Integrated electronic injection/ignition system for aviation fuel engine

An aviation fuel and ignition system technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as increasing the probability of electromagnetic interference, ignition and fuel injection not being optimally matched, waste of resources, etc., to achieve Improved dynamic performance, precise matching of ignition times, and less carbon accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

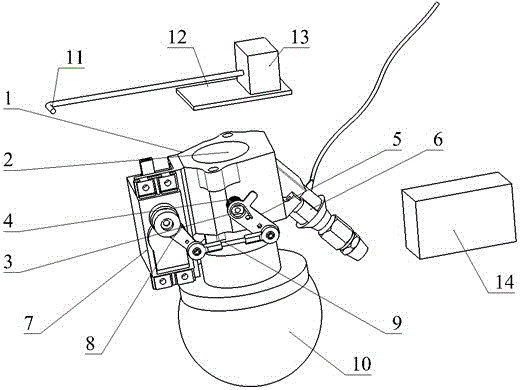

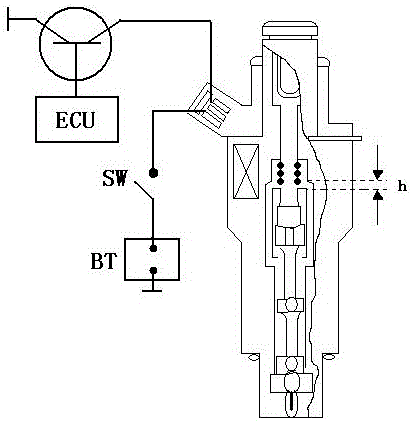

[0034] An integrated EFI / ignition system solution for aviation fuel engines, such as figure 1 As shown, its composition includes throttle body 1, throttle valve 2, throttle shaft 3, throttle return spring 4, throttle lever 5, electric nozzle 6, steering gear 7, steering gear rocker arm 8, ball head rod 9, Air filter 10, spark plug 11, ECU 12, igniter 13 and oil supply system 14.

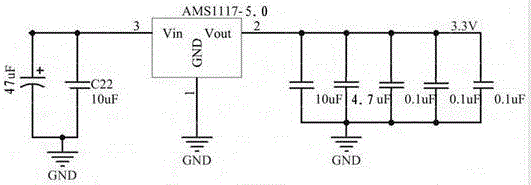

[0035] The design of the integrated EFI / ignition system for aviation fuel engines is mainly divided into two parts: (1) The design of the actuator, including the design of the throttle assembly, the design of the fuel supply system, the selection and installation of the steering gear, and the selection and installation of the spark plug . (2) Integrated circuit board design, including ECU electronic control unit design and capacitor discharge igniter design.

[0036] The throttle assembly is mainly composed of a throttle body 1, a throttle valve 2, a throttle shaft 3, a throttle return spring 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com