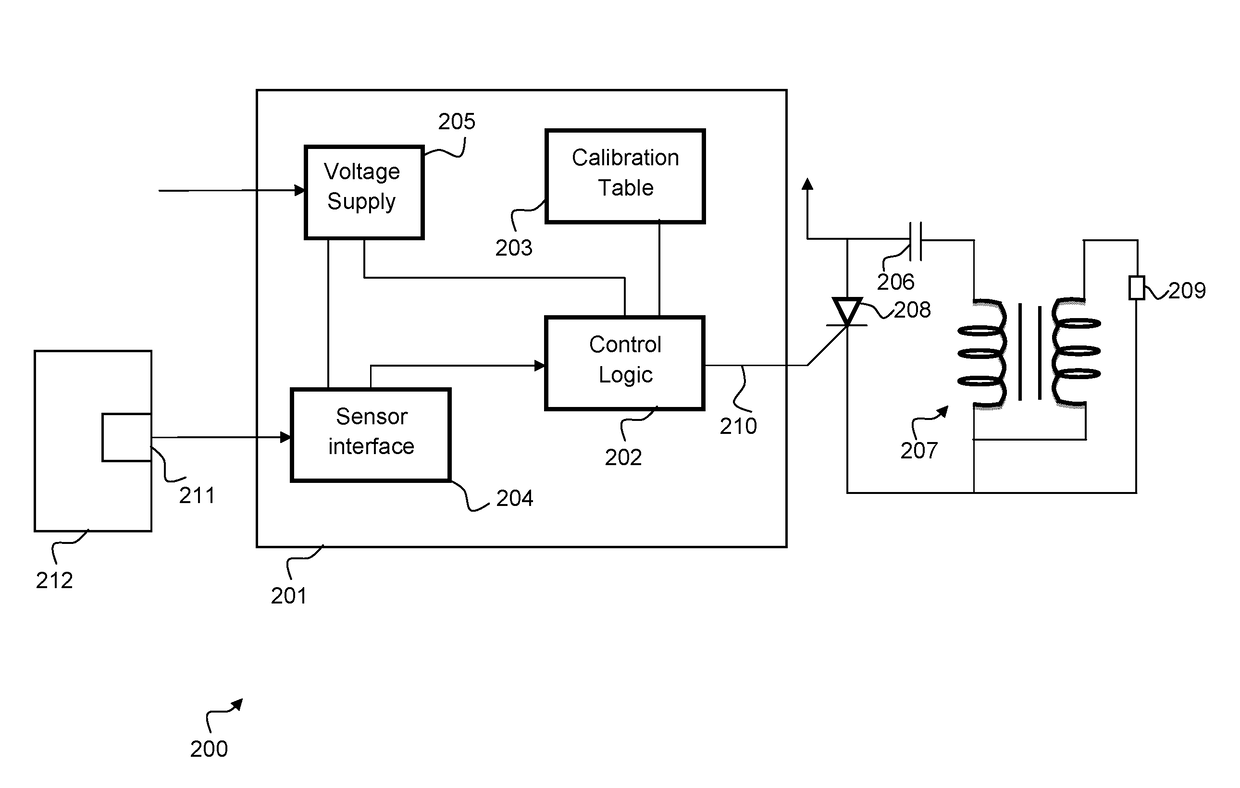

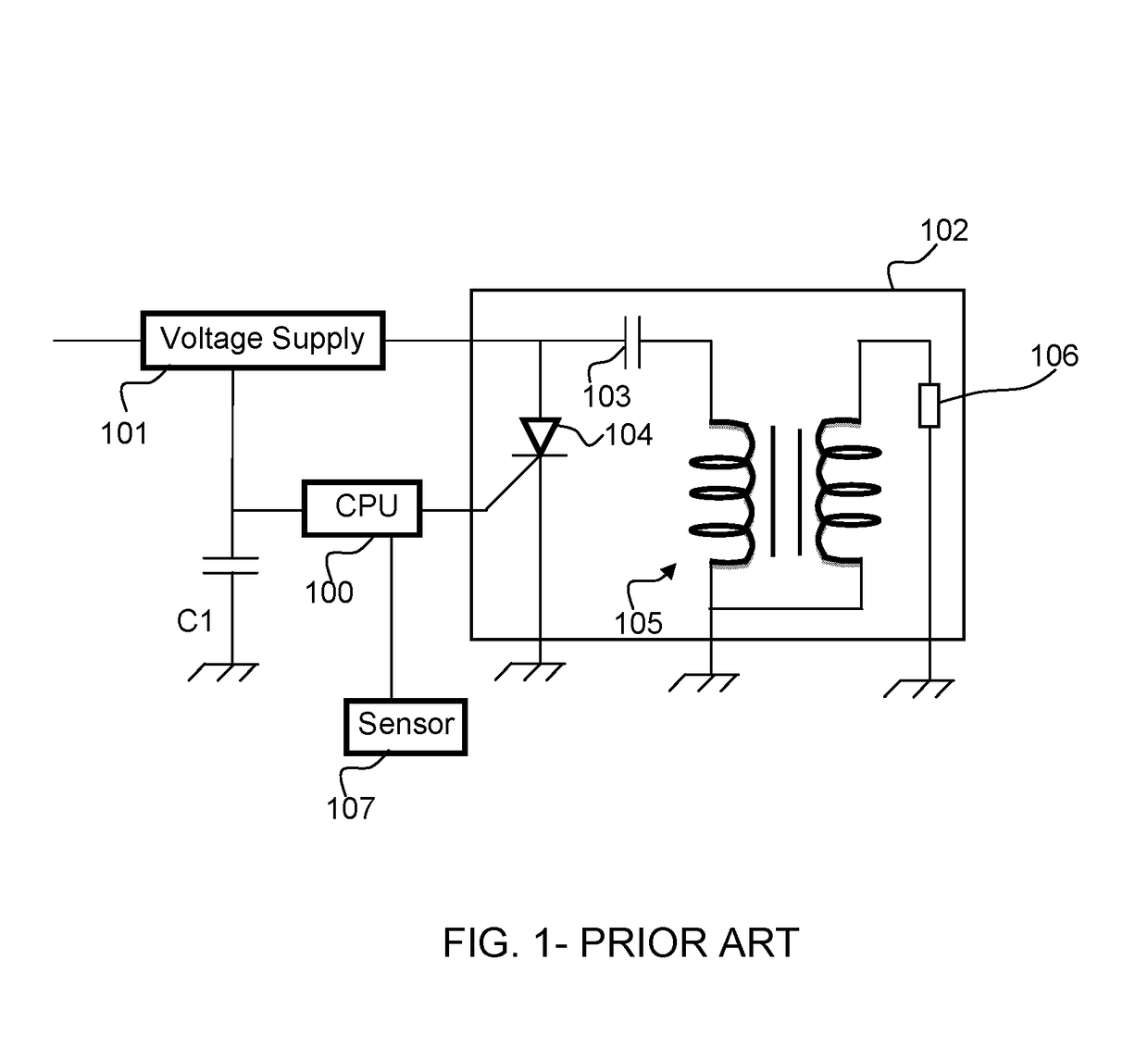

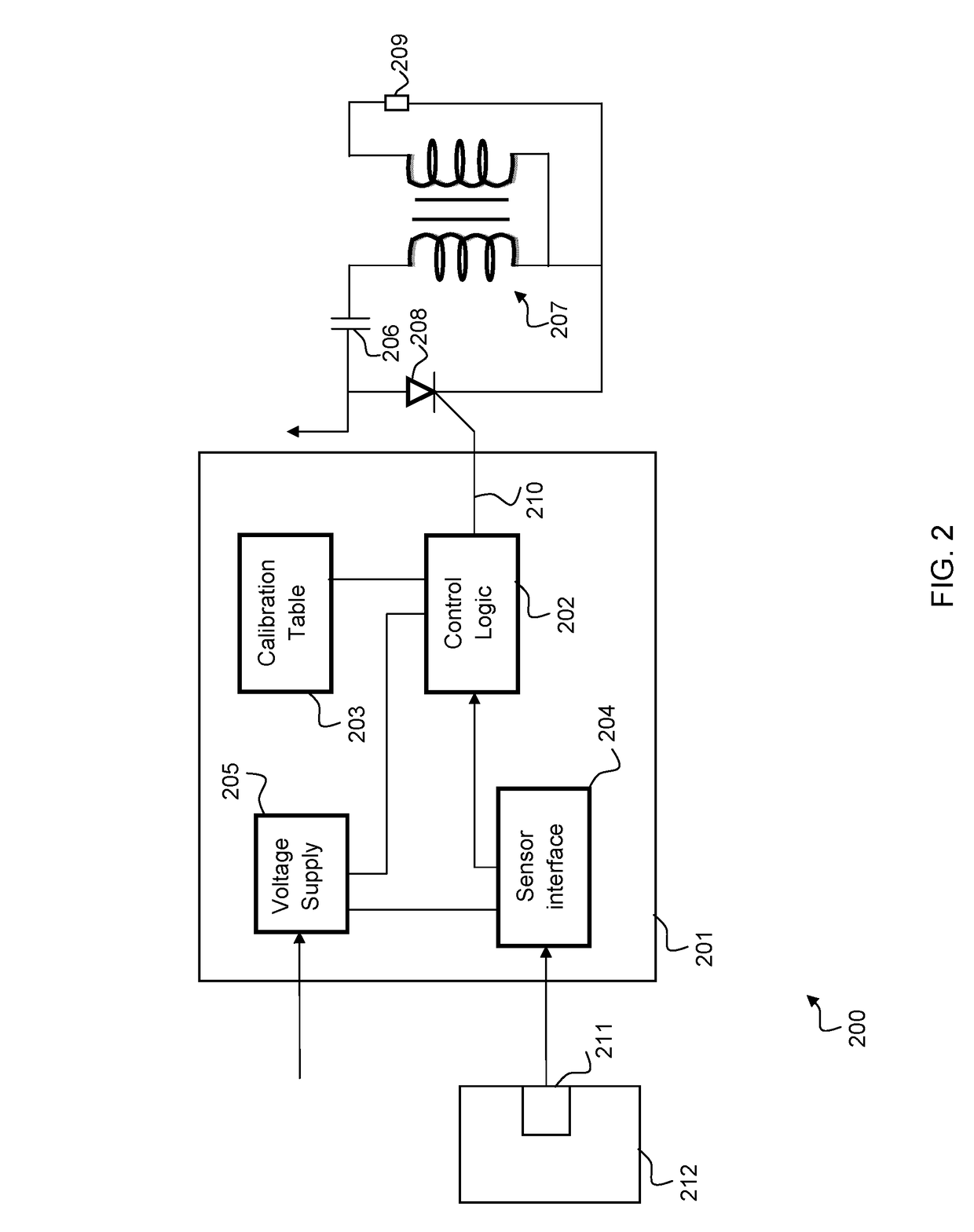

Method and apparatus for determining a value of a variable parameter

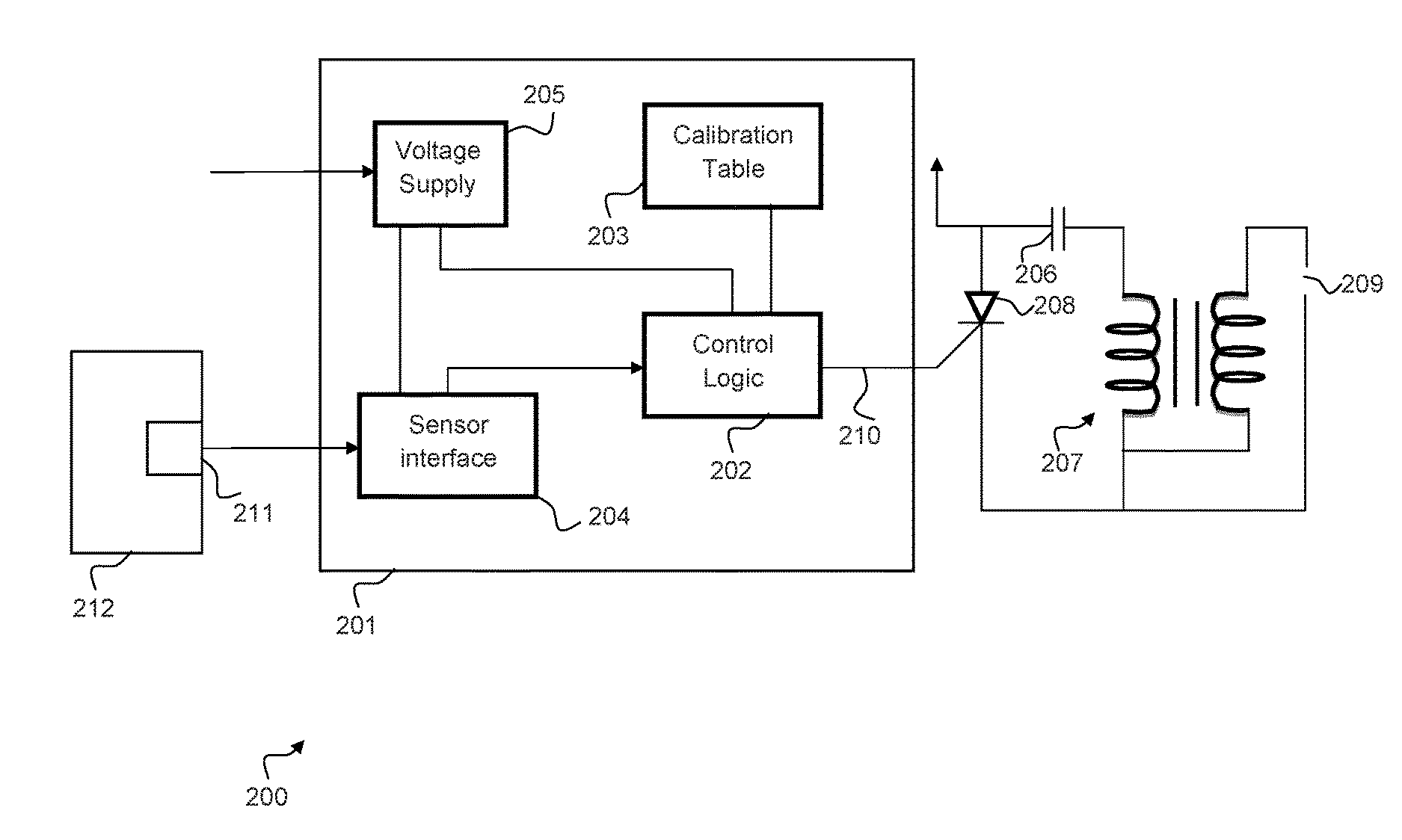

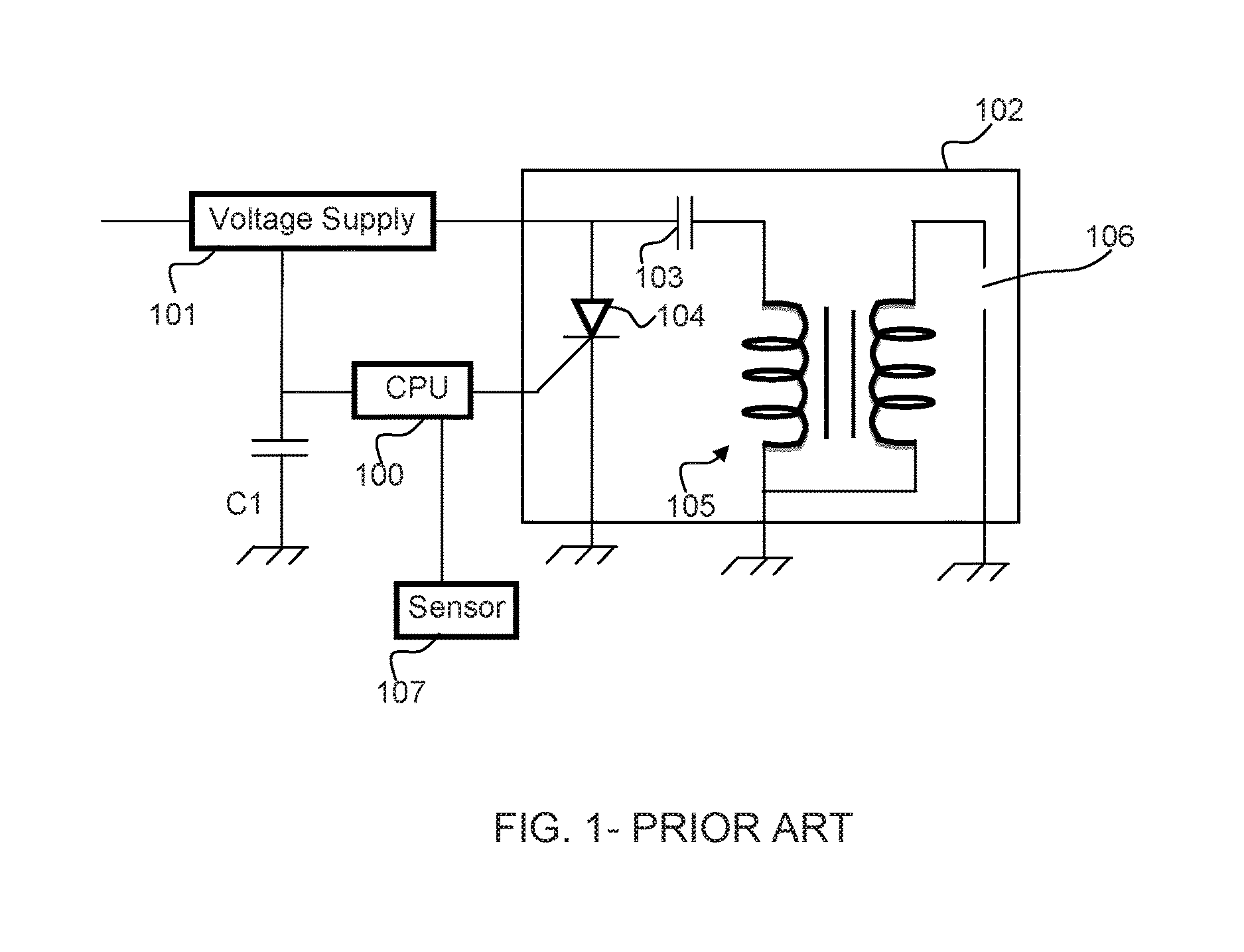

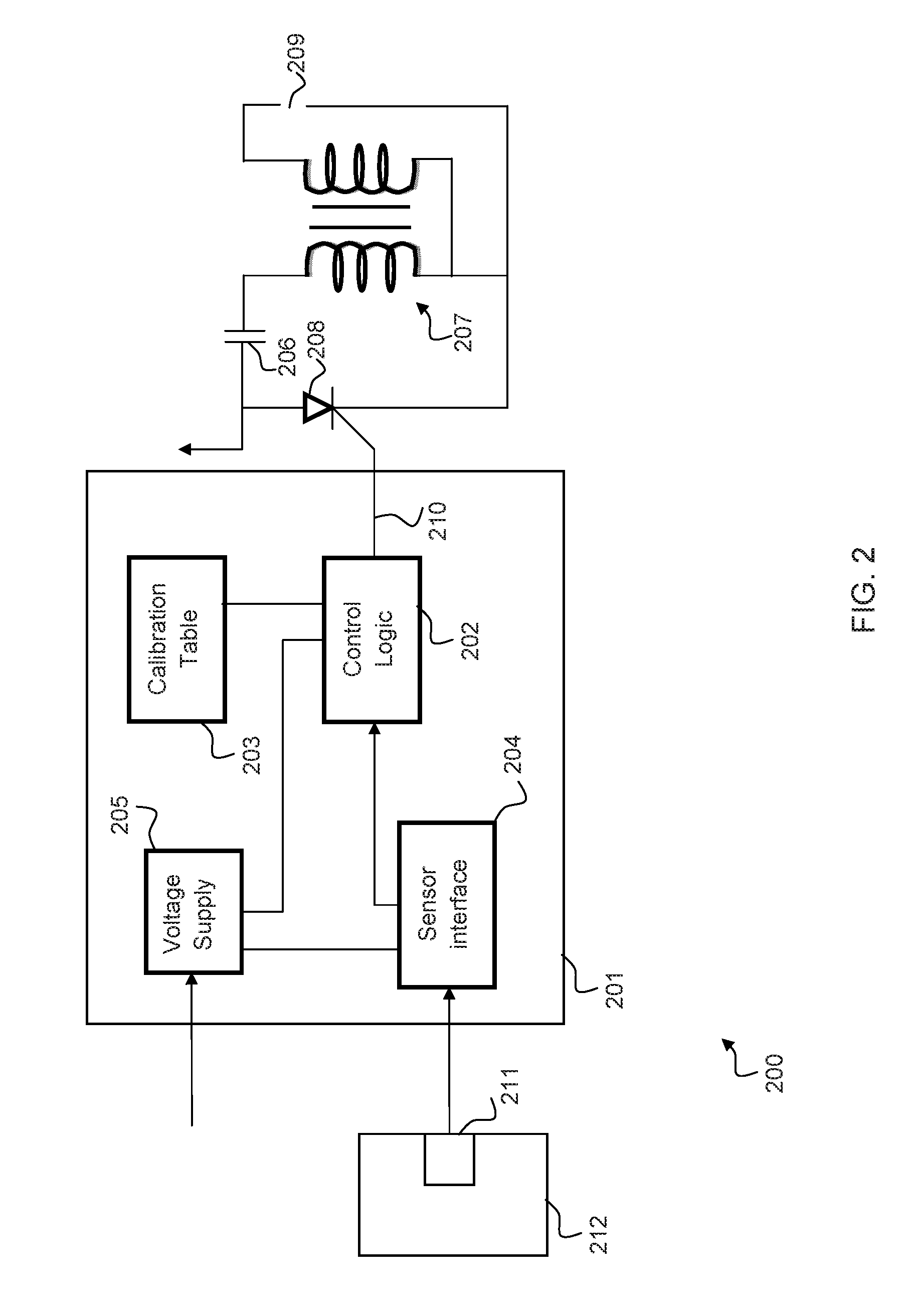

ActiveUS20170016423A1Space minimizationElectrical controlAC motor controlControl signalCapacitor discharge ignition

A control methodology and apparatus for an engine suitable for use in capacitor discharge ignition systems for internal combustion engines or brushless DC motors is provided, which make use of a simple logic block to determine for instance an ignition timing advance angle or duty cycle signal based on actual engine speed versus engine control parameter data stored in a table, which is a read-only memory, preferably configurable. To minimise memory space, a small number of values of engine control parameter versus engine speed are stored in the table and the logic block determines the required engine control signal for a measured value of engine speed by an interpolation process, preferably linear interpolation.

