Anti-rust emulsified oil and preparation method thereof

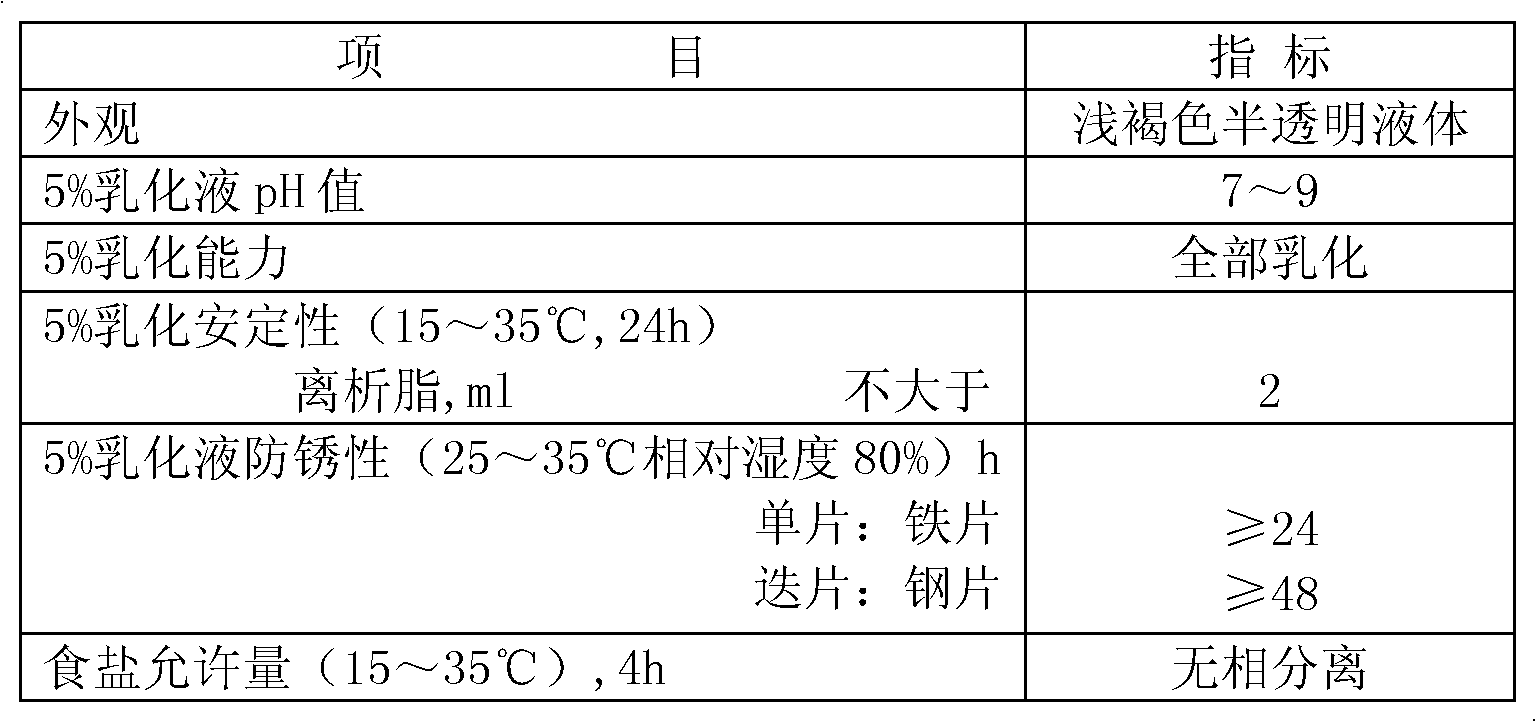

A technology of anti-rust emulsified oil and emulsifier, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of easy skin allergies, easy corrosion of equipment, short anti-rust cycle, etc., and achieve low cost, lubricity and cooling Good performance and long anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Based on light mineral oil. During the production process, add 62.45kg of base oil into the reactor, stir, add 10kg of anti-rust compound agent 1, 0.5kg of anti-rust compound agent 2, and 3kg of anti-rust compound agent 3 in turn, stir for 10-20 minutes and then add in order 2kg of emulsifier 1 and 18kg of emulsifier 2 were stirred for 10 to 20 minutes respectively; 2.5kg of stabilizer and 0.5kg of bactericide were added in turn, stirred for 10 to 20 minutes respectively, and then 1.5kg of surfactant was added and stirred for 25 to 45 minutes to obtain this product Invented antirust emulsified oil.

Embodiment 2

[0052] Based on light mineral oil. During the production process, add 60kg of base oil into the reaction kettle, stir, add 9kg of antirust compound agent 1, 0.7kg of antirust compound agent 2, and 5kg of antirust compound agent 3 in turn, stir for 10 to 20 minutes, and then add 1kg in turn Emulsifier 1 and 20kg emulsifier 2 were stirred for 10 to 20 minutes respectively; 2kg of stabilizer and 0.6kg of bactericide were added successively, and after stirring for 10 to 20 minutes respectively, 1.7kg of surfactant was added and continued to stir for 25 to 45 minutes to obtain the emulsifier of the present invention. Anti-rust emulsified oil.

Embodiment 3

[0054] Based on light mineral oil. During the production process, add 65kg of base oil into the reaction kettle, stir, add 11kg of antirust compound agent 1, 0.4kg of antirust compound agent 2, and 1kg of antirust compound agent 3 in turn, stir for 10 to 20 minutes, then add 3kg in turn Emulsifier 1 and 15kg emulsifier 2 were stirred for 10 to 20 minutes respectively; 3kg of stabilizer and 0.4kg of bactericide were added successively, and after stirring for 10 to 20 minutes respectively, 1.2kg of surfactant was added and continued to stir for 25 to 45 minutes to obtain the emulsifier of the present invention. Anti-rust emulsified oil.

[0055]In the embodiment of the present invention, light mineral oil is used as the base oil, which is a commercially available product purchased from Shanghai Oil Refinery. Antirust composite agent 1 is a mixture of barium petroleum sulfonate and No. 10 machine oil, wherein the barium petroleum sulfonate accounts for 40% of the total weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com