Aircraft carrier ejector

An aircraft carrier and catapult technology, applied in the field of aircraft catapults, can solve the problems of high maintenance cost, large consumption of fresh water, complex structure, etc., and achieve the effects of low maintenance cost, high energy utilization rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

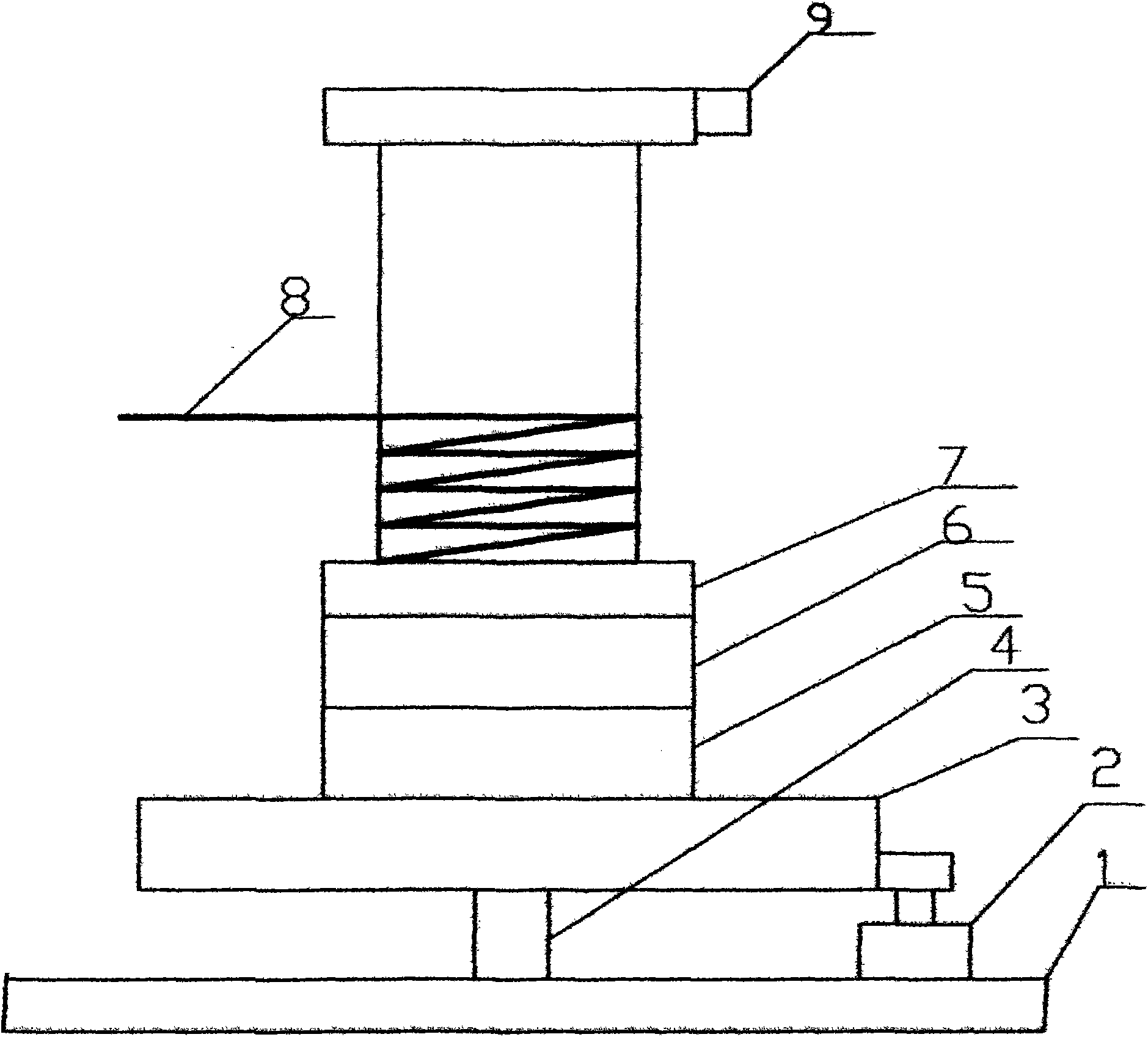

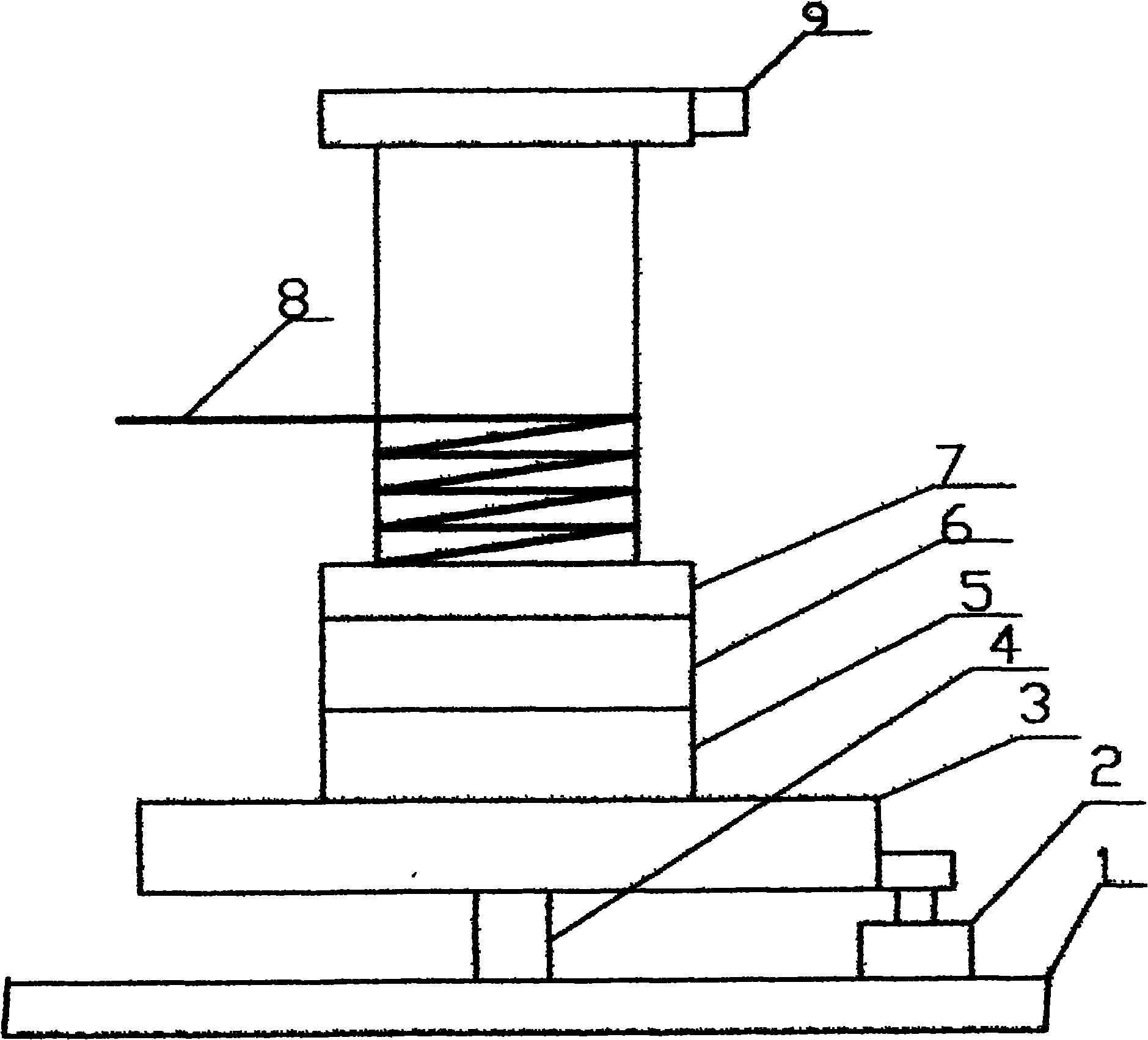

[0011] The embodiment of the present invention is like this, with reference to Figure 1 As shown, a kind of aircraft carrier catapult, the wheel 3 is installed on the body 1 through the shaft 4, the clutch 5, the speed reducer 6 are installed, the reel 7 is on the shaft 4, and one end of the steel cable 8 is installed on the reel 7, The other end of the steel cable 8 is connected to the aircraft hook, and the driver 2 drives the wheel 3. The outer diameter of the wheel 3 is greater than 1000mm, and the mass of the wheel ring is greater than 1000kg. good.

[0012] Working principle: the clutch 5 is in the disengaged state, and the brake 9 is released, so that one end of the steel cable 8 wrapped around the winch wheel 7 is pulled to the hook at the predetermined position of the aircraft by traction force, and the wheel disc 3 reaches the rated speed under the drive of the driver 2. That is, the take-off energy of the aircraft is 3 to 10 times, and the aircraft starts to meet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com