Bearing plate group and bearing plate thereof

A technology for carrying trays and carrying surfaces, applied to rigid containers, containers to prevent mechanical damage, containers with multiple items, etc., can solve the problems of object 9 damage, increased packaging costs, occupation, etc., to increase support and strengthen Structural strength and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

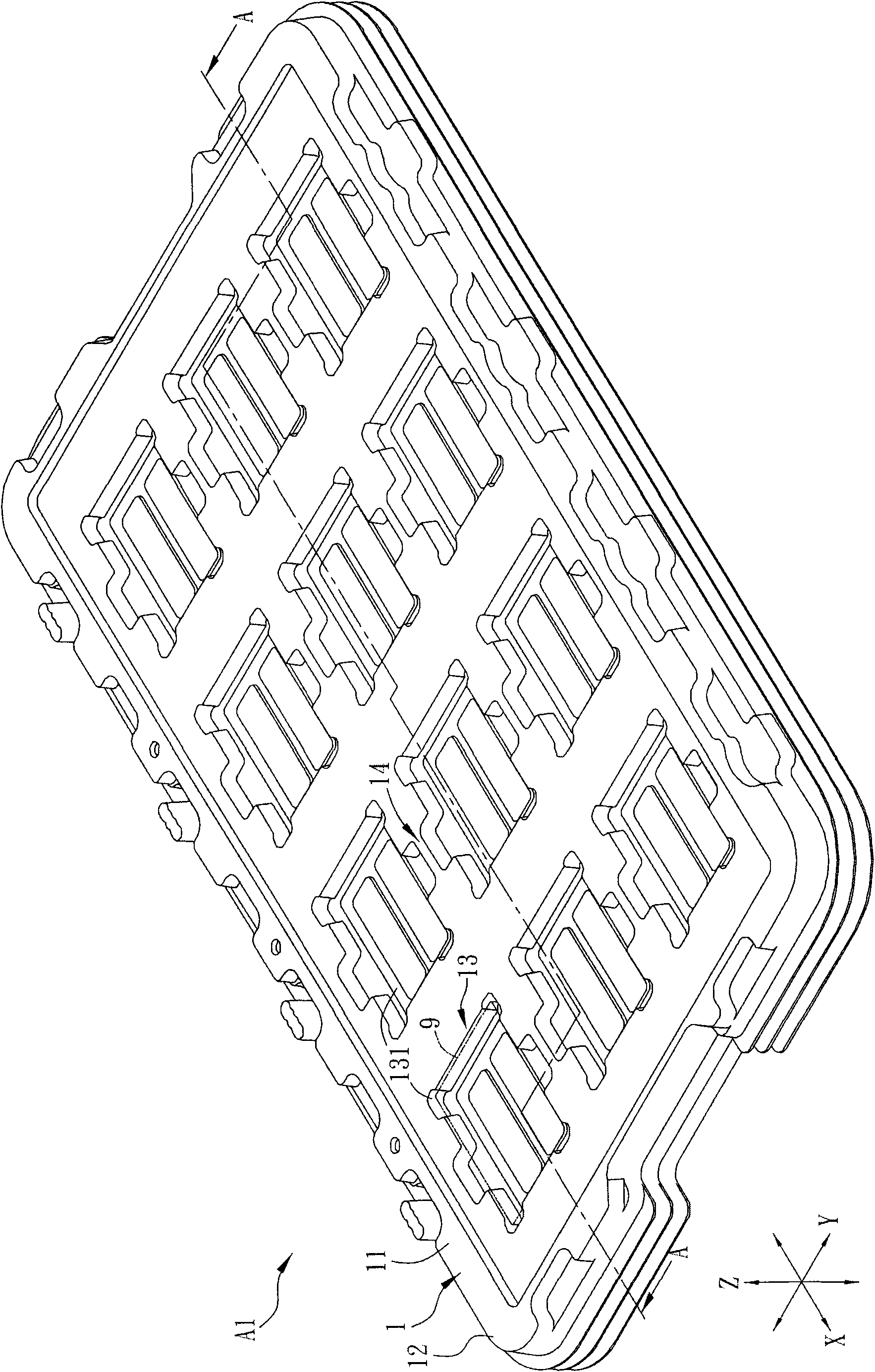

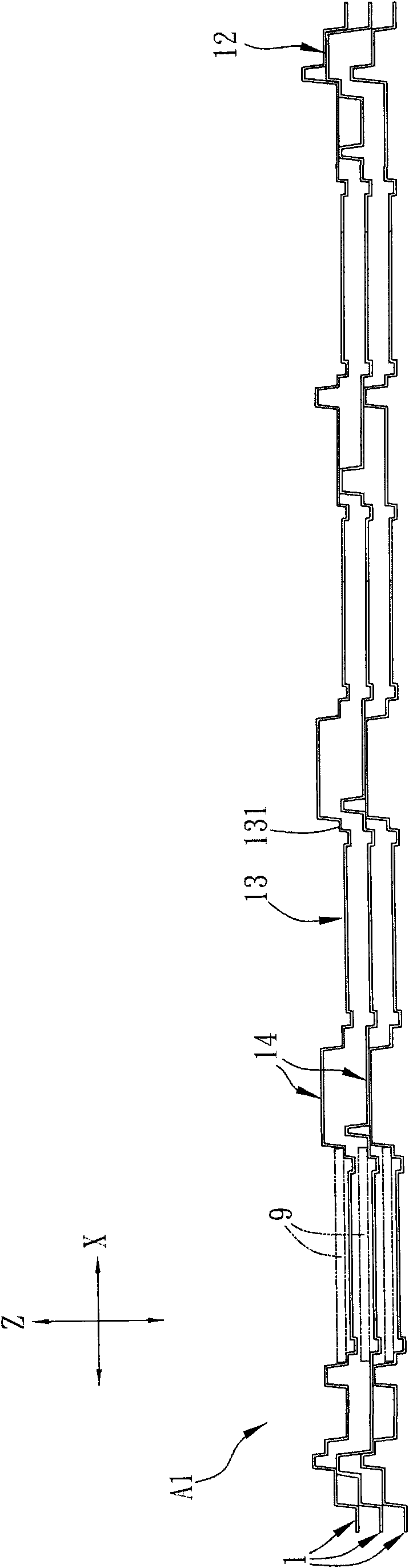

[0067] A set of trays and trays thereof according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same symbols.

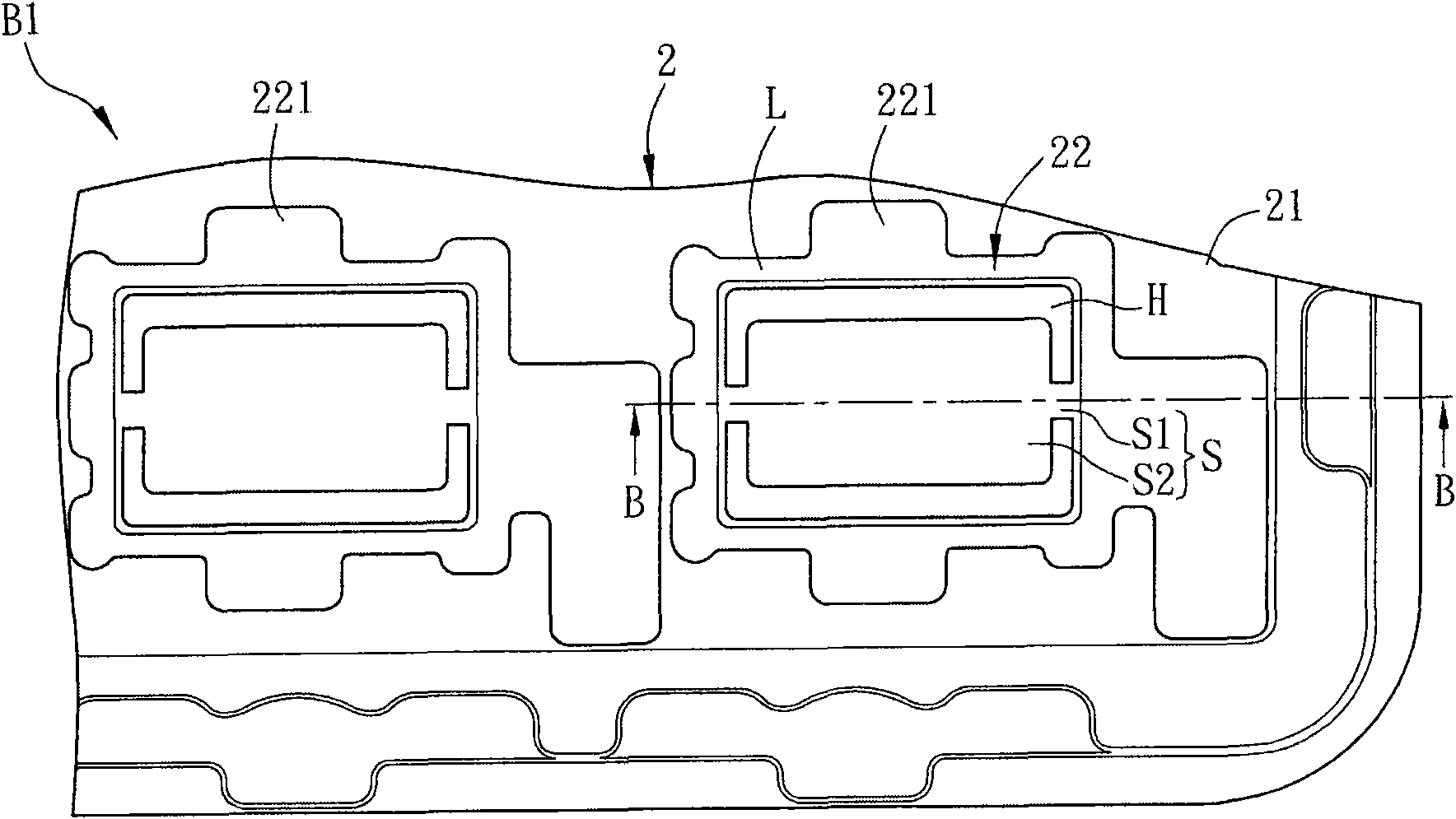

[0068] Please refer to Figure 2A and Figure 2B shown, where Figure 2A It is a partial schematic diagram of the carrier group B1 of the preferred embodiment of the present invention, Figure 2B For the carrier group B1 along Figure 2A Sectional view of the B-B line in the middle. The tray group B1 includes at least two trays 2 stacked horizontally at 180°, and each tray 2 includes a body 21 , a loading structure 22 , a first buffer structure 23 and a second buffer structure 24 .

[0069] The material of the body 21 can be, for example, plastic or polymer, such as polyethylene terephthalate (PET) or polystyrene (PS). The bearing structure 22 is arranged in an array in the body 21 and includes a plurality of bearing grooves 221. Each bearing gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com