Method for preparing tree-starch based natural biomass detergent

A starch-based, biomass-based technology, applied in the preparation of detergent mixture compositions, detergent preparation of liquid components, detergent compositions, etc., can solve problems such as limited experience in molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

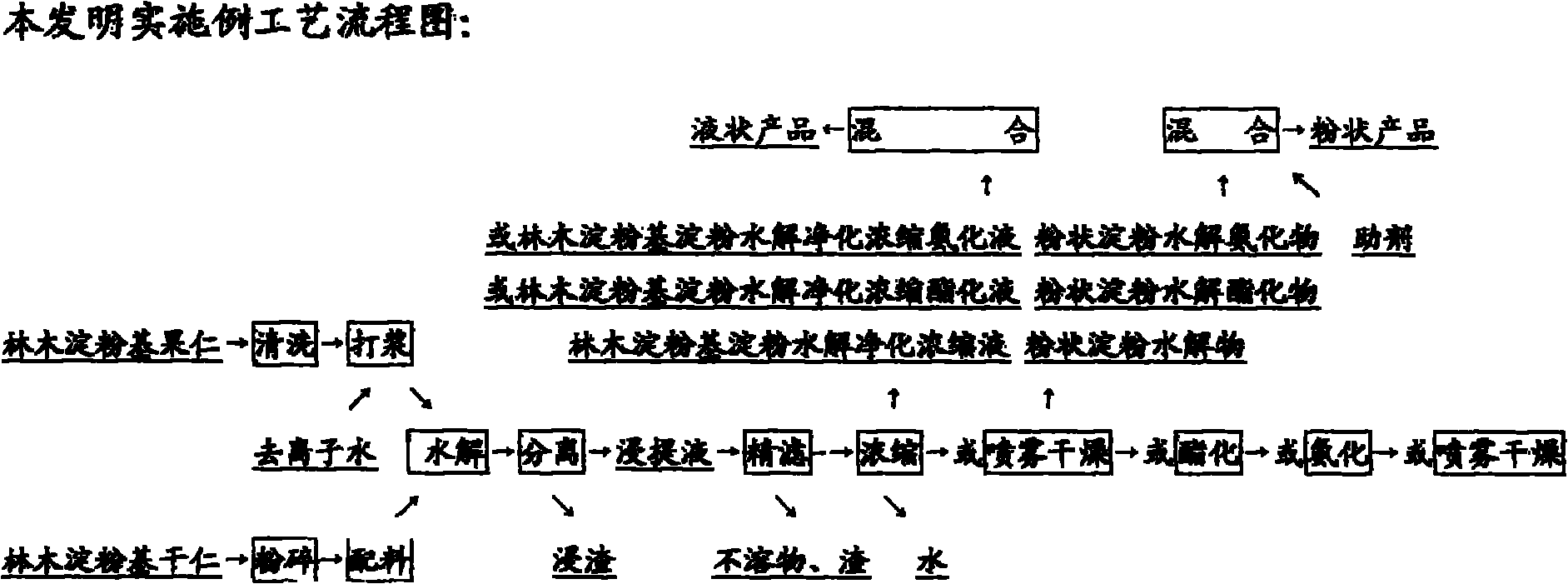

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of preparation and method of forest wood starch-based natural biomass detergent, is characterized in that comprising the following steps:

[0029] The first step is the selection of tree starch-based plant varieties: acorns, horse chestnuts, chestnuts, pueraria, sapindus, soil tuckahoe, fern root, amaryllis.

[0030] In the second step, a forest wood starch-based natural biomass detergent contains forest wood starch-based biomass extract such as forest wood starch-based starch hydrolysis purification concentrate or its alkyl glucoside or glucosamine. It can be a liquid product or a powdered product.

[0031]The third step, preparation of forest wood starch-based biomass hydrolyzate or powder

[0032] The collected starch-based fruits of forest trees were sun-dried or dried in a dryer (60-65° C.) until air-dried to constant weight. Air-dried forest tree starch-based dried fruit to constant weight is separated from the shell and kernel, and the separ...

Embodiment 2

[0043] The collected forest tree starch-based acorn fruit was sun-dried or dried in a dryer (60-65°C) until air-dried to a constant weight. Air-dried forest tree starch-based dried acorns to constant weight undergo shell and kernel separation operations, and the separated acorn kernels can be crushed with high crushing ratio materials for raw material preparation. Or make fresh acorn kernels for a backup.

[0044] Take the prepared pulverized forest tree starch-based acorn kernels or take 5 kg of crushed fresh acorn kernels and add them to the hydrolysis cooking tank, add acid and deionized water until the solid-liquid ratio is controlled in the range of 1:6-12 Inside, the hydrolysis cooking operation is carried out, the hydrolysis temperature is controlled at 100-105°C, and the extraction time is controlled at 2-3 hours. After hydrolysis, neutralization, beating, refining, and separation of the hydrolyzed feed liquid are carried out, passed through a 100-mesh sieve, and part...

Embodiment 3

[0050] The collected forest tree starch-based horse chestnut is dried in the sun or with a dryer (60-65°C) until air-dried to a constant weight. Air-dried to constant weight forest tree starch-based dried horse chestnut is subjected to the shell kernel separation operation, and the separated horse chestnut kernel can be crushed with high crushing ratio materials for raw material preparation. Or prepare fresh horse chestnuts as an alternate raw material.

[0051] Take the prepared ground wood starch-based aescin nuts or take 5 kg of crushed fresh aescin nuts and put them into a hydrolysis cooking tank, add acid and deionized water until the solid-liquid ratio is controlled within the range of 1:6-12, and then hydrolyze In the cooking operation, the hydrolysis temperature is controlled at 100-105°C, and the extraction time is controlled at 2-3 hours. After hydrolysis, neutralization, beating, refining, and separation of the hydrolyzed feed liquid are carried out, passing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com