Owner:NXP USA INC

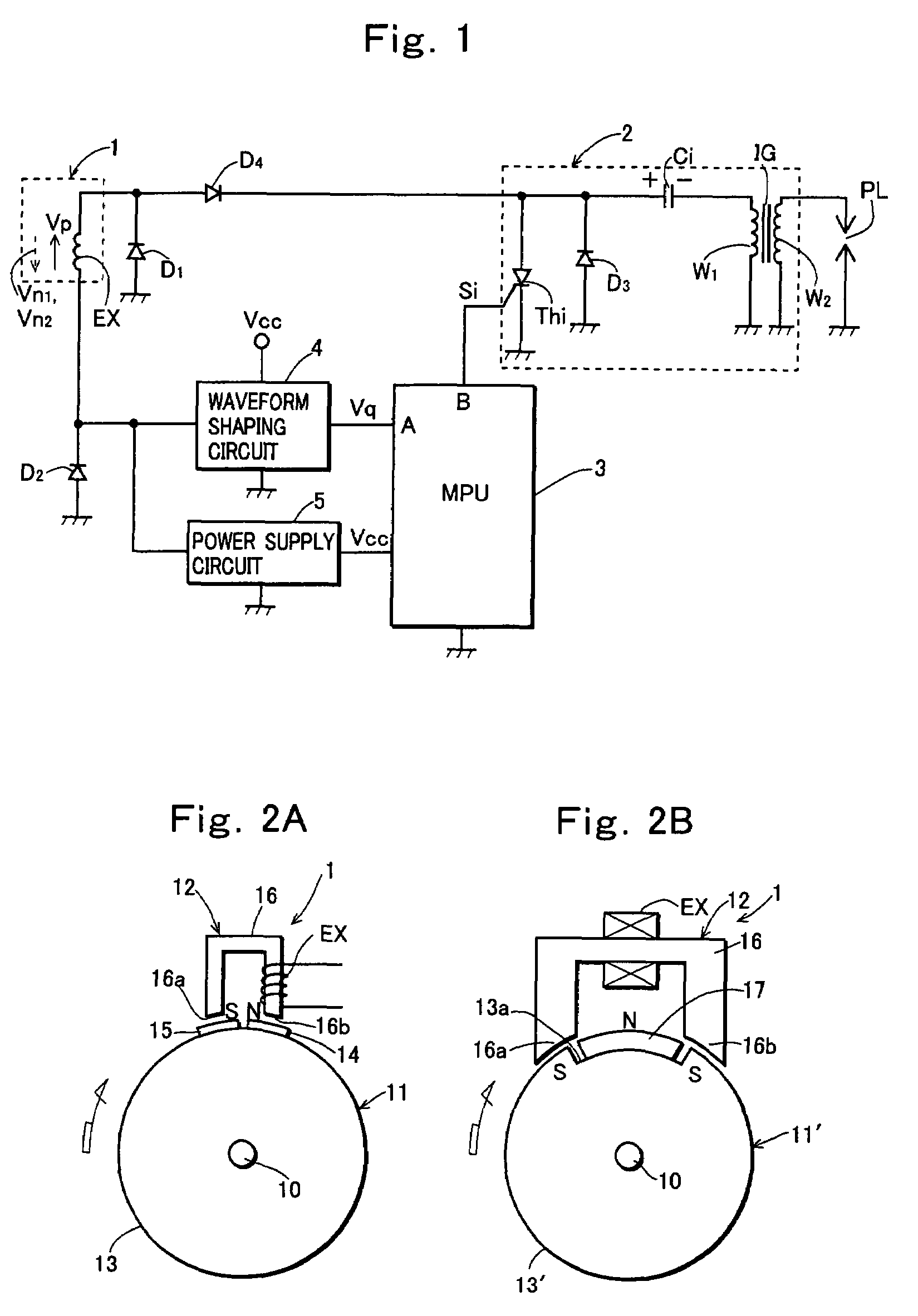

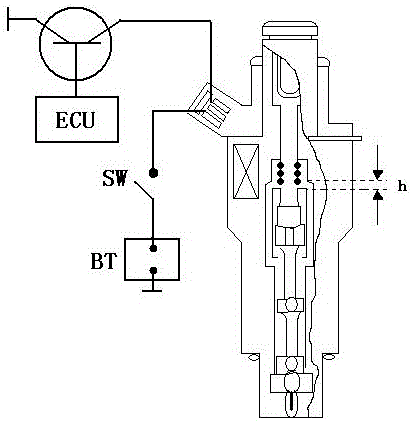

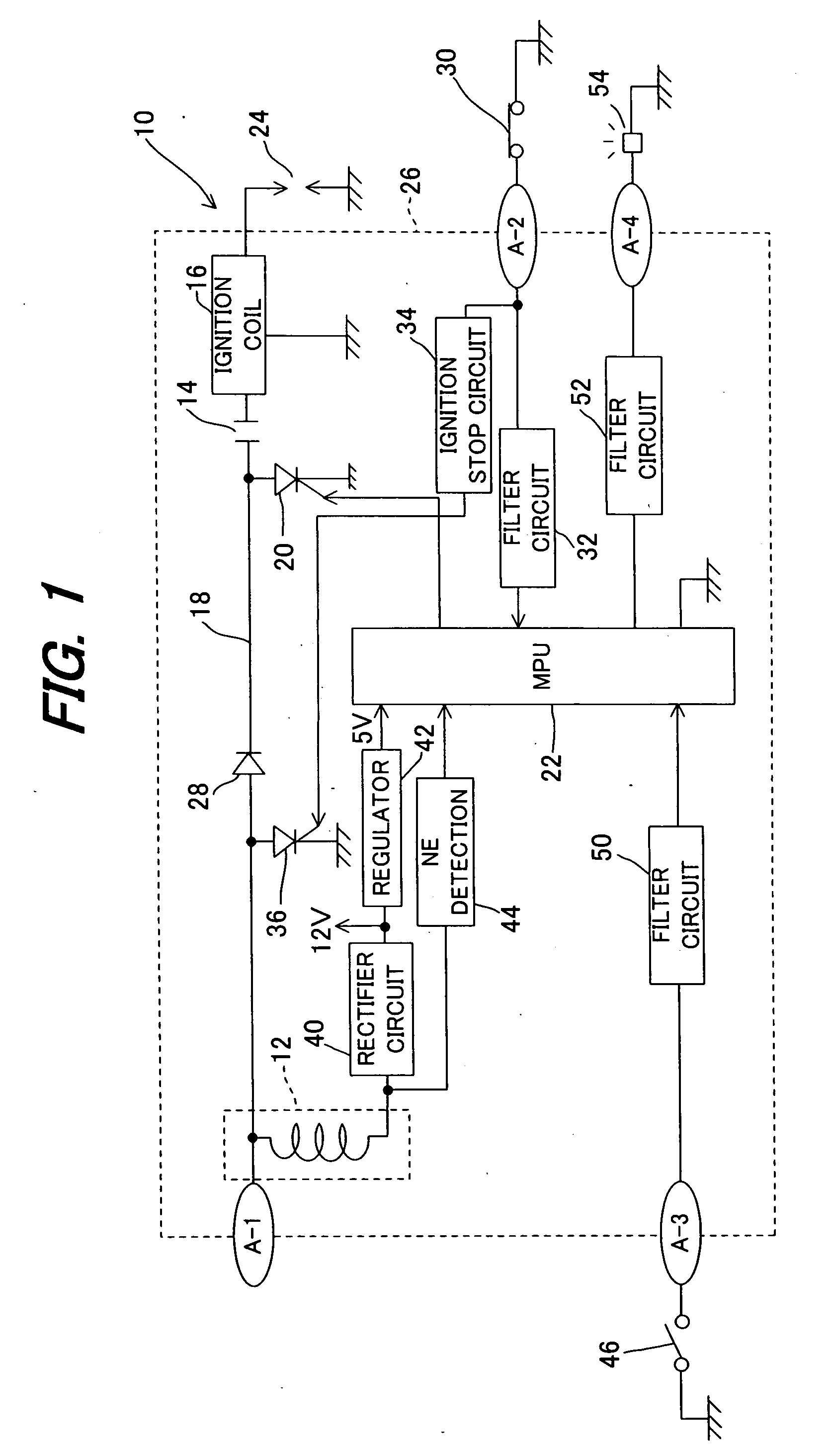

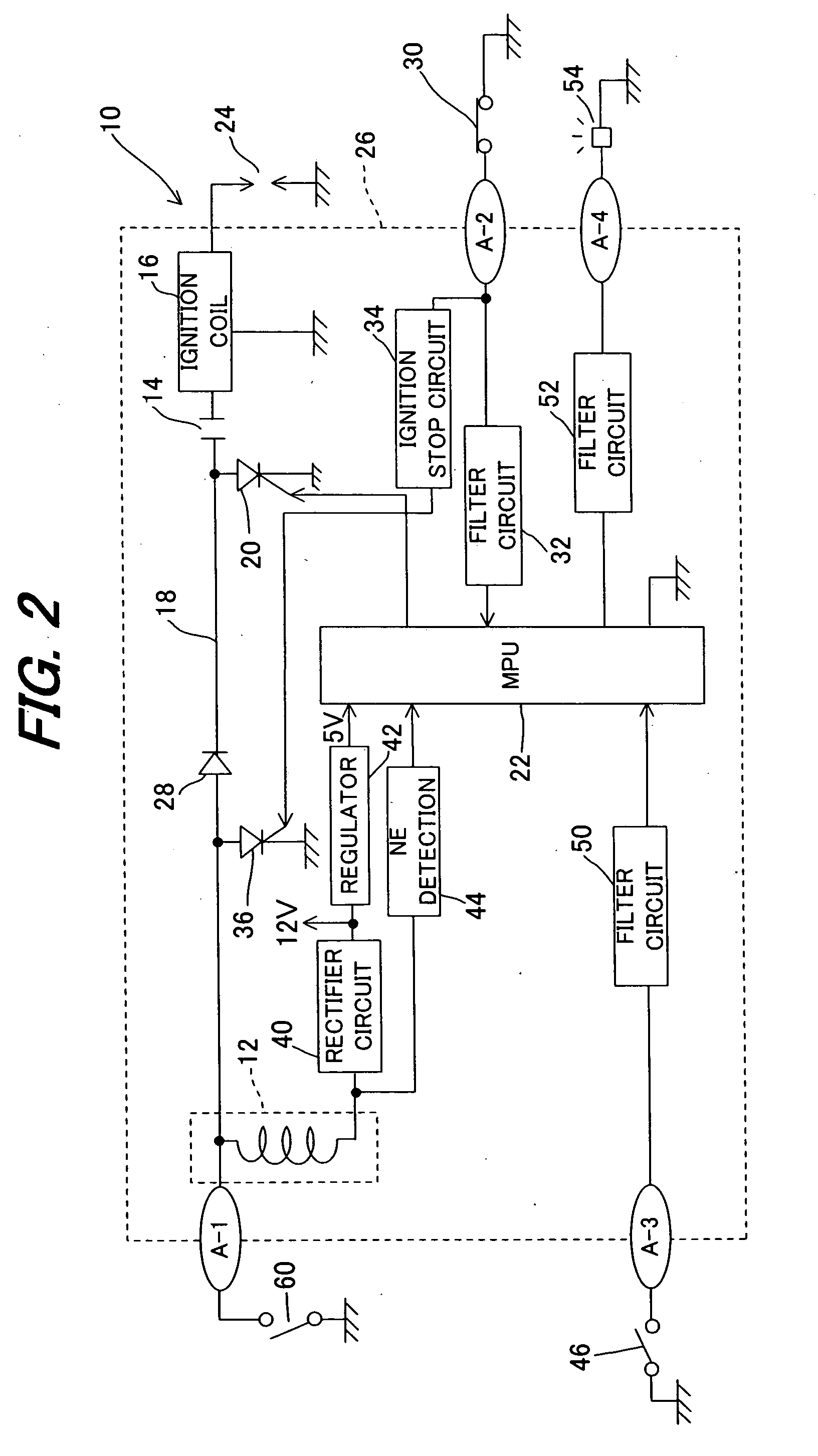

Capacitor-discharge ignition system for internal combustion engine

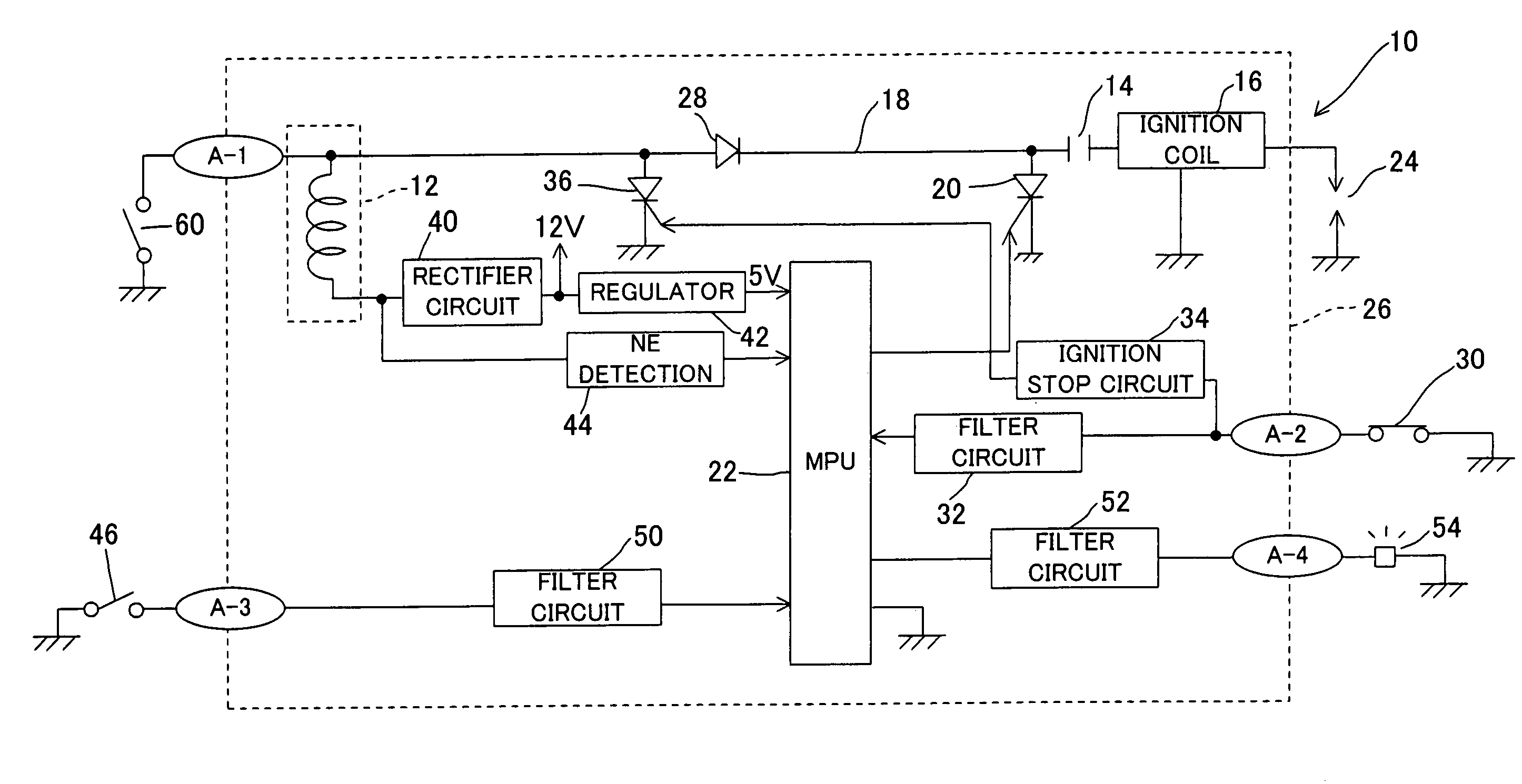

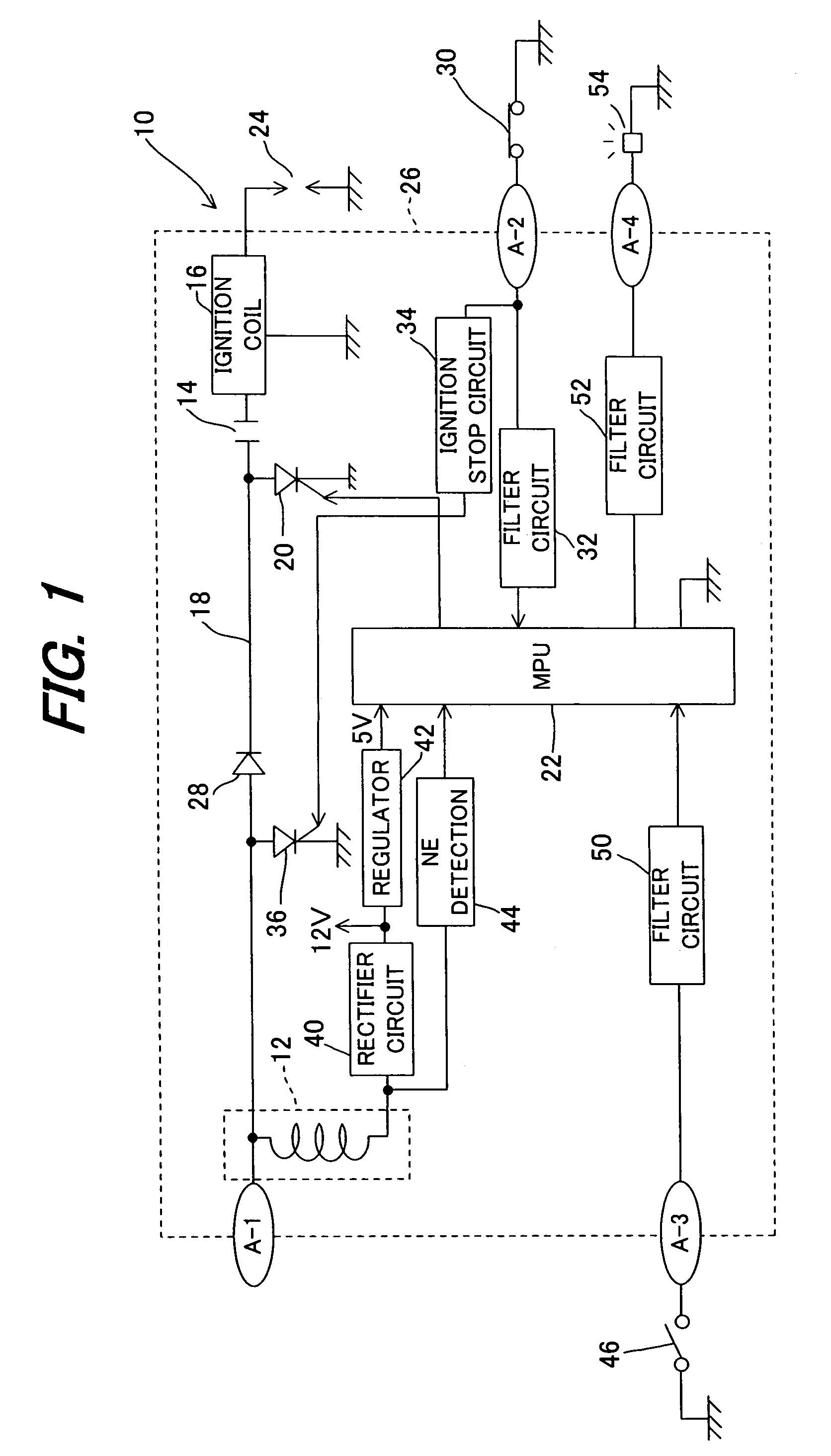

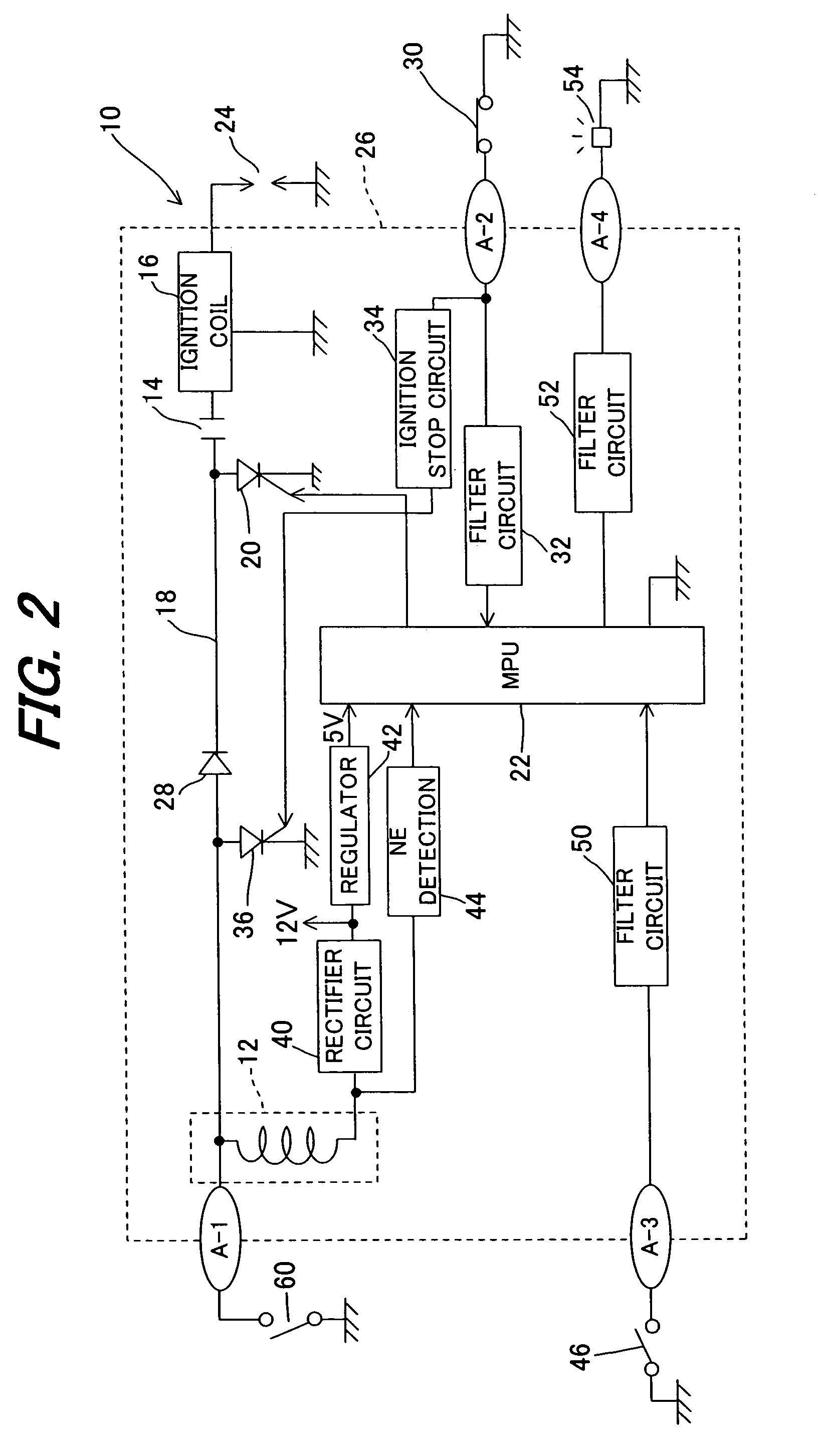

ActiveUS7706960B2Analogue computers for vehiclesMachines/enginesCapacitanceCapacitor discharge ignition

In a capacitor-discharge ignition system for an internal combustion engine having a power generation coil, a capacitor connected to the power generation coil, an ignition coil having a primary winding connected to the capacitor through a thyristor and a secondary winding connected to a spark plug, and a microprocessor which turns on the thyristor at a predetermined crank angular position to produce ignition in the spark plug, an engine stop switch is installed to input an engine-stop command signal to the microprocessor when being turned off by the operator. With this, it becomes possible to surely stop the engine at any time if desired.

