Single row crossed roller bearing harmonic speed reducer

A technology of crossed roller bearing and harmonic reducer, applied in aerospace field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

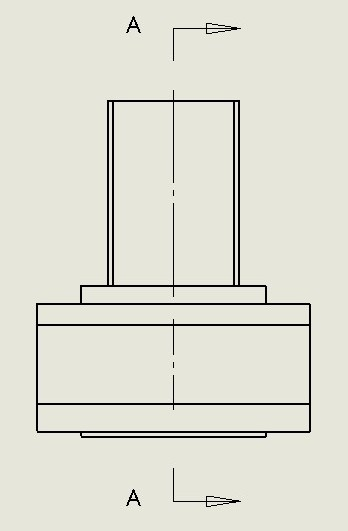

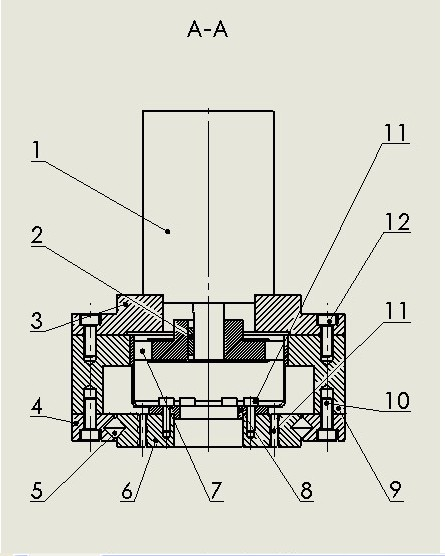

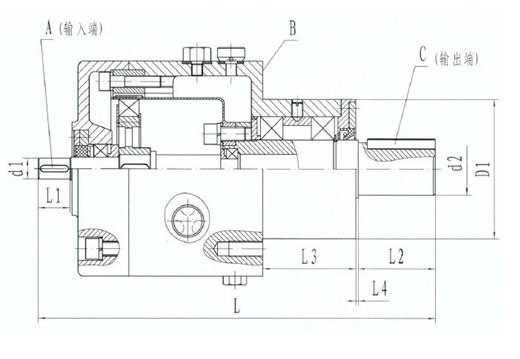

[0009] Specific implementation: The wave generator (7) is installed on the shaft of the motor (1), and the wave generator (7) is connected to the shaft of the motor (1) by a flat key (2), and the motor (1) is installed on the flange On (3), the flange (3) is connected to the rigid gear (9) through bolts (12), the rigid gear (9) is connected to the cross roller bearing outer ring (4) through bolts (10), and the flexible gear (8 ) is connected with the cross roller bearing inner ring (6) through bolts (11); the bearing roller (5) is installed between the cross roller bearing outer ring (4) and the cross roller bearing inner ring (6), and the flexible gear (8) Installed between the wave generator (7) and the rigid gear (9), the shaft of the motor (1) drives the wave generator (7) to rotate, and the flexible gear (8) meshes with the rigid gear (9). The tooth number difference between the flexible gear (8) and the rigid gear (9) is 2, resulting in a large reduction ratio; the flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com