Multistage drive ore dissolution method used for mining salt mines

A technology for dissolving ore and salt mines, which is applied in the field of water-dissolving mining for collecting low-grade soluble salts. It can solve the problems of long tank construction period, reduced ore dissolving efficiency, and low brine output, so as to reduce waste of direct discharge and improve dissolving ore efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments of the present invention are described in detail as follows.

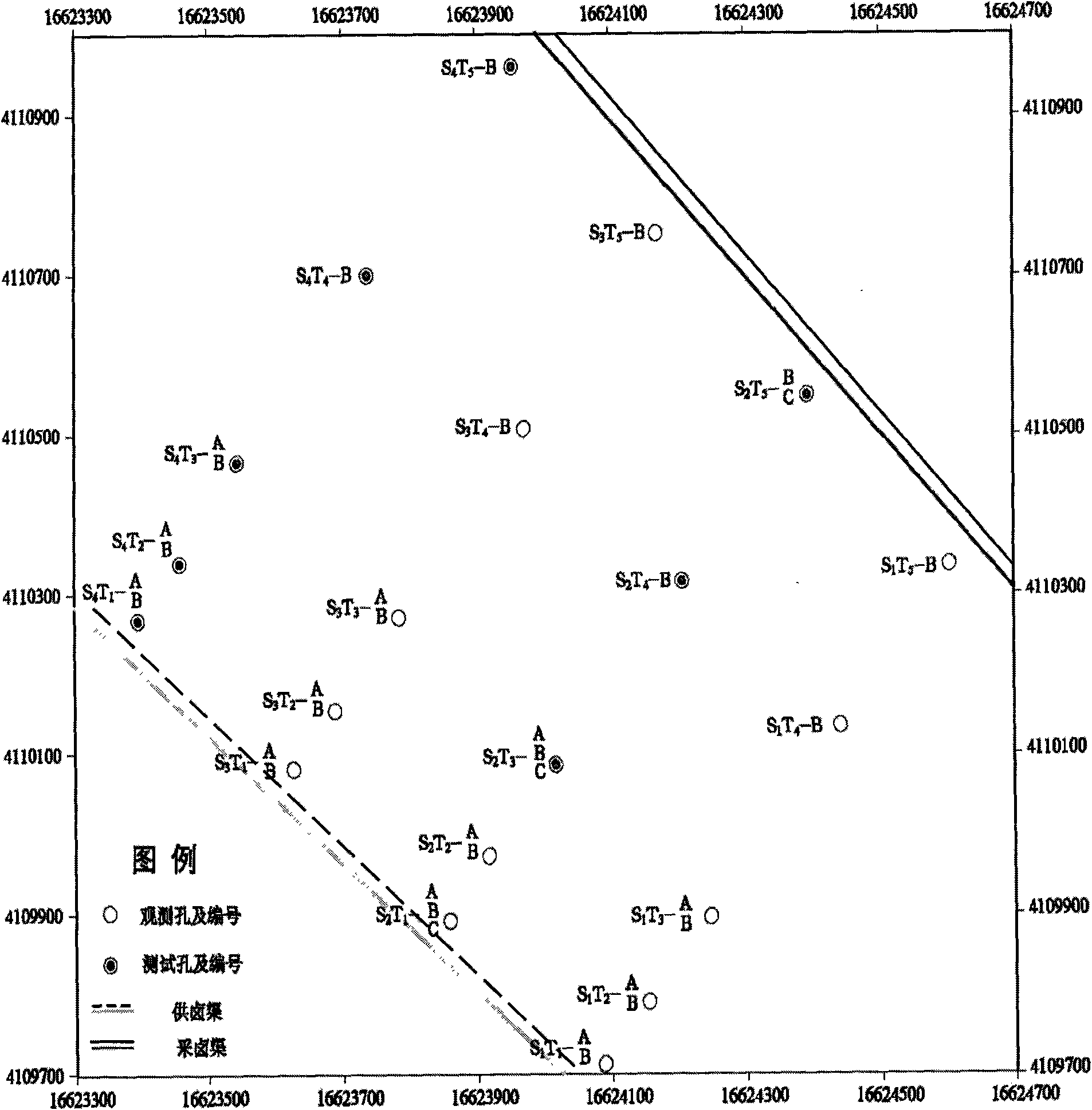

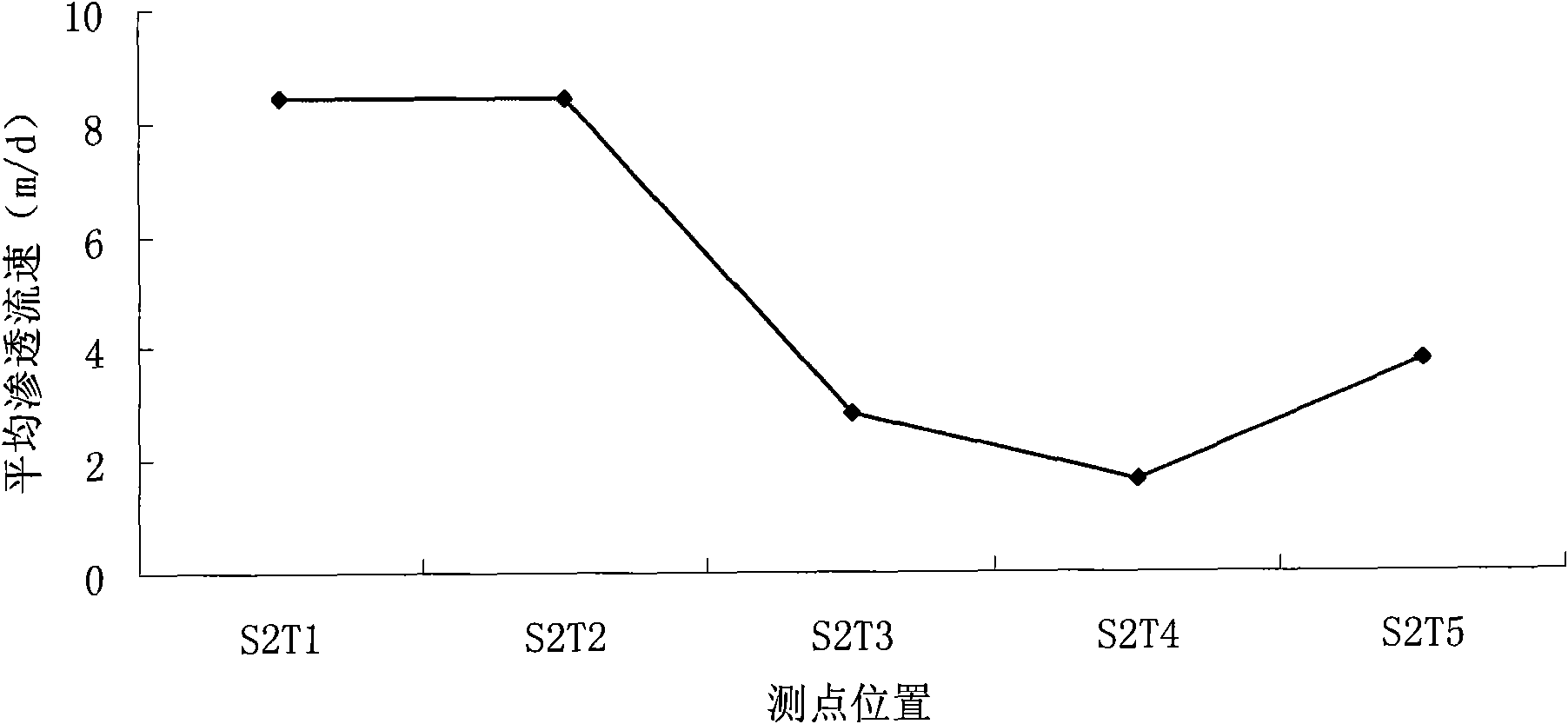

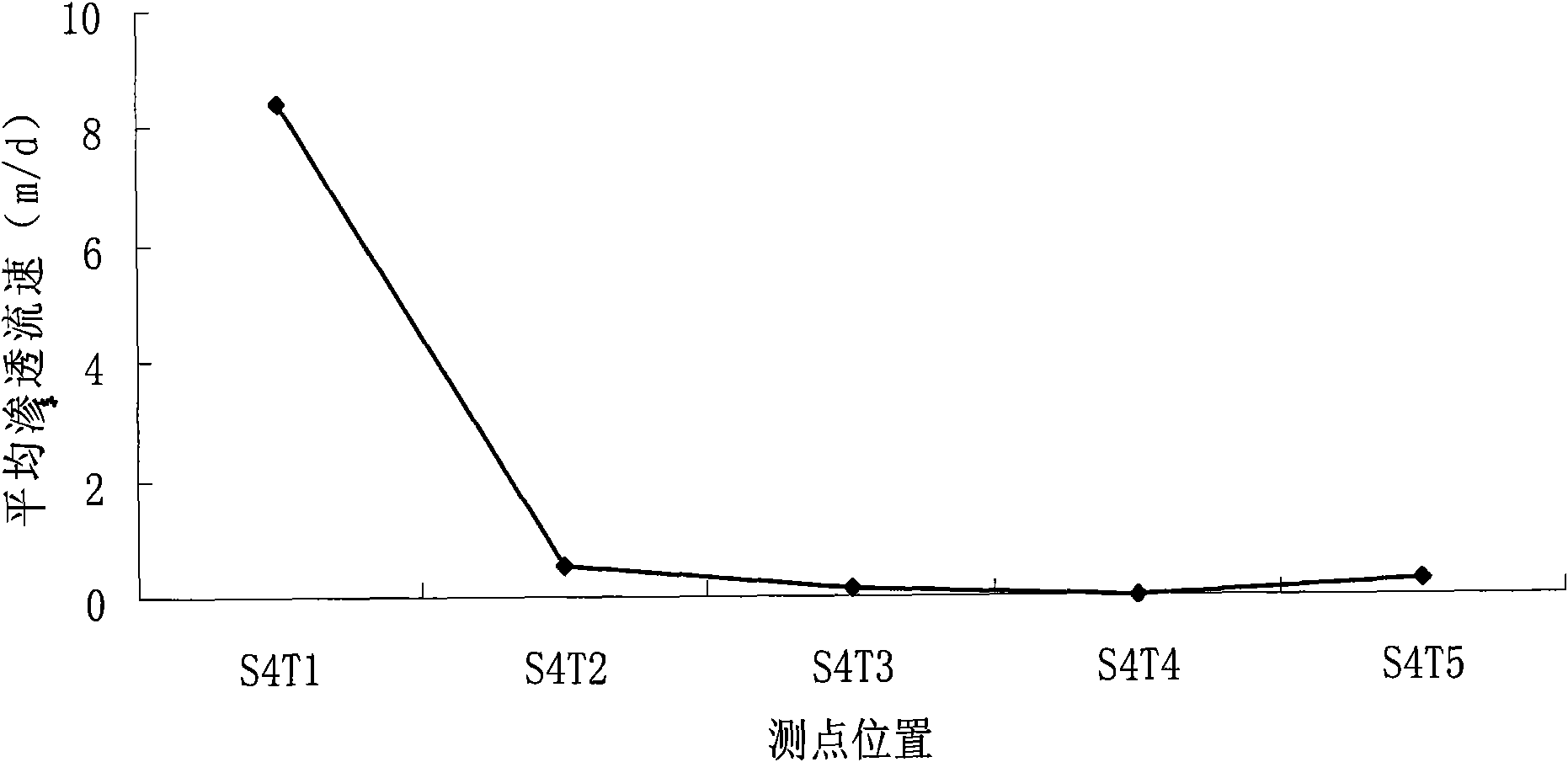

[0042] In 2007, field ore dissolution test (single-stage drive) was carried out in Bieletan mining area, Qinghai. The excavated water replenishment channel was 7km long, 2m wide, and 4m deep. The drainage channel was the brine mining channel of Qinghai Salt Lake Industry Group Co., Ltd. The area is about 0.8km2. A total of 4 longitudinal and 5 horizontal long observation hole monitoring sections were arranged in the test area, and a total of 42 monitoring holes of various types and 4 channel flow measurement sections were designed. During the 4-month driving test, 490 solid samples of various types were collected, 638 brine samples were collected, 1011 water levels were monitored, and 733 sample components were tested. The ore dissolution effect is manifested in the increase of the potassium ion content in the solvent by 18g / g. After calculation, a total of 58,000 tons of KCl was disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com