Drop test bed with speed controllable rotation driving mechanism

A technology of a test bench and a test bench, which is applied in the field of a type of test device, can solve the problems that the accuracy of the tire contact speed is difficult to guarantee, and achieve the effects of avoiding the loss of the wheel speed, occupying a small space, and having a compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

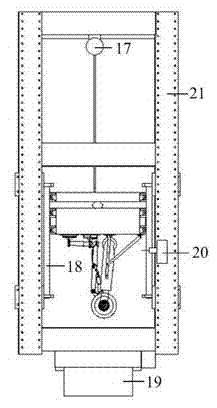

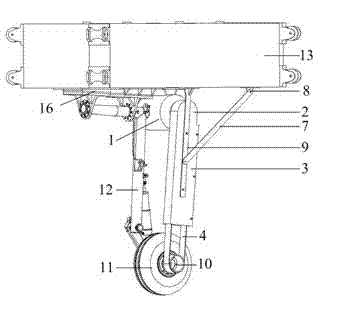

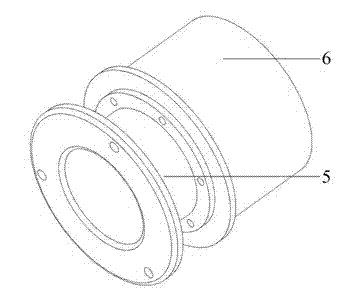

[0014] The invention relates to a drop shock test bench with a speed-controllable belt-rotating mechanism, which comprises a test bench, a hanging basket and a landing gear. The motor 1 is installed on the bottom plate of the hanging basket 13 through bolts, and the wheel pulley 10 is installed on the landing gear wheel 11. The wheel pulley 10 is composed of a pulley 5 and a connecting hub 6, and the connecting hub 5 passes through the wheel hub bolts 14 Fixed, for the convenience of installation, install the connecting hub 5 first, and then install the pulley 6 on the connecting hub 5. Make sure that the axes of the motor pulley 2 and the pulley 6 are parallel. The belt 4 is an ordinary flat belt. In order to prevent the belt 4 from being loose Wounding people, belt box 3 is installed on belt periphery, and belt box 3 is fixed on hanging basket 13 base plates by support 9. During the test, the electric motor pulley 2 rotates, and the belt 4 drives the machine wheel 11 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com