Work transporting cart, work processing system, gas feeding system and gas feeding method

A technology for transporting trolleys and processing systems. It is applied to machines with sequential working positions, electric tube/lamp filling, etc., which can solve the problems of reduced luminous performance and damage to product functions, and achieve the effect of reducing equipment costs and operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

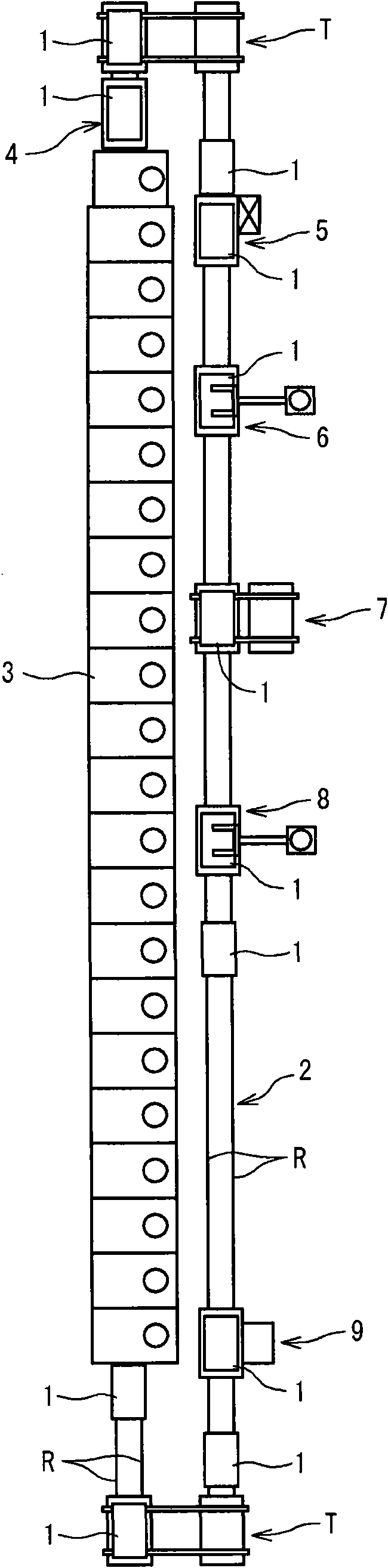

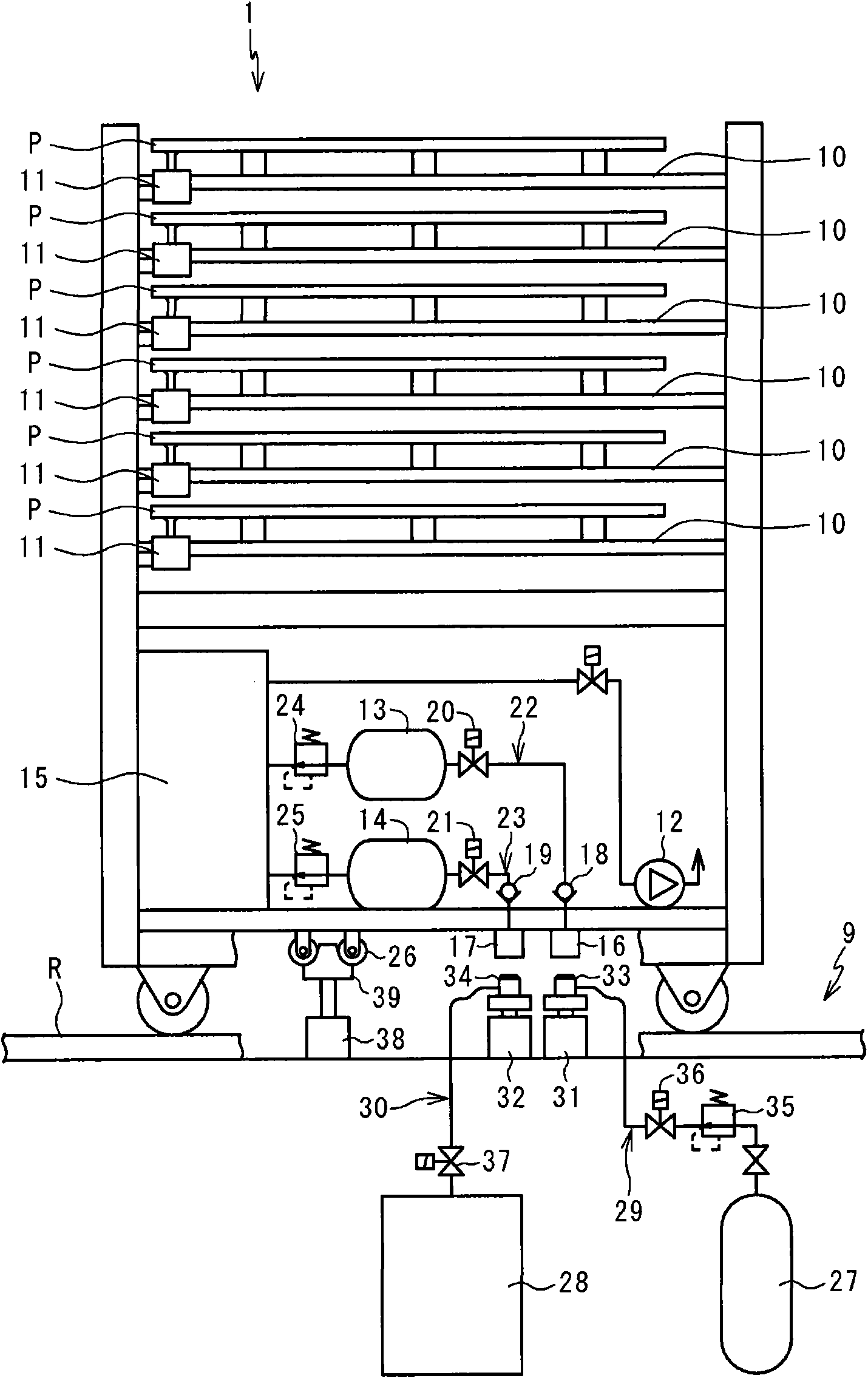

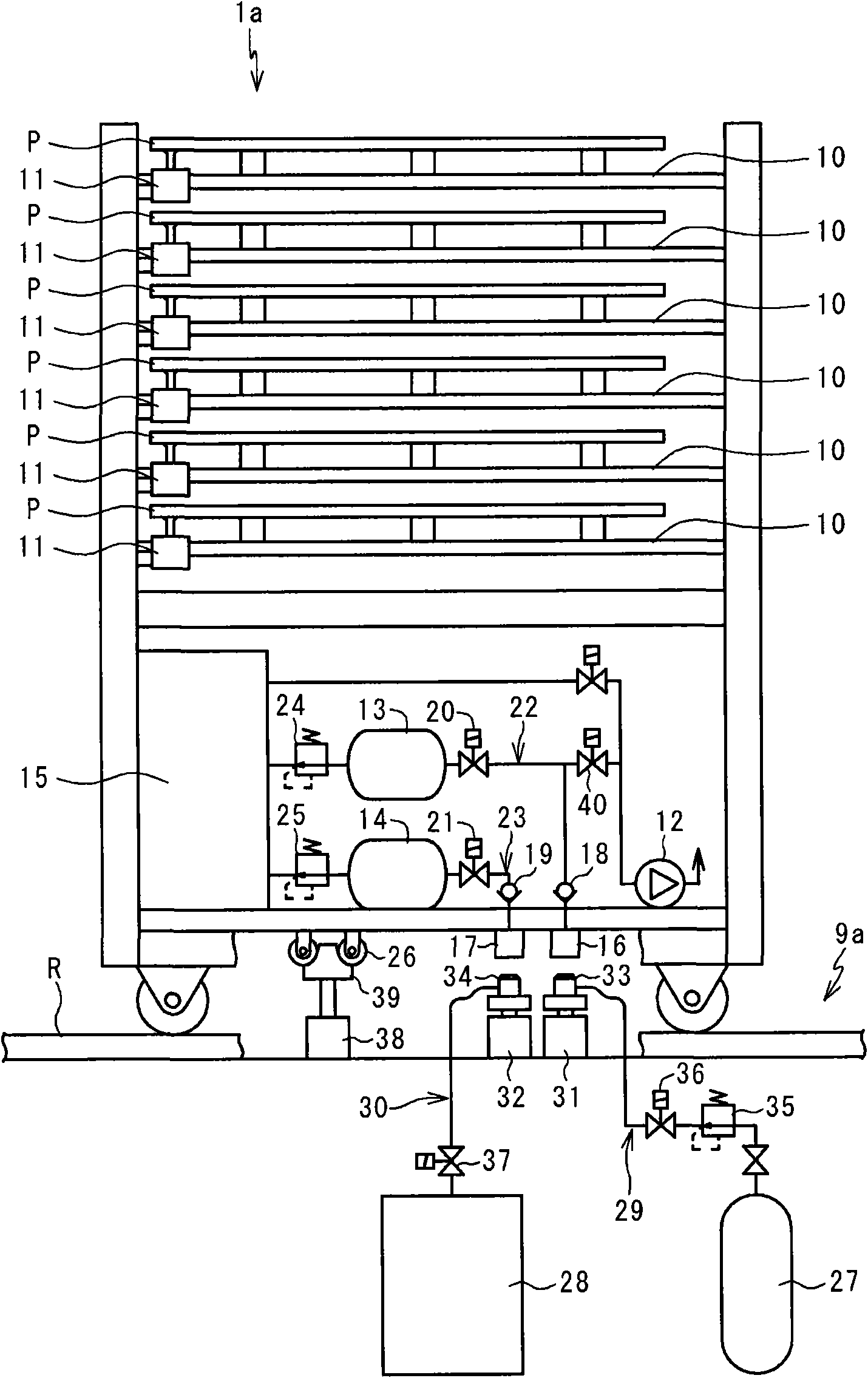

[0094] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a layout view of the flat panel display panel manufacturing facility (workpiece processing system) according to the first embodiment of the present invention. Such a flat panel display panel manufacturing facility circulates on closed rails 2 a plurality of workpiece transport carts 1 that move after loading glass substrates (workpieces) for flat panel display panels.

[0095] The rail 2 is composed of an outgoing path and a loop and a transmission device T, wherein the outgoing path and the loop are respectively composed of linear rails R, and the transmission device T is arranged at both ends of the outgoing path and the loop, and switches the workpiece transport trolley 1 from the outgoing path to Loop or switch from loop to outbound movement.

[0096] Most of the outward path of the rail 2 extends in the heating furnace 3 for heating the glass substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com