Owner:HONDA MOTOR CO LTD

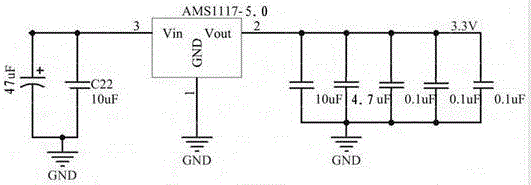

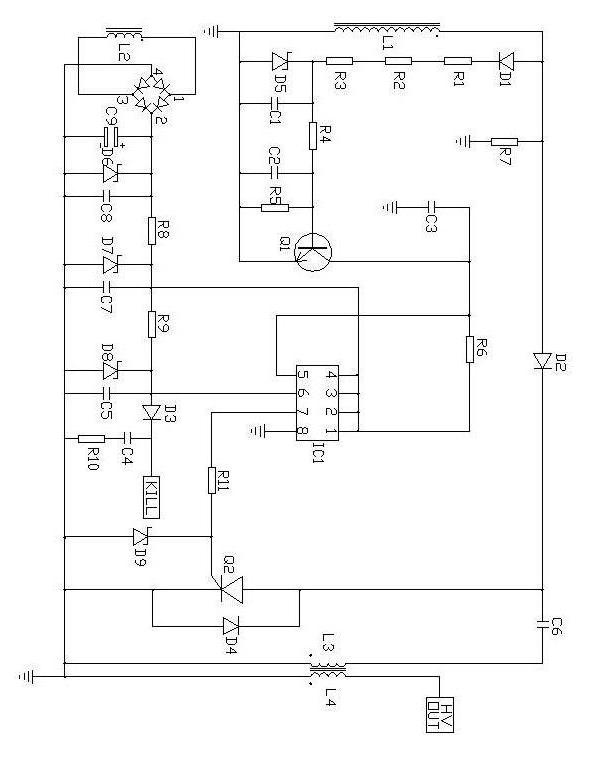

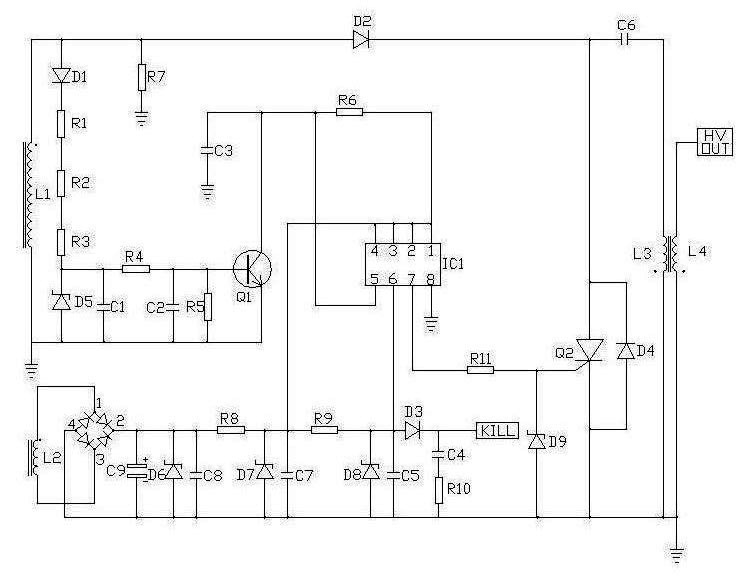

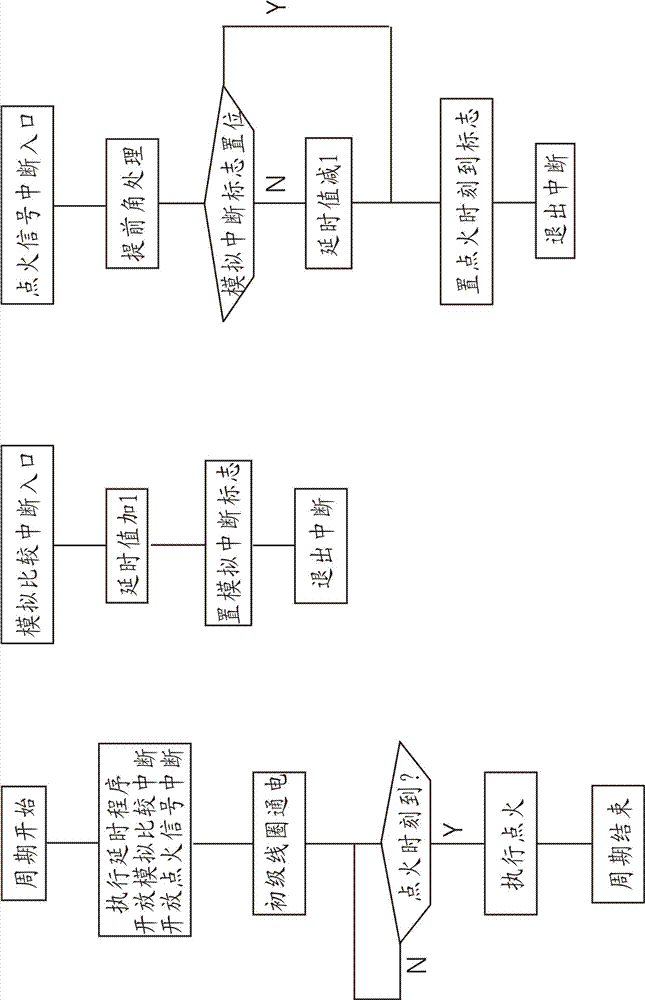

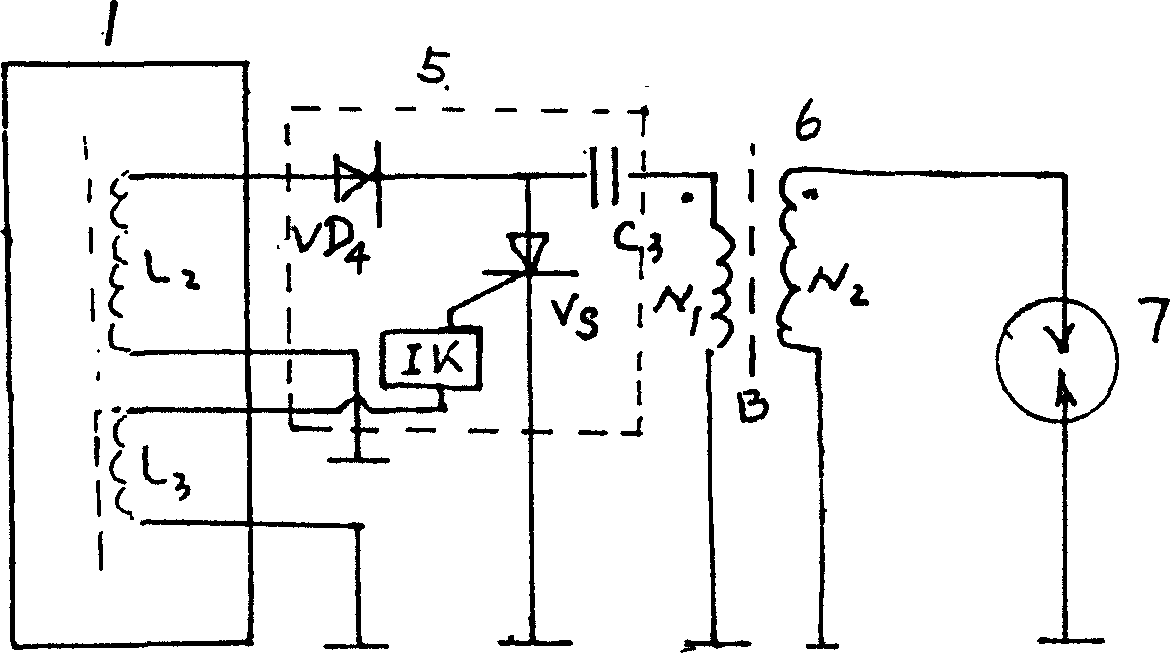

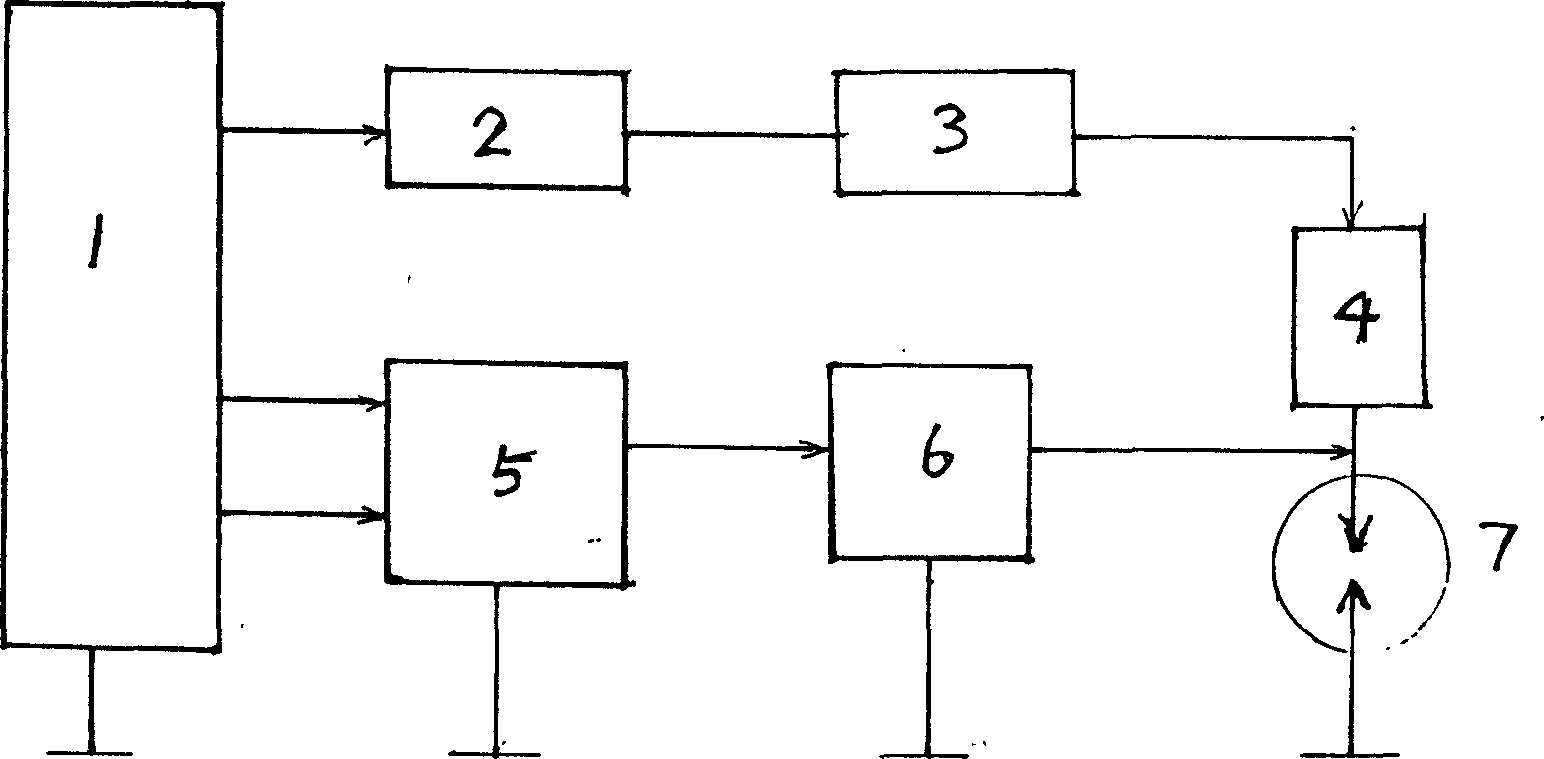

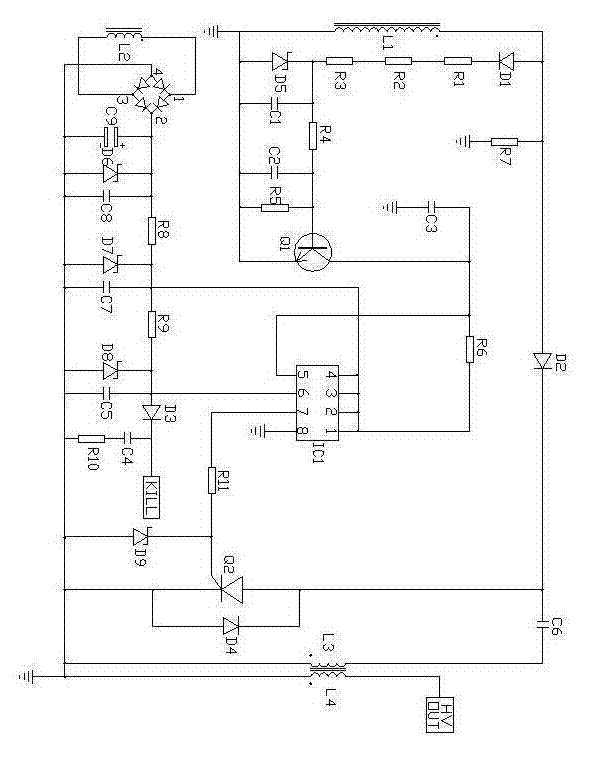

Gasoline engine igniter controlled by single-chip microprocessor (SCM)

InactiveCN102032086ABurn fullyImprove stabilityIgnition automatic controlInstallations with induction energy storageCapacitanceMicrocontroller

The invention relates to a gasoline engine igniter controlled by a single-chip microprocessor (SCM). The gasoline engine igniter comprises a capacity discharge ignition circuit, a signal trigger circuit, an SCM chip power supply circuit and an SCM chip integrated circuit (IC) 1, wherein, the capacity discharge ignition circuit, the signal trigger circuit and the SCM chip power supply circuit are controlled by an SCM chip; and as the signal trigger circuit and the SCM chip power supply circuit are mutually independent without interfering with each other, the SCM chip power supply circuit does not adsorb the current in the trigger coil of the signal trigger circuit, thus increasing ignition energy, improving the stability of the whole circuit, ensuring sufficient combustion of thegasoline in an engine, and reducing environmental pollution.

Owner:余姚市兰山电机企业有限公司

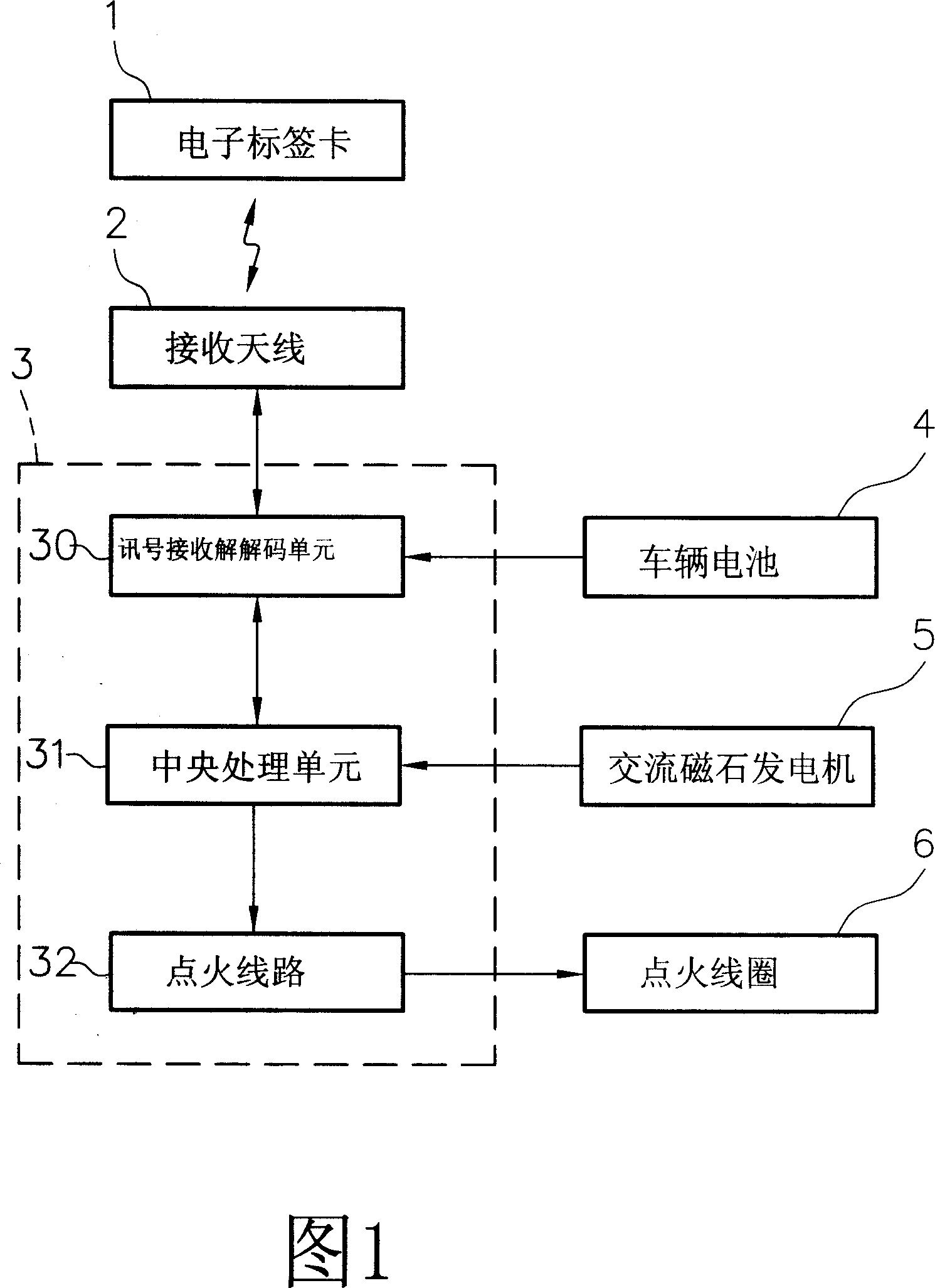

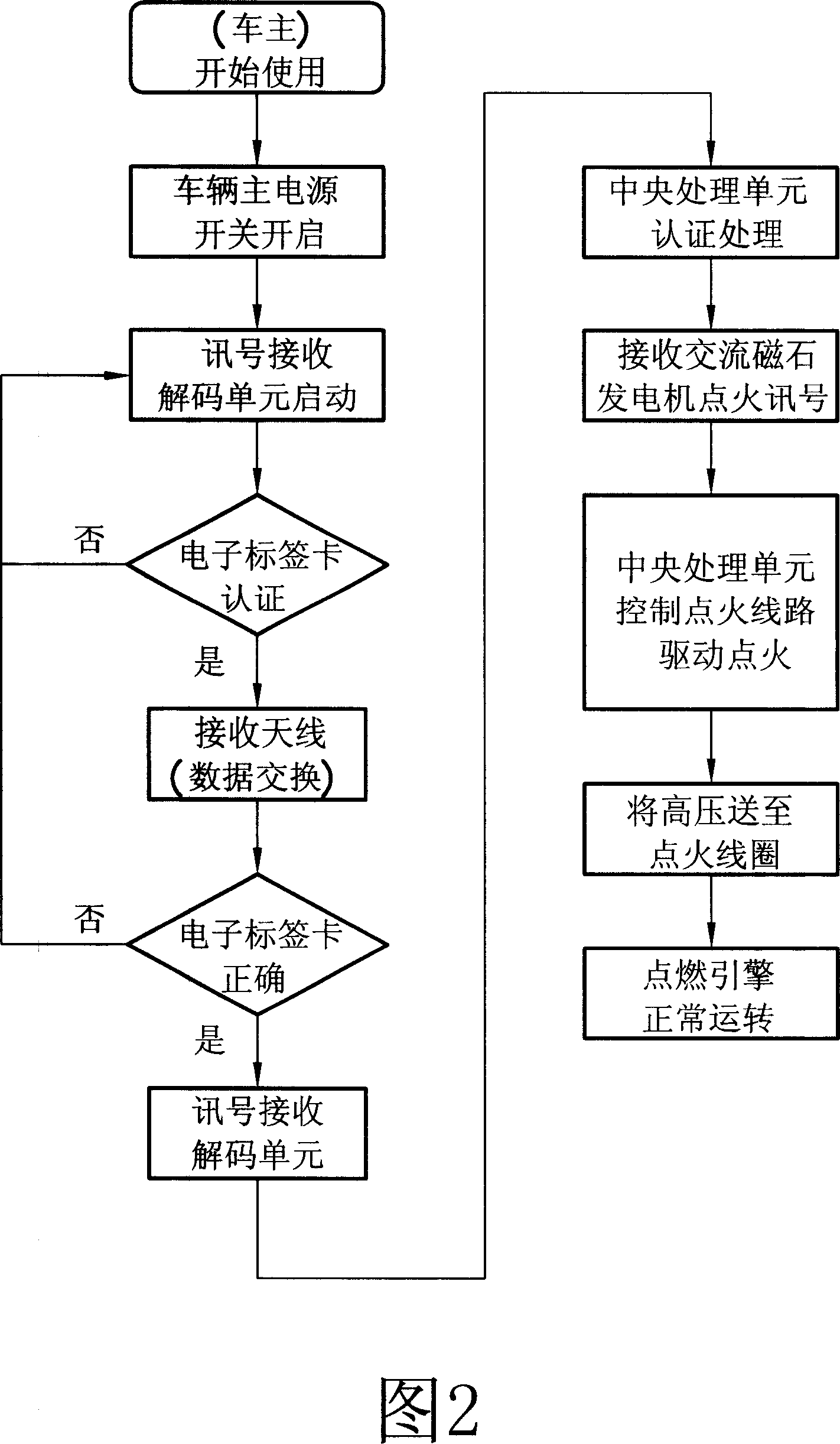

RFID embedded capacitor discharge ignited anti-theft system

The present invention provides one kind of embedded capacitor discharge ignition (CDI) anti-theft system with RFID. When the automobile owner turns on the main power switch, the voltage is transmitted to the signal receiving and decoding unit of the CDI anti-theft system to start the confirmation of the electronic volume label card, and the electronic volume label card performs data exchange with RF wave and receiving antenna, so that the signal is induced in the signal receiving and decoding unit and confirmed in the CPU, the CPU receives the ignition signal from the ACG and controls the ignition coil to ignite, and high voltage is fed to the ignition coil to ignite the engine. In this way, the unauthorized electronic volume label card can not start the CDI anti-theft system.

