Dolomite magnesium cement concrete and preparation method thereof

A manufacturing method and a technology of magnesium cement, applied in the field of chemical construction, can solve the problems of high cost, difficult to popularize and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

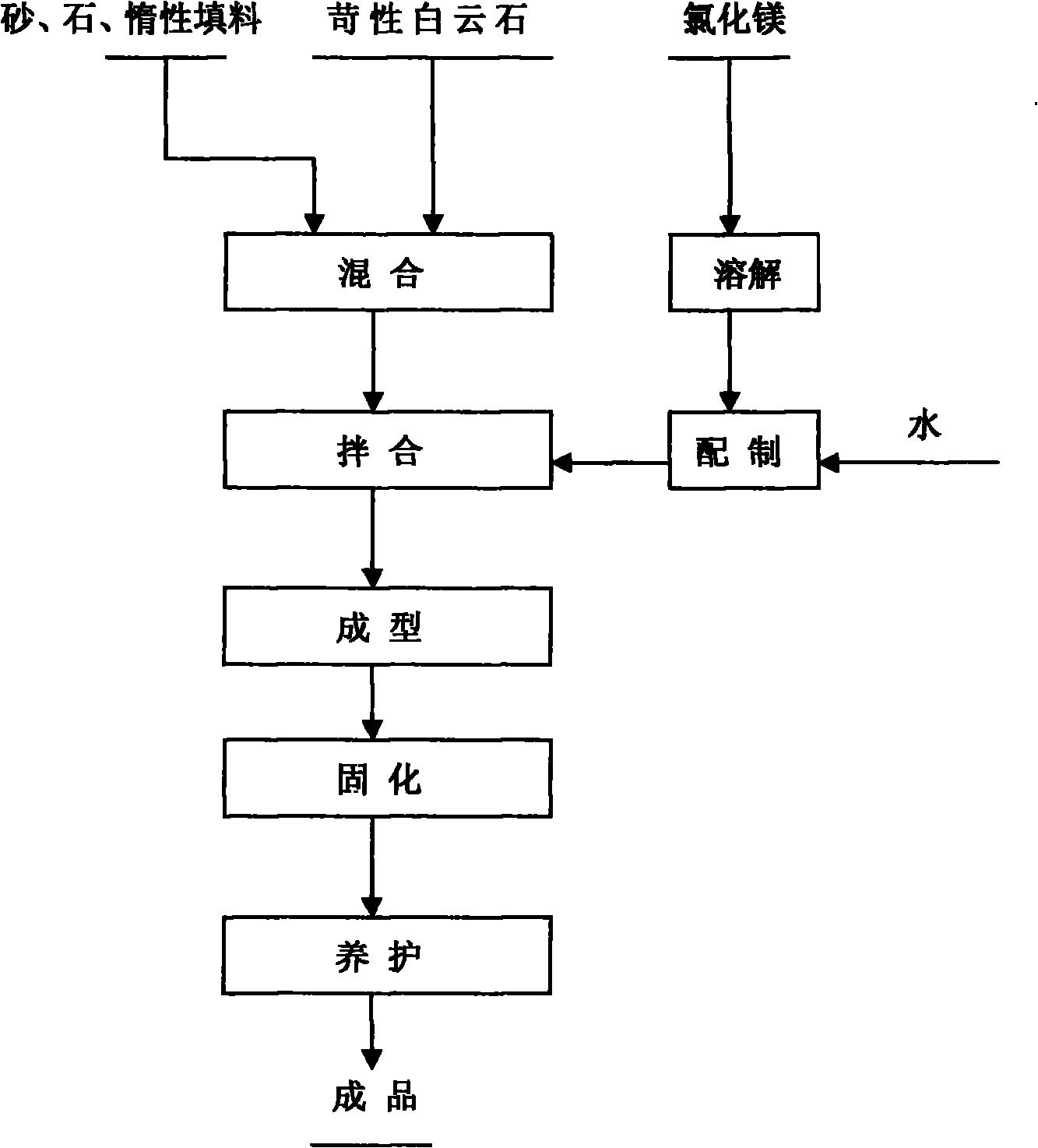

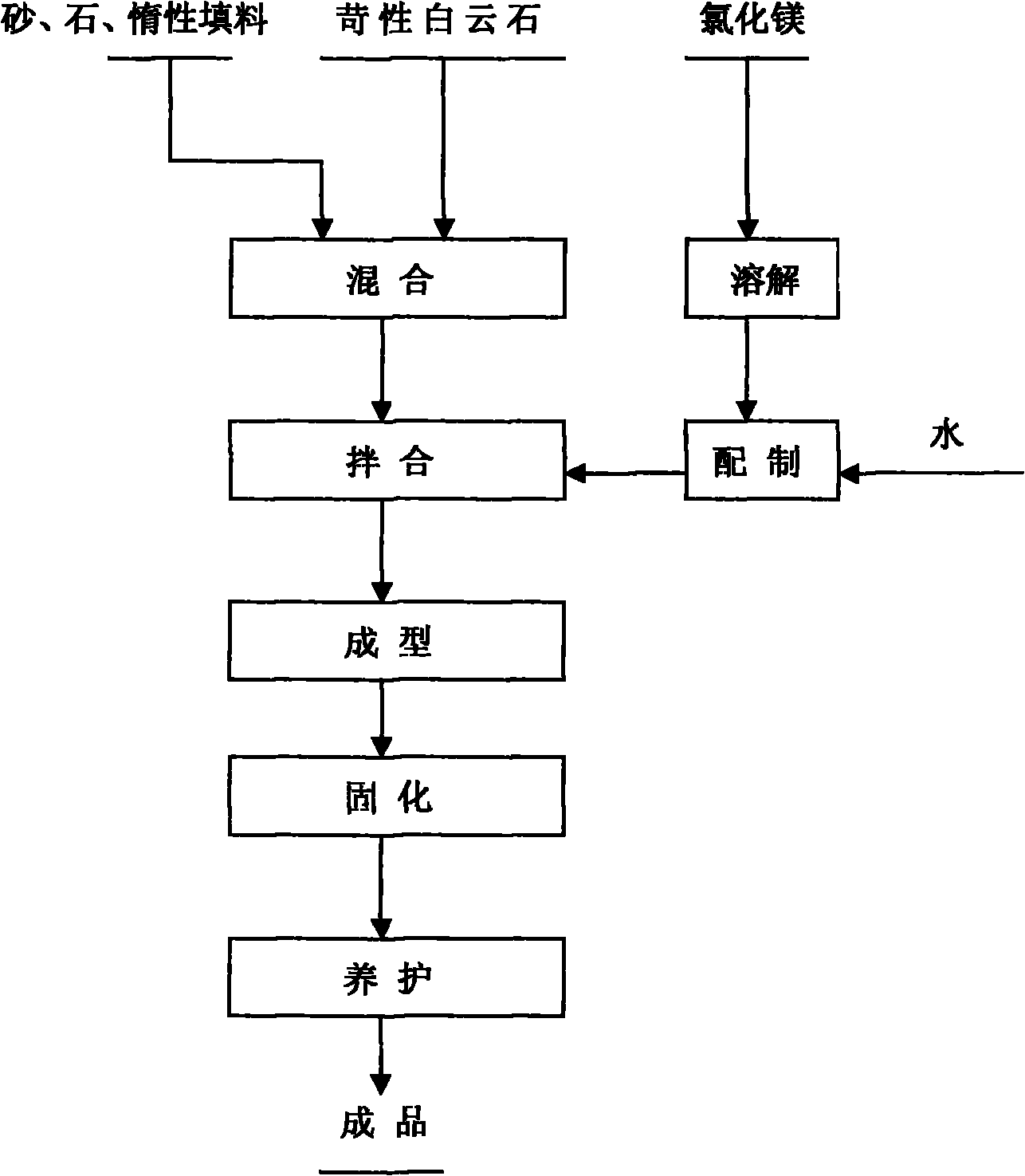

Method used

Image

Examples

Embodiment 1

[0005] Embodiment 1: a kind of dolomite magnesium cement concrete manufacture method, get caustic dolomite powder 10.0kg, sand 30kg, fly ash 1.0kg, 1.2kg magnesium chloride is mixed with solution with 4.4kg water, solution and material in mixer Stir evenly, inject the slurry into the formwork or the standard mold and form it under ambient temperature conditions, after demoulding, maintain it at ambient temperature and air relative humidity less than 80% for 28 days to become mortar concrete, and measure its mechanical properties .

[0006] Its main technical indicators are as follows:

[0007] Density grade: 1800kg / m 3 Compressive strength: 41.5MPa Axial compressive strength: 27.1MPa

[0008] Axial tensile strength: 2.42MPa Static compressive modulus of elasticity: 3.12×10 4 MPa

[0009] Splitting tensile strength: 5.92MPa Flexural strength: 8.4MPa

Embodiment 2

[0010] Embodiment 2: a kind of manufacturing method of dolomite magnesium cement concrete, get caustic dolomite powder 10.0kg, sand 1kg, talcum powder 3.0kg, with 6.1kg water 1.9kg magnesium chloride is mixed with solution, solution and material are stirred in mixer Uniform, made into