Detection method of degree of damage of plasma

A technology of damage degree and plasma, which is applied in the direction of semiconductor/solid-state device testing/measurement, measuring devices, and measuring electrical variables. Testing procedure, effect of reducing testing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

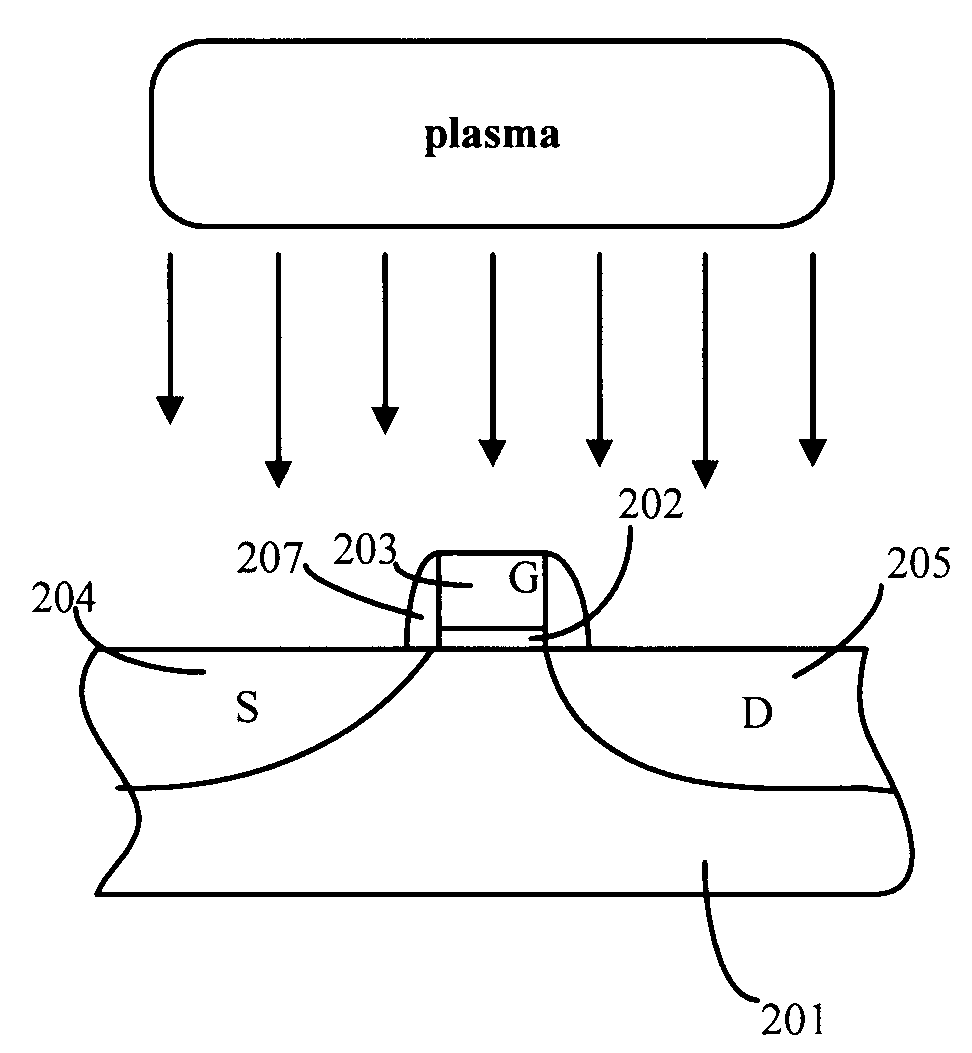

Problems solved by technology

Method used

Image

Examples

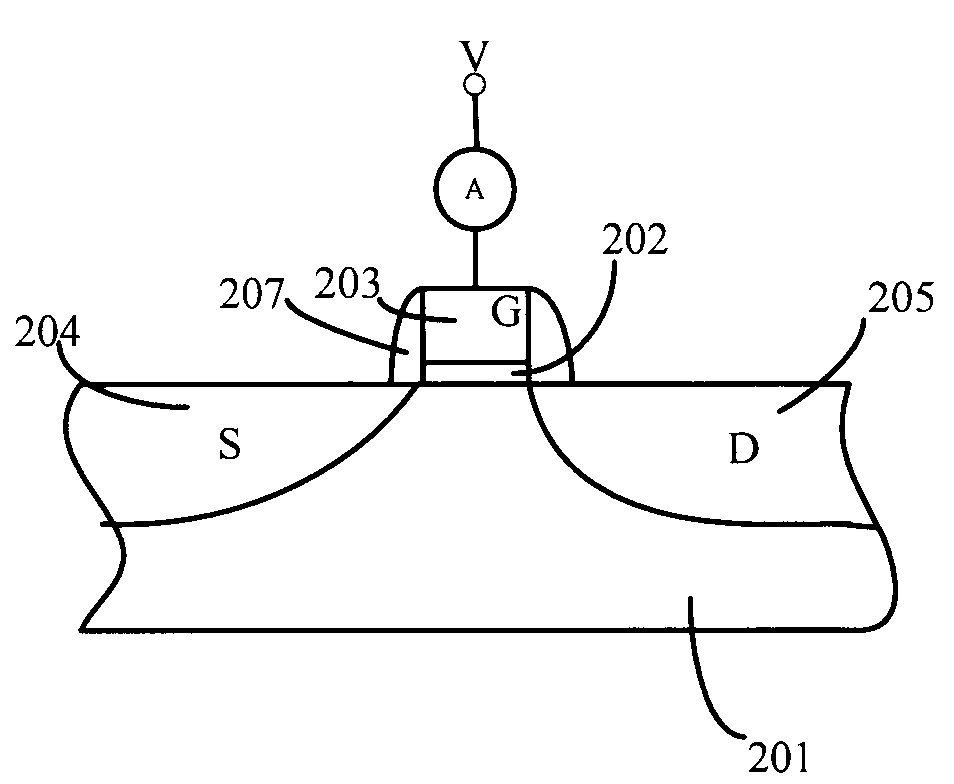

Embodiment Construction

[0040] The method of the present invention provides a detection method for the degree of plasma damage, and only a part of the chips are extracted for the threshold voltage drift test, which reduces the detection cost; the leakage current is used as the detection standard, which can