Method for enhancing mass transfer through suspension bed hydrogenation technology

A suspended bed technology, applied in hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of low mass transfer efficiency and inability to obtain a large number of microbubbles, so as to improve mass transfer efficiency, reduce daily operating costs, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

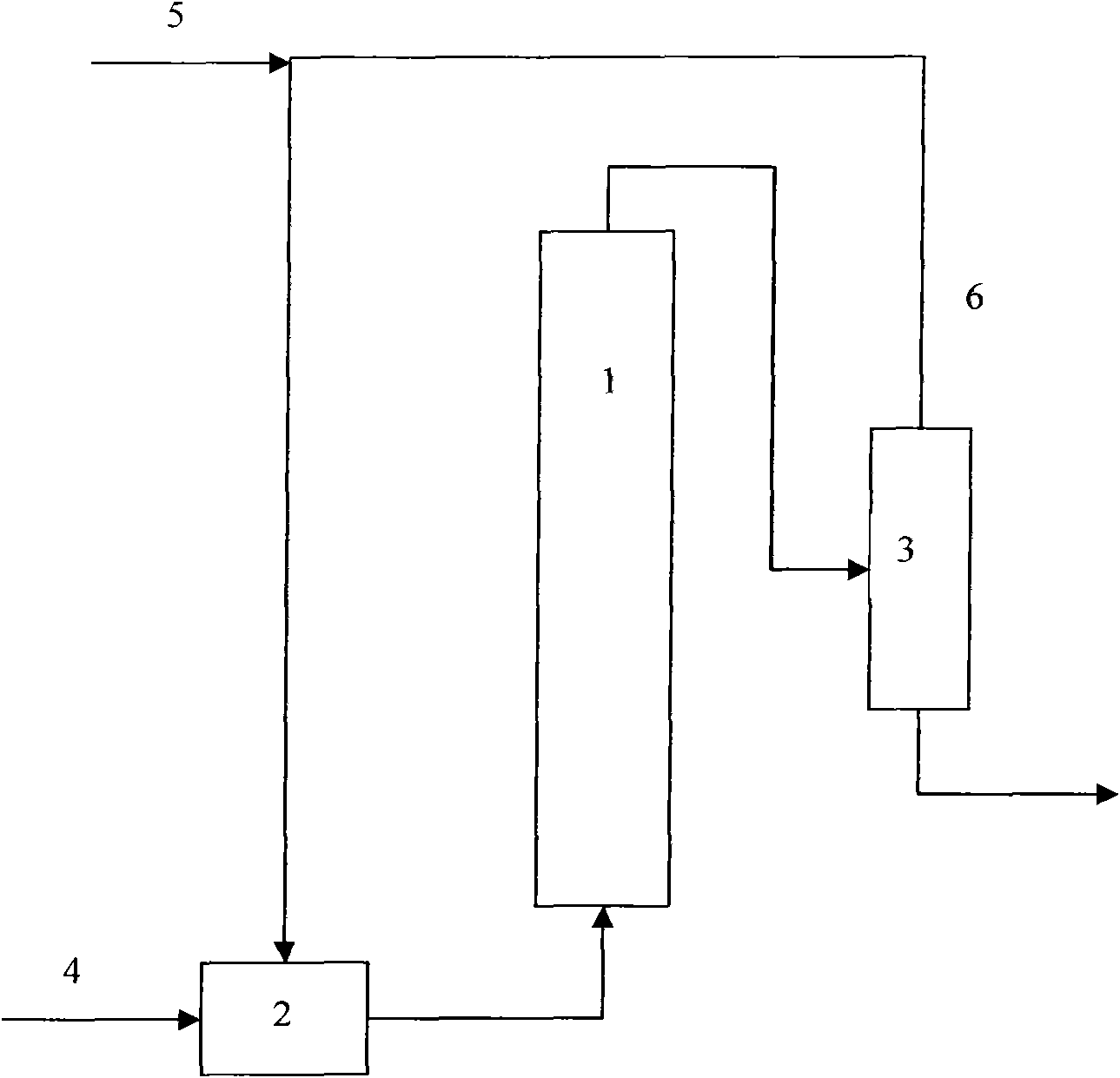

[0025] This example is an implementation of residual oil hydrotreating, and the schematic diagram of the operation process refers to the figure 1 .

[0026] The raw material oil 4, fresh hydrogen gas 5, and circulating hydrogen gas 6 that are added to the suspended bed catalyst enter the microbubble generator 2 for enhanced contact. The hydrogen gas in the raw material oil is fully dissolved, and the undissolved hydrogen gas produces a large number of microbubbles with a diameter less than 0.5mm. The proportion of microbubbles is About 80%. The hydrogen-oil mixture enters the suspended bed reactor 1, and the effluent from the reactor enters the high-pressure separator, the separated hydrogen is recycled, and the separated liquid enters the low-pressure separator and fractionation system in turn to obtain light oil products.

