Overhaul management system and service life management method for important compressor parts in coal chemical industry

A management system, compressor technology, applied in the direction of instruments, etc., can solve the problems of relying on online monitoring technology, lack of comprehensive statistical analysis software of various data for condition maintenance, lack of scientific grasp of equipment evaluation methods, etc., to ensure the effect of safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

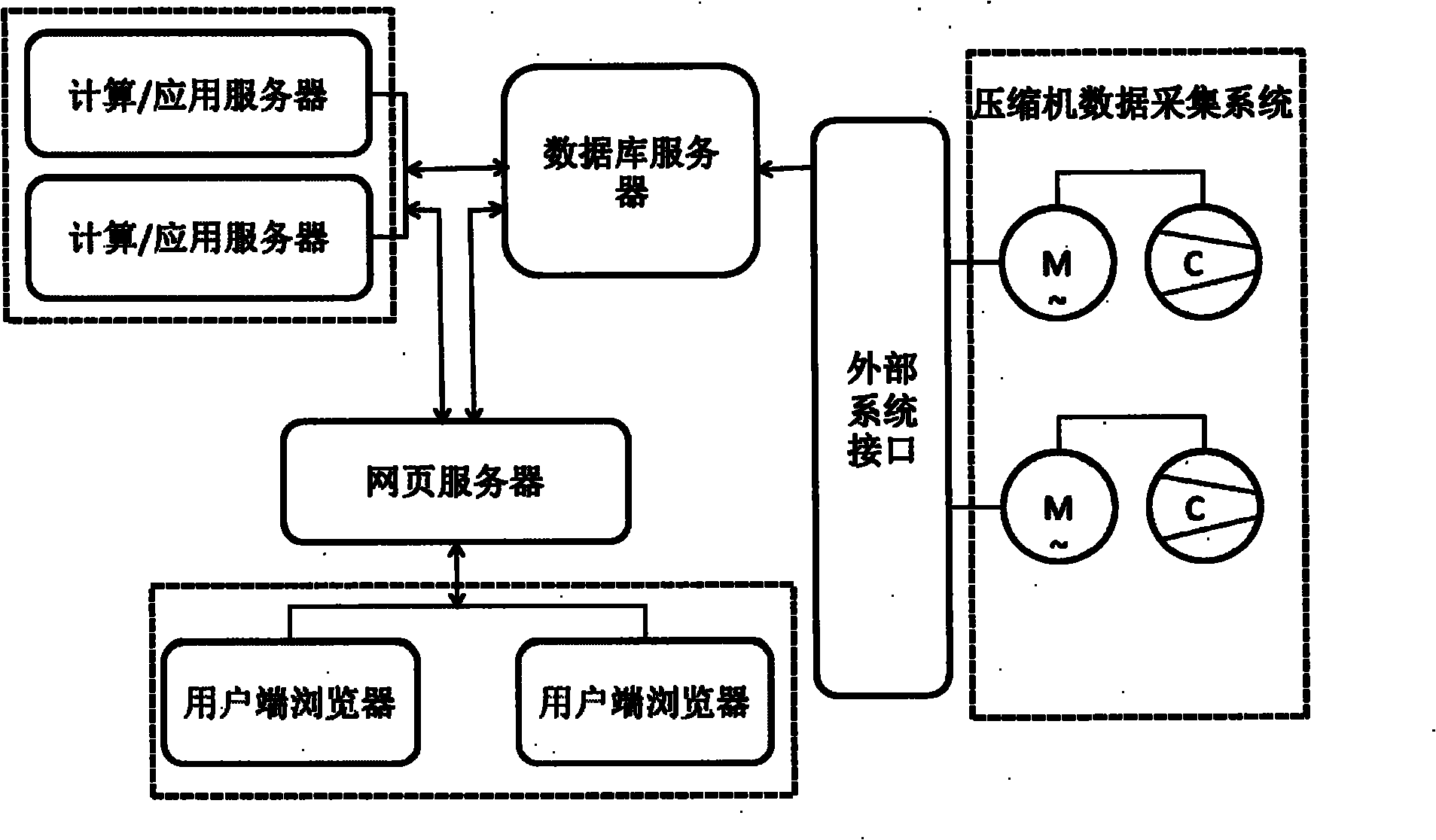

[0048] Such as figure 1 As shown, the active condition maintenance management system for important components of multiple compressor units is composed of computing / application server, database server, web server, client browser, external system interface and compressor data acquisition system. The web server is connected to the calculation / application server, the database server, and the client browser respectively, the calculation / application server is connected to the database server, and the database server is connected to the compressor data acquisition system through an external system interface.