quickly detect plasma damage and improve detection efficiency , can carry out online real-time detection; no need to apply forced voltage, and will not cause damage to the chip.

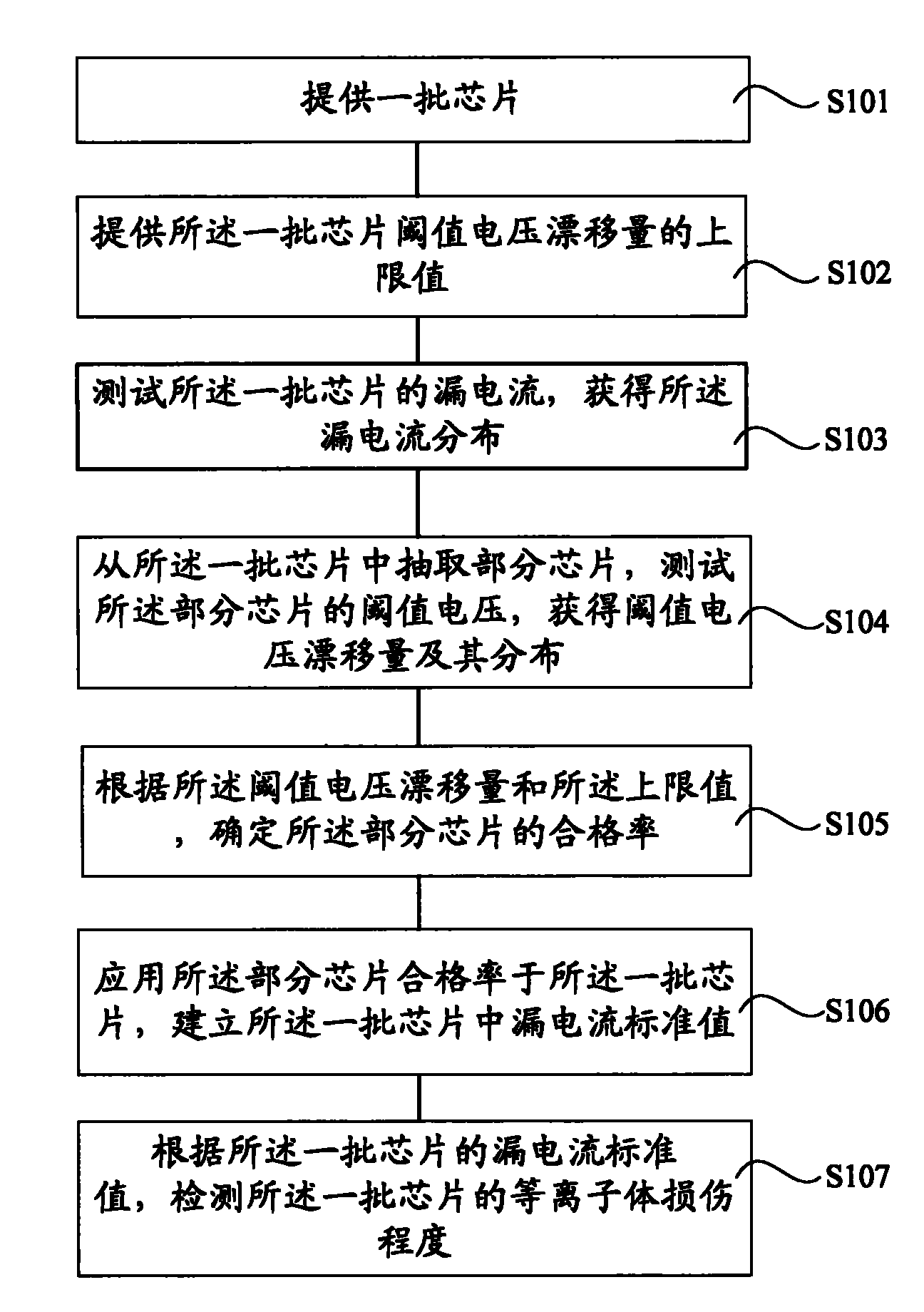

[0041] figure 2 It is a schematic flow chart of the method for detecting the degree of plasma damage of the present invention. Such as figure 2 shown, including:

[0042] Execute step S101 to provide a batch of chips;

[0043] Execute step S102, providing the upper limit value of threshold voltage drift of the batch of chips;

[0044] Execute step S103, test the leakage current of the batch of chips, and obtain the leakage current distribution;

[0045] Execute step S104, extract some chips from the batch of chips,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com