Energy forest harvesting platform

A harvesting table and energy technology, applied in forestry, application, agriculture and other directions, can solve the problems of difficult to guarantee material quality, high harvesting cost, high labor intensity, etc., to improve operation quality and efficiency, comprehensive economic benefits, and improve transportation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

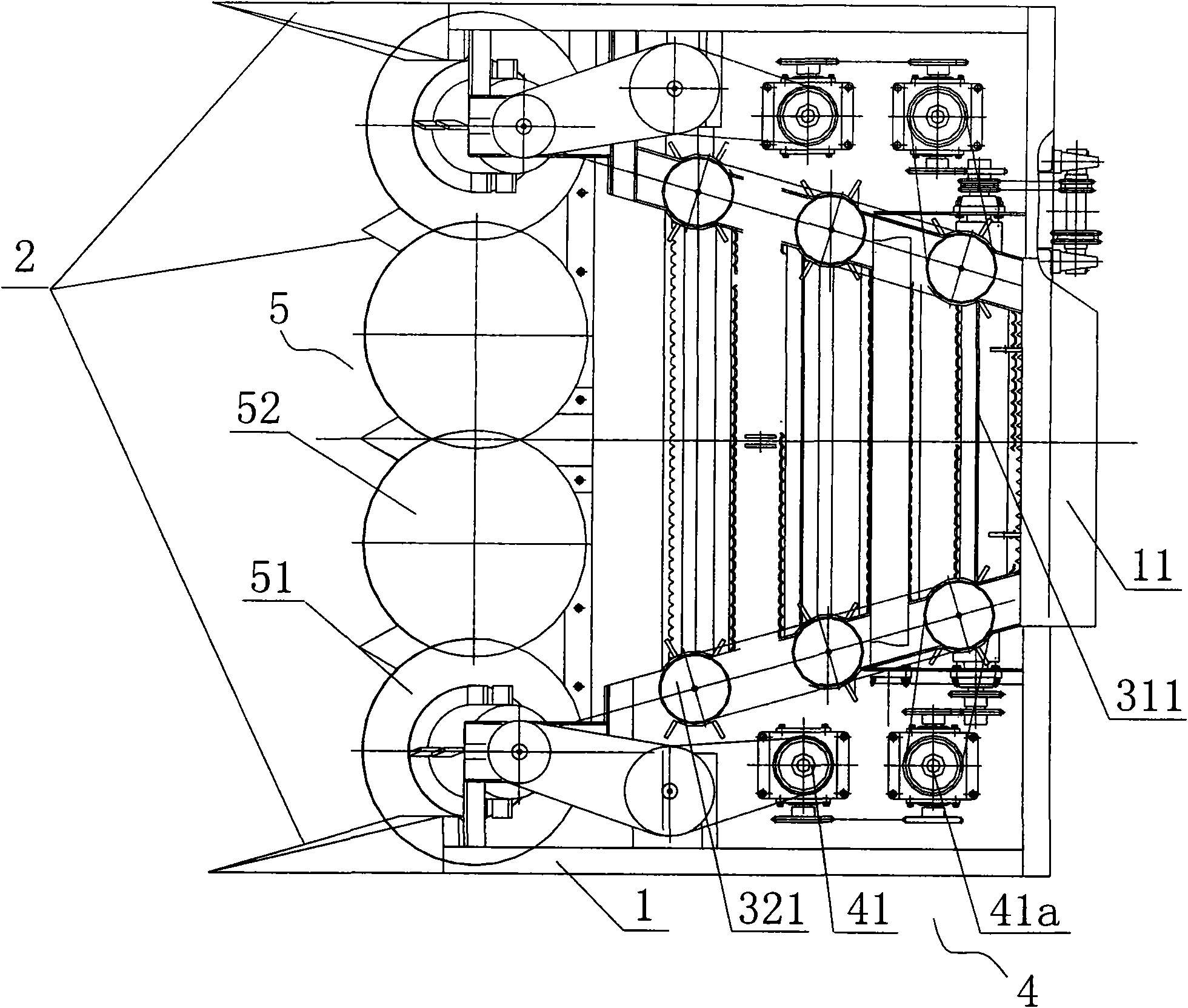

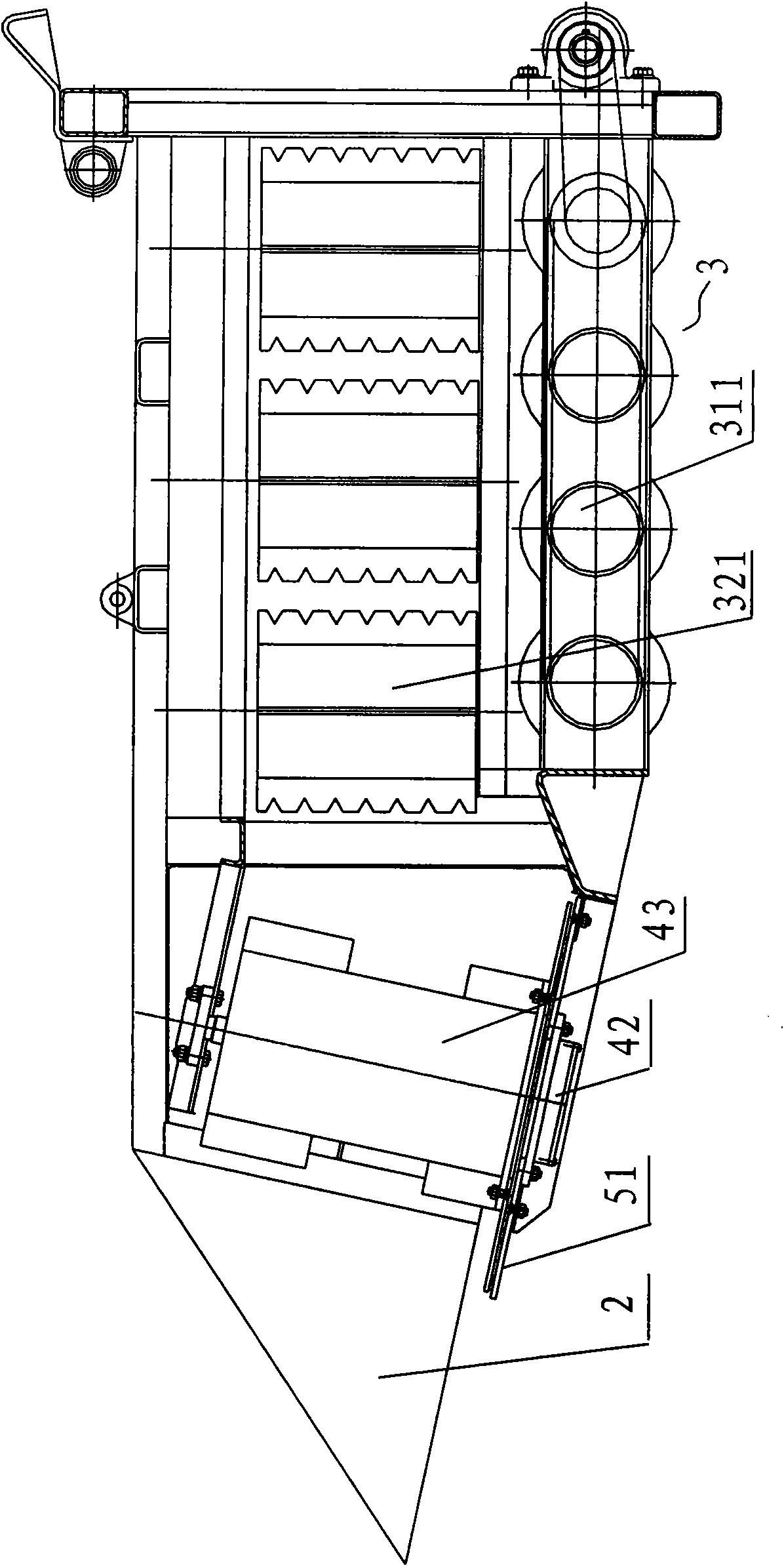

