Method for manufacturing composite floor with low formaldehyde emission through heat treatment

A low-formaldehyde release, composite floor technology, used in building structures, floors, buildings, etc., can solve the problems of slowing down formaldehyde, difficult coating agents, and difficult sealing of saw sections, and achieves simple production control, good physical properties, The effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

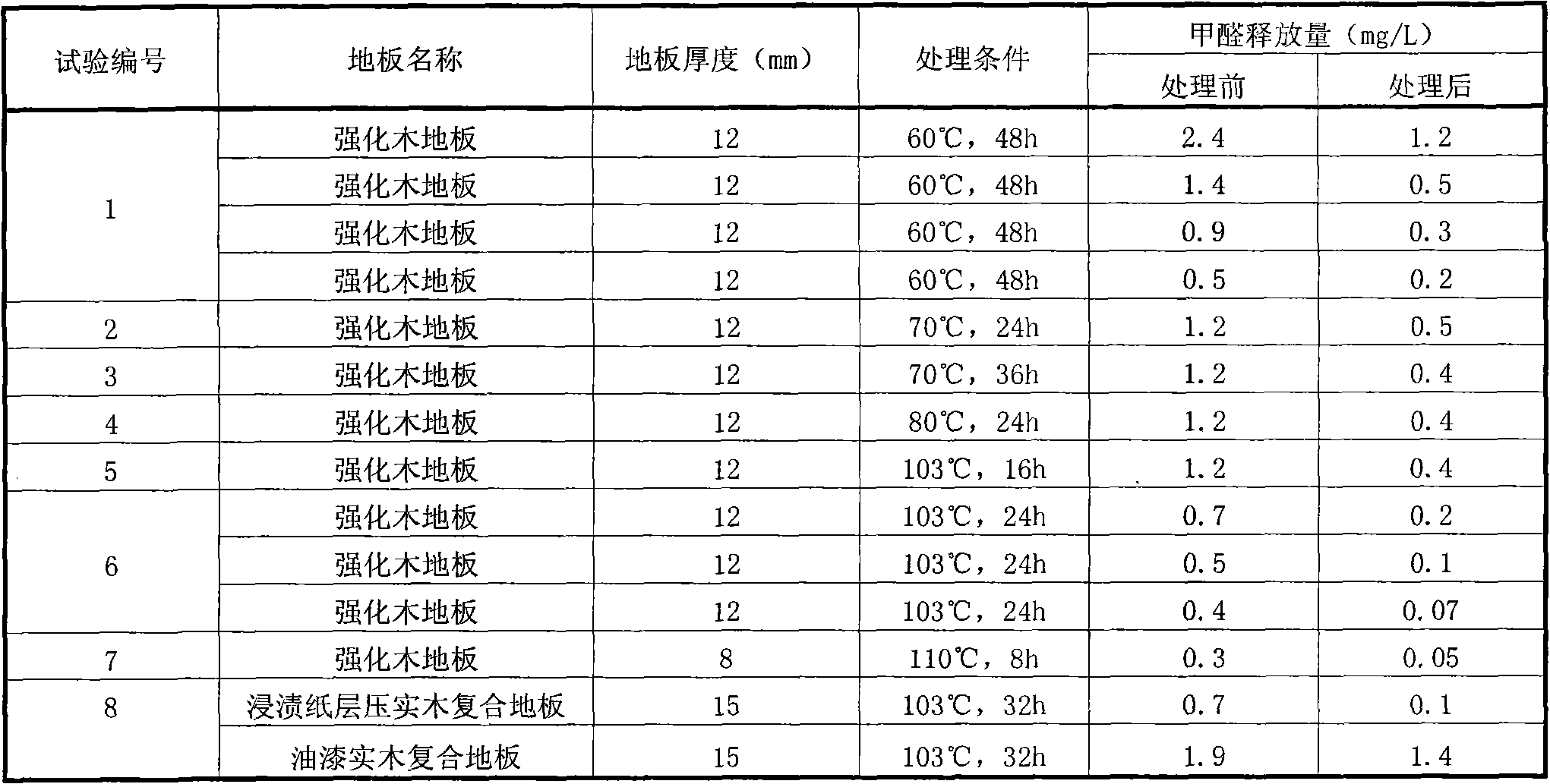

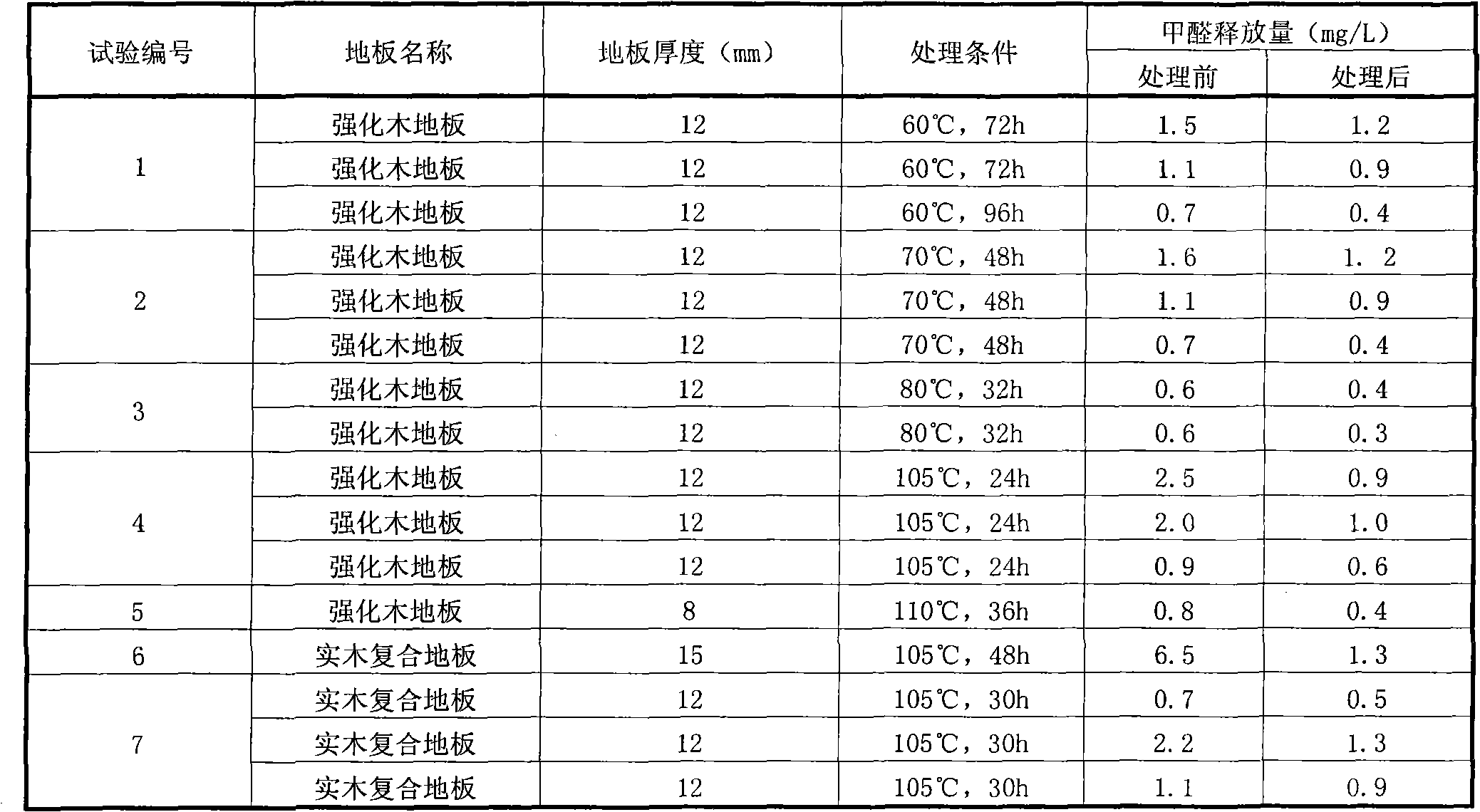

Embodiment 1

[0028] Example 1 The formaldehyde emission is 2.0mg / L (40L dryer value), and the semi-finished solid wood composite flooring with a specification of 930×129×15mm is stacked into stacks according to the “well” shape, placed in a heat treatment box, the box door is closed, and the box door is opened. Circulating fan, open the heat medium valve, keep it for 72 hours after the temperature rises to 60°C, take out the plate, and maintain it under natural indoor conditions for 7 days, then process the groove and tenon, paint, and pack, and the formaldehyde emission is 0.9mg / L and the physical and mechanical properties of solid wood composite flooring in line with national standards.

Embodiment 2

[0029] Example 2 The formaldehyde emission is 0.8mg / L (9-11L dryer value), the size is 2450 × 175 × 12mm Laminate flooring slabs are stacked into stacks according to the "well" shape, placed in the heat treatment room, and the door of the room is closed , turn on the circulating fan, open the heat medium valve, keep the temperature for 32 hours after the temperature rises to 105°C, take out the plate, and maintain it under natural indoor conditions for 10 days, then process the groove and tenon, pack it, and make the formaldehyde emission of 0.4mg / L And the physical performance of laminated wood flooring in line with national standards.

Embodiment 3

[0030] Example 3 The formaldehyde emission is 0.4mg / L (40L dryer value), and the specification is 1228 × 205 × 8mm Laminate flooring slabs are stacked into stacks according to the "well" type, placed in a heat treatment tank, and the tank door is closed. Turn on the circulating fan, open the heat medium valve, keep the temperature for 16 hours after the temperature rises to 110°C, take out the plate, and keep it under natural conditions indoors for 20 days, then process the groove and tenon, pack it, and make it with a formaldehyde emission of 0.07mg / L and Laminate flooring whose physical properties meet national standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com