Arch-breaking sliding rack system of feed bin

A carriage and silo technology, which is applied in the field of flat-bottomed round or flat-bottomed square bins, can solve the problems of high energy consumption, high driving power, and large wear of the carriage coupling, and achieve low energy consumption and low wear rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

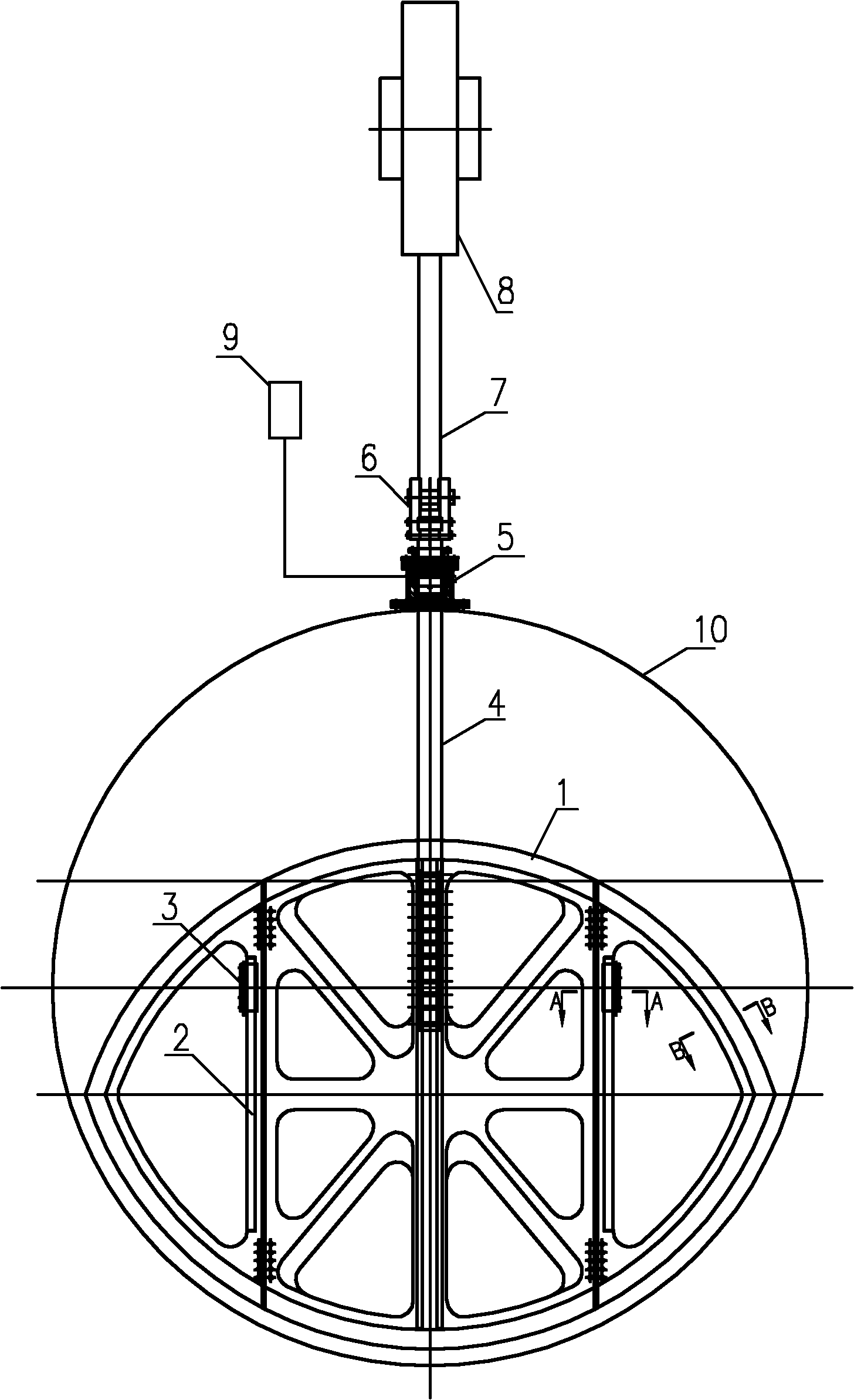

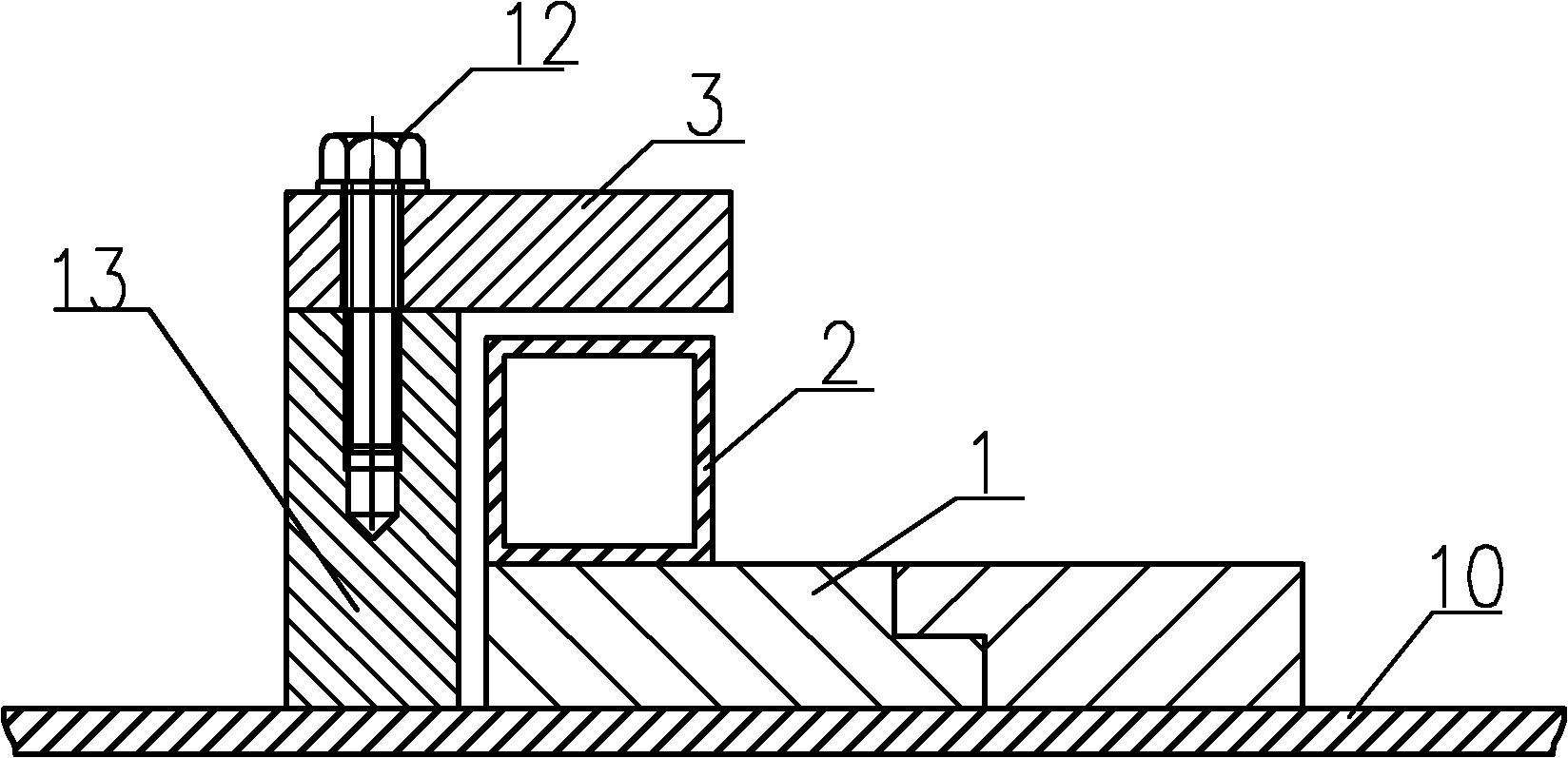

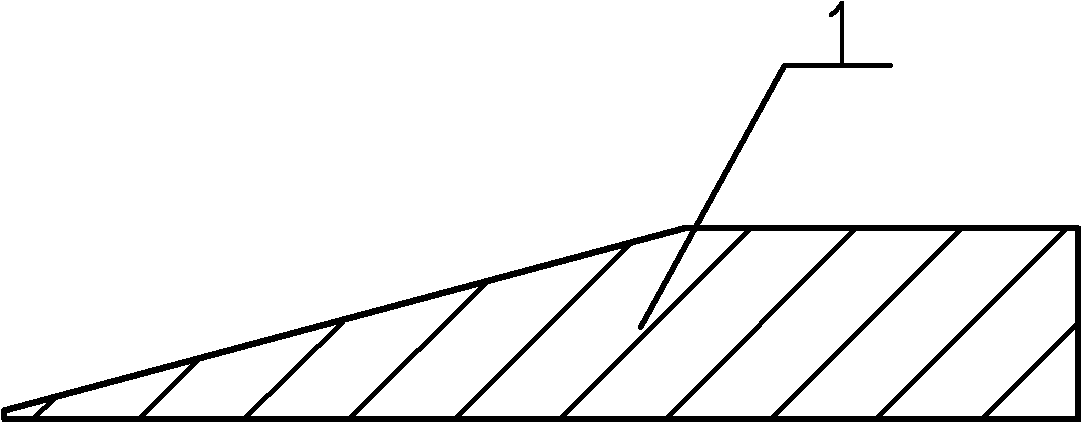

[0018] Such as figure 1 As shown, the silo arch breaking carriage system of the present invention includes a carriage frame body 1 , a carriage push rod 4 , a coupling 6 , a piston rod 7 , a hydraulic cylinder 8 , a carriage guide rail 2 and a guide rail positioning block 3 . The section of the carriage frame body 1 is a wedge-shaped section, such as image 3 As shown, the carriage frame body 1 and the carriage push rod 4 are arranged in the bin body 10, the piston rod 7 and the hydraulic cylinder 8 are arranged outside the bin body 10, and the carriage frame body 1 and the carriage push rod 4 Bolts are used for connection and fixation, the carriage push rod 4 is connected with the piston rod 7 through a coupling 6, and the piston rod 7 is connected with the hydraulic cylinder 8. A steel plate 13 is welded on the bottom of the silo body 10, and the guide rail positioning block 3 is fixed on the steel plate 13 by bolts 12. A limit track is formed between the guide rail positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com