[0027] The microbubble generator is a porous venturi bubble generator.

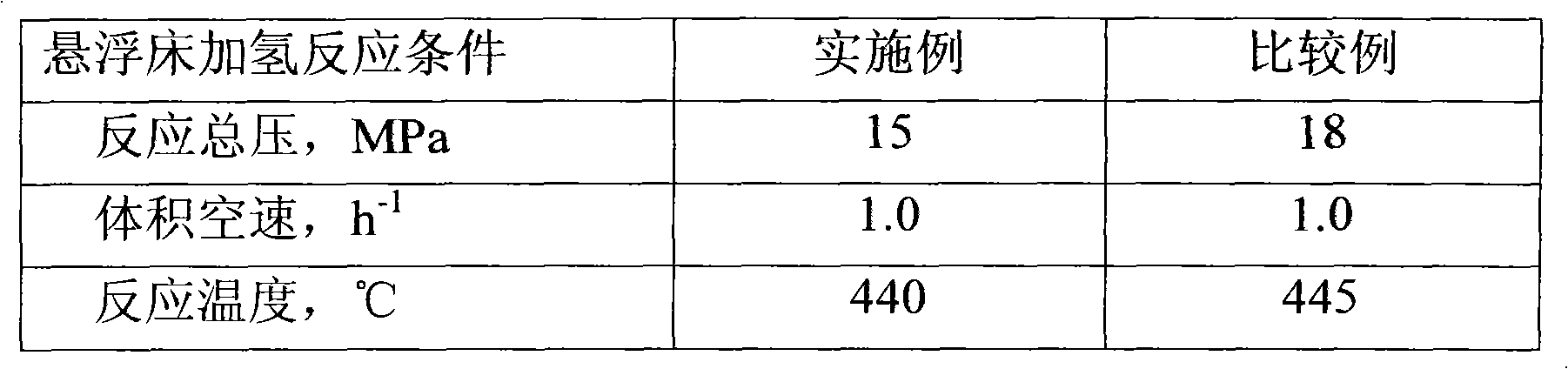

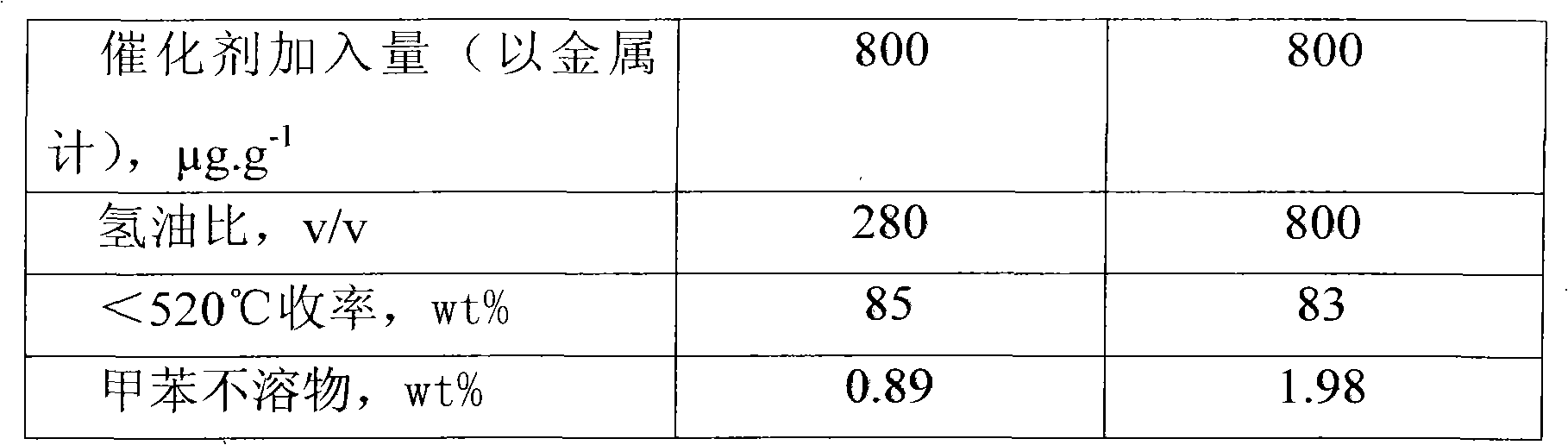

[0028] The catalyst used in the suspension bed hydrogenation test is a water-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com