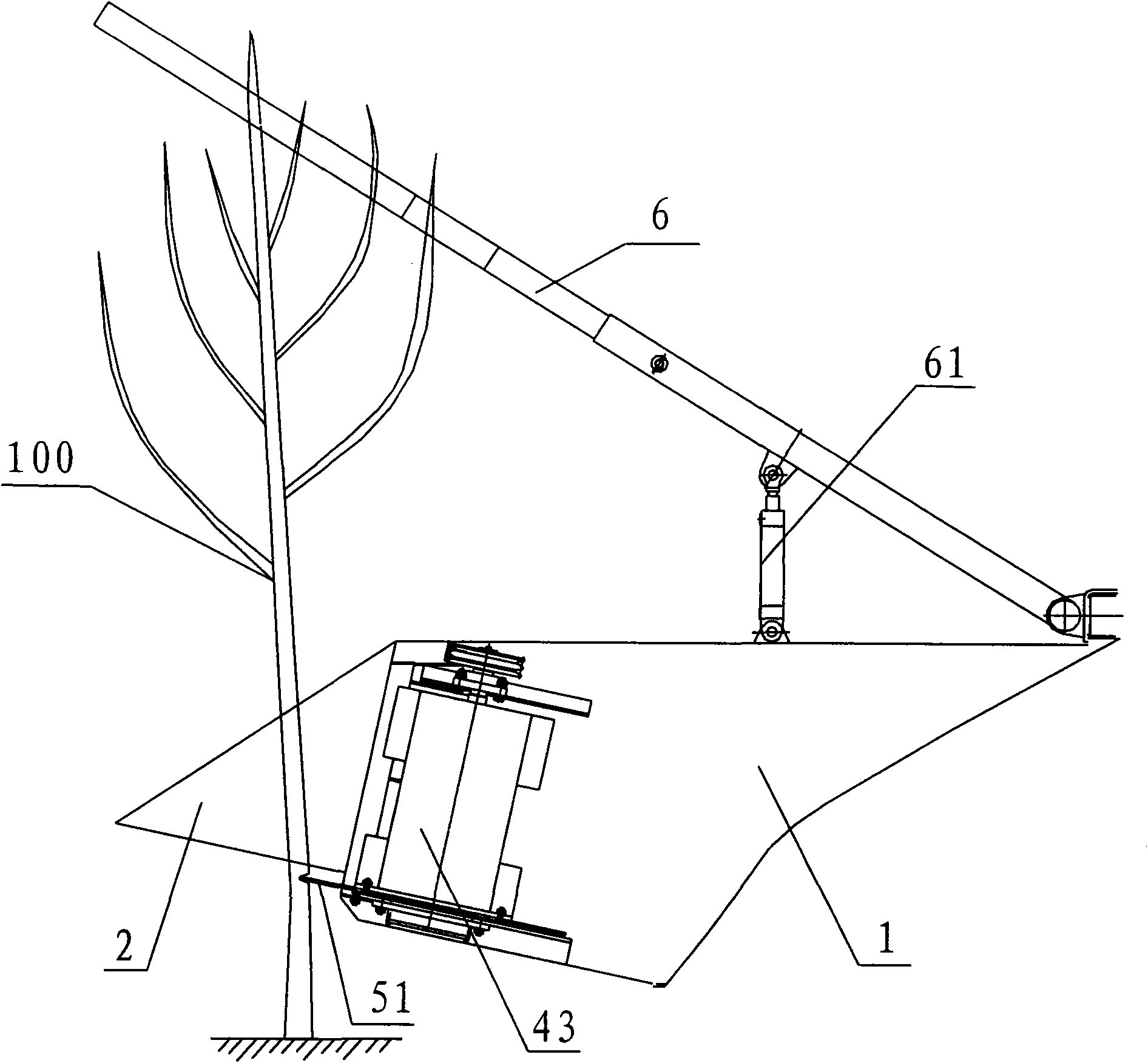

[0051] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0052]The invention relates to an energy forest harvesting platform, which is mainly used for harvesting energy forest (including shrub forest and fast-growing forest, etc.), and belongs to the technical field of forestry machinery. The energy forest harvesting platform of the present invention is installed on the energy forest harvesting machine, comprising: a harvesting platform 1; at least one grouping device 2, which is respectively arranged on the front end of the harvesting platform 1, and its function is to gather the plants ahead Divide to the corresponding cutter 5 to help cutting. The crop divider 2 in the present embodiment has three kinds of left, middle and right, which are respectively welded at the front, lower, left, middle and right places of the harvesting platform 1; 5. It is arranged at the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com