Owner:HERNG SHAN ELECTRONICS

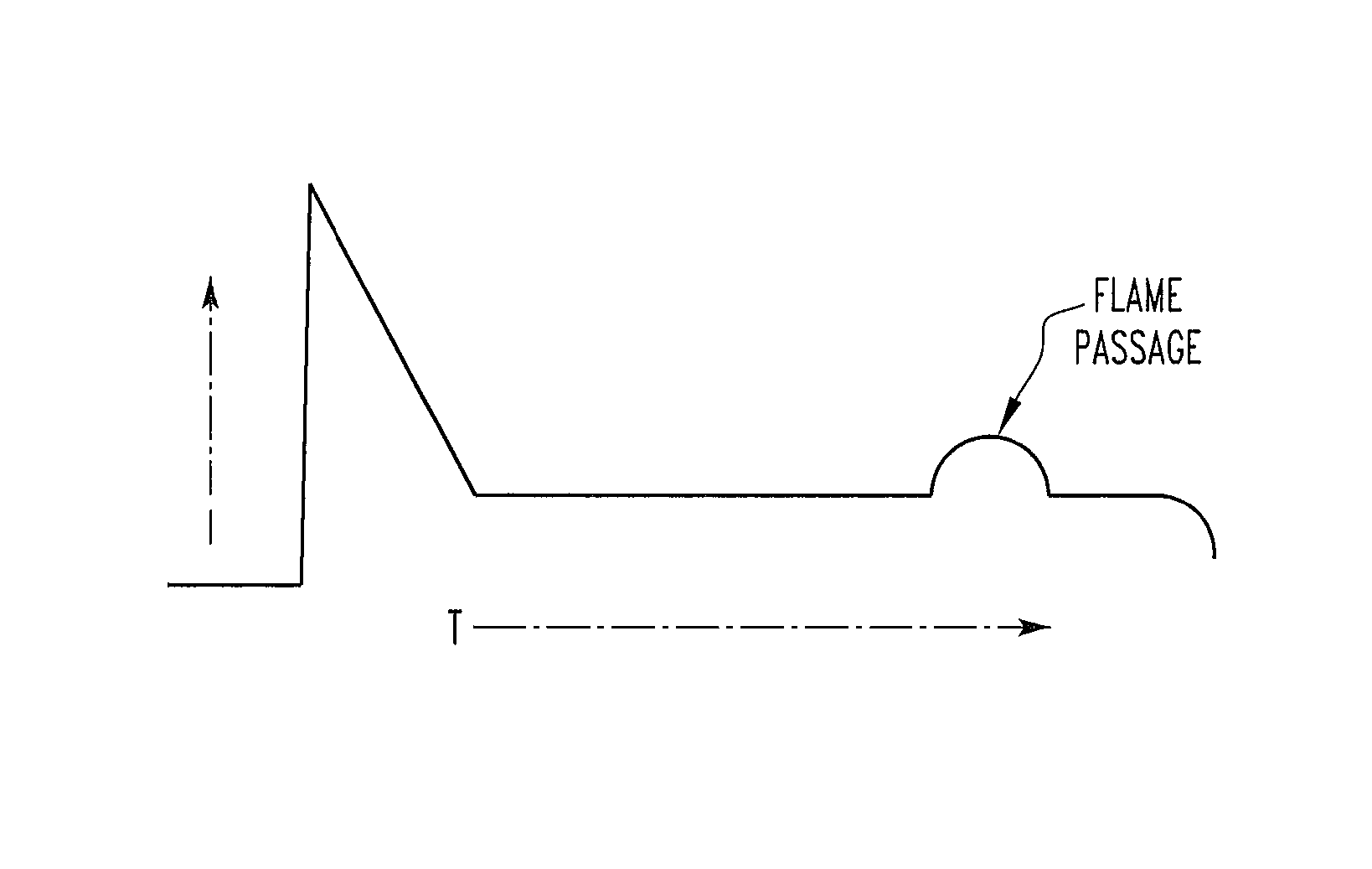

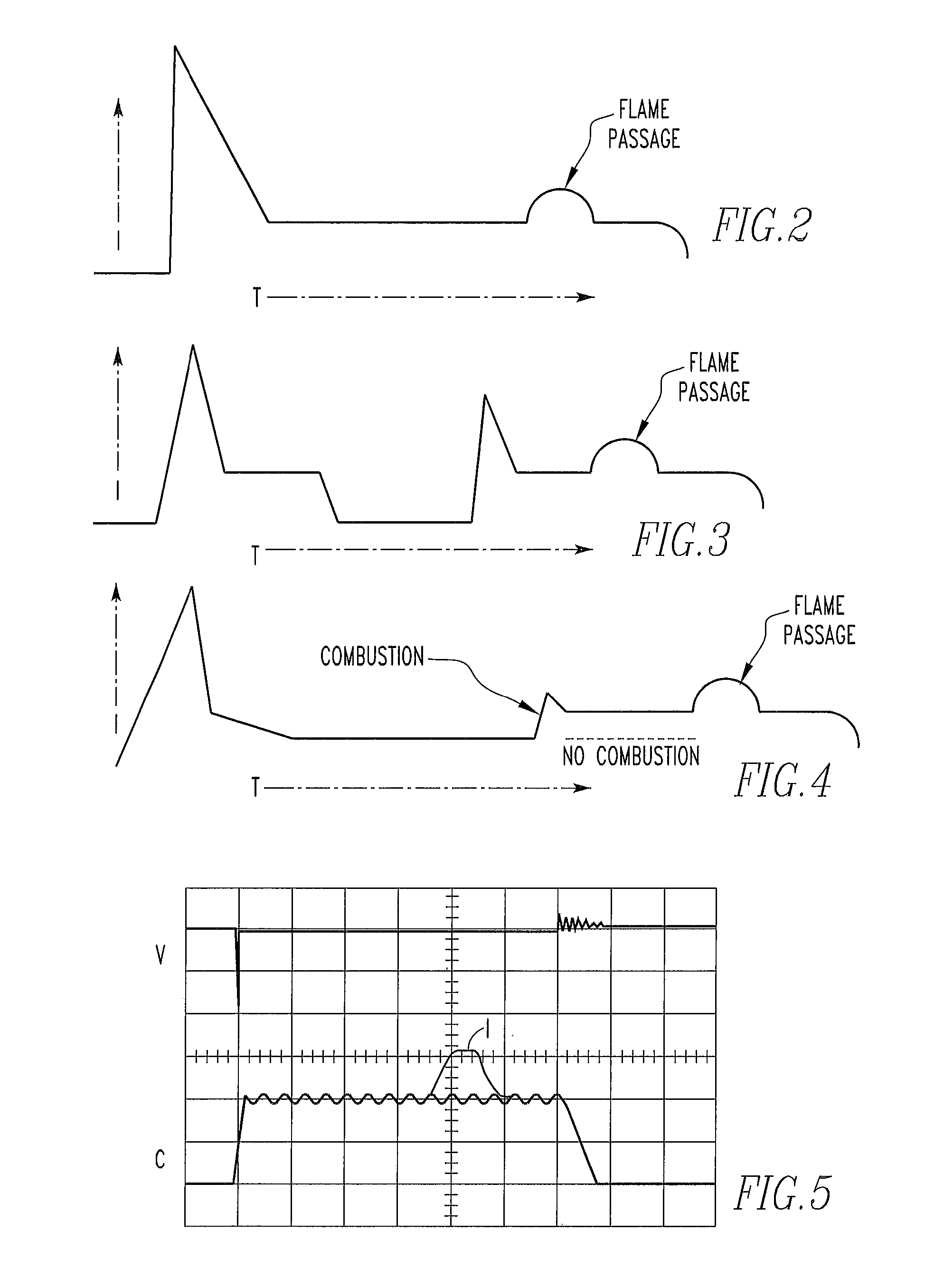

Ion sensing method for capacitive discharge ignition

Owner:ALTRONIC

Method and apparatus for determining a value of a variable parameter

ActiveUS9970405B2Space minimizationElectrical controlAC motor controlControl signalCapacitor discharge ignition

Owner:NXP USA INC

Diagnosis device of capacitor discharge ignition device for engine

A diagnosis device of a capacitor discharge ignition device for an engine that detects, as a singularity, a leading edge or a trailing edge of a voltage between output terminals of an ignition power supply portion that generates a voltage for charging an ignition capacitor, counts the number of singularities detected while a crankshaft rotates through a measurement section, which is a section of a certain crank angle determined with reference to a pulse signal obtained by a signal generator that generates a pulse signal at a specific crank angle position of an engine, and diagnoses an abnormality of the ignition device and a cause of the abnormality by comparing the count value of singularity with the number of times of normal ignition of the engine performed while the crankshaft rotates through the measurement section.

Owner:MAHLE INT GMBH

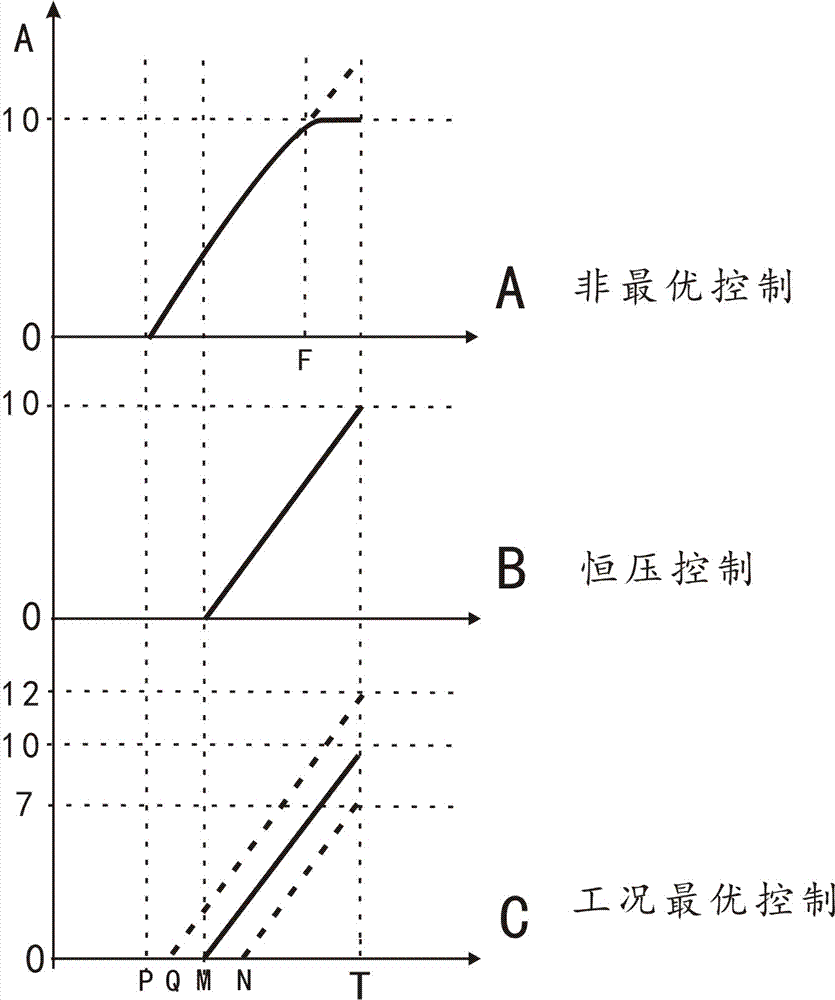

Optimal dwell angle ignition circuit and optimal control method of gasoline engine

InactiveCN103032247AImprove reliabilityAvoid overall overheatingIgnition automatic controlAutomatic controlMathematical modelOptimal control

The ignition dwell angle cannot be accurately controlled yet in the prior art; and in order to guarantee ignition energy, the dwell angle is set to be larger, so that the efficiency and the equipment reliability are reduced. The energy consumption caused thereby also has a strong impact on application of inductive ignition to a motorcycle. The scheme provided by the invention comprises a control circuit, a high pressure pack, a driving circuit, a switching circuit and a detection circuit, wherein the detection circuit is used for detecting a primary current up-to-standard moment and comparing with an ignition moment to obtain dwell angle deviation and correct the dwell angle so as to keep the ignition voltage at the optimal design value constantly. A detection working condition parameter is increased and a mathematical model is referred, so that the ignition energy period and working condition requirement are accurately and quantitatively matched, collectively referring to as an optimal dwell angle ignition circuit and an optimal control method of a gasoline engine. The problem that the ignition energy is configured according to a constant value or a working condition by the gasoline engine is completely solved. The ignition energy consumption is further reduced by using development of an ignition technology and matching with a new technology of the engine. A battery and a magnetic motor cannot be increased by upgrading CDI (Capacitor Discharge Ignition) of a motorcycle to inductive ignition.

Owner:曹杨庆

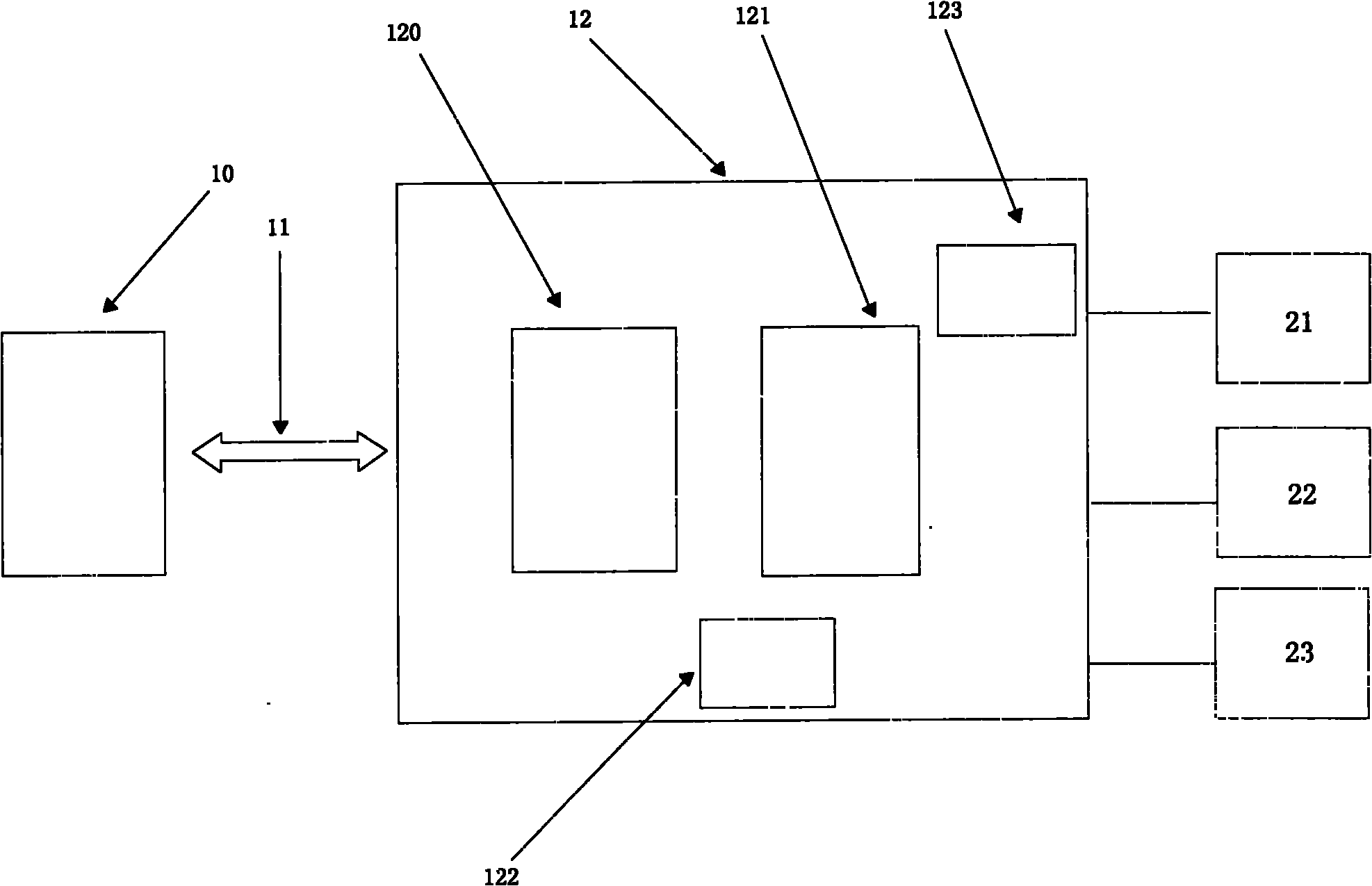

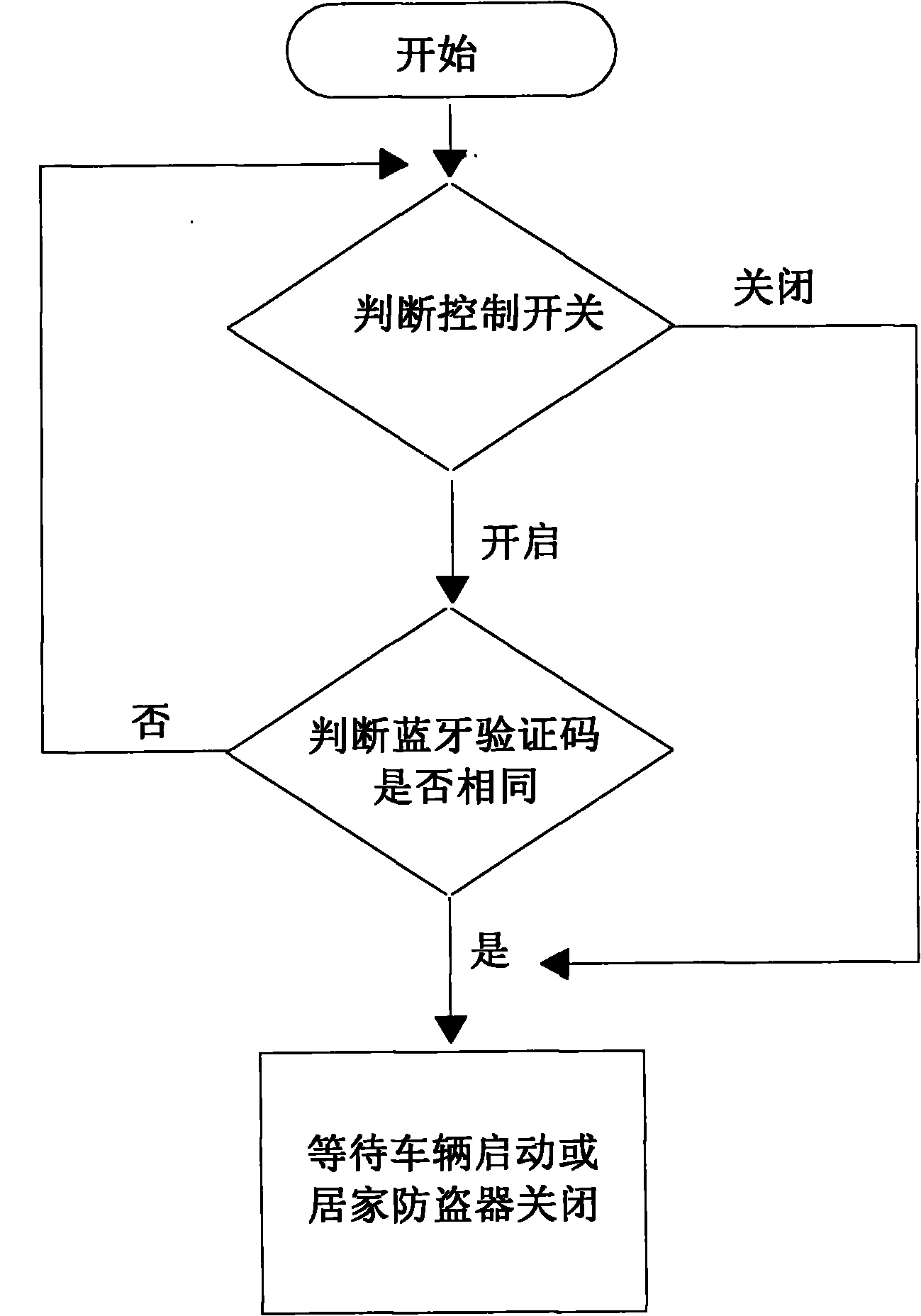

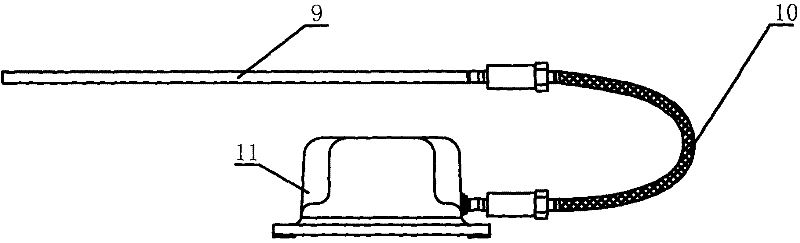

Bluetooth transmission control and anti-theft device

The invention relates to a Bluetooth transmission control and anti-theft device comprising a Bluetooth handheld device, a Bluetooth transmission module, a controller device and a control switch. The Bluetooth handheld device and the Bluetooth transmission module are connected wirelessly, and the Bluetooth transmission module is connected with the controller device which is connected with a peripheral computer directly or through the control switch. Preferably, the Bluetooth transmission control and anti-theft device also comprises a USB (Universal Serial Bus) device, and the Bluetooth transmission module is connected with an external computer through the USB device. By the Bluetooth transmission control and anti-theft device, equipment, such as a driving computer, a CDI (Capacity Discharge Ignition) system or a household alarm, and the like can be controlled so as to achieve the anti-theft aim; the USB component can be also utilized to change the identifying code and the solely set identifying code so as to achieve better anti-theft effect. In brief, the invention has the efficacy of excellent anti-theft effect, hard password interception and decipherment, and the like.

