Casting method of aluminum-magnesium alloy movable coil for vibrating table

A technology of aluminum-magnesium alloy and vibrating table, which is applied in the casting field of alloy workpieces, can solve problems such as no description or report found, no data collected, etc., and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

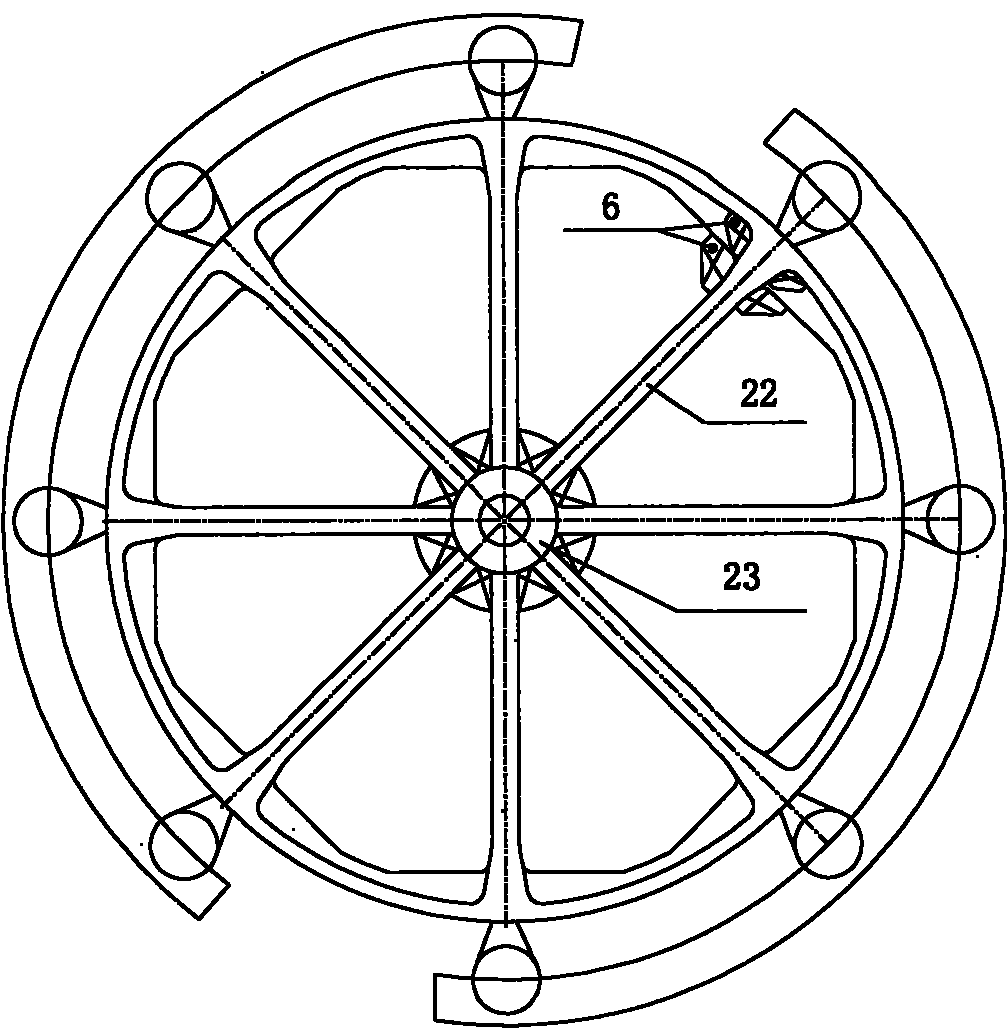

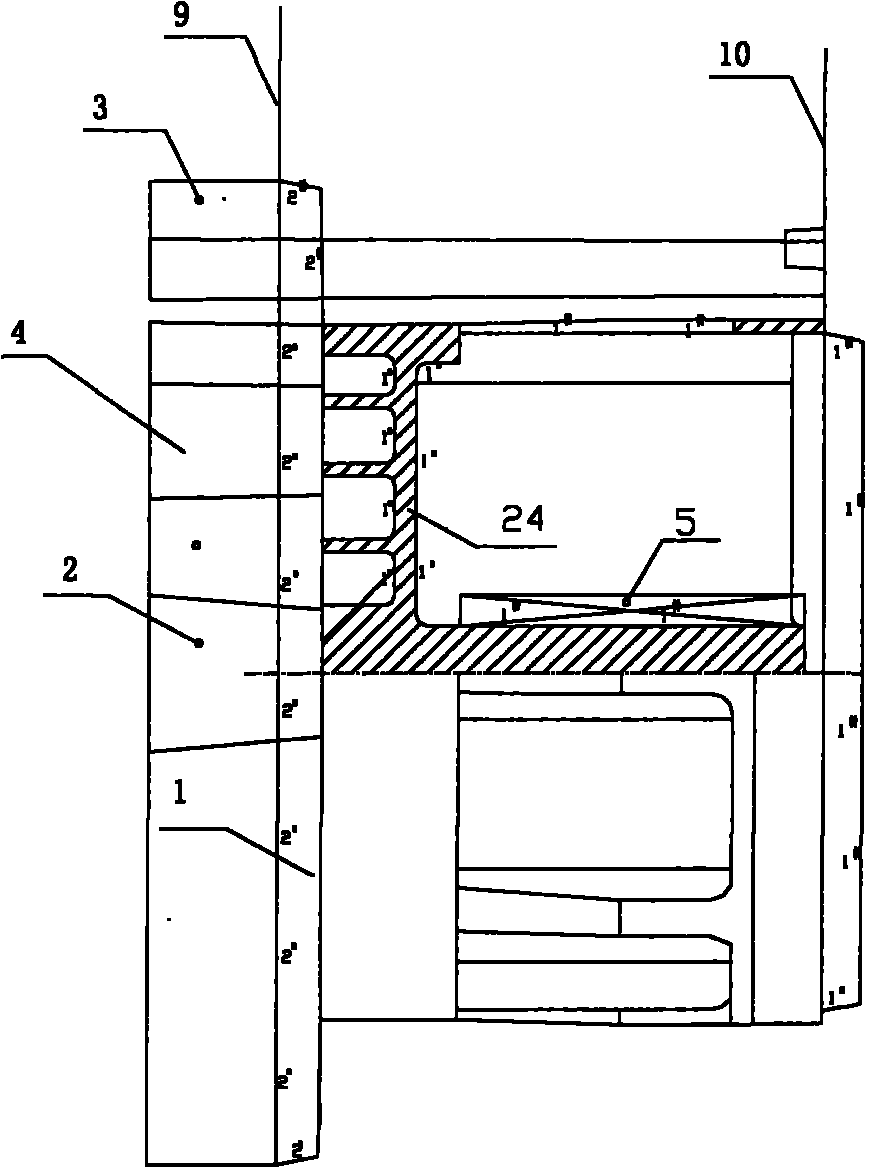

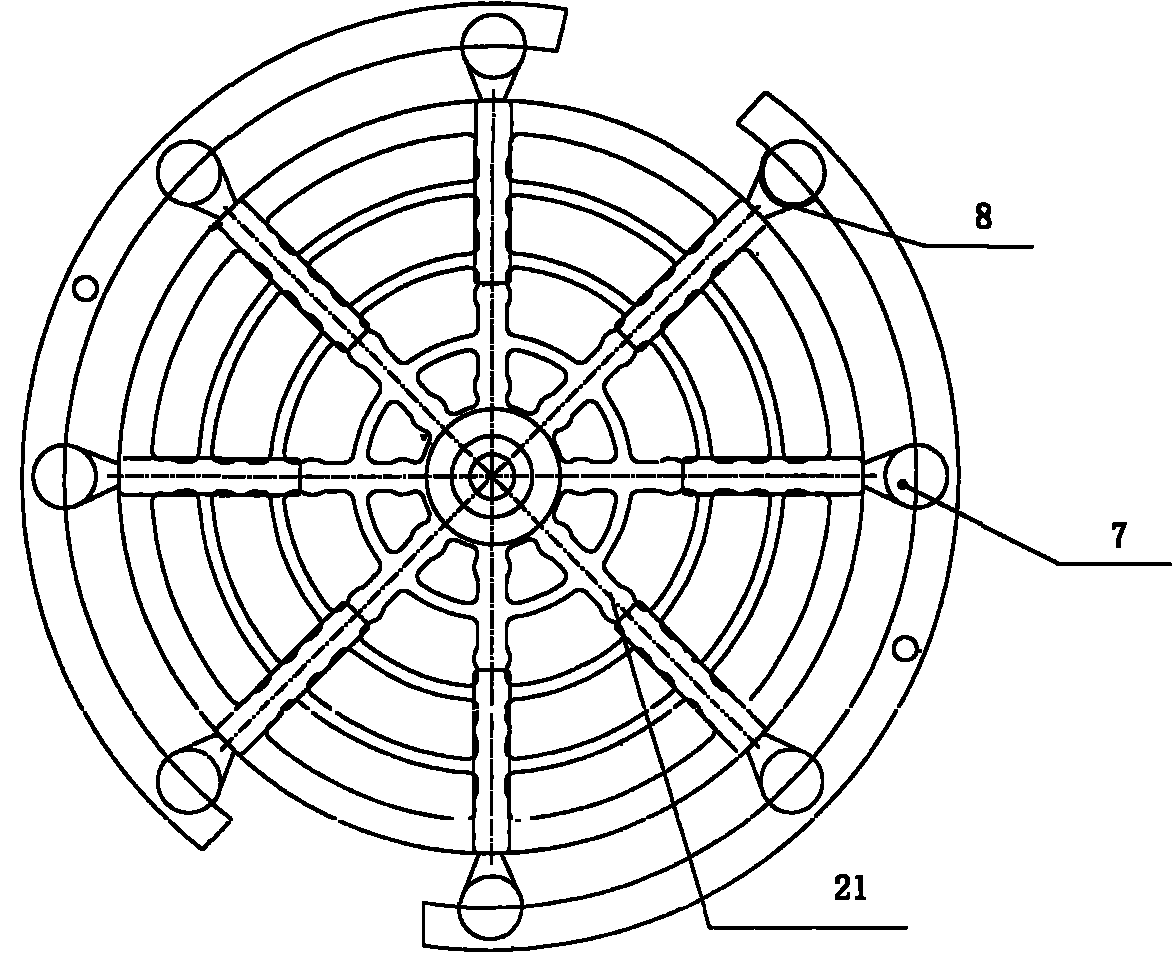

[0016] Figure 1 ~ Figure 3 It is a structural diagram and a process diagram of a vibrating table moving coil manufactured by the method of the present invention. figure 1 is the front view of the moving coil of the vibrating table; figure 2 is the top view of the moving coil of the vibrating table; image 3 It is the bottom view of the moving coil of the vibrating table.

[0017] As shown in the above drawings, the outline size of the largest aluminum-magnesium alloy moving coil skeleton to be cast by the method of the present invention is: ¢850×610 (mm), and its central position has 8 reinforcing ribs uniformly radiating to the surroundings. It is two parts up and down, with a partition 24 between the two parts of the ribs, and the width of the upper rib 21 is 32mm (see figure 2 ), the width of the lower rib 22 is 28mm (see image 3 ); There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com