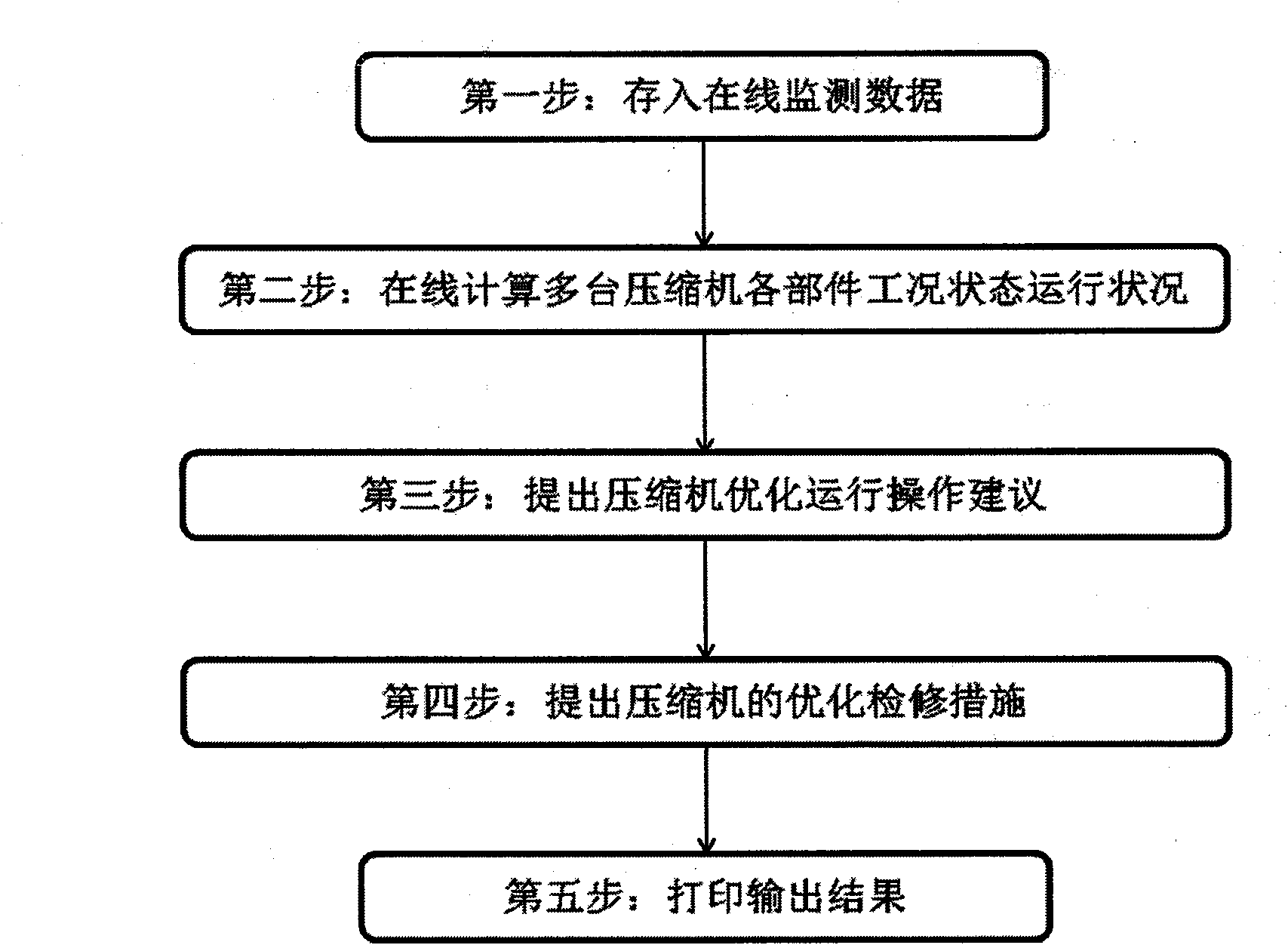

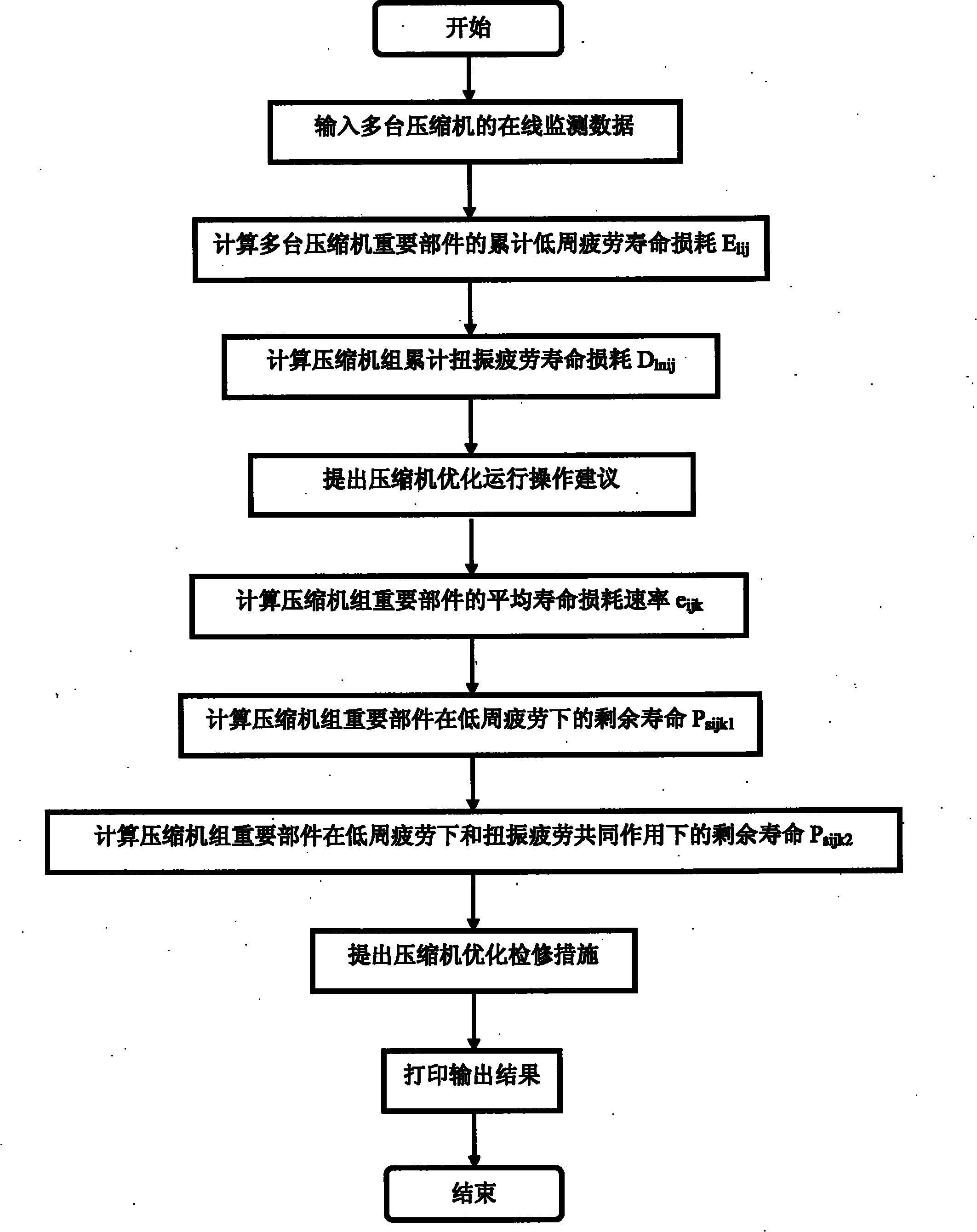

[0049] Such as figure 2 Shown, the flow chart of method is provided for the present invention. Such as image 3 As shown, it is a block diagram of the remaining life analysis software for important parts of coal chemical compressors written in c language adopted by the present invention. The software is installed on the computing / application server and is suitable for active...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com