Owner:余阿文 +1

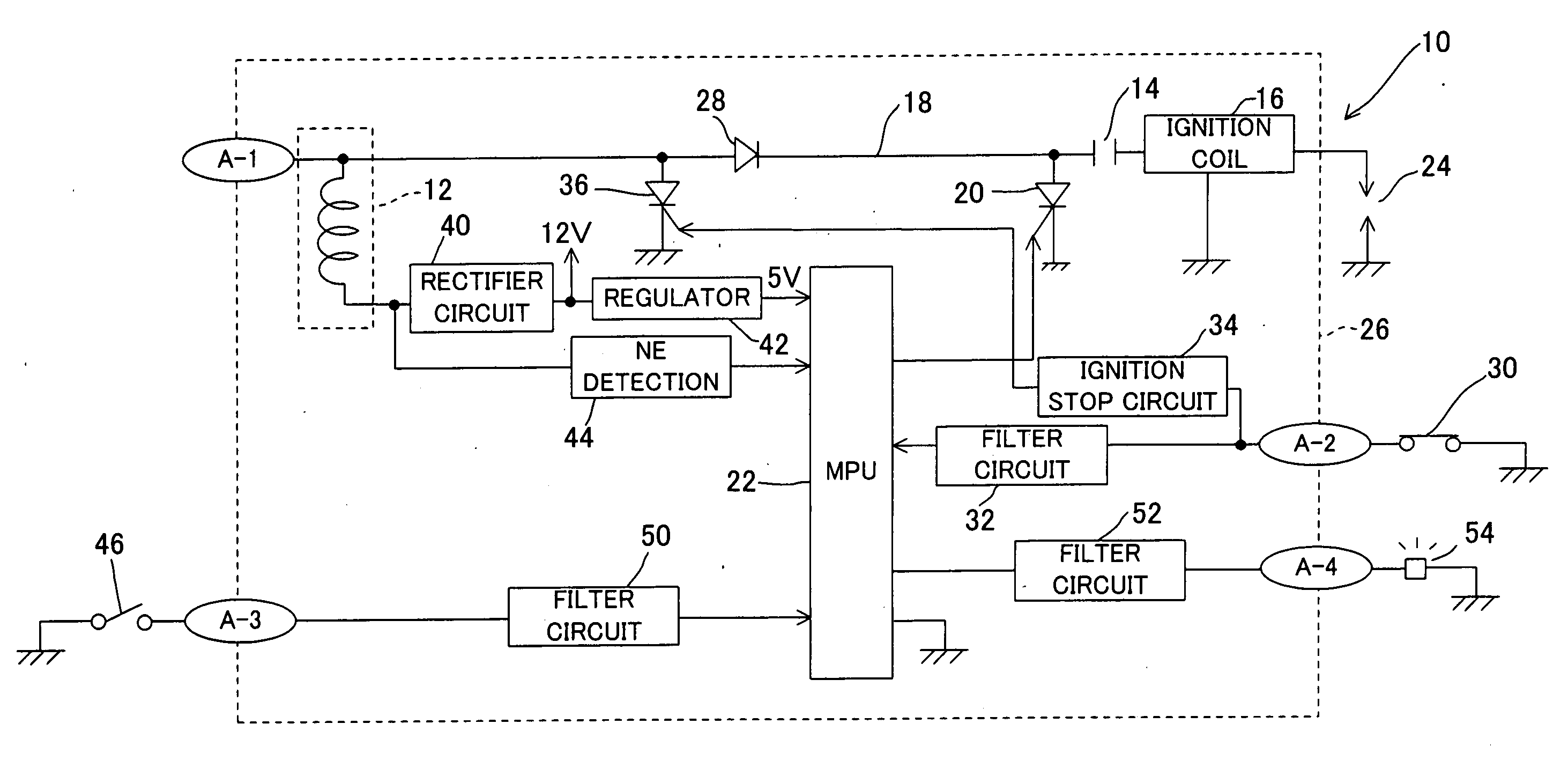

Capacitor-discharge ignition system for internal combustion engine

ActiveUS20080257322A1Firmly connectedEasily manipulateAnalogue computers for vehiclesMachines/enginesCapacitanceCapacitor discharge ignition

In a capacitor-discharge ignition system for an internal combustion engine having a power generation coil, a capacitor connected to the power generation coil, an ignition coil having a primary winding connected to the capacitor through a thyristor and a secondary winding connected to a spark plug, and a microprocessor which turns on the thyristor at a predetermined crank angular position to produce ignition in the spark plug, an engine stop switch is installed to input an engine-stop command signal to the microprocessor when being turned off by the operator. With this, it becomes possible to surely stop the engine at any time if desired.

Owner:HONDA MOTOR CO LTD

Method and device for recycling heat energy in reduction exhaust in polysilicon production process

ActiveCN102070145BReduce consumptionReduce loadSiliconIncreasing energy efficiencyBuffer tankReboiler

The invention discloses a method and device for recycling heat energy in reduction exhaust in a polysilicon production process. The method comprises the following steps: reduction exhaust and chlorsilane are subjected to primary heat exchange in a tower bottom reboiler; and after heat exchange, part of the chlorsilane is vaporized and delivered into a chlorsilane purification tower to serve as a heat source for the chlorsilane purification tower, the reduction exhaust subjected to heat exchange is delivered into a condenser, and the chlorsilane in the reduction exhaust is condensed into liquid to be delivered into the chlorsilane purification tower. The device for recycling the heat energy in reduction exhaust in the polysilicon production process comprises a tower top condenser, a purification tower, a tower bottom reboiler, an exhaust condenser, a chlorsilane buffer tank and a chlorsilane delivery pump which are sequentially connected, wherein the outlet of the chlorsilane delivery pump is connected with the purification tower. By means of the technical improvement provided by the invention, the steam consumption of the reduction rectification system can be reduced by 40%, the load of the refrigerator of a CDI (capacitor discharge ignition) system can be reduced by 7% simultaneously, and the circulating water consumption is reduced by about 52.44%, thereby achieving the purposes of favorable energy conservation and consumption reduction.

Owner:XINTE ENERGY

Ignition control system of tube furnace

ActiveCN101576314BEnsure reliabilityAchieve automatic ignitionFuel supply regulationElectric spark ignitersCapacitanceHigh energy

The invention relates to an ignition control system of a tube furnace. The system comprises a high-energy ignition device, a burner, an automatic ignition control system and a burning control system, wherein the high-energy ignition device adopts a capacitive discharge type igniter capable of providing the safe and reliable ignition performance; the burner is provided with a flame detection deviceand can realize the regulation of burning-supporting air and fuel in certain proportion; and the automatic ignition control system has the functions of flame detection, safety protection of the furnace and self diagnosis. The invention has the advantages of high heat efficiency, safety and reliability, stable and controllable burning, energy saving and emission reduction.

