Lithium ion battery and preparation method thereof

A lithium-ion battery and electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor battery stability, fast capacity decay, and poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention simultaneously provides the preparation method of above-mentioned lithium ion battery, and the steps comprise:

[0020] Preparation of positive electrode sheet: electrolytically activate the positive electrode active material precursor to prepare the positive electrode active material, add the positive electrode active material and materials including conductive agent and binder into the solvent and mix to prepare the positive electrode slurry, and then coat the obtained positive electrode slurry Covering the positive electrode collector on the positive electrode sheet;

[0021] Or mix the material including the conductive agent and the binder with the positive electrode active material precursor to obtain a mixture, electrolytically activate the mixture and add it to the solvent to prepare the positive electrode slurry, and then apply the obtained positive electrode slurry on the positive electrode current collector to prepare the positive electrod...

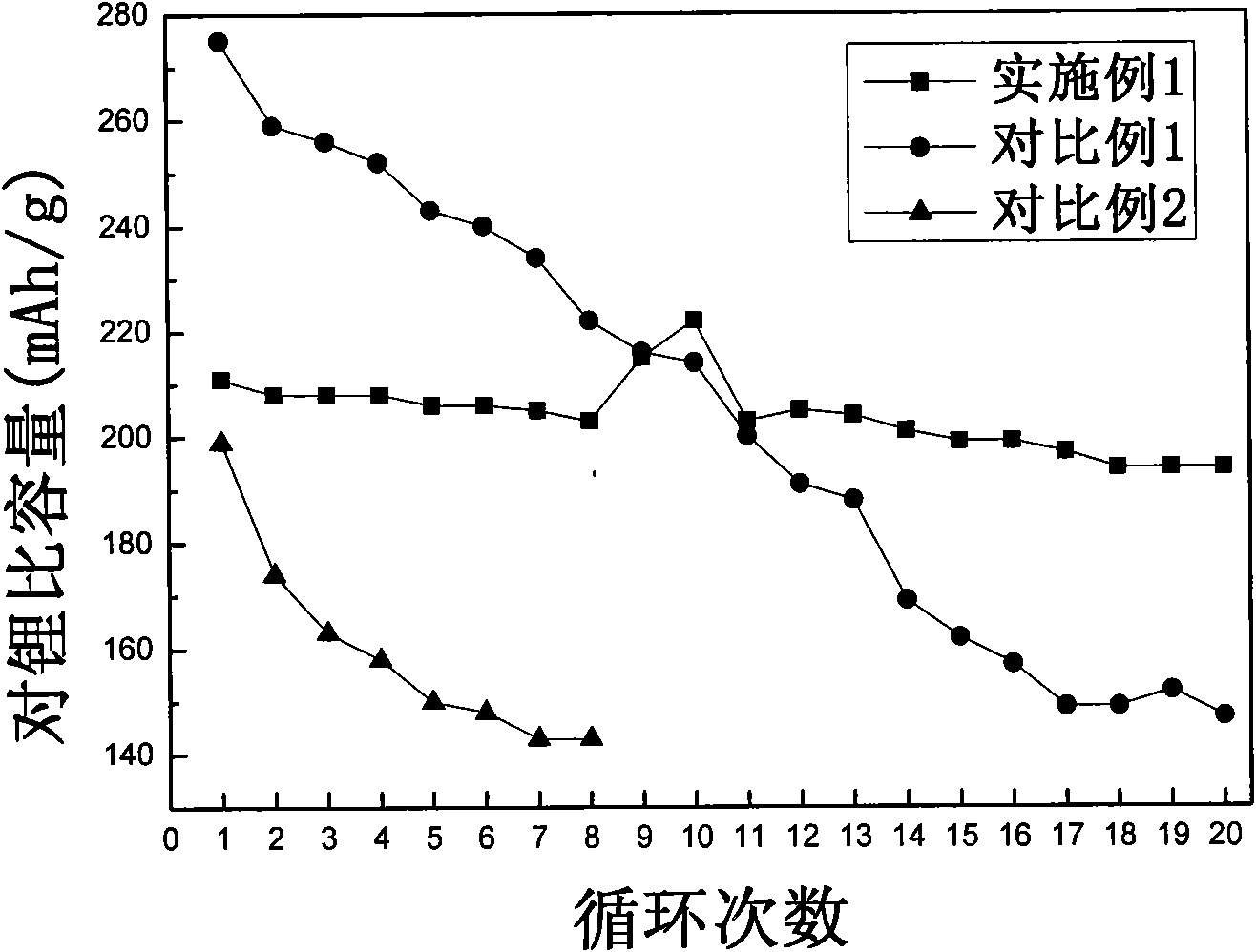

