Iron core insulation component for dry-type transformer

A dry-type transformer and iron core insulation technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, electrical components, etc., can solve the problem that the insulating varnish is easily damaged, affects the insulation performance of the iron core, and endangers the safety of the transformer Operation and other issues, to achieve the effect of improving heat dissipation capacity, simple structure, and satisfying long-term safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

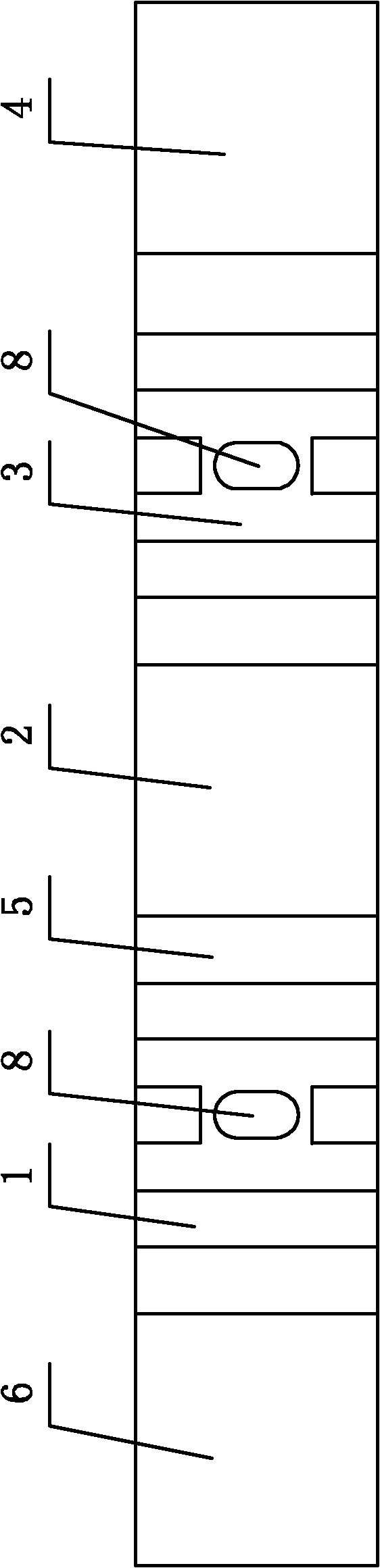

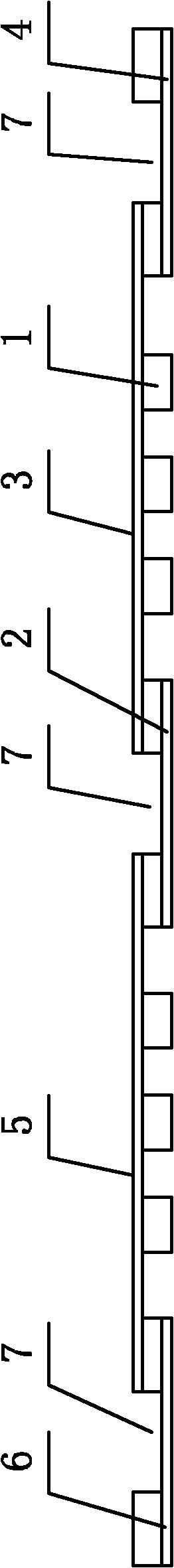

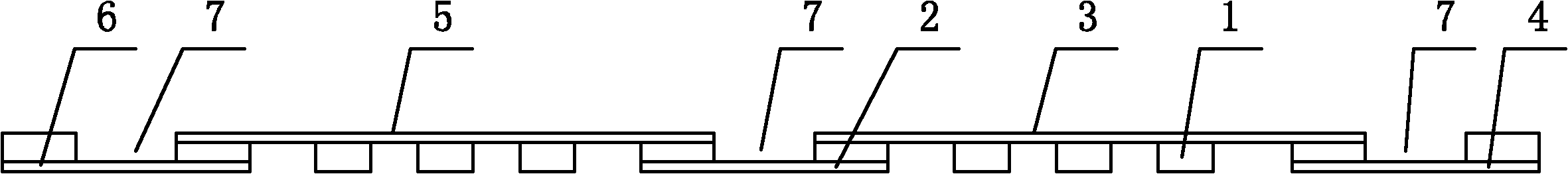

[0010] Such as Figure 1~2 As shown, the present invention comprises two insulating long webs and three insulating short webs, on the long webs there are arranged several longitudinally arranged insulating long pads 1 evenly spaced in the transverse direction, and at the two adjacent ends of the two long webs The first short web 2 is fixedly connected on the long spacer 1, the long spacer 1 at the other end of the first long web 3 is connected with one end of the second short web 4, and the other end of the second short web 4 is symmetrically arranged There is a long spacer 1, the long spacer 1 at the other end of the second long web 5 is connected to one end of the third short web 6, and a long spacer 1 is arranged symmetrically at the other end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com