Owner:ACRE AUTOMATION CO LTD MCC

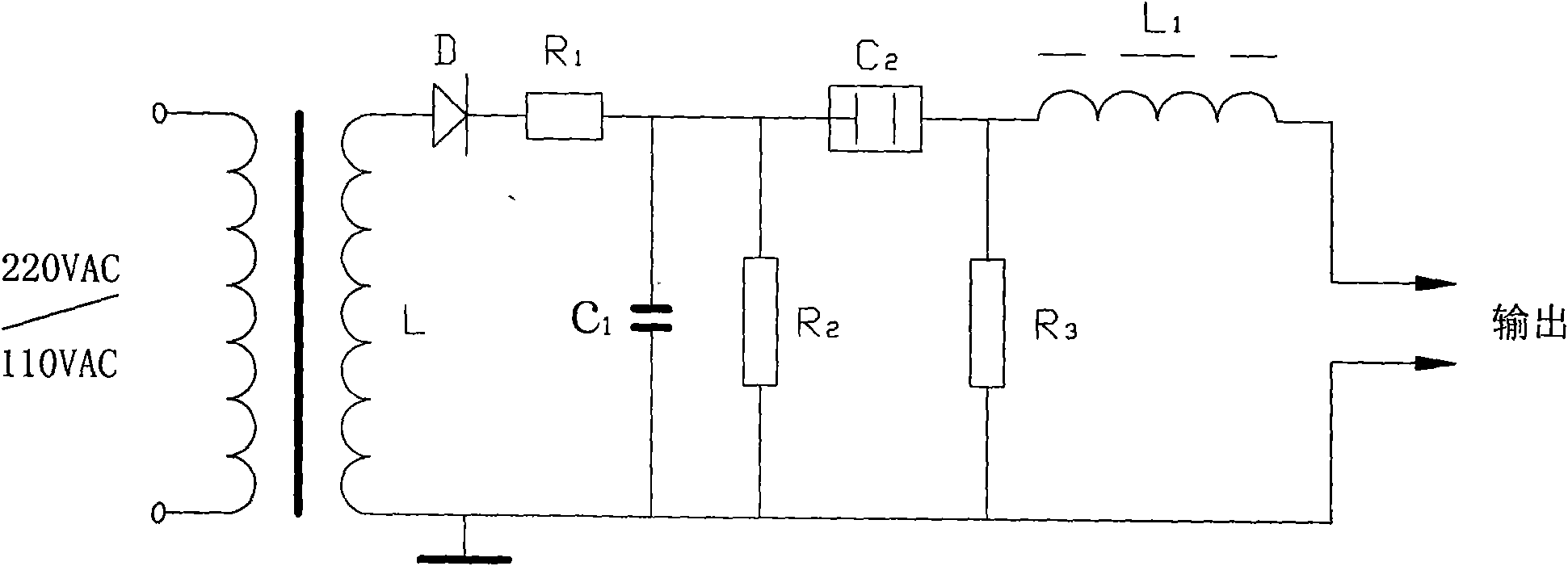

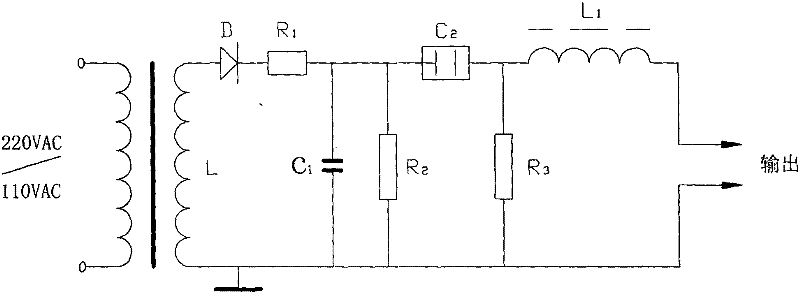

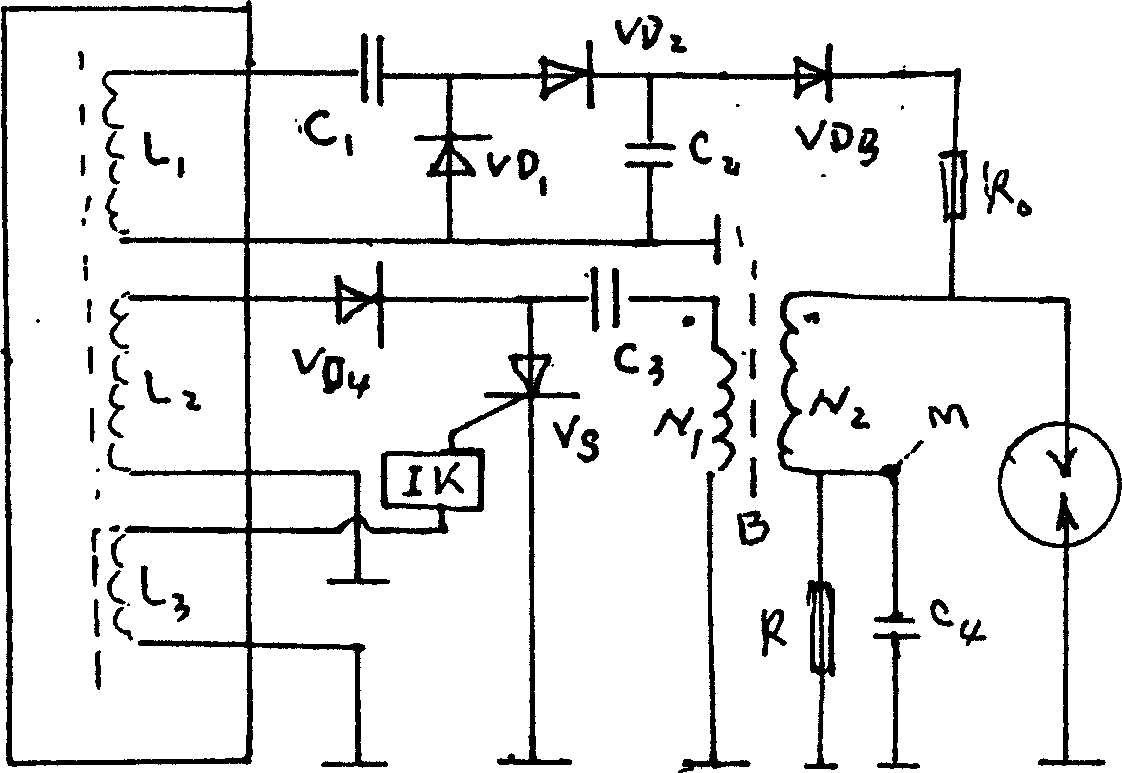

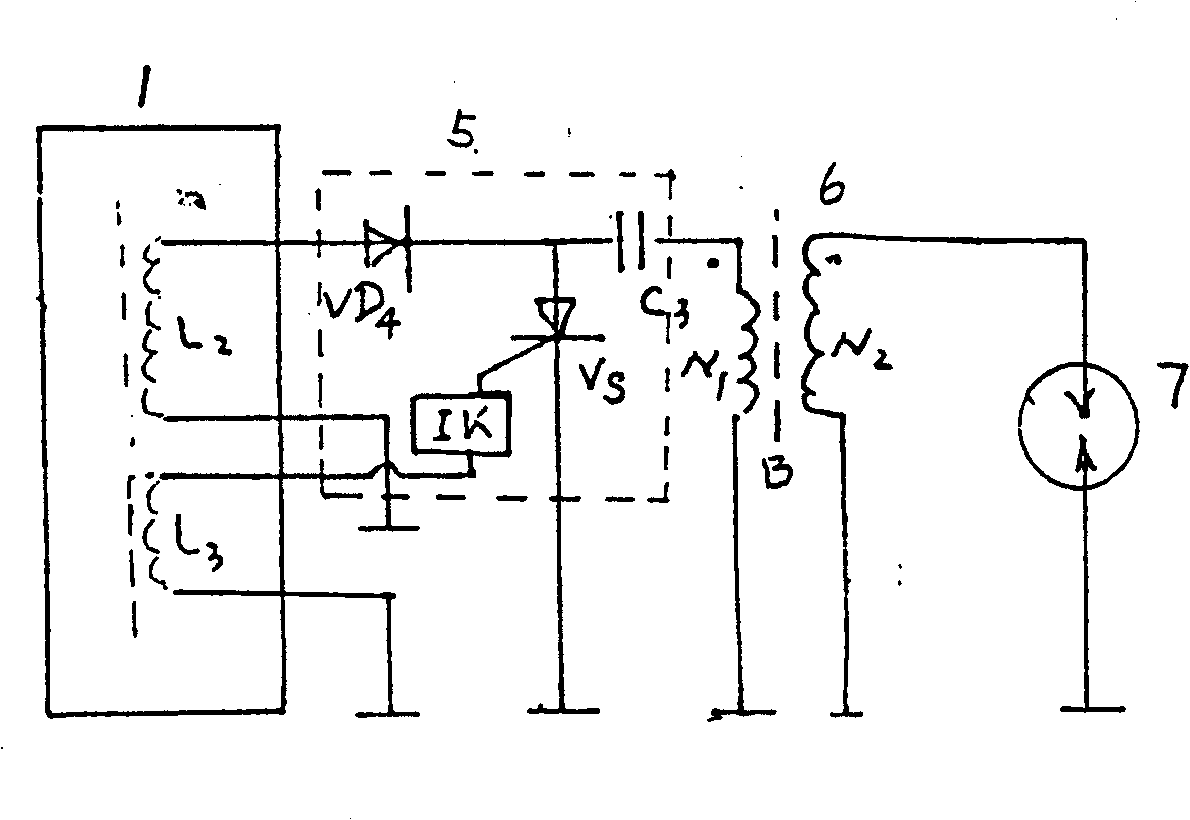

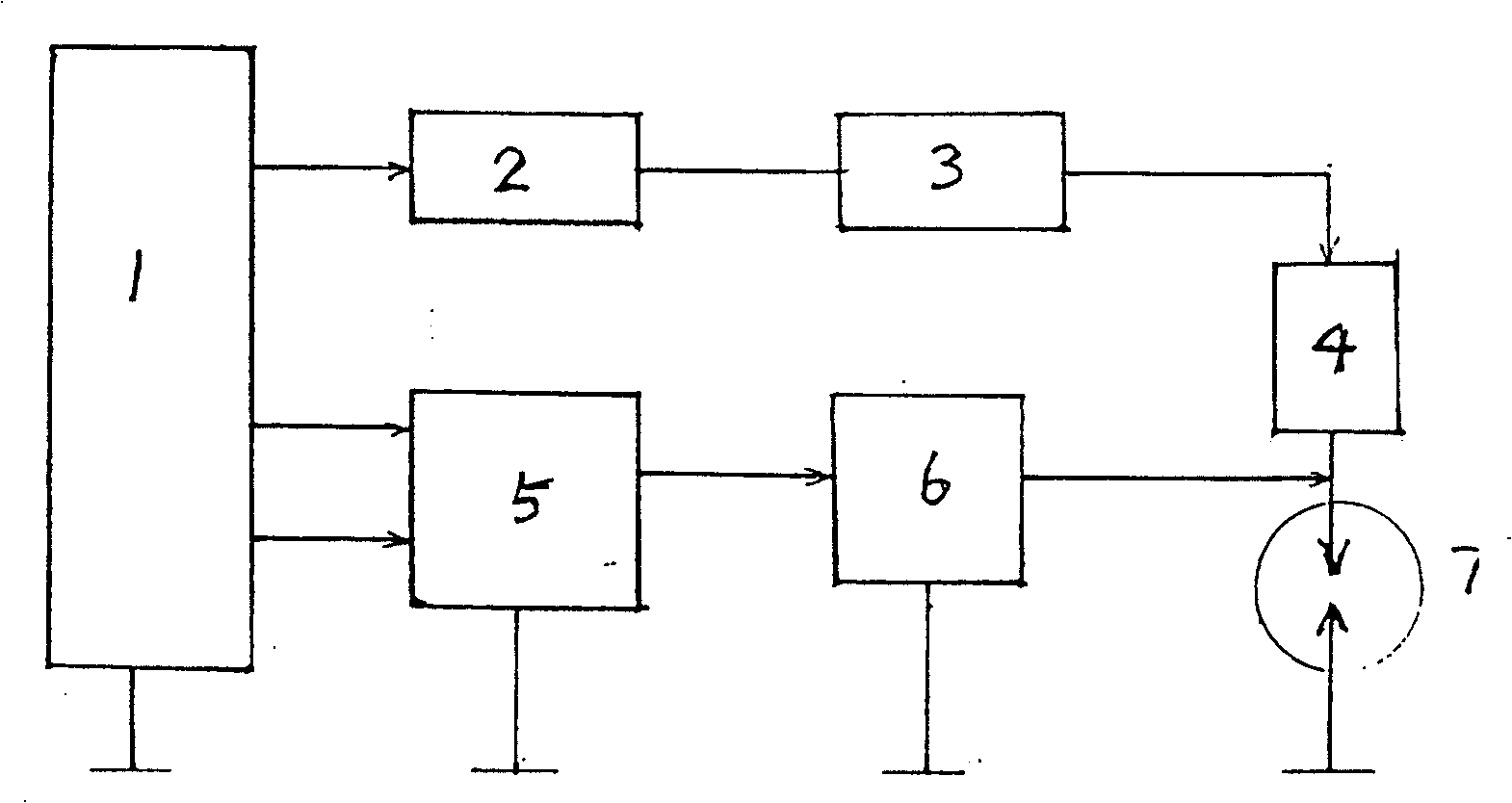

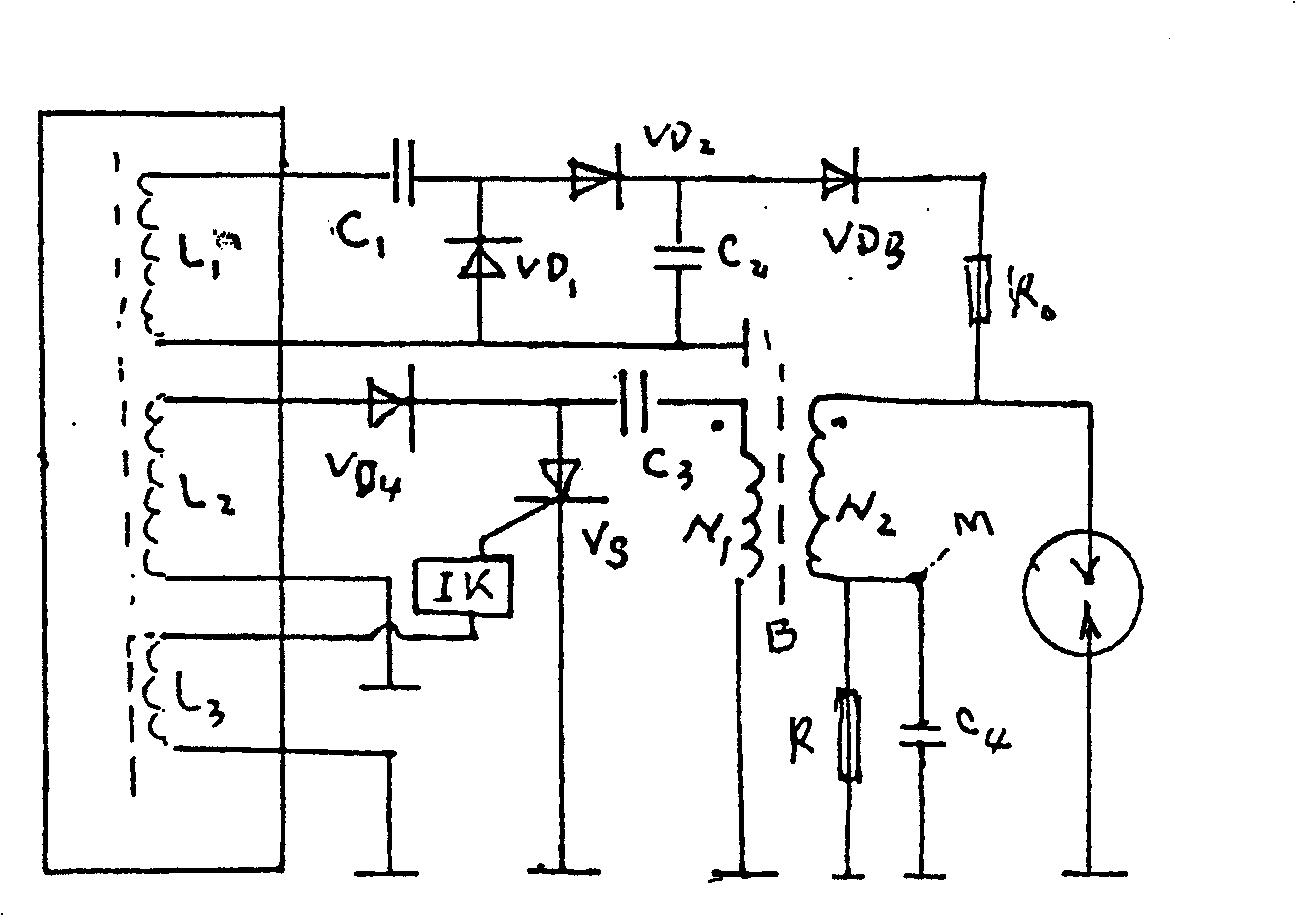

High energy high efficiency direct current ignition device of motorcycle

InactiveCN1654813AImprove powerImprove economyOther installationsMachines/enginesCapacitanceHigh energy

This invention relates to motorcycle direct current portfire with high efficiency, which belongs to motorcycle portfire technique and adds one magnetic machine coil on the base of motorcycle original capacity portfire system. The portfire coil second adopts floating earth method and realizes the aim by multiplying the coil through high reverse diode and connecting the piston electrode.

Owner:白承基 +1

Gasoline engine igniter controlled by single-chip microprocessor (SCM)

InactiveCN102032086BBurn fullyImprove stabilityIgnition automatic controlInstallations with induction energy storageCapacitanceMicrocontroller

The invention relates to a gasoline engine igniter controlled by a single-chip microprocessor (SCM). The gasoline engine igniter comprises a capacity discharge ignition circuit, a signal trigger circuit, an SCM chip power supply circuit and an SCM chip integrated circuit (IC) 1, wherein, the capacity discharge ignition circuit, the signal trigger circuit and the SCM chip power supply circuit are controlled by an SCM chip; and as the signal trigger circuit and the SCM chip power supply circuit are mutually independent without interfering with each other, the SCM chip power supply circuit does not adsorb the current in the trigger coil of the signal trigger circuit, thus increasing ignition energy, improving the stability of the whole circuit, ensuring sufficient combustion of thegasoline in an engine, and reducing environmental pollution.

Owner:余姚市兰山电机企业有限公司

High energy high efficiency direct current ignition device of motorcycle

InactiveCN100441858CImprove powerImprove economyMachines/enginesInstallations with induction energy storageCapacitanceHigh energy

This invention relates to motorcycle direct current portfire with high efficiency, which belongs to motorcycle portfire technique and adds one magnetic machine coil on the base of motorcycle original capacity portfire system. The portfire coil second adopts floating earth method and realizes the aim by multiplying the coil through high reverse diode and connecting the piston electrode.