Embodiment 1

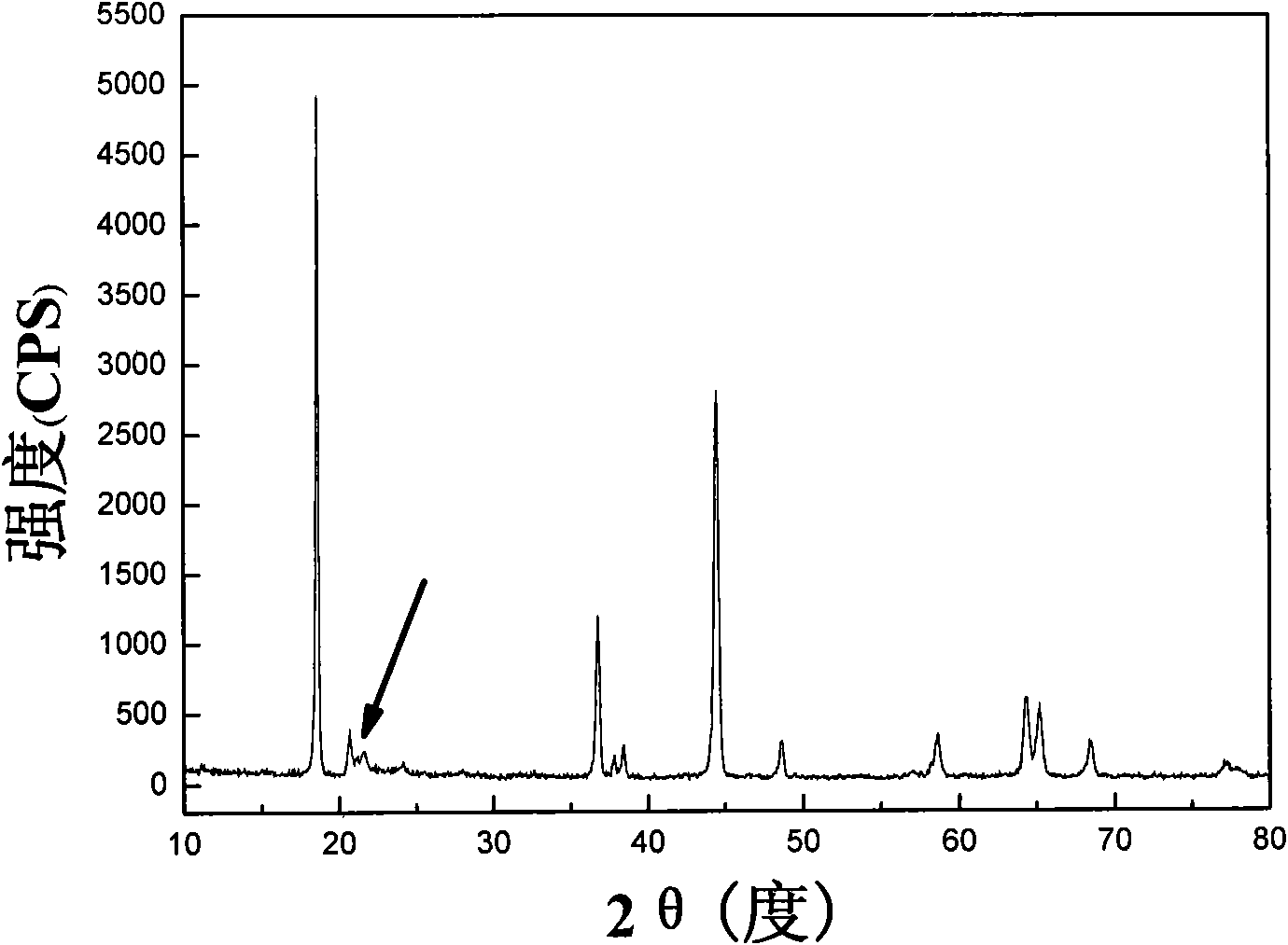

[0035] (1) Preparation of positive electrode active material

[0036] 63.42gNi can be 2 (OH) 2 CO 3 , 206.90g MnCO 3 and 133.00g Li 2 CO 3 Mix well, and then add absolute ethanol to the mixture for high-efficiency ball milling. After the ball-milled raw materials are fully dried, they are pre-sintered at 450° C. to prepare the precursor. The precursor is compacted and sintered at a high temperature of 980°C to prepare the average particle size D 50 1.15μm, tap density 1.7g / cm 3 0.5Li 2 MnO 3 0.5LiNi 0.5 mn 0.5 o 2 Composite solid solution.

[0037] 150.0g0.5Li 2 MnO 3 0.5LiNi 0.5 mn 0.5 o 2 The composite solid solution is placed in a barrel prepared by copper mesh, and placed in an electrolysis device. The counter electrode is a Cu sheet, and the electrolytic medium is 1moL / L LiPF6-EC+DEC+EMC electrolyte. The two electrodes are electrolyzed at 4.6V, and the initial current When the current is less than 0.1mA, the electrolysis is stopped to obtain a positive ...

Embodiment 2

[0043] The positive electrode active material and the battery were prepared by the same method as in Example 1, except that the electrolysis voltage was 4.8V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com