Ignition control system of tube furnace

An ignition control and control system technology, which is applied in the directions of combustion ignition, combustion control, and ignition by electric spark, etc., can solve the problems of poor ignition device performance, low efficiency, poor ignition reliability, etc., to ensure reliability and installation, high thermal efficiency, to achieve the effect of automatic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

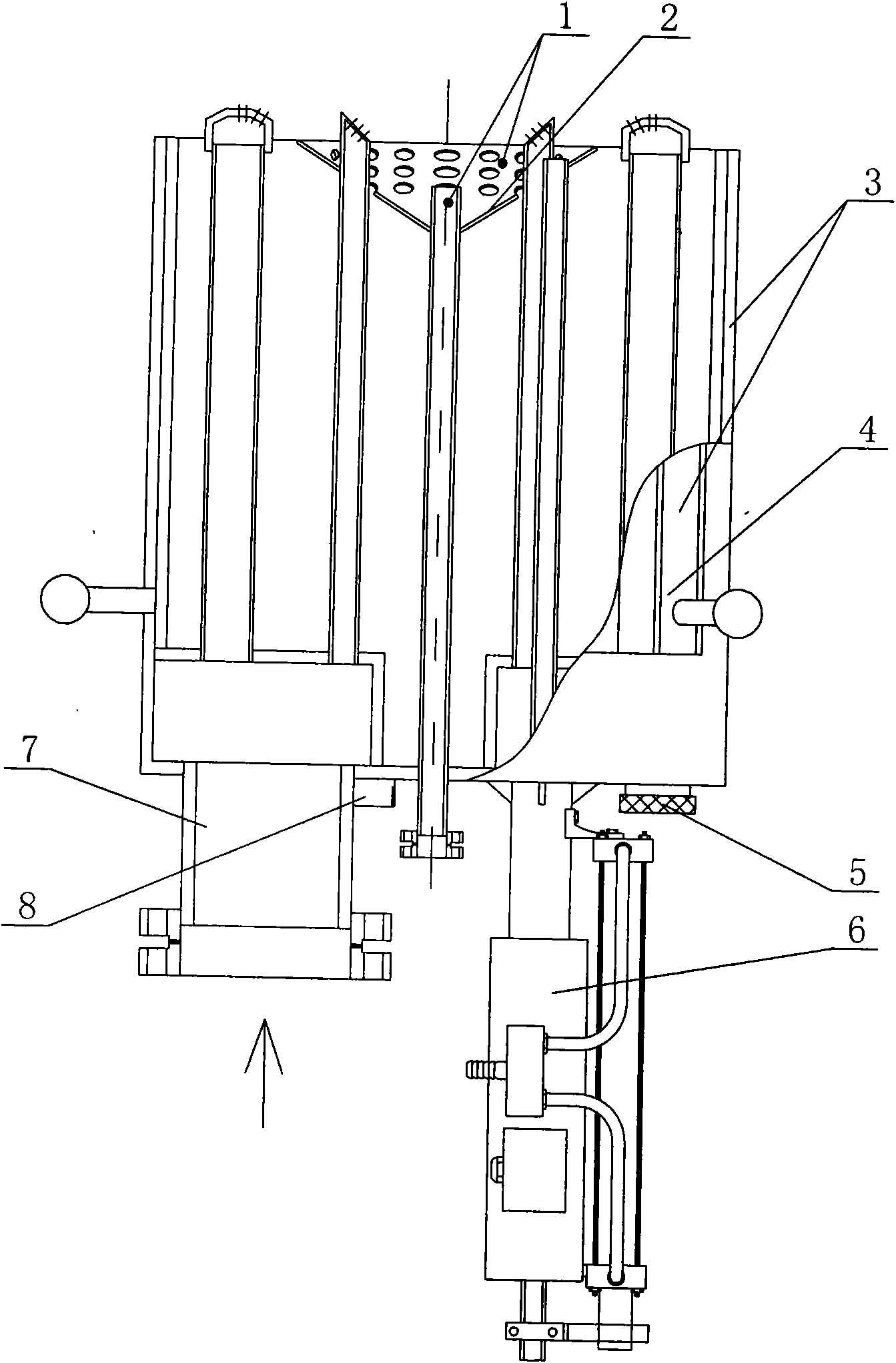

[0060] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing:

[0061] Tube furnace ignition control system, which includes high-energy ignition device, burner, and automatic ignition control system. The high-energy ignition device adopts a capacitor discharge igniter to provide safe and reliable ignition performance; the burner has a flame detection device and can realize combustion. The air and gas are adjusted in proportion; the automatic ignition control system has the functions of flame detection, furnace safety protection and self-diagnosis.

