Online deuterium and nitrogen mixing equipment for lowering hydrogen sensitivity of optical fiber

An optical fiber hydrogen, sensitive technology, applied in the direction of gas and gas/vapor mixing, etc., can solve the problems of only suitable processing equipment, complex process, high cost, and achieve the effect of reducing processing cost, production cost and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

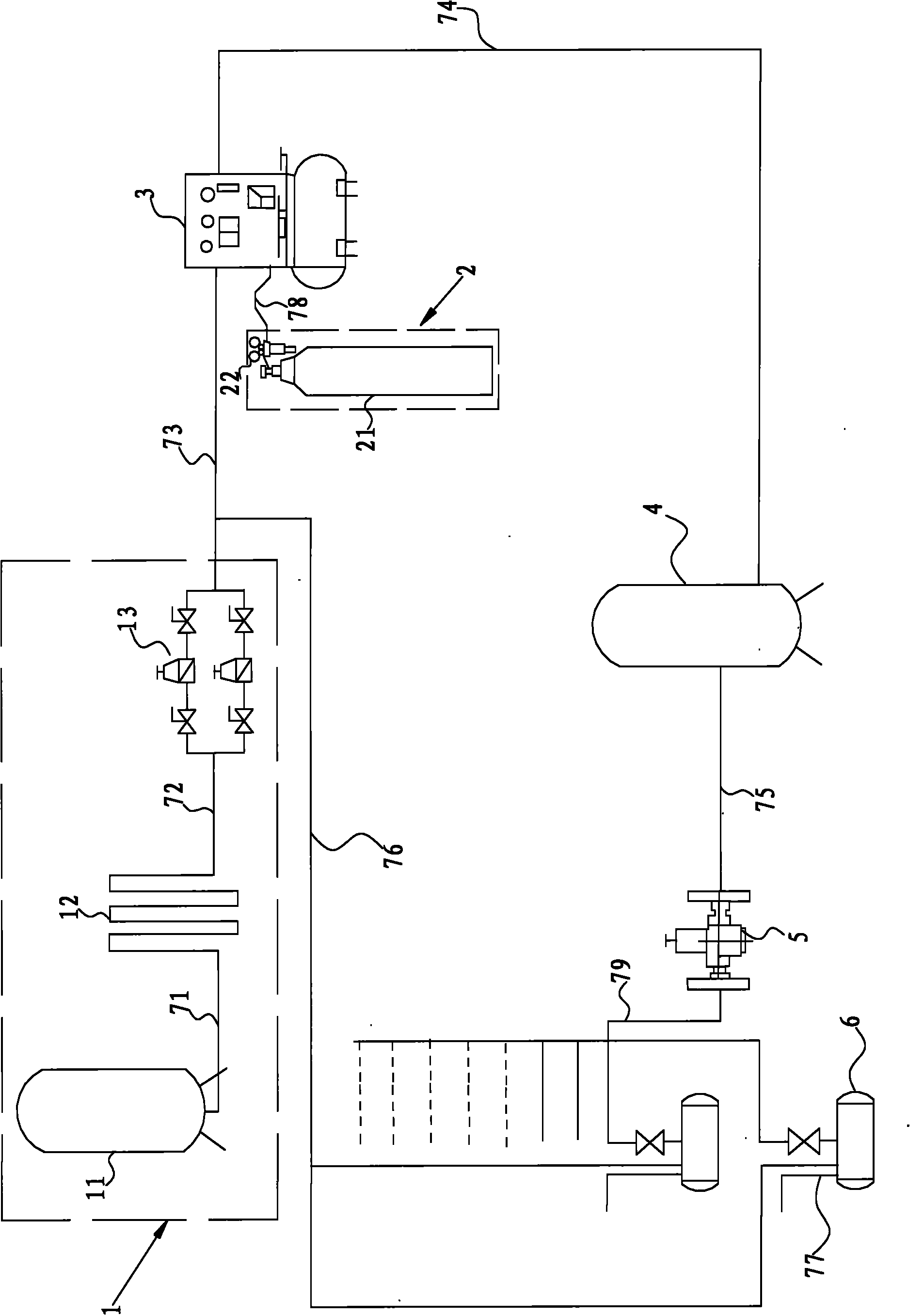