Owner:白承基 +1

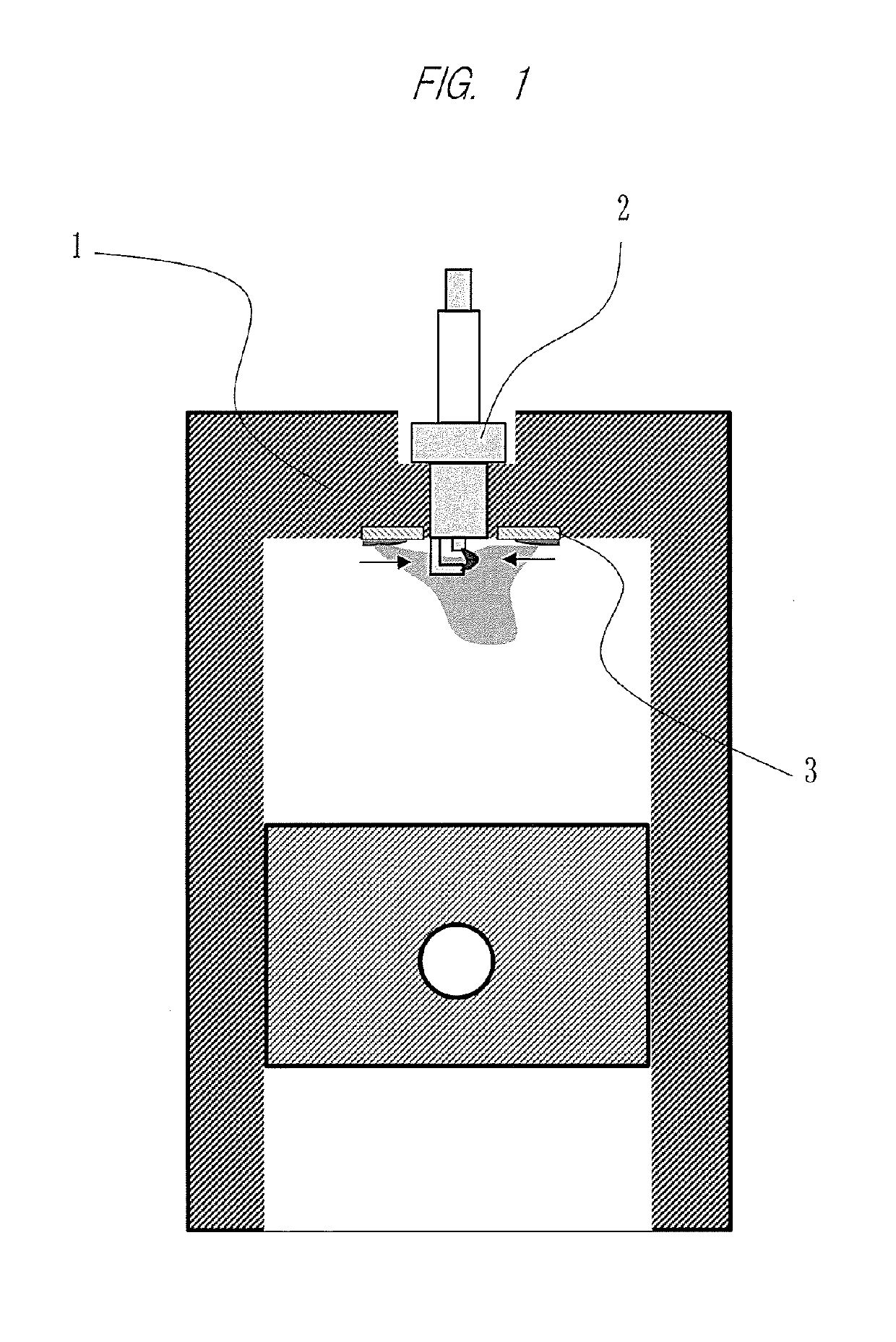

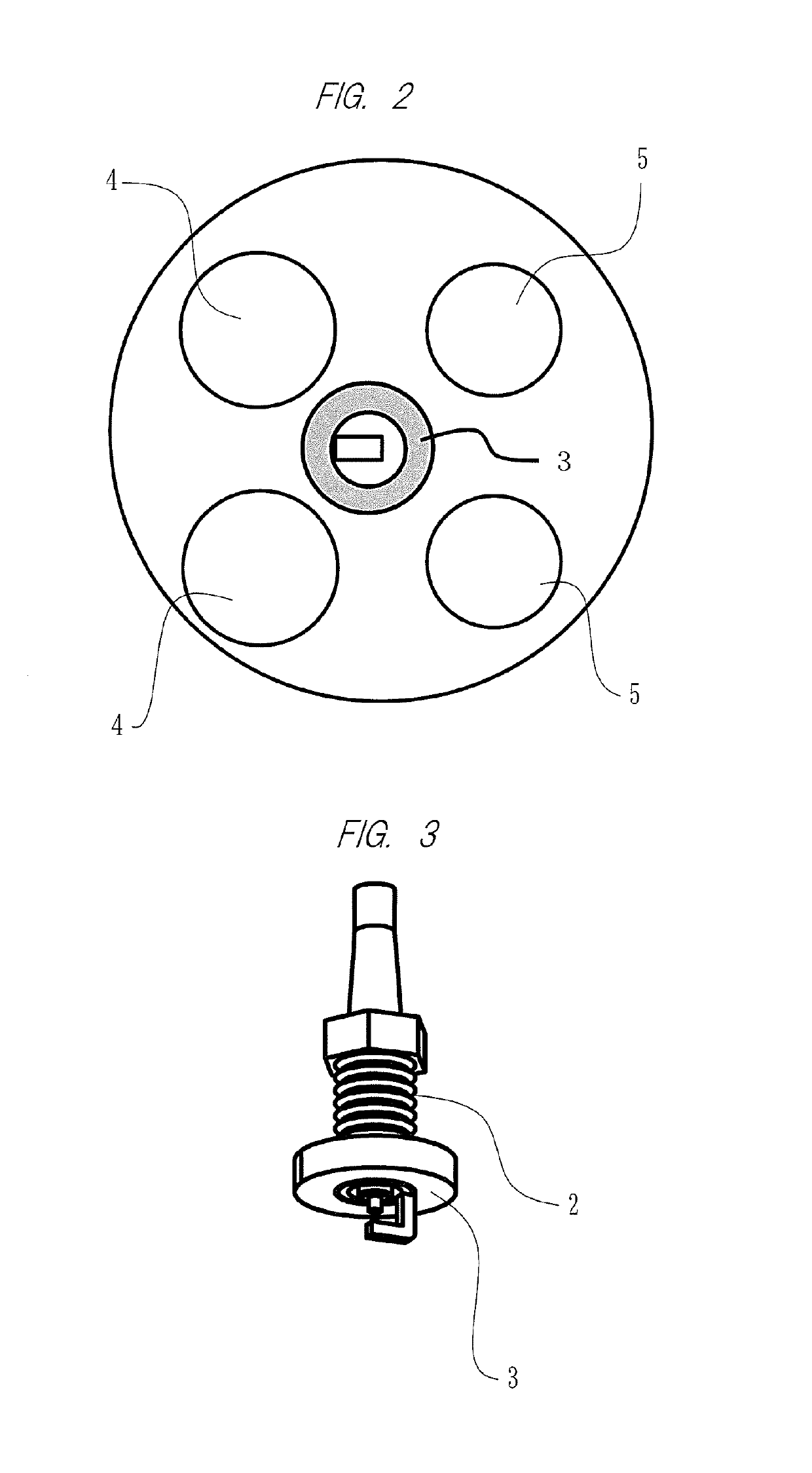

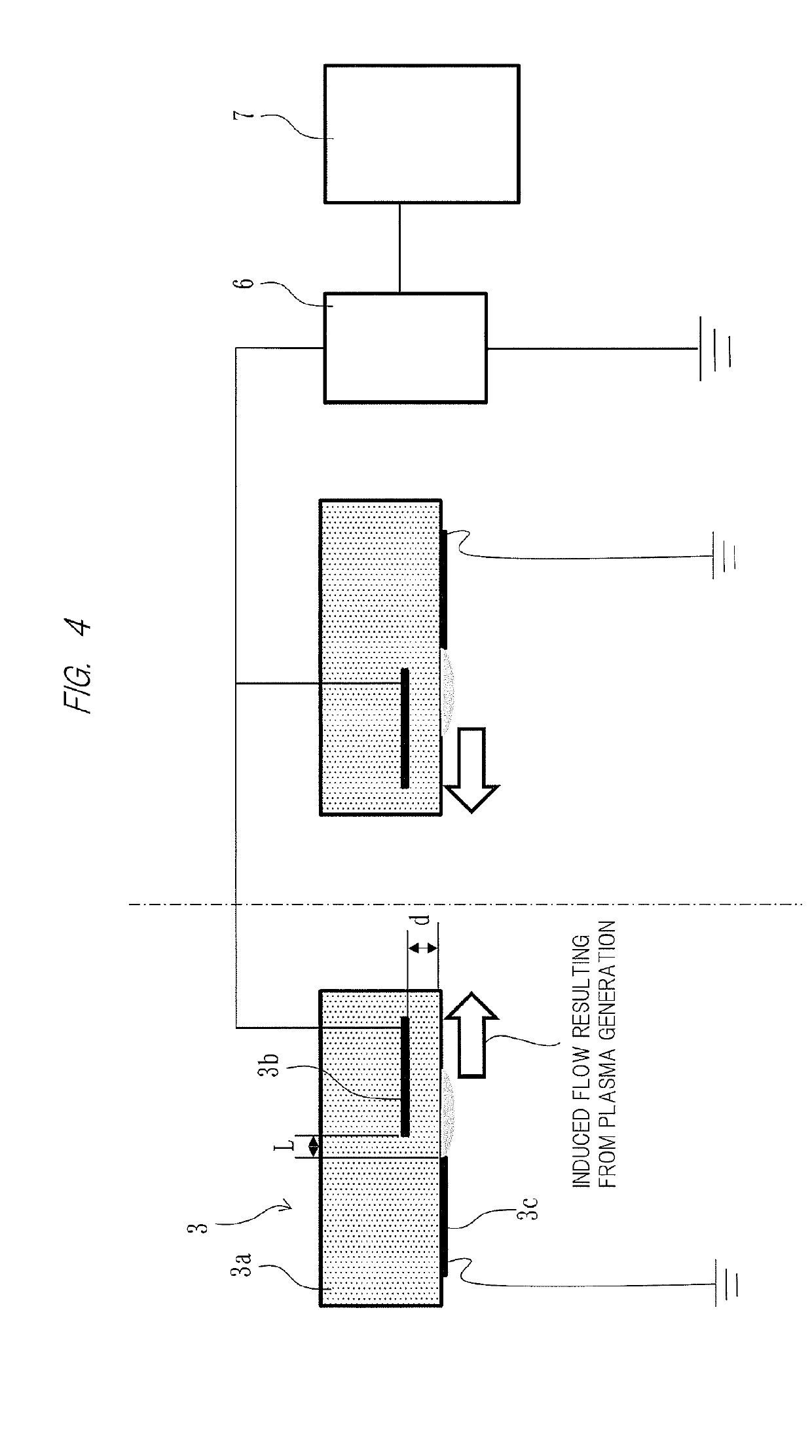

Spark discharge ignition promoting method, spark discharge ignition promoting apparatus, and engine with spark discharge ignition promoting apparatus

InactiveUS20190323476A1Save energySmall sizeSparking plugsCombustion enginesCombustionCapacitor discharge ignition

Stable combustion becomes possible even in a super-lean combustion engine or an engine that carries out a large amount of EGR. In a spark discharge ignition promoting apparatus, non-thermal plasma is generated in a cylinder by a non-thermal plasma generating unit. The non-thermal plasma generating unit is provided at a location where a processed air-fuel mixture by the non-thermal plasma reaches a spark plug after an in-cylinder flow or where the air-fuel mixture exists around an electrode of the spark plug in a time when the air-fuel mixture keeps an easy combustion state. The spark plug ignites the processed air-fuel mixture by discharge of the spark plug at timing when the processed air-fuel mixture by the non-thermal plasma of an easy combustion state reaches the spark plug after an in-cylinder flow or timing when the air-fuel mixture of the easy combustion state exists around an electrode of the spark plug in the time when the air-fuel mixture keeps the easy combustion state.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Capacitor discharge ignition device for engine

InactiveUS20090272354A1Constant output voltageAvoid chargingElectric spark ignitersMachines/enginesCapacitanceCapacitor discharge ignition

A capacitor discharge ignition device for an engine including: an exciter coil provided in a magneto generator driven by the engine; a voltage increasing circuit that increases an induced voltage of the exciter coil; a capacitor charged by an output voltage of the voltage increasing circuit; and a discharge switch that is turned on at ignition timing of the engine and discharges charges in the capacitor through a primary coil of the ignition coil, wherein the ignition device further includes a voltage increasing control portion that controls the voltage increasing circuit so as to increase an output voltage of the voltage increasing circuit when a rotational speed of the engine is a set value or less, and limit the output voltage of the voltage increasing circuit when the rotational speed of the engine exceeds the set value.

