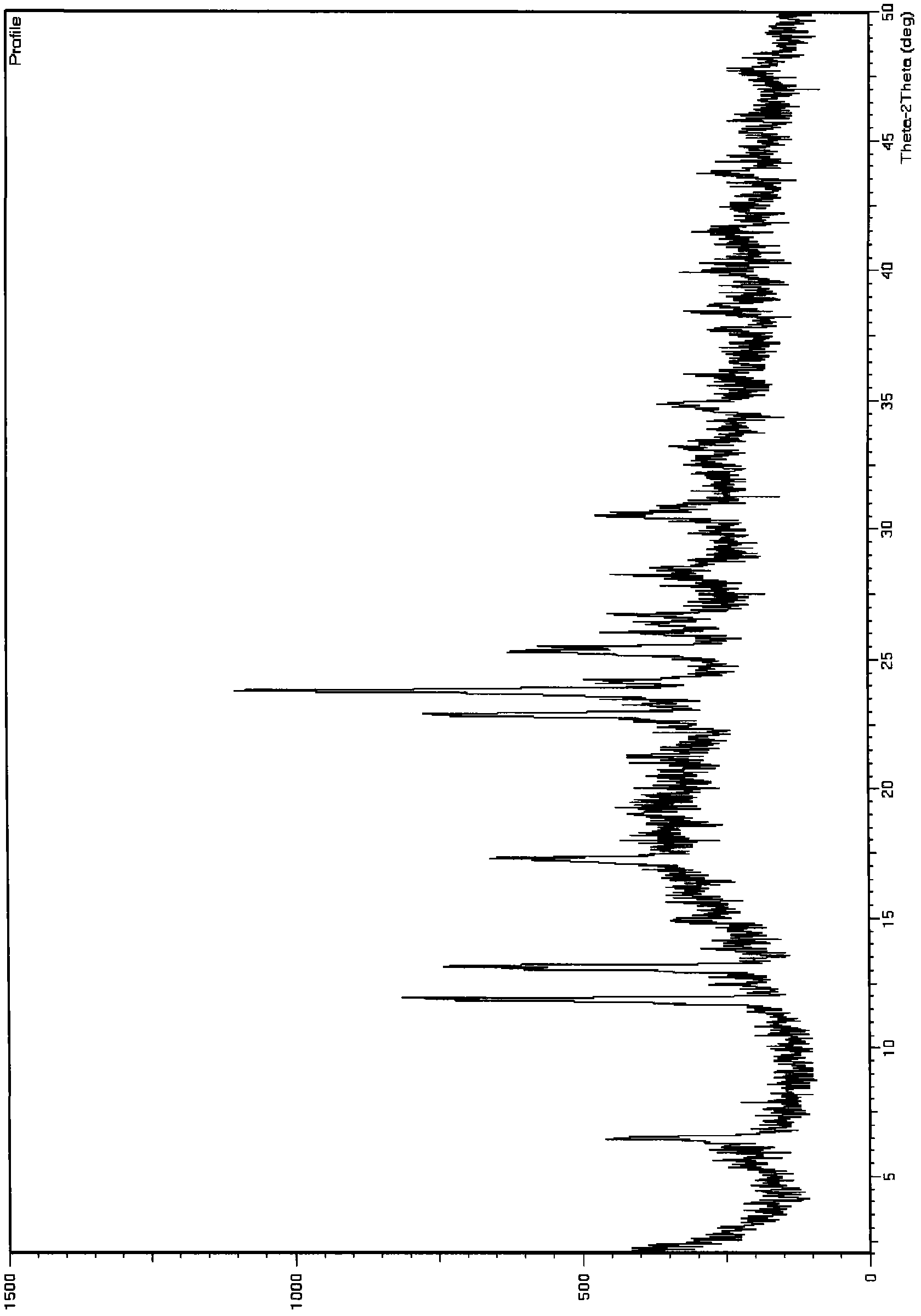

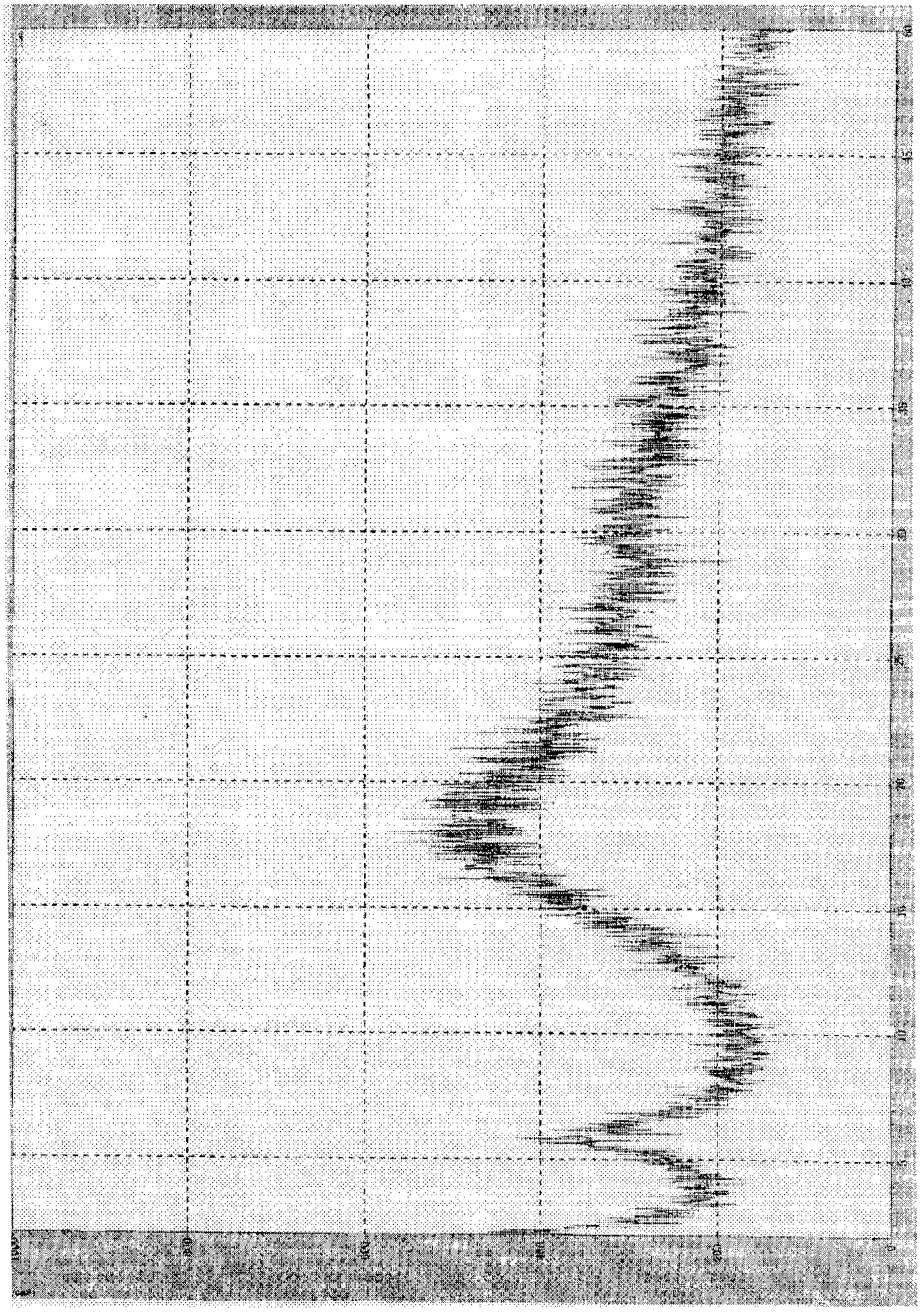

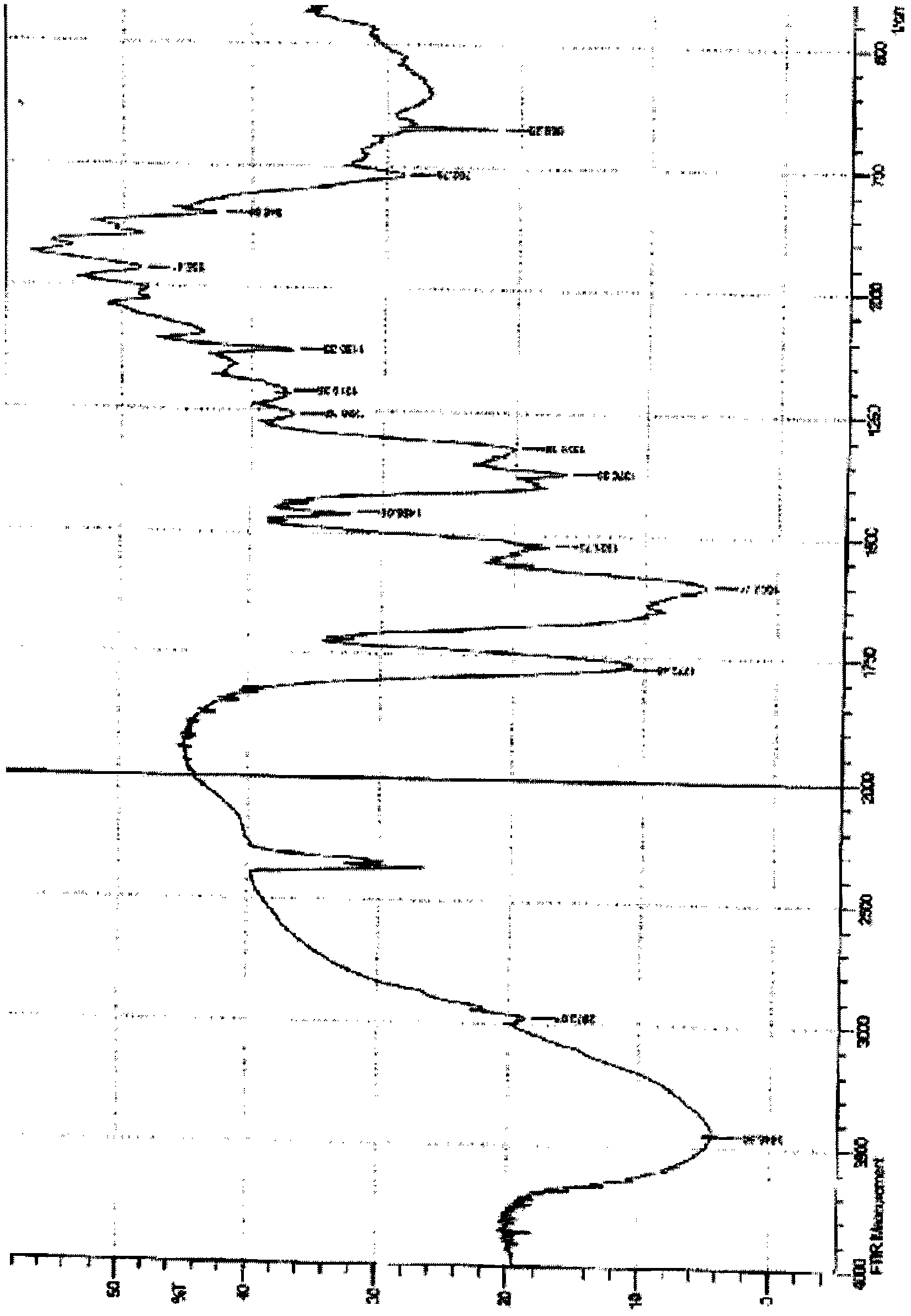

Ticarcillin sodium clavulanic acid potassium freeze-dried powder as well as preparation and preparation method thereof

A technology of carcillin sodium clavulanate potassium and ticarcillin sodium, which is applied in the field of medicine, can solve the problems of increased risk of bacterial contamination and unqualified visible foreign matter, difficulty in mixing uniformly, difficulty in process control, etc., and achieves good product uniformity , High safety in clinical use, good solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Get content and be 100kg of ticarcillin sodium aqueous solution of 20% (ticarcillin content), add gac 5kg in reaction tank, and content be 78% (clavulanic acid content, moisture: 0.9%) potassium clavulanate 1.78kg , after stirring for 25 minutes, flush the pressing system, sweep the thread, filter for sterilization, and start the freeze dryer. Rapidly lower the temperature to -45°C to solidify. Under 10 mbar vacuum, raise