Optical glass

An optical glass, glass technology, applied in optics, optical components, glass molding, etc., can solve problems such as polluting the environment, reducing chemical stability, and reducing surface precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Table 1 contains examples of embodiments within preferred compositional ranges. The glasses described in the examples were prepared as indicated below:

[0048] The raw materials we use are oxides, hydroxides, carbonates, nitrates, etc.

[0049] After weighing and mixing, the mixture was placed in a platinum crucible. It is melted in an electric furnace at 1000-1300°C and stirred in time, then cast into a metal mold preheated to an appropriate temperature, and then slowly cooled and manufactured.

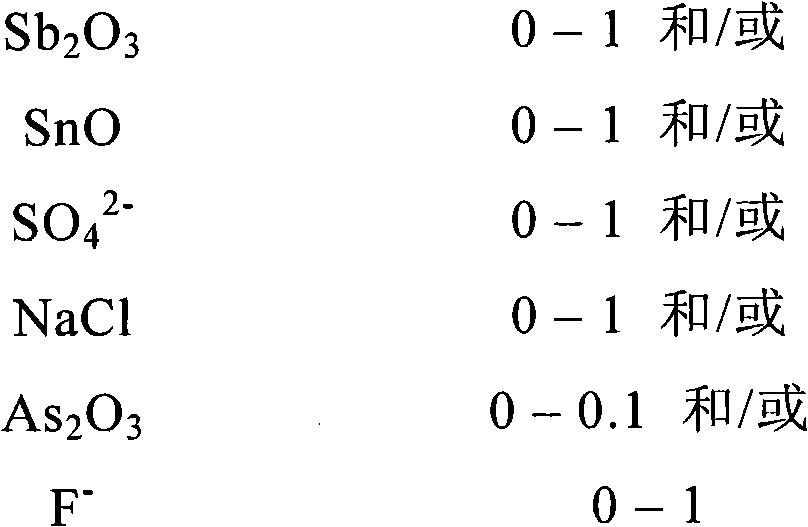

[0050] The compositions (wt% based on oxide weight), refractive indices, Abbe numbers and transition temperatures of Examples 1-5 are shown in Table 1.

[0051] Table 1 (composition, wt% based on oxide)

[0052]

[0053] Yb 2 o 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com