Stacking method of PET (Polyethylene Terephthalate) packaging bottles

A bottle and bottle body technology, which is applied in the field of bottles with a structure suitable for multi-layer placement, can solve the problems of serious deformation, dumping, low compressive strength, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

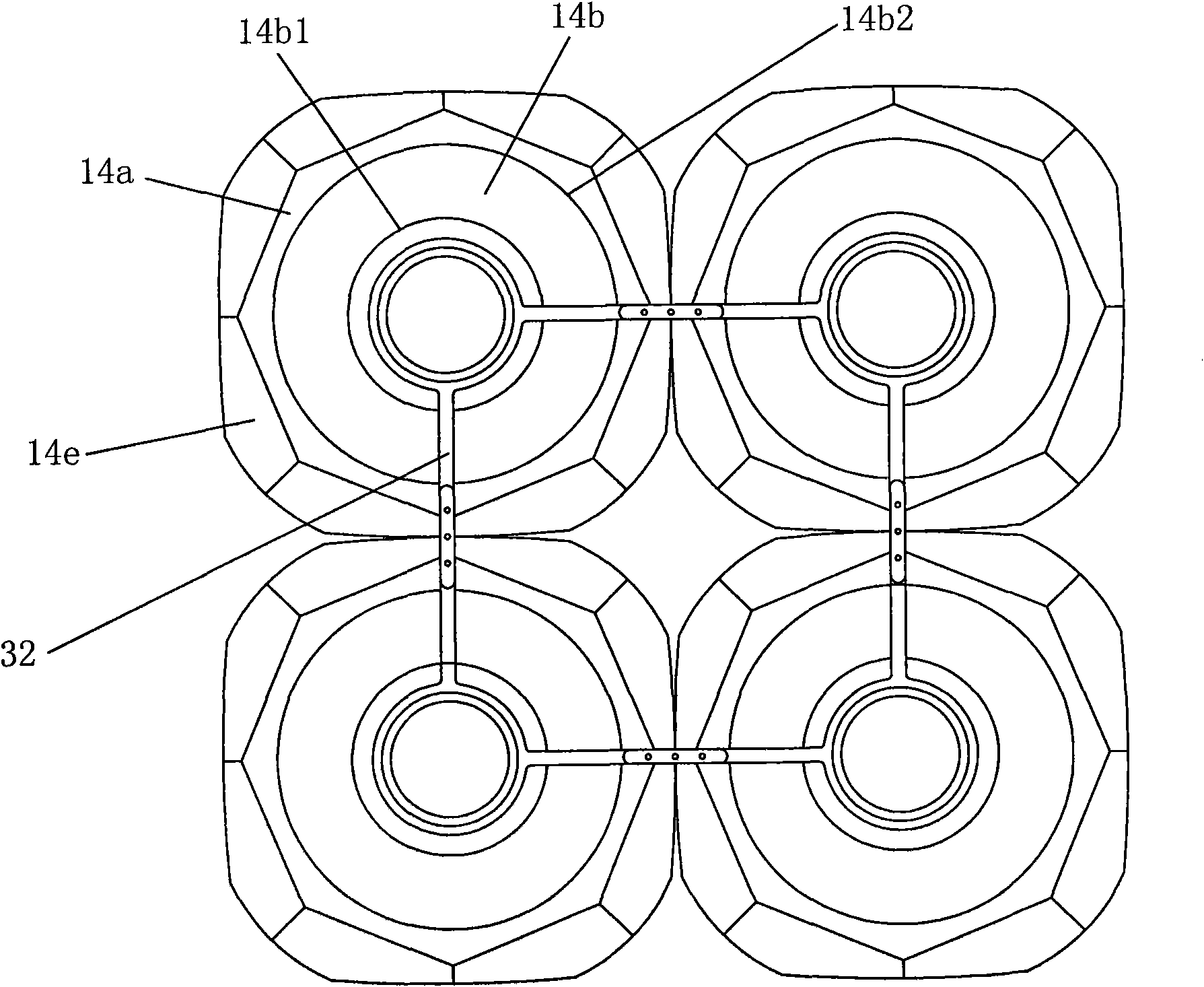

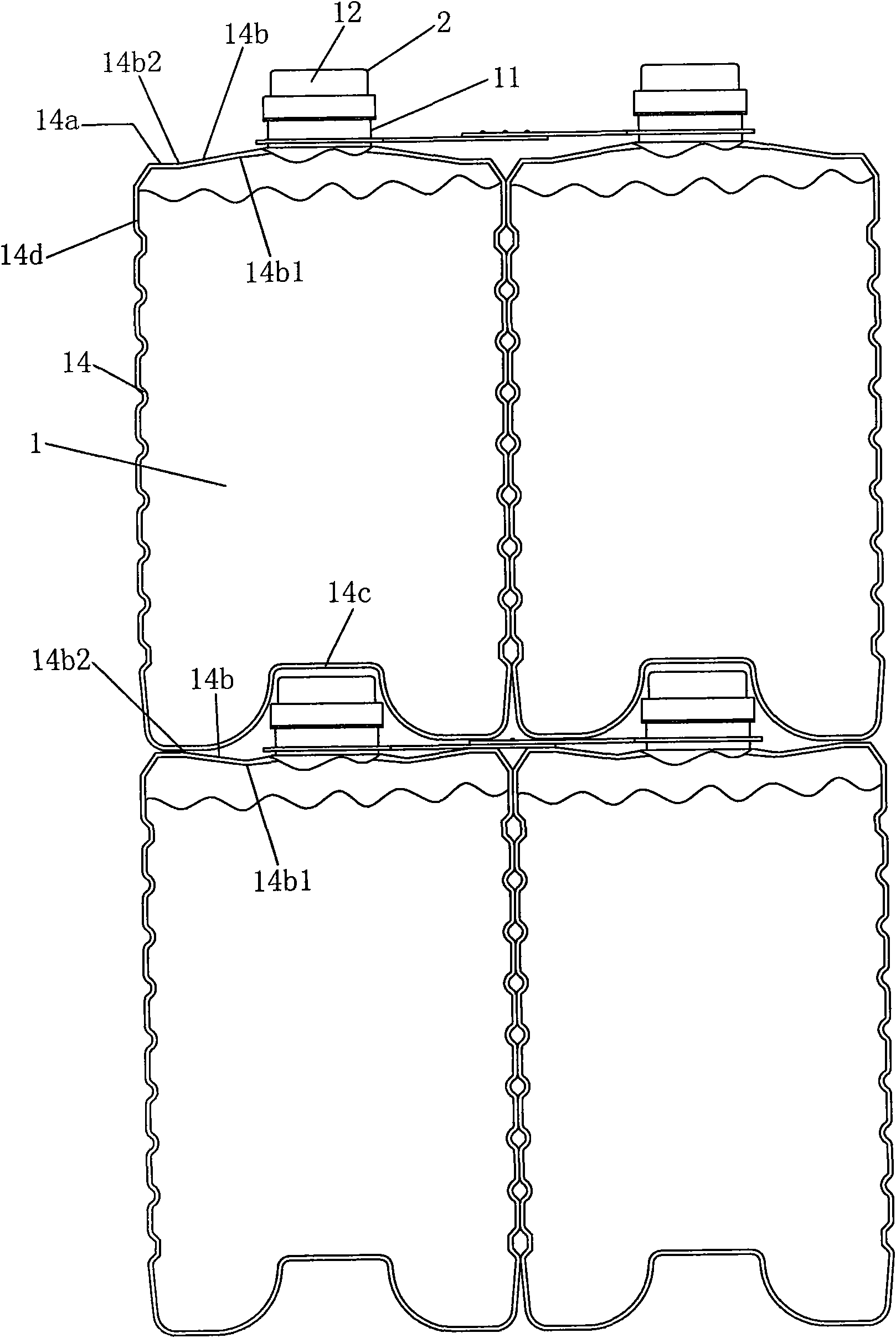

[0040] Implementation Mode 1: Refer to figure 1 and figure 2 , the PET packaging bottle used in this method: bottle 1 is made of PET material, the bottle body presents a shape similar to a square cylinder, and its four corners roughly present as R angles. Its neck 11 and mouth 12 of bottle 1 are formed by die-casting process; bottle body 14 is formed by blow-drawing process, and forms horizontal plane 14a and inclined plane 14b on the top of bottle body, and inclined plane 14b is connected with the bottom of neck portion 11, simultaneously , a circular crease 14b1 is reserved on the part of the top of the bottle body 14 located on the slope 14b, and there is also a circular bend 14b2 at the junction of the horizontal plane 14a and the slope 14b; the bottle body 14 is formed at the bottom There is a recess 14c that can match the lid 2 and the neck 11, and the side wall of the bottle body 14 is formed with multiple ribs 14d; in addition, the outer edge of the horizontal plane 14...

