Multistage combinational continuous countercurrent ultrasonic extraction device

An extraction equipment and countercurrent ultrasonic technology, which is applied in the field of multi-stage combined continuous countercurrent ultrasonic extraction equipment, can solve the problems of technical problems that are not well solved, popularized and applied, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

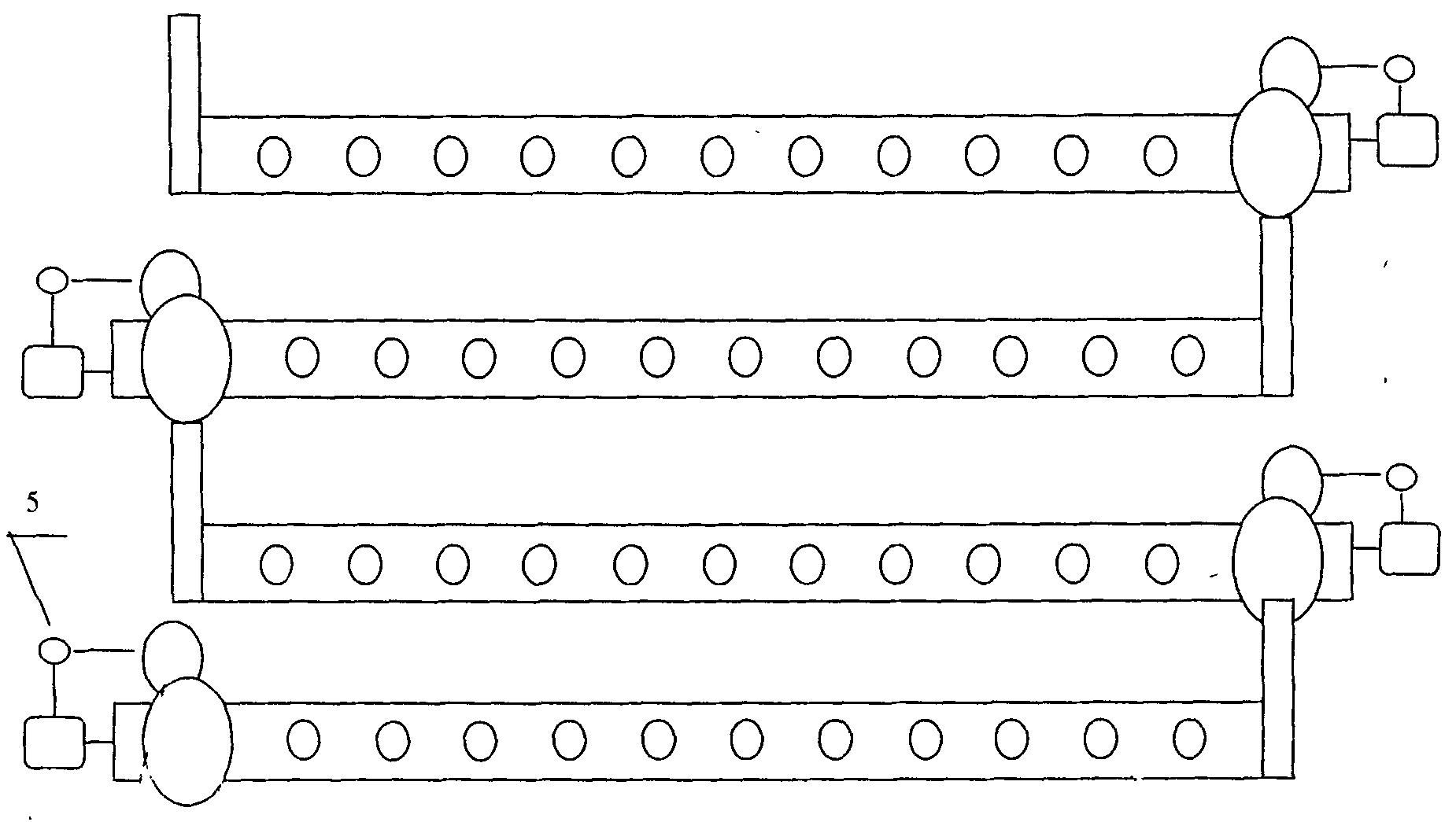

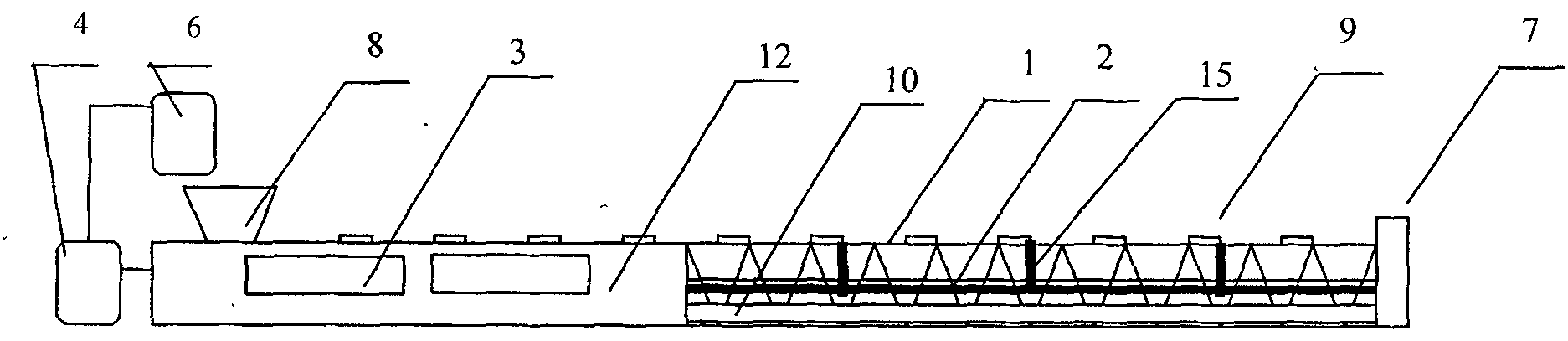