the temperature to 10°C within 6 hours, maintain this temperature for 3 hours, and then raise the temperature to 30°C in 5 hours, and maintain this temperature to continue vacuum drying. 8 hours, get ticarcillin sodium clavulanate potassium lyophilized powder, measure content: ticarcillin 82.0%, clavulanic acid 5.7% (the content determination method of ticarcillin, clavulanic acid is with reference to import drug registration standard (standard No. JX20050203) execution, the same below).

Embodiment 2

[0045] Get content and be 100kg of ticarcillin sodium aqueous solution of 20% (ticarcillin content), add gac 5kg in reaction tank, and content be 78% (clavulanic acid content, moisture: 0.9%) potassium clavulanate 1.72kg , after stirring for 25 minutes, flush the pressing system, sweep the thread, filter for sterilization, and start the freeze dryer. Rapidly lower the temperature to -40°C to solidify. Under 10 mbar vacuum, raise the temperature to 10°C within 4 hours, maintain this temperature for 3 hours, and then raise the temperature to 30°C in 5 hours, and maintain this temperature to continue vacuum drying After 8 hours, the freeze-dried powder of ticarcillin sodium and potassium clavulanate was obtained, and the measured content was: 83.5% of ticarcillin and 5.6% of clavulanic acid.

Embodiment 3

[0047] Getting content is 100kg of ticarcillin sodium aqueous solution of 20% (ticarcillin content), adds gac 5kg in reaction tank, content is 0.85kg of potassium clavulanate of 78% (clavulanic acid content, moisture: 0.9%), After stirring for 25 minutes, flush the pressing system, sweep the thread, sterilize and filter, and start the freeze dryer. Rapidly lower the temperature to -30°C to solidify, then raise the temperature to 10°C within 4 hours under a vacuum of 10 mbar, maintain this temperature for 2 hours to freeze-dry, then raise the temperature to 40°C within 5 hours, and maintain this temperature to continue vacuum drying After 8 hours, the freeze-dried powder of ticarcillin sodium and potassium clavulanate was obtained, and the measured content was: 94.2% of ticarcillin and 3.1% of clavulanic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com