Embodiment approach 2

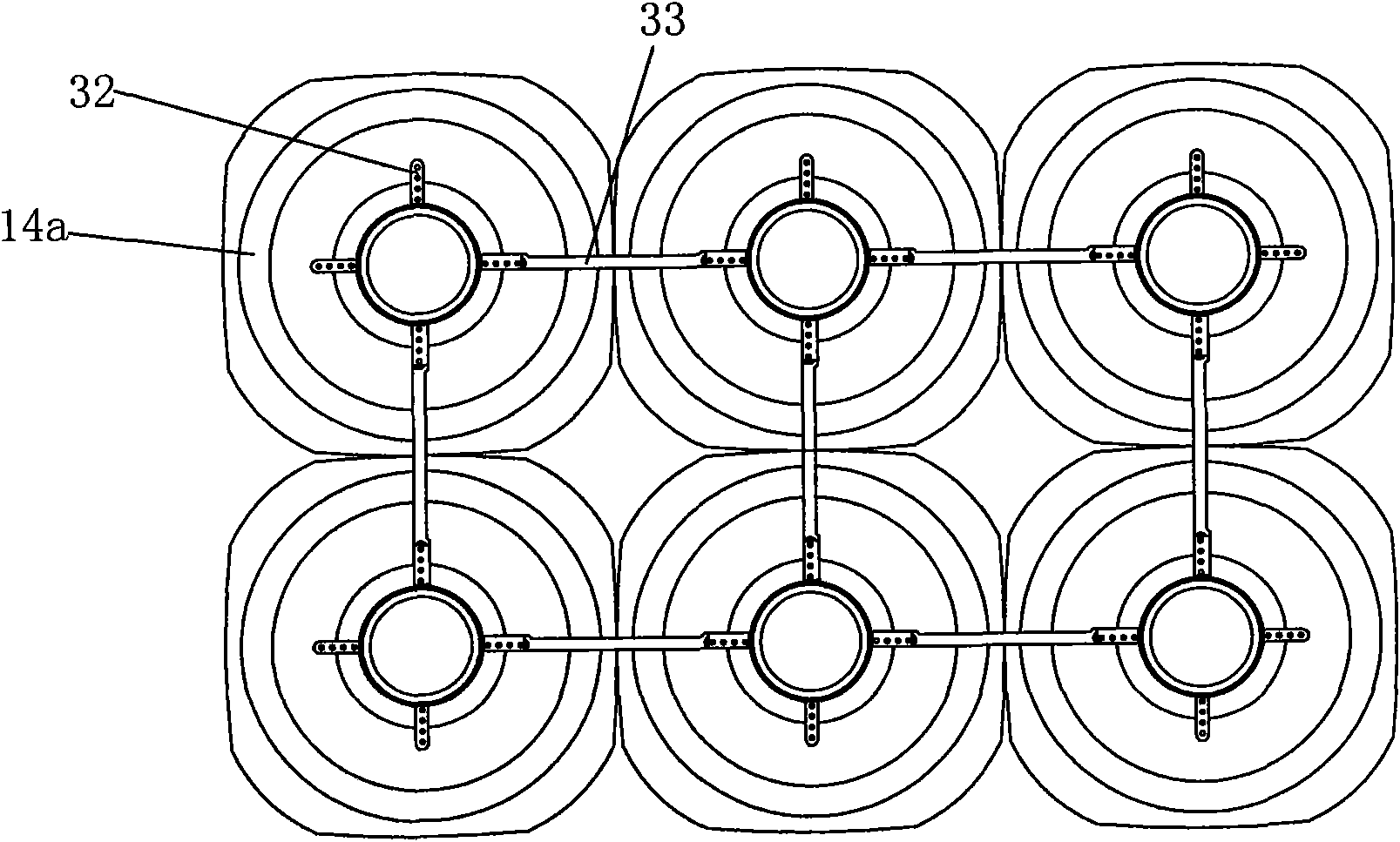

[0044] Implementation mode two: refer to image 3 and Figure 4 The difference between this embodiment and Embodiment 1 is that the outer edge of the horizontal plane 14a is made into a circle, and the fixed connector 3 extends outwards with four straps 32, and two adjacent straps 32 form a mutual To be vertical, it can connect more bottles together, and also can fix two straps 32 together by rod 33 again. The purpose of the present invention can also be achieved. For other structures, refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com