Owner:KOKUSAN DENKI CO LTD

A polysilicon reduction furnace temperature control and energy saving system and process

ActiveCN103466629BTake advantage ofReduce energy consumptionChemical industrySilicon compoundsFurnace temperatureGas phase

Owner:MORIMATSU (JIANGSU) HEAVY IND CO LTD

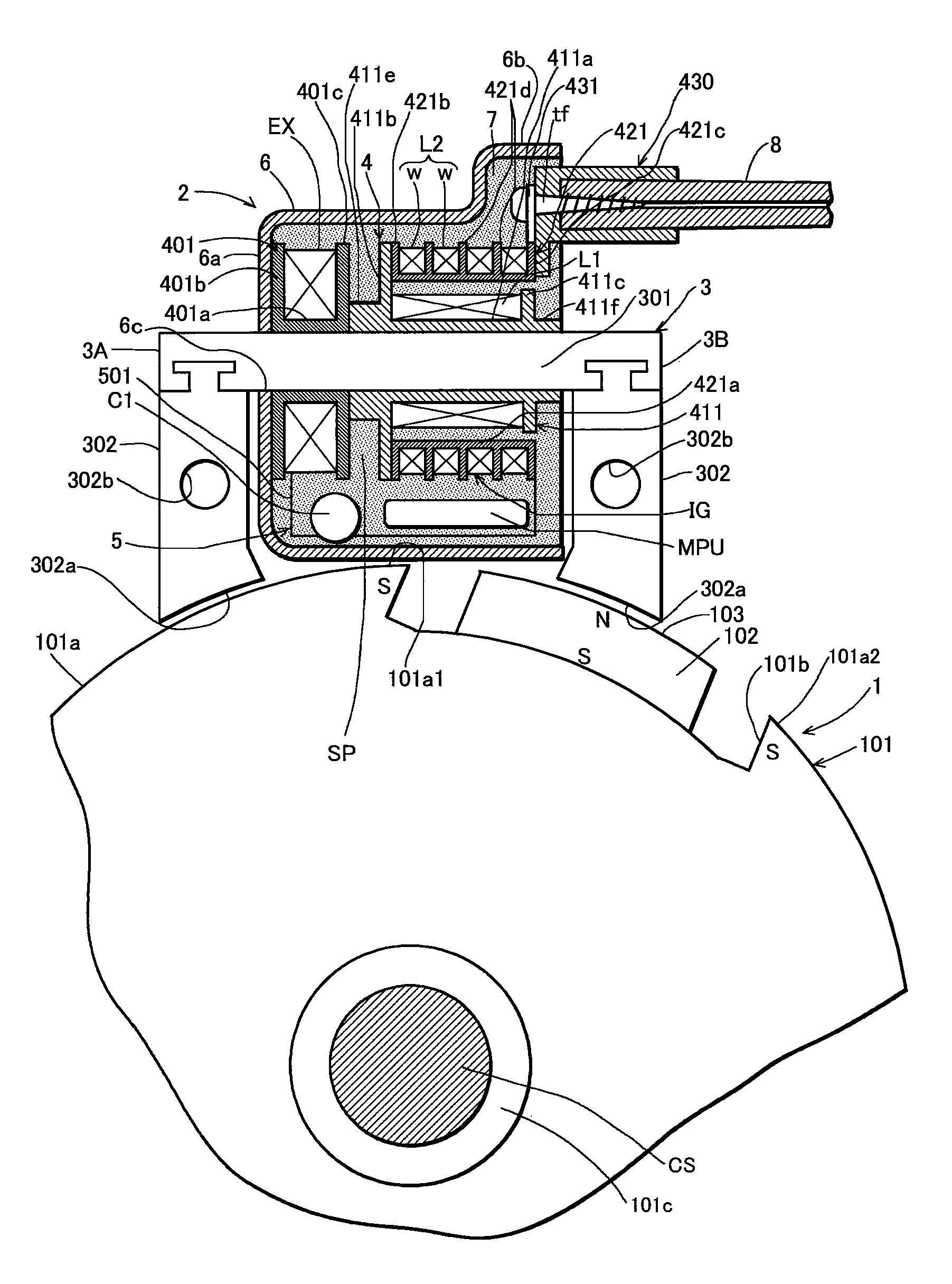

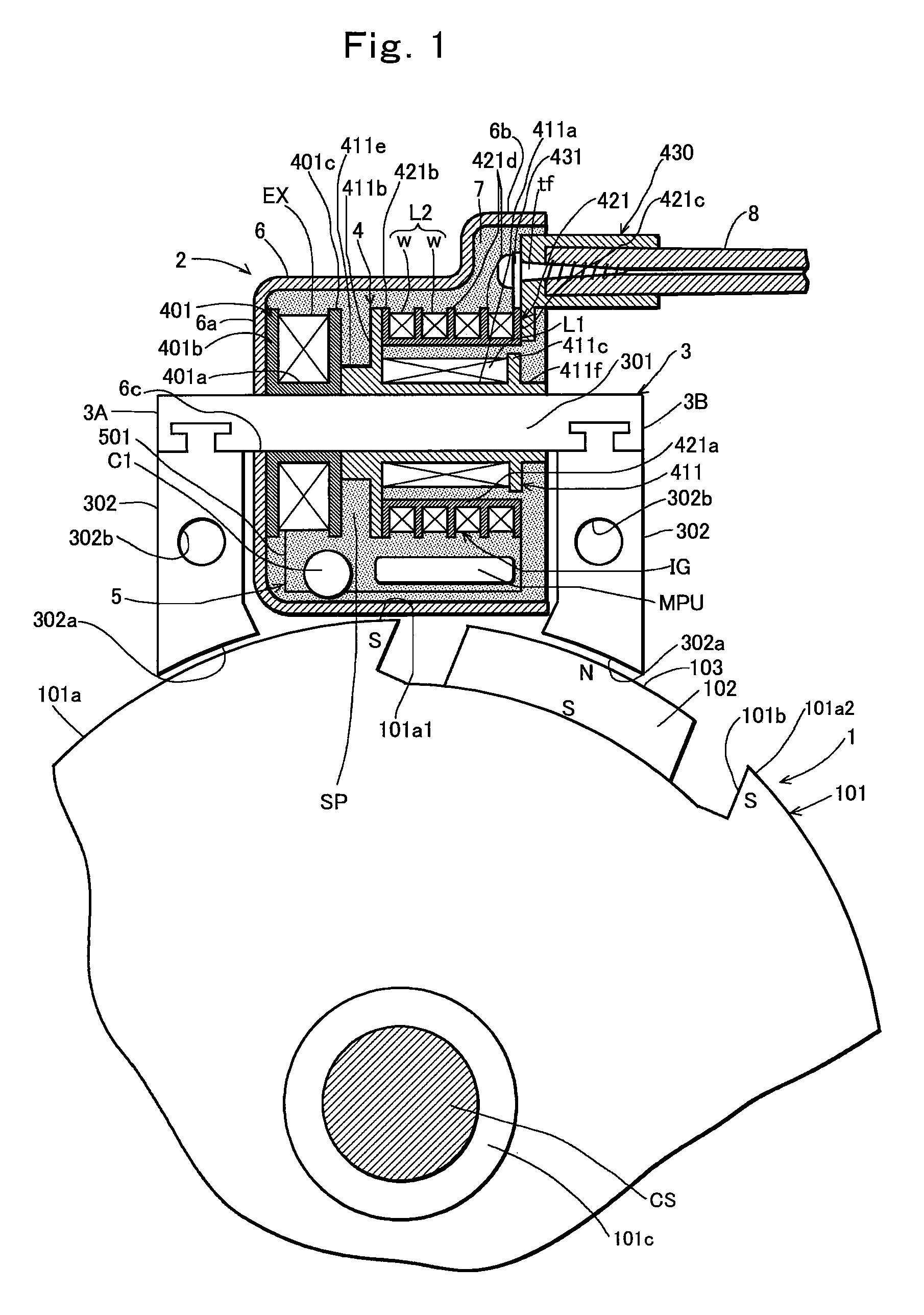

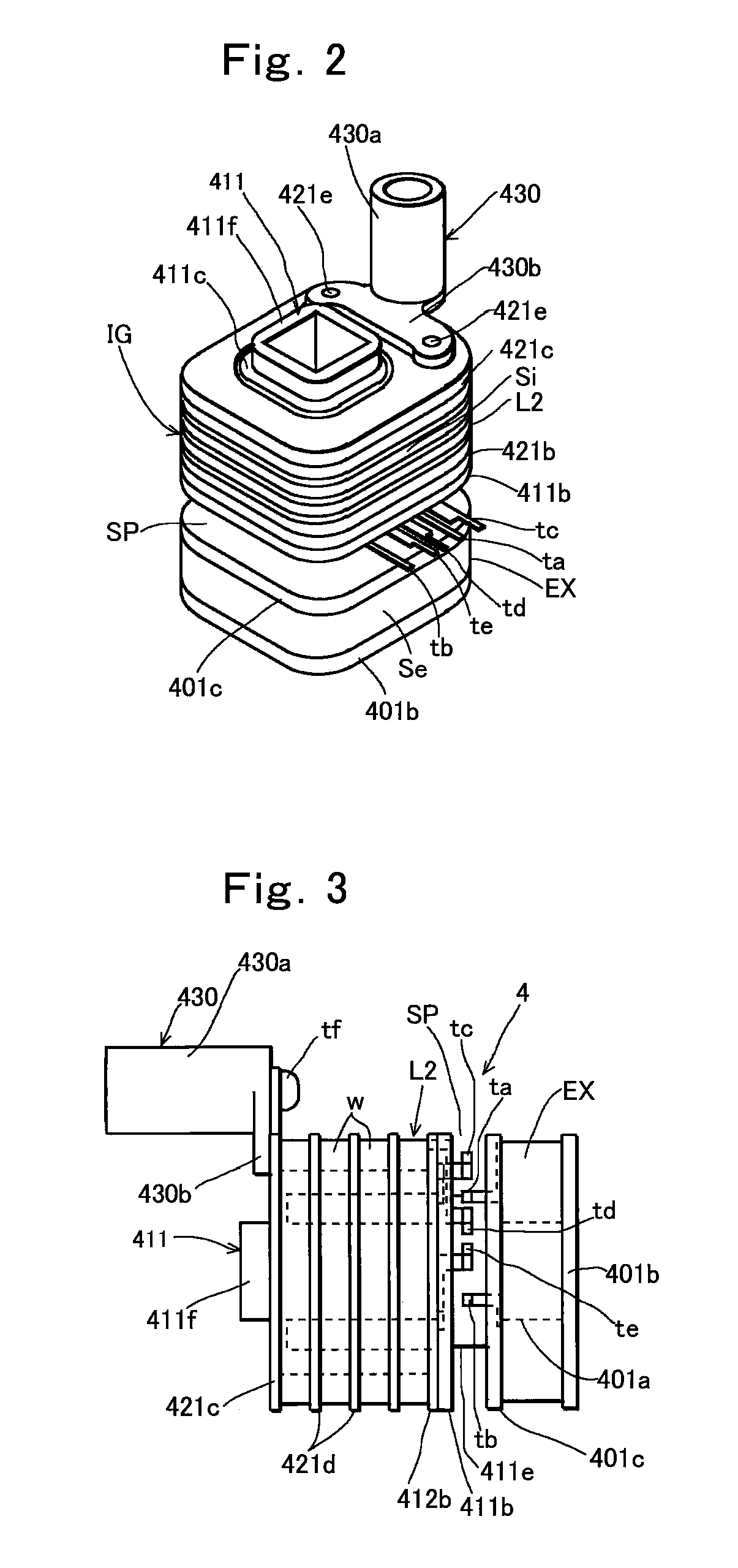

Capacitor discharge engine ignition device

ActiveUS7603982B2High voltageGenerator generated ignition energyMachines/enginesCapacitanceCapacitor discharge ignition

A capacitor discharge ignition device in which a coil unit including an ignition coil and an exciter coil wound around a common core, and an ignition unit including a circuit board and components of an ignition circuit mounted to the circuit board are housed in a case and molded with resin poured into the case, wherein the ignition coil and the exciter coil are placed axially with a spacing therebetween and a space is formed between the coils, the circuit board of the ignition unit is placed on a lateral side of the coil unit, and terminals for connecting the ignition coil and the exciter coil to the circuit board are all connected to the circuit board through the space between the ignition coil and the exciter coil.

Owner:MAHLE INT GMBH

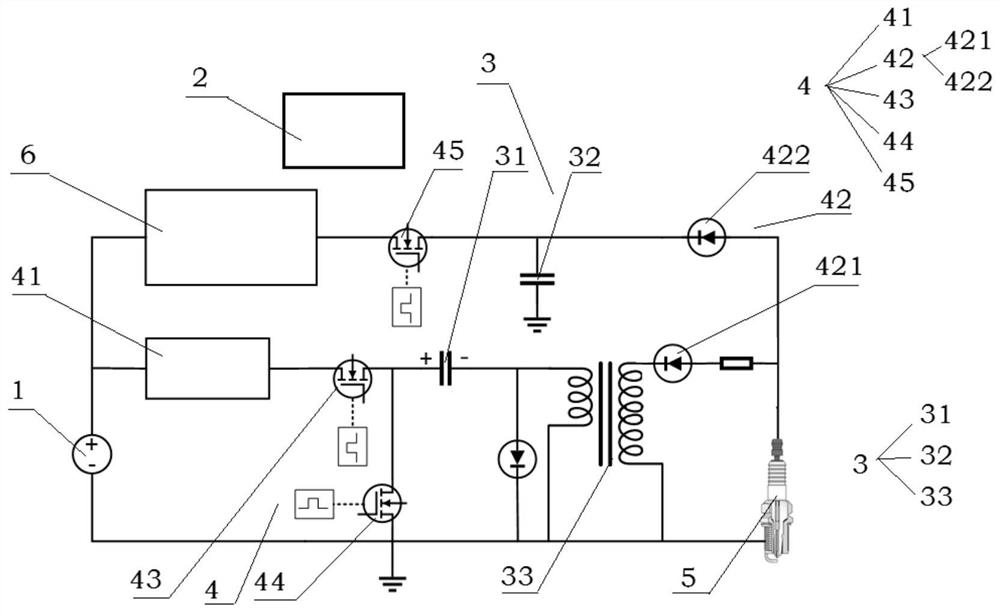

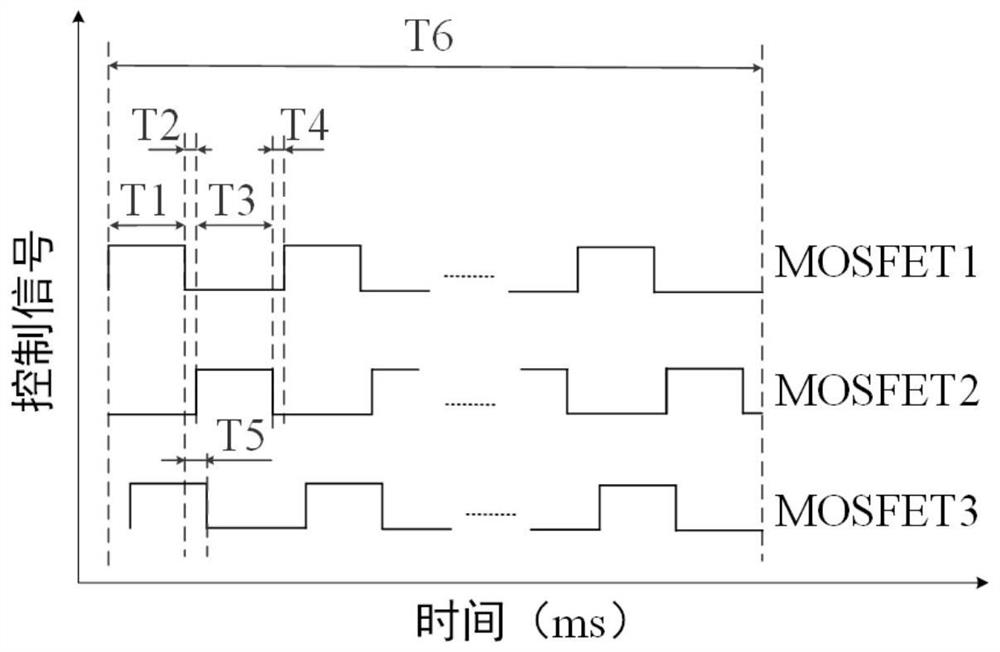

A high-frequency high-energy spark discharge ignition device

ActiveCN111779608BHigh energyIncrease the discharge frequencyMachines/enginesInstallations with capacitive energy storageCapacitanceControl signal

The invention discloses a high-frequency and high-energy spark discharge ignition device, which belongs to the technical field of ignition engines. The invention includes a low-voltage on-board power supply, a control module, a high-frequency discharge module, a high-energy supplementary module and a spark plug; the low-voltage on-board power supply provides power supply for the entire system; the control module includes the logic allocation of the control signals of the high-frequency discharge control module and the high-energy supplementary module , to achieve precise control of discharge frequency and discharge duration; the high-frequency discharge module includes a first capacitor, a second capacitor and a high-voltage coil for providing high-frequency breakdown voltage; the first input end of the high-voltage coil is connected to the first capacitor discharge ignition output end, The first output end of the high-voltage coil is connected to the ground wire, the second input end of the high-voltage coil is connected to the output end of the high-voltage coil, and the second output end of the high-voltage coil is connected to the spark plug and the high-energy supplementary module. The invention is applied to the ignition of an ignition type engine, improves the energy of the ignition device, and precisely controls the discharge frequency and the discharge duration.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com