Testing device and method for defocused spot and color bias of optical system

An optical system and testing device technology, applied in the direction of testing optical performance, etc., can solve the problems of time-consuming and laborious adjustment process, large aiming error, low testing efficiency, etc., and achieve the effect of improving measurement accuracy, convenient real-time adjustment, and excellent imaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

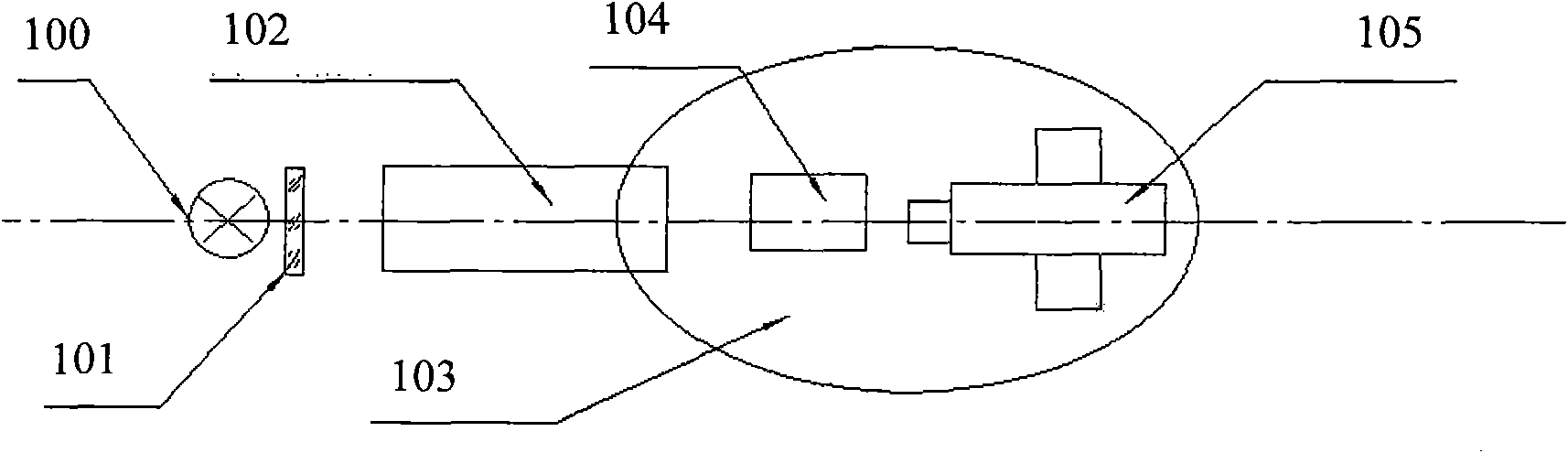

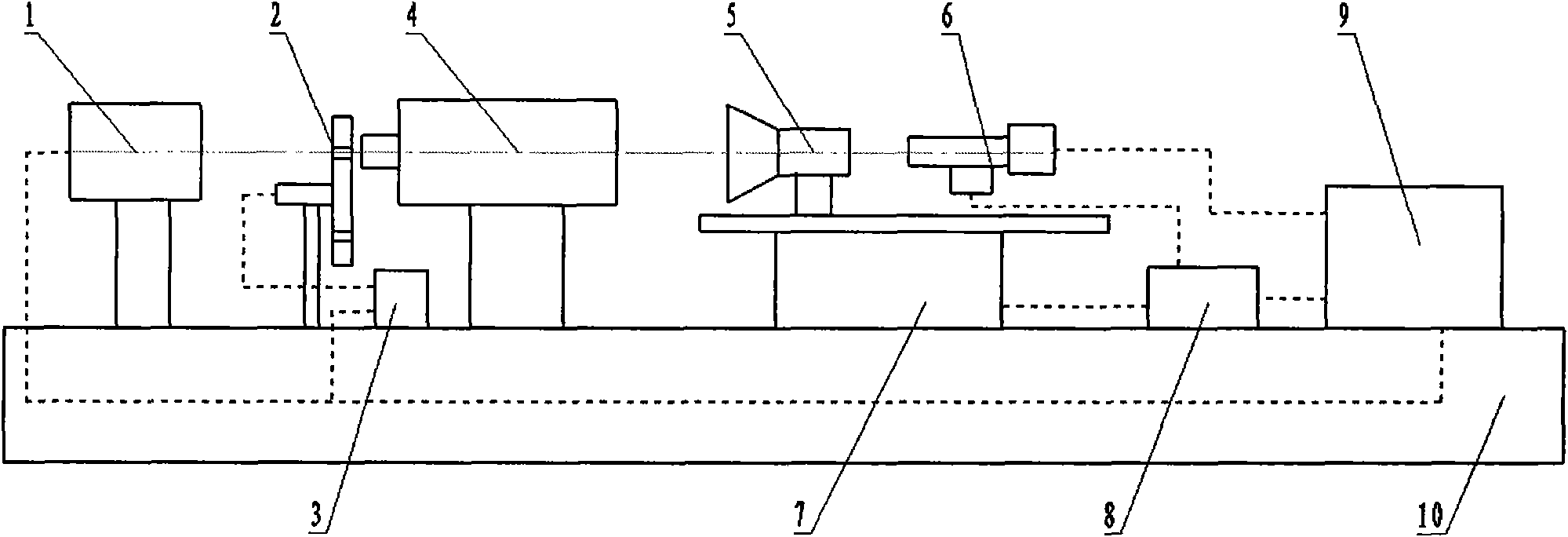

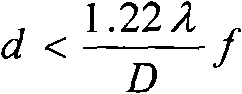

[0037] see figure 2, the sensor optical system diffuse spot and color deviation testing device provided by the present invention comprises a monochromator 1, a target target wheel 2, a target controller 3, a collimator 4, an optical system under test 5, and a two-dimensional CCD microscopic measurement Unit 6, digital display turntable 7, controller 8, acquisition and control computer 9, shock absorption platform 10; the spectral range of the monochromator 1 is required to be able to cover the spectral range of the measured optical system; the monochromator 1 is controlled by a computer, and the The target unit is illuminated; the target target wheel 2 and the target controller 3 form a target unit. The target target wheel 2 is equipped with a plurality of target plates on a disc at the same time, and its rotation is controlled by the target controller 3. It is mainly used for Provide star point targets of different sizes; the target target wheel 2 is connected to the target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com