Method for cleaning combustion engine exhaust gases

A technology of internal combustion engine and exhaust gas, applied in the direction of internal combustion piston engine, separation method, combustion engine, etc., can solve the problem of increased pressure loss of filter exhaust gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

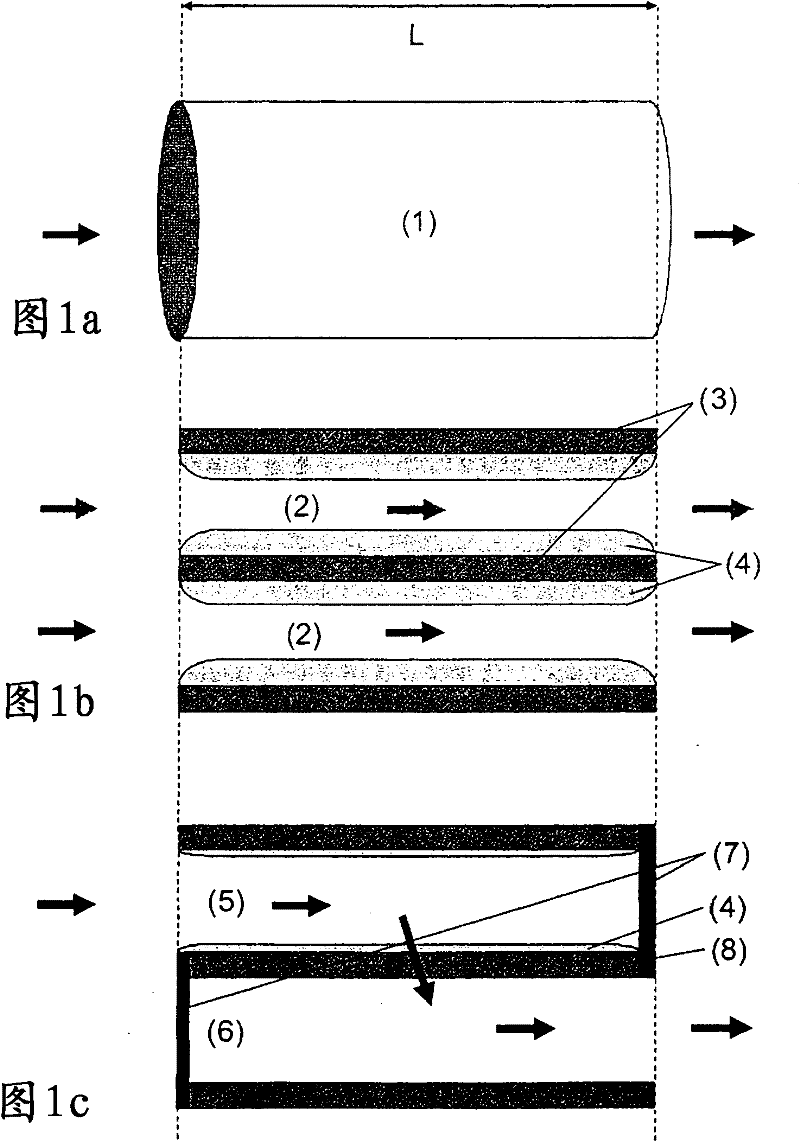

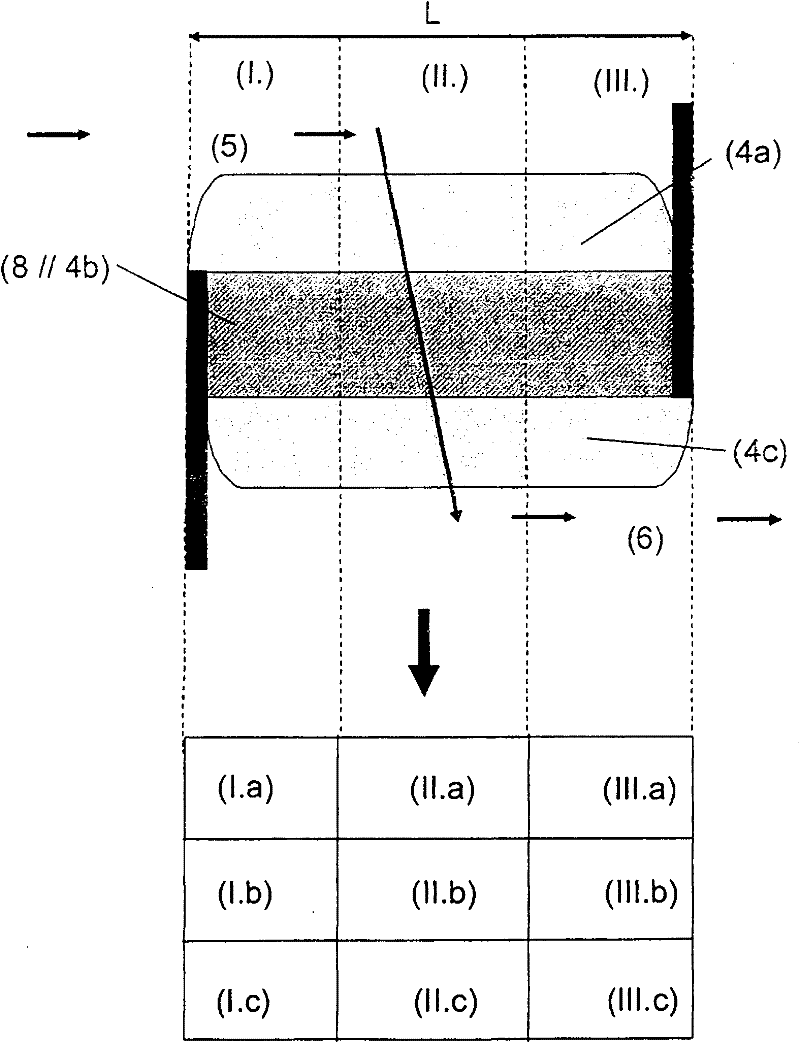

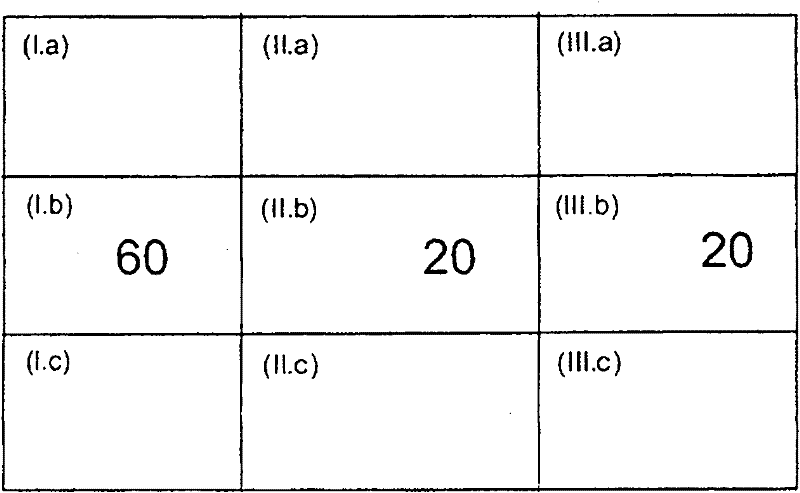

[0061] To produce the first filter PF1 according to the invention, first of all, 48 g / L of the above-mentioned paint suspension relative to the total volume of the wall-flow filter is introduced uniformly on the inflow side over the entire length of the wall-flow filter base body The wall between the inflow and outflow ducts. After drying and intermediate calcination, an additional 32 g / L (relative to the total length of the part) of paint suspension is introduced into the wall between the inflow and outflow ducts in the inflow side region, the length of which corresponds to the part 1 / 3 of the total length. This gets the corresponding image 3 A filter PF1 according to the invention comprising 80 g / L of the above-mentioned paint suspension.

example 2

[0063] In order to produce the additional filter PF2 according to the invention, first of all, 68.8 g / L of the above-mentioned paint suspension relative to the total volume of the wall-flow filter is uniformly introduced on the inflow side between the inflow and outflow ducts in the area of the inflow side The length of the inflow-side region corresponds to 2 / 3 of the total length of the wall-flow filter base body. After drying and intermediate calcination, an additional 11.2 g / L of coating suspension relative to the total volume of the wall-flow filter is applied as wall coating in the outflow conduit as an outflow-side region of a length of Corresponds to 1 / 3 of the total length of the part. This gets the corresponding Figure 8 A filter PF2 according to the invention comprising 80 g / L of the above-mentioned coating suspension.

[0064] The filters VPF, PF1 and PF2 produced as described were tested on an engine test bench with real exhaust gases of an engine operating wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com