Vertical energy-saving dryer of incense products arranged compactly

A technology for dryers and products, applied in dryers, drying, local stirring dryers, etc., can solve the problems of high labor consumption, multiple overlapping, inconsistent drying speed, etc. Production line, effect of low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

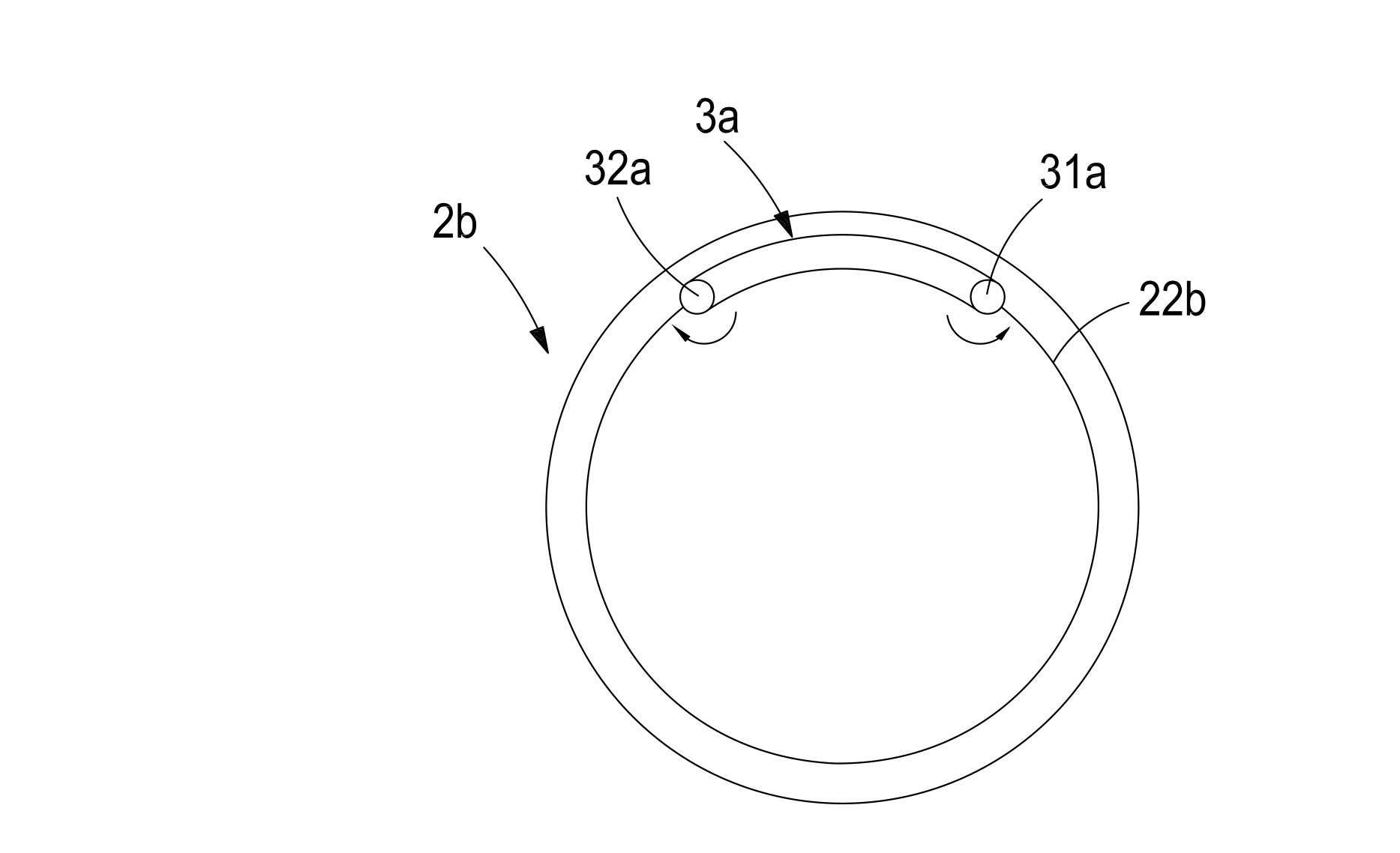

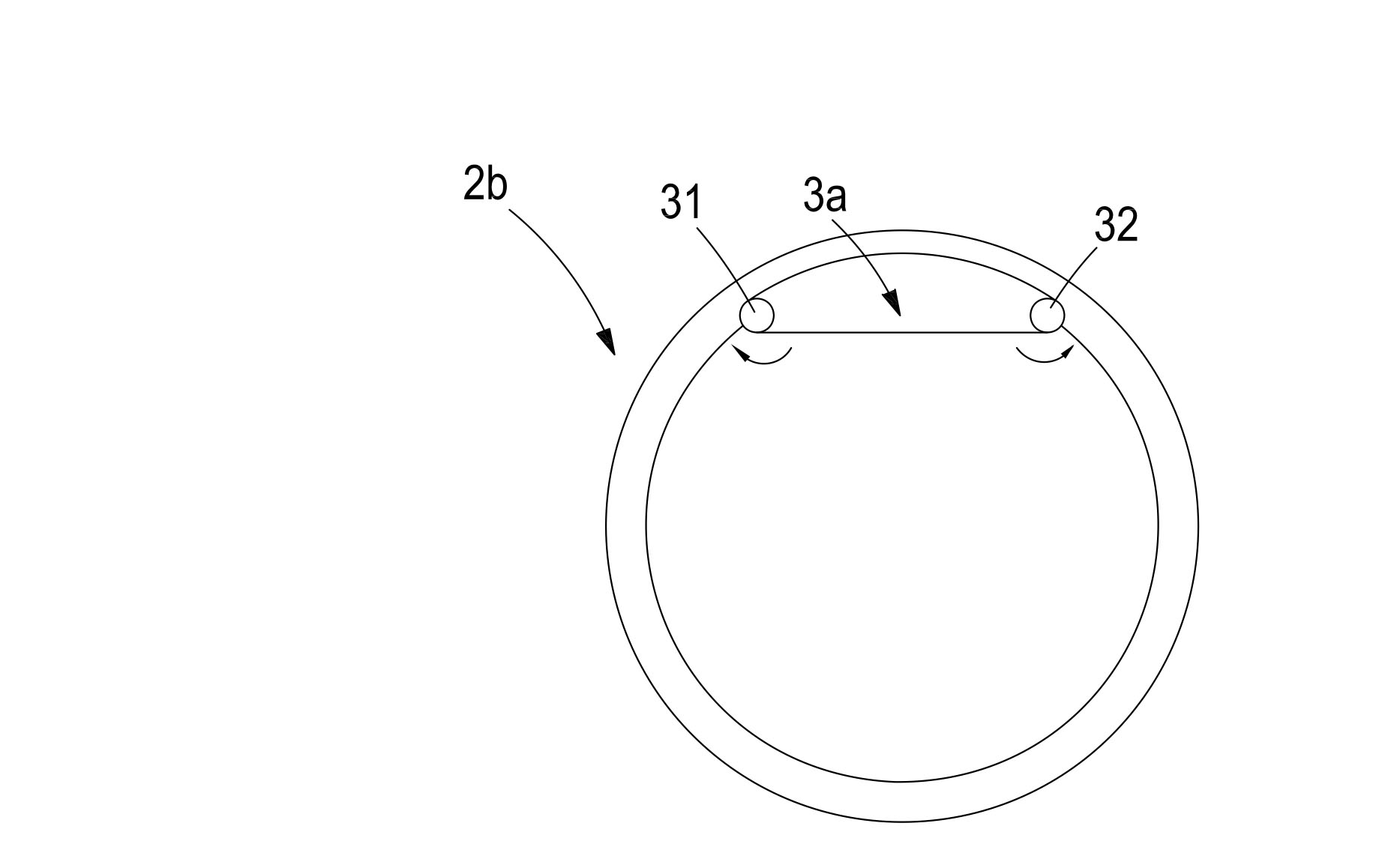

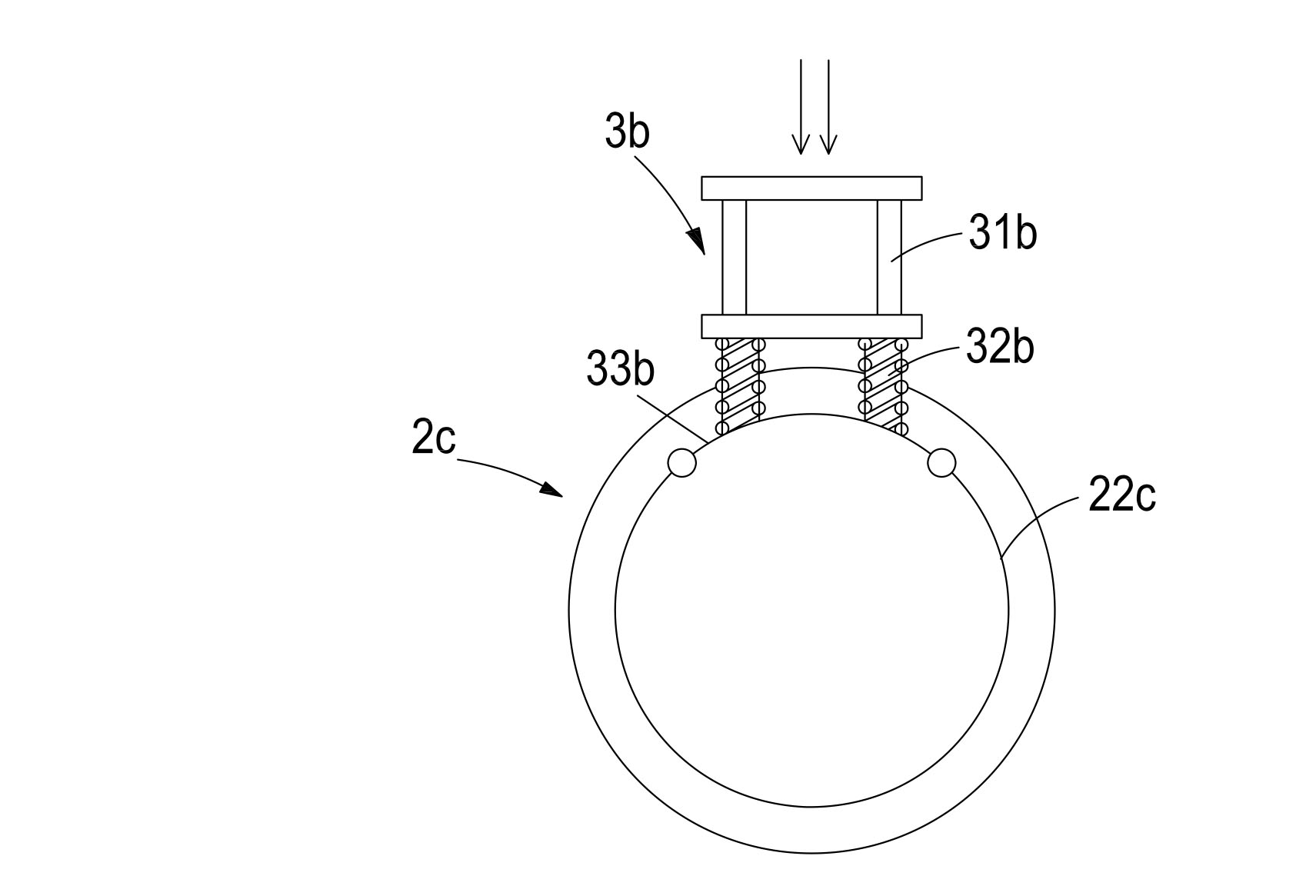

[0032] see figure 1 , figure 2 A preferred embodiment of the present invention is shown. The present invention includes a hot air supply device 1 and a drying barrel 2. The hot air supply device is connected to the drying barrel 2 and delivers hot air to the drying barrel 2. It is characterized in that: the drying The dry barrel 2 is provided with a barrel cavity 26 for vertically and compactly placing fragrant products. The bottom wall 24 of the barrel cavity 26 is provided with a ventilation hole 23. Fragrant products fall into the hot air device from the air hole, and the hot air supply device 1 delivers hot air to the barrel cavity 26 through the vent hole 23. The drying barrel 2 is provided with an air outlet 25 communicating with the barrel cavity 26, and the drying The barrel cavity 26 of the barrel 2 is a cavity that is automatically tightened to hold the fragrant product tightly according to the volume reduction of the fragrant product inside it.

[0033] The autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com