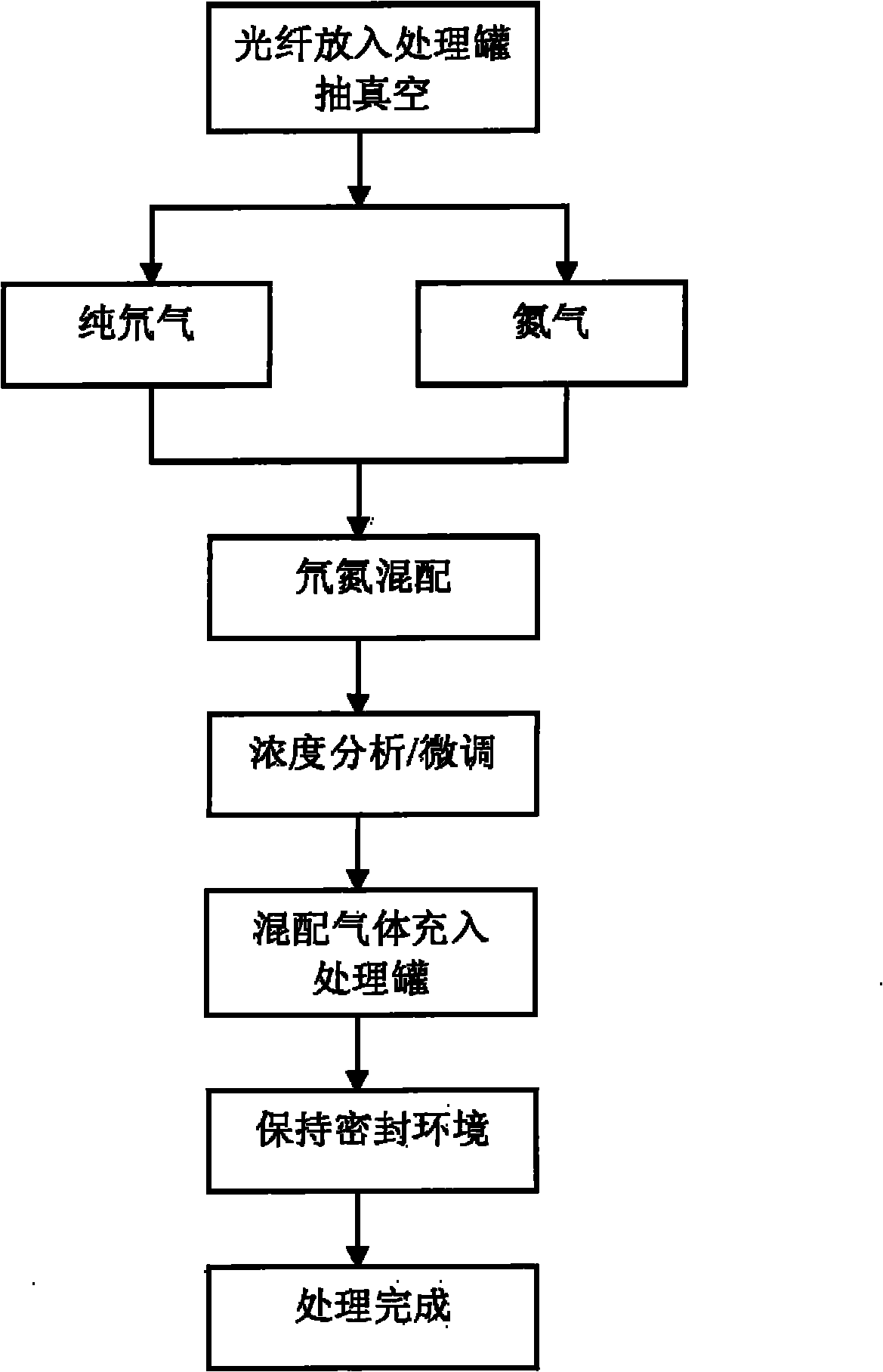

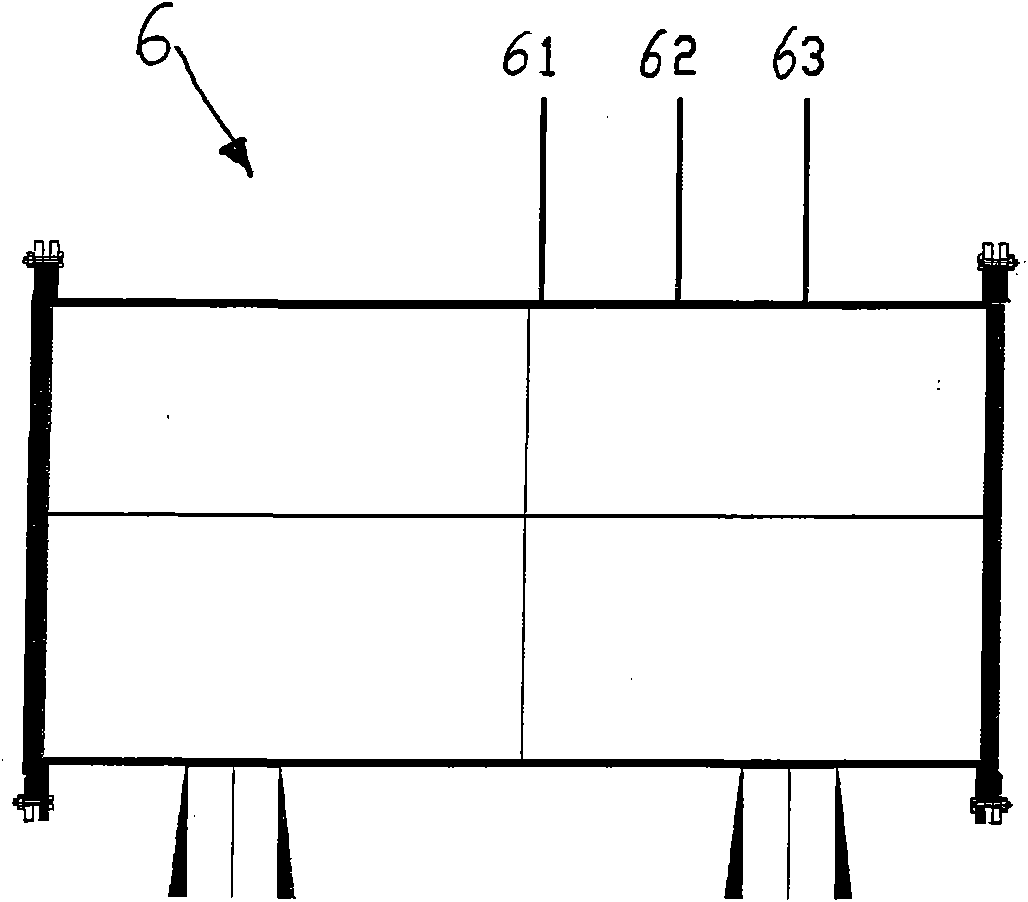

[0017] figure 1 It is a schematic diagram of equipment implemented according to the technical solution of the present invention. The equipment includes a nitrogen gas supply device 1, a deuterium gas supply device 2, a mixer 3, a buffer tank 4, a pipeline decompression tank 5, and an optical fiber processing tank 6. The devices are mainly connected by pipelines, and the specific structure is described as follows:

[0018] Nitrogen supply device 1 comprises liquid nitrogen storage tank 11 respectively, and it is used for storing liquid nitrogen; Air-temperature type vaporizer 12, is used for vaporizing liquid nitrogen; Gas decompression device 13, is used for controlling gas pressure; The tank 11 is connected to the gasifier 12 through a pipeline 71 , the gasifier 12 is connected to the gas decompression device 13 through a pipeline 72 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com