[0062] High energy ignition device:

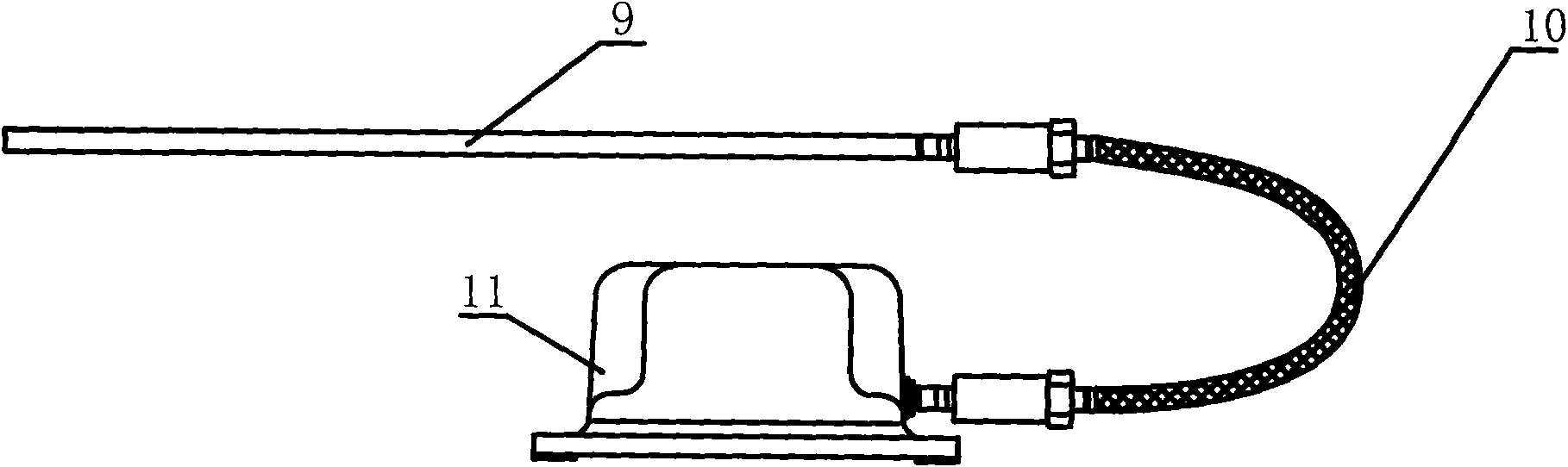

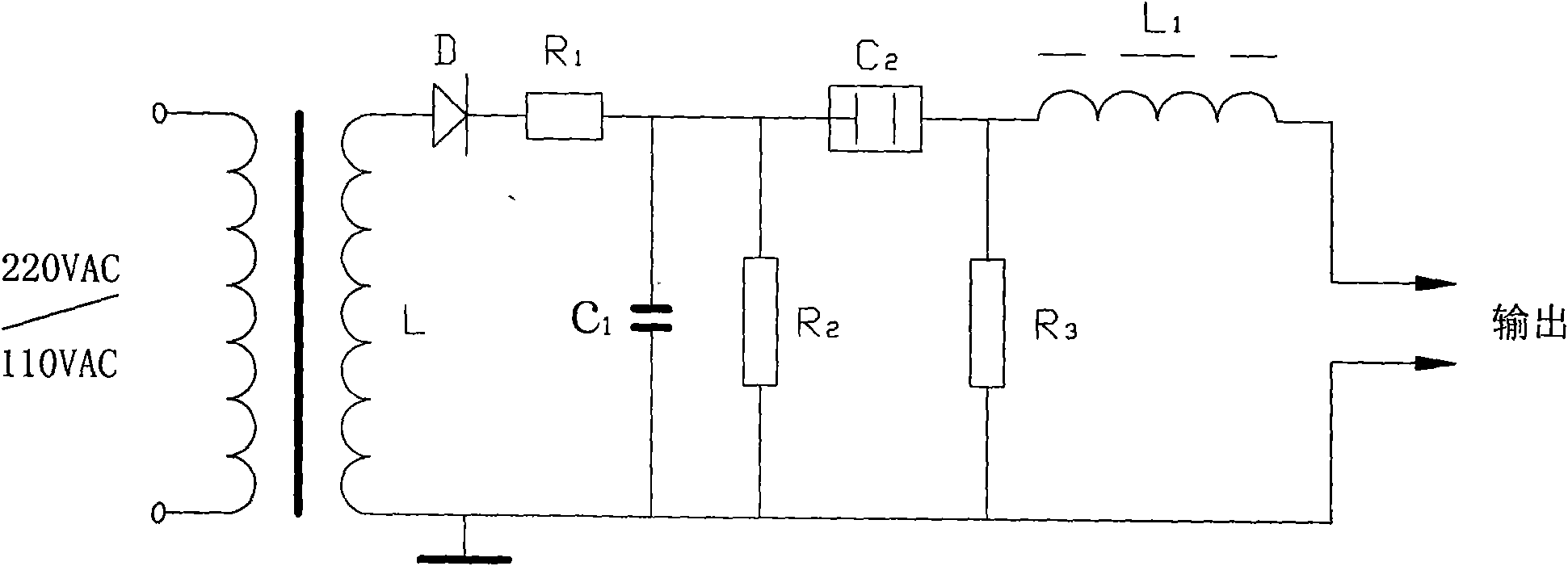

[0063] See figure 1 , the high-energy ignition device is composed of an igniter 11, a high-voltage shielded cable 10, and an ignition gun 9 connected in sequence, see figure 2 , the igniter is composed of a step-up transformer L, a rectifier D, a capacitor C1, a discharge tube C2, a choke coil L1, a resistor R1, a resistor R2, and a resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com