Damped stacking baffle

A damping and stacking technology, applied in the field of stackers, can solve the problems of poor thrust control, low work efficiency, uneven stacking of steel plates, etc. The effect of disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

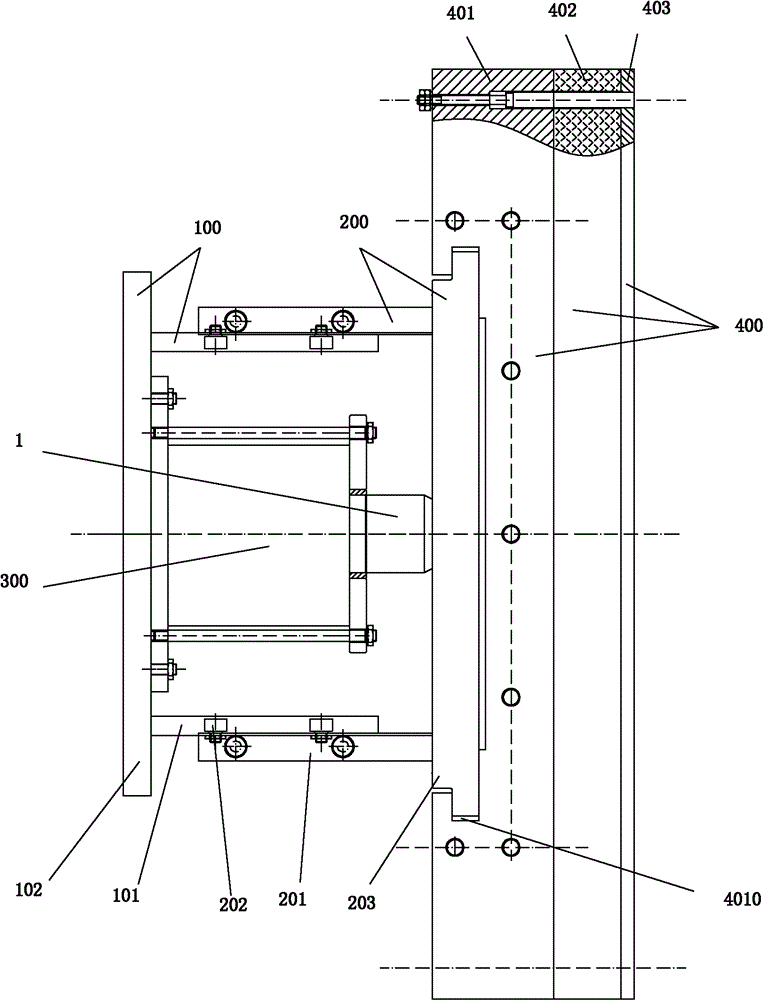

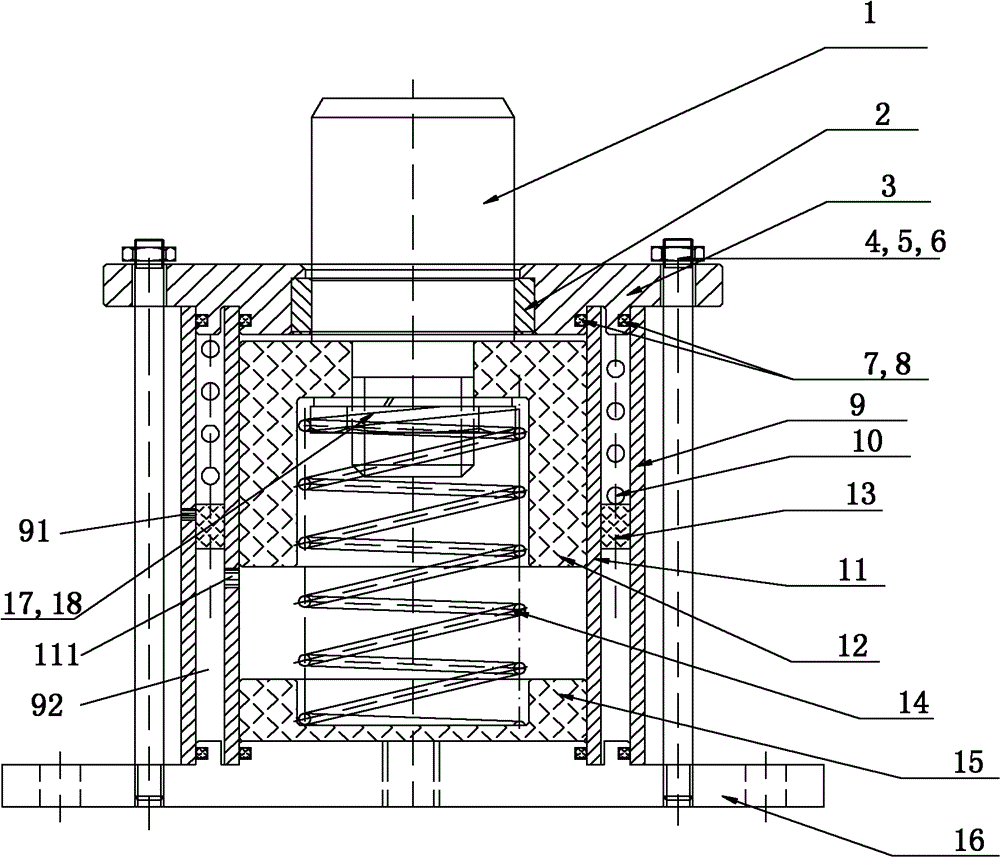

[0014] see figure 1 and 2 , the embodiment of the present invention is provided with a fixed bracket 100 , a movable bracket 200 , a double cylinder damping cylinder 300 and a baffle 400 . Fixed support 100 is fixed on the stacker ( figure 1 and 2 not shown in). The fixed bracket 100 is movably connected with the mobile bracket 200 through the guide rail 101 . The double cylinder damping cylinder 300 is fixed on the fixed bracket 100 , the piston rod 1 of the double cylinder damping cylinder 300 is in contact with the moving bracket 200 , and the baffle plate 400 is connected with the moving bracket 200 .

[0015] The fixed bracket 100 and the mobile bracket 200 are combined into a symmetrical rectangular frame structure, that is, the fixed bracket 100 is provided with four guide rails 101, and the guide rails 101 are vertically fixed on the seat plate 102, and the mobile bracket 200 is provided with clamping plates 203, 4 slide bars 201 equipped with pulleys 202, each sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com