Method and device for recycling heat energy in reduction exhaust in polysilicon production process

A heat energy recovery and polysilicon technology, applied in the direction of silicon, waste heat treatment, energy efficiency improvement, etc., can solve the problem that the heat energy of the reduced exhaust gas is not effectively recycled, and achieve the effect of reducing the consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

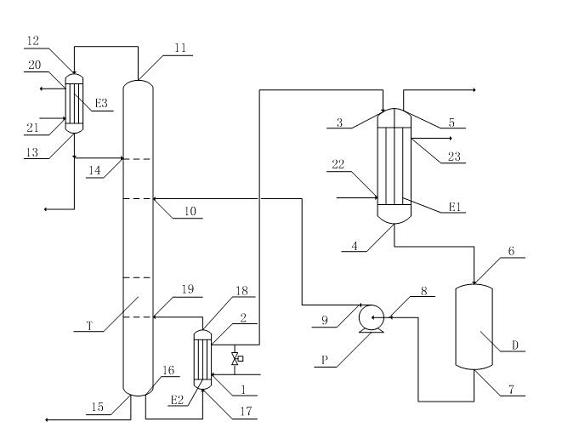

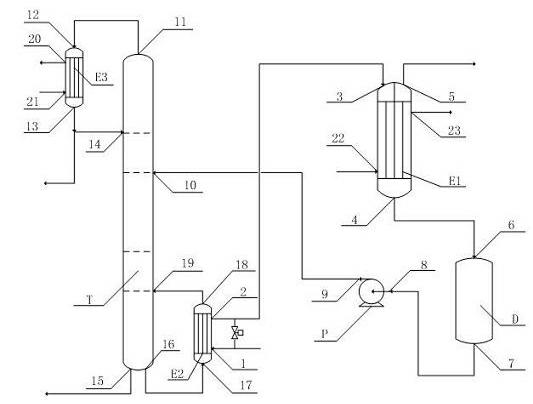

[0025] In the technical solution provided by the present invention, the equipment is mainly divided into three parts according to functions:

[0026] 1. The separation and purification part of chlorosilane is mainly composed of a purification tower (T), a bottom reboiler (E2), and a top condenser (E3);

[0027] 2. The chlorosilane condensation and separation part in the reduction tail gas is mainly composed of the tail gas condenser (E1);

[0028] 3. The chlorosilane storage and delivery part is mainly composed of a chlorosilane buffer tank (D) and a chlorosilane delivery pump (P).

[0029] The bottom of the purification tower (T) is provided with a chlorosilane outlet 16, a high boiler outlet 15, and a chlorosilane gas inlet 19, wherein the chlorosilane outlet 16 is connected to the bottom chlorosilane inlet 17 of the bottom reboiler (E2), and the chlorine The silane gas inlet 19 is connected with the chlorosilane gas outlet 18 at the top of the bottom reboiler (E2); the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com