slurry, poured into templates or standard molds and molded under ambient temperature conditions, after demoulding, cured for 28 days under the conditions of ambient temperature and air relative humidity less than 80%, and became mortar concrete, and its mechanical properties were measured.

[0011] Its main technical indicators are as follows:

[0012] Density grade: 1700kg / m 3 Compressive strength: 63.8MPa Axial compressive strength: 28.8MPa Flexural strength: 15.6MPa Axial tensile strength: 2.42MPa Static compressive modulus of elasticity: 3.18×10 4 MPa splitting tensile strength: 9.1MPa

Embodiment 3

[0013] Embodiment 3: a kind of manufacture method of dolomite magnesium cement concrete, get caustic dolomite powder 10.0kg, sand 20kg, stone 60.0kg, fly ash 20kg, 2.4kg magnesium chloride is mixed with solution with 7.6kg water, solution and material are mixed Stir evenly in the feeder, inject the slurry into the standard mold and form it under the condition of ambient temperature. After demoulding, it will be cured for 28 days under the condition of ambient temperature and air relative humidity less than 80%, and it will become sandstone concrete. Measure its mechanical properties performance.

[0014] Its main technical indicators are as follows:

[0015] Density level: 2435kg / m 3 Compressive strength: 41.5MPa Axial compressive strength: 28.5MPa

[0016] Axial tensile strength: 2.45MPa Static compressive modulus of elasticity: 3.31×10 4 MPa

[0017] Splitting tensile strength: 5.9MPa Flexural strength: 8.4MPa

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com