High energy high efficiency direct current ignition device of motorcycle

An ignition device, motorcycle technology, applied to other devices, engine ignition, spark ignition controller, etc., can solve the problems of short spark duration, incomplete combustion of mixed gas, increased pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

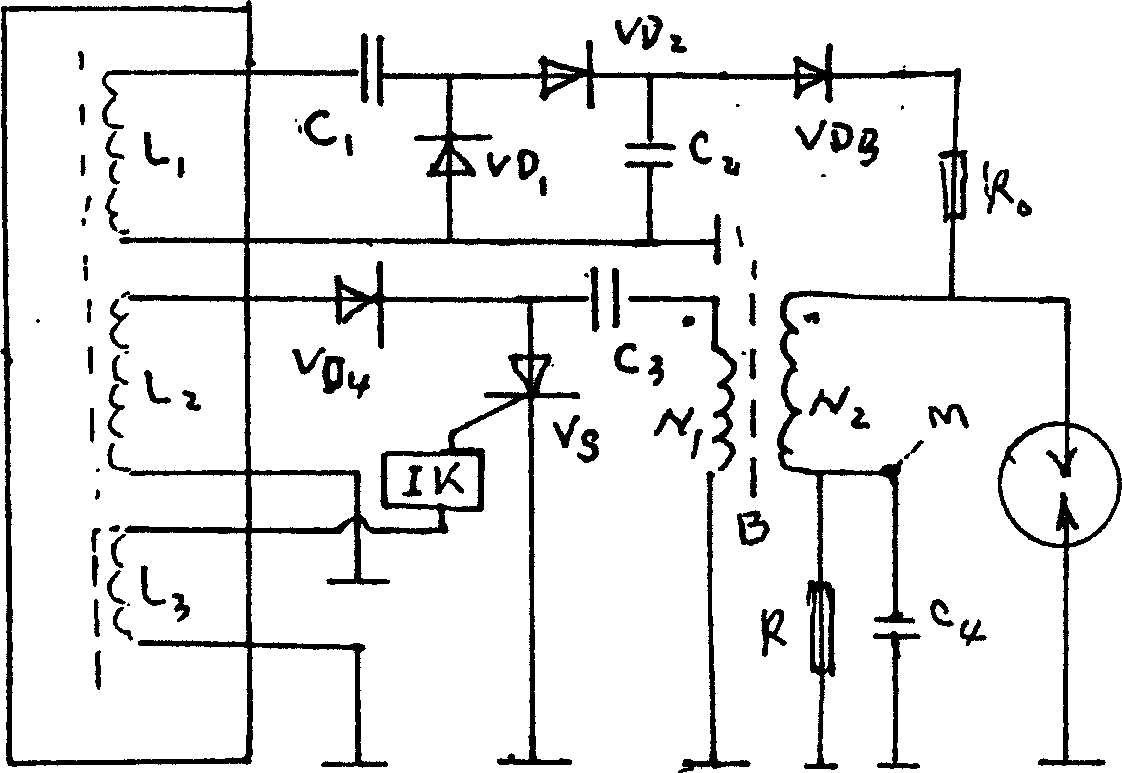

[0013] Describe the structure and working principle of the motorcycle DC ignition device of the present invention below in conjunction with accompanying drawing.

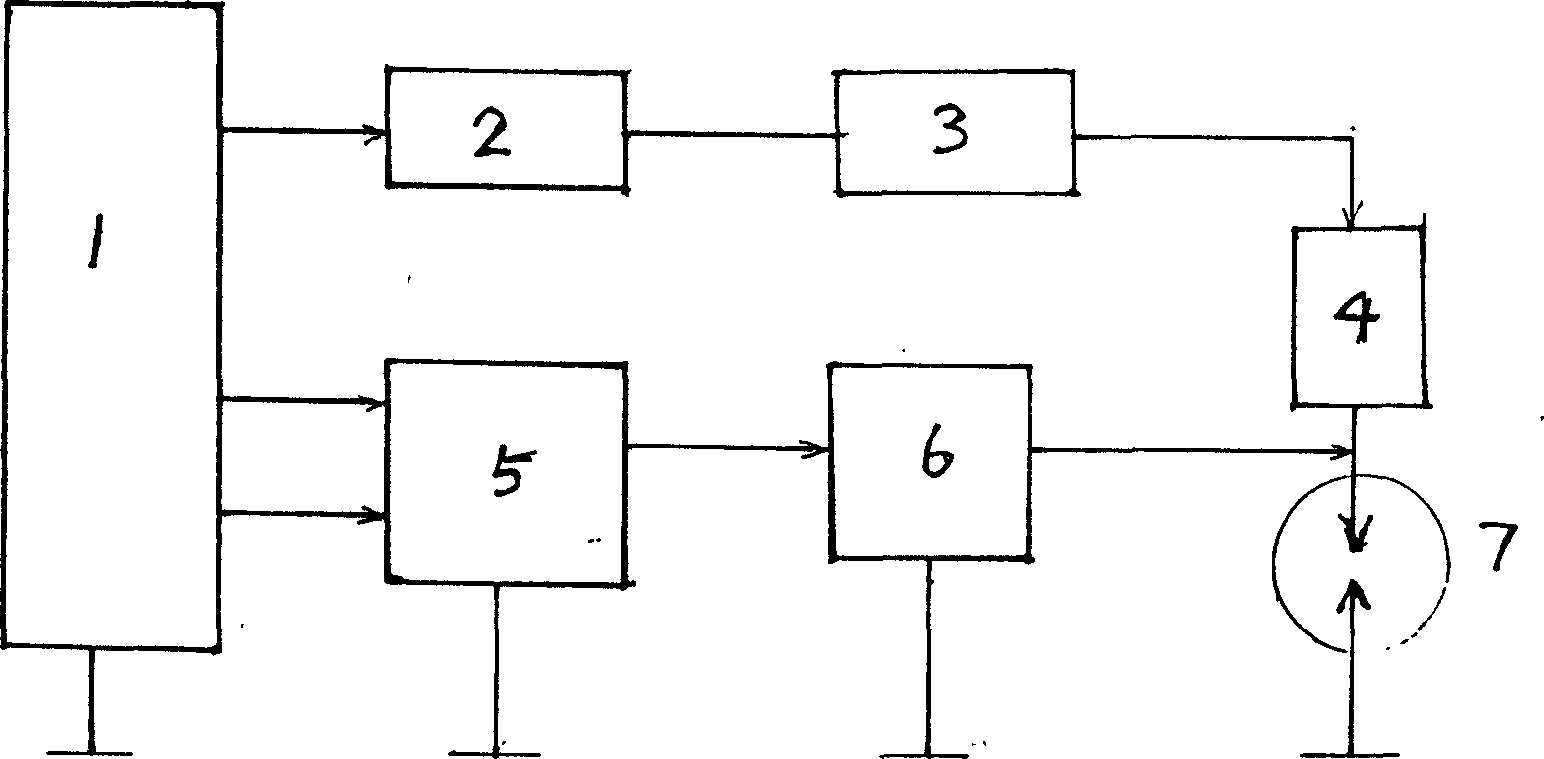

[0014] like figure 2 As shown, the motorcycle DC ignition device of the present invention includes a magneto 1 , a CDI ignition system 5 , an ignition coil 6 , a spark plug 7 , a DC voltage booster 2 , an isolation system 3 , and a delayer 4 . Among them, one winding of the magneto is connected to the DC voltage booster 2, the output of the DC voltage booster 2 is connected to the spark plug 7 through the isolation system 3 and the delayer 4, and the other two windings of the magneto are connected to the CDI system 5, and the CDI The output of the system 5 is connected to the primary of the ignition coil 6, and the secondary of the ignition coil 6 is connected to the spark plug.

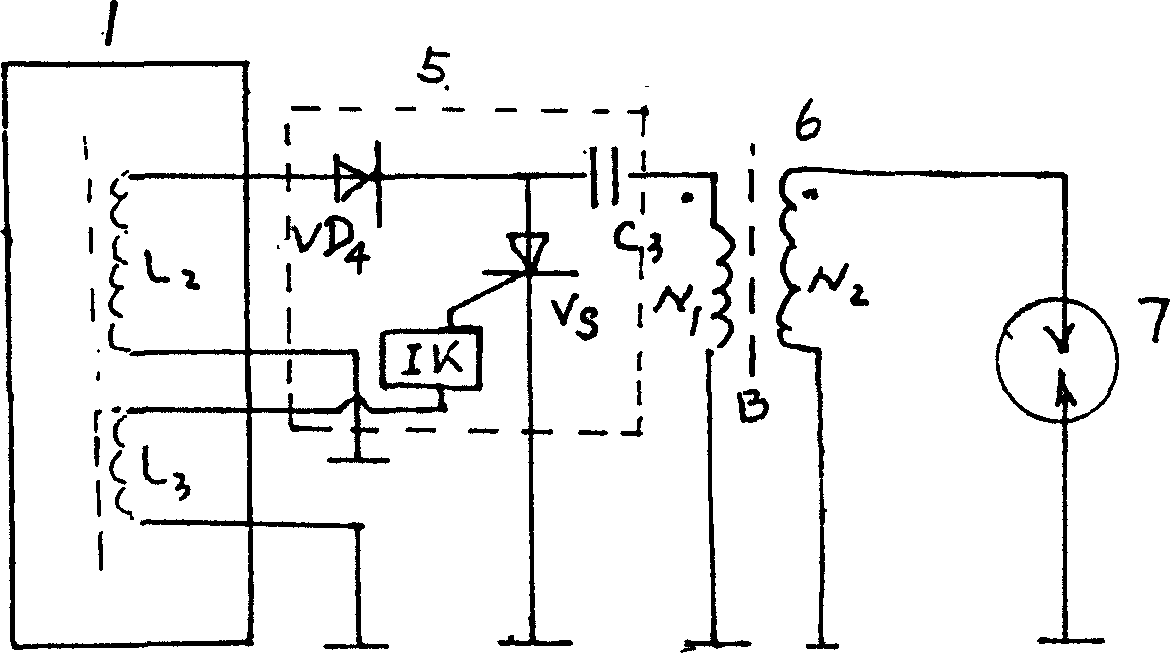

[0015] Combine below image 3 The electrical schematic diagram of the detailed description of the working process of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com