Cushion pad for transfer transport of solar cell

A technology of solar cells and cushioning pads, which is applied in the directions of transportation and packaging, types of packaging items, special packaging items, etc., and can solve the problems of silicon chip fragmentation, easy damage, and high brittleness of crystalline silicon chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

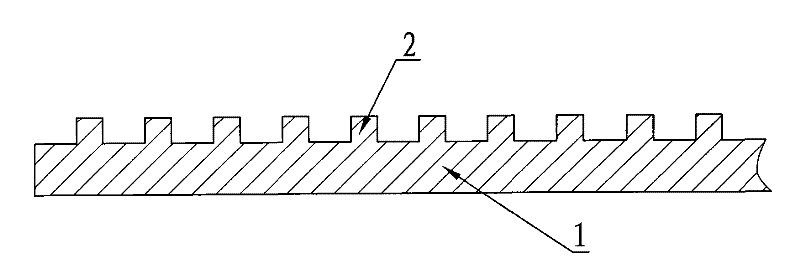

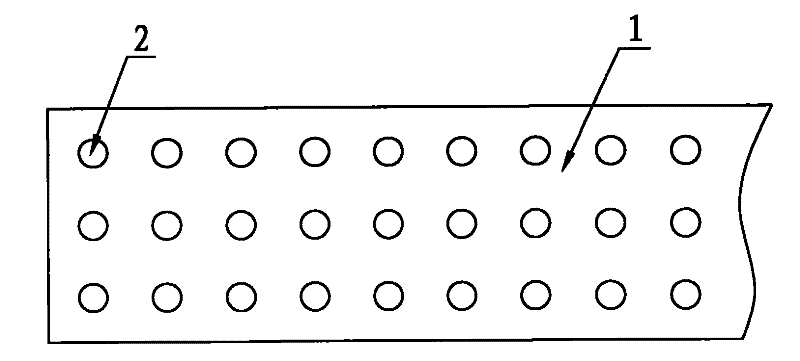

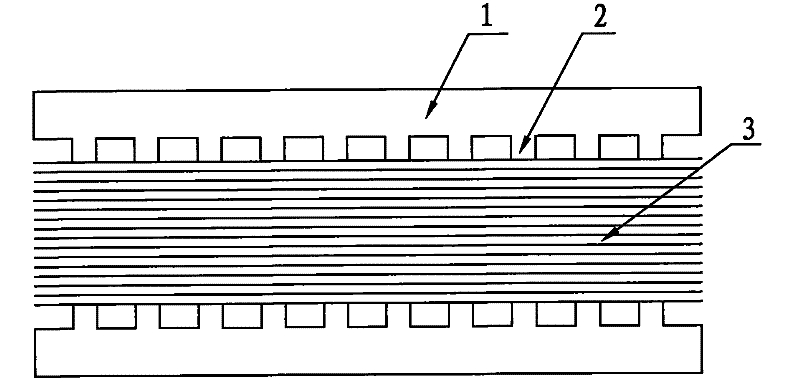

[0013] Embodiment 1: The solar battery sheet transit transportation cushion, such as figure 1 , figure 2 As shown, it includes an elastic substrate 1 and an elastic convex body 2 arranged on the surface of the elastic substrate 1 in contact with the silicon chip 3. The thickness of the elastic substrate 1 is 1.0 mm, and the height of the elastic convex body 2 is 0.5 mm. The diameter of the convex body 2 is 0.5 mm, and the distribution density of the elastic convex body 2 is 150 per square centimeter. The shape and size of the elastic substrate 1 are the same as those of the solar cells. Silicone Rubber.

Embodiment 2

[0014] Embodiment 2: The solar battery sheet transit transportation cushion, such as figure 1 , figure 2 As shown, it is made up of elastic substrate 1 and the elastic convex body 2 that is arranged on the surface of elastic substrate 1 and contacts with silicon chip 3, the thickness of elastic substrate 1 is 5.0 millimeters, and the height of elastic convex body 2 is 1.0 millimeter, The diameter of the elastic convex body 2 is 0.8 mm, and the distribution density of the elastic convex body 2 is 100 per square centimeter. The shape and size of the elastic substrate 1 are the same as those of the solar cells. For silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com