Whirlwind milling machine for chamfering of large bar

A bar, chamfering technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment and other directions, can solve the problems of easy to produce vibration lines, low processing efficiency, low precision, etc., to achieve high processing efficiency, high processing precision, The effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

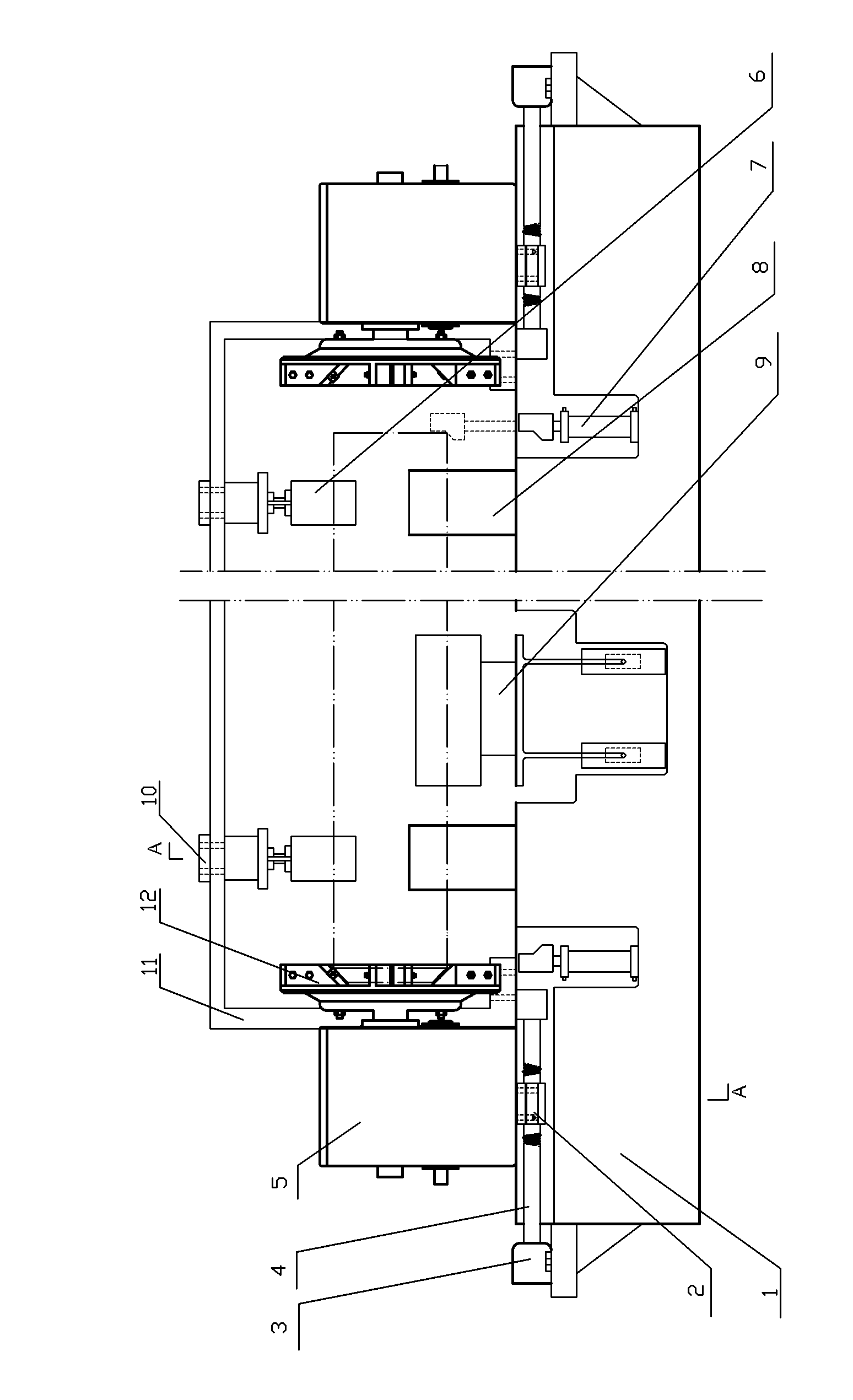

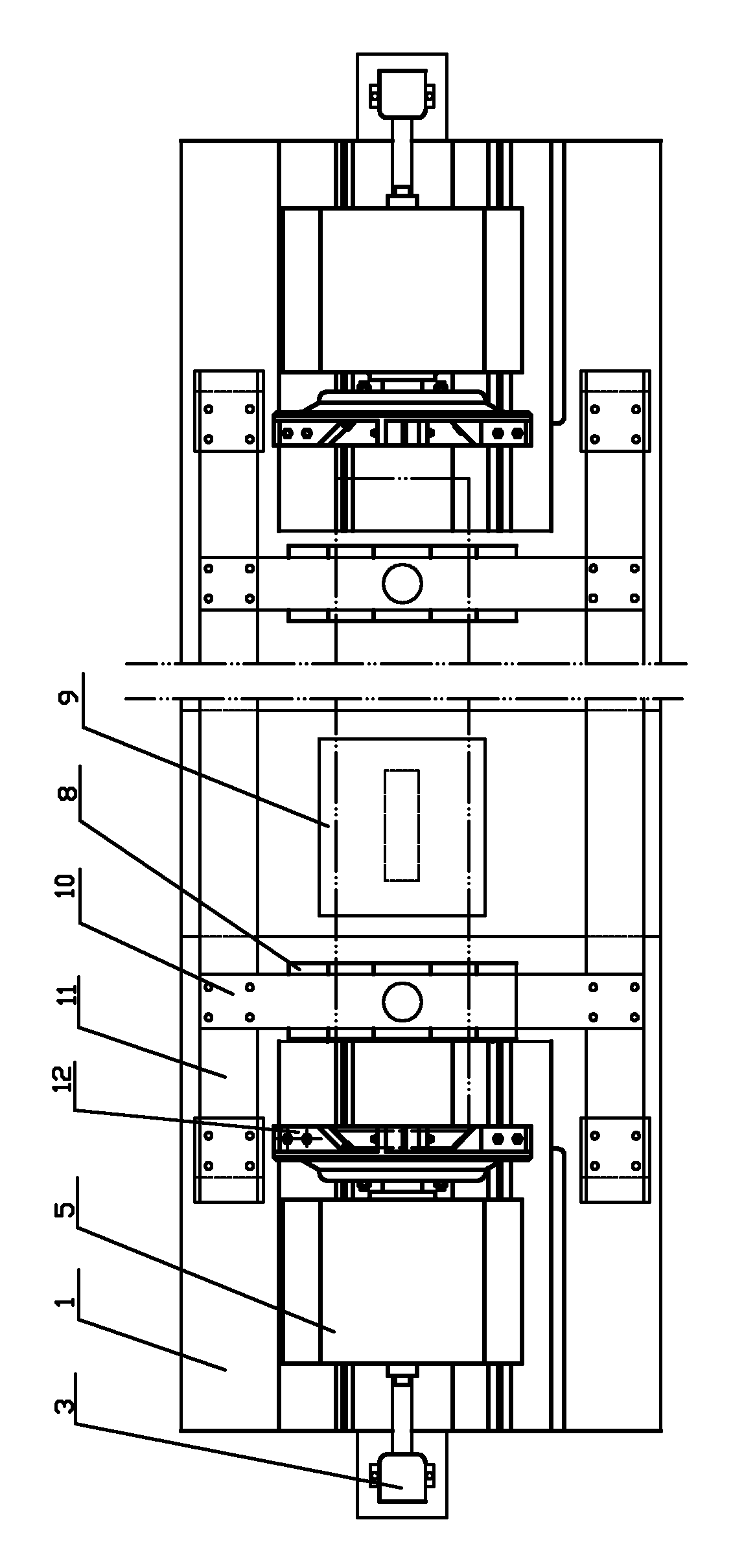

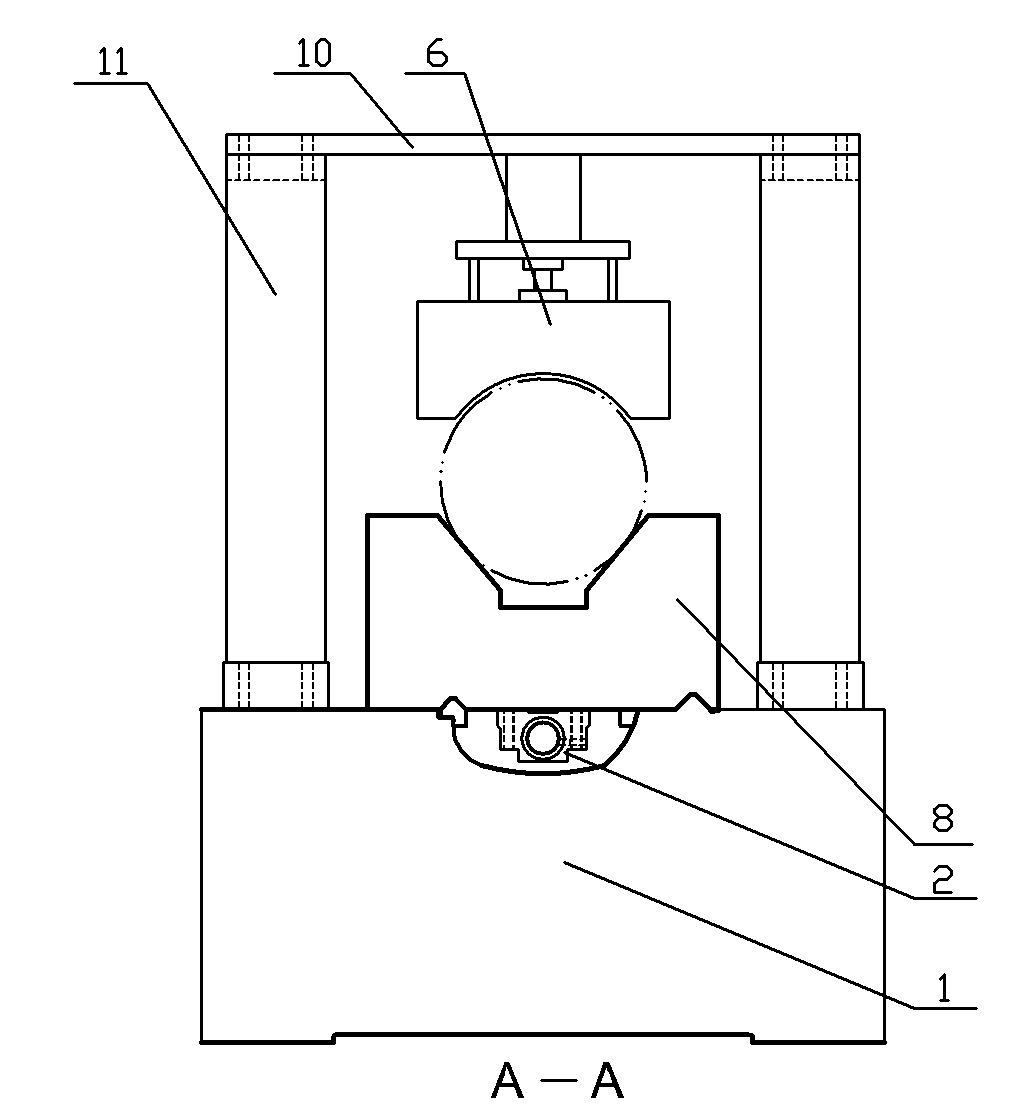

[0020] The specific embodiment of the present invention is shown in the attached drawings, which is composed of a machine bed 1, a head box 5, a cutter head 12, a pressing device 6, a material transfer device 9 and an axial positioning inclined block 7; a machine bed 1 Servo motors 3 are installed symmetrically on both ends of the headstock. The headstock 5 is connected to the servomotor 3 through the screw nut 2 and the lead screw 4; the cutter head 12 is mounted on the spindle of the headstock 5; it is characterized by the machine bed 1 Vertical beam frames 11 are installed on both sides of the upper part, two cross beams 10 are installed on the upper part, and a compression device 6 is installed on the cross beam 10. In the lower part of the compression device 6, two tables are installed on the machine bed 1 V-shaped iron 8; a feeding device 9 is installed in the middle groove of the machine bed 1, and axial positioning inclined blocks 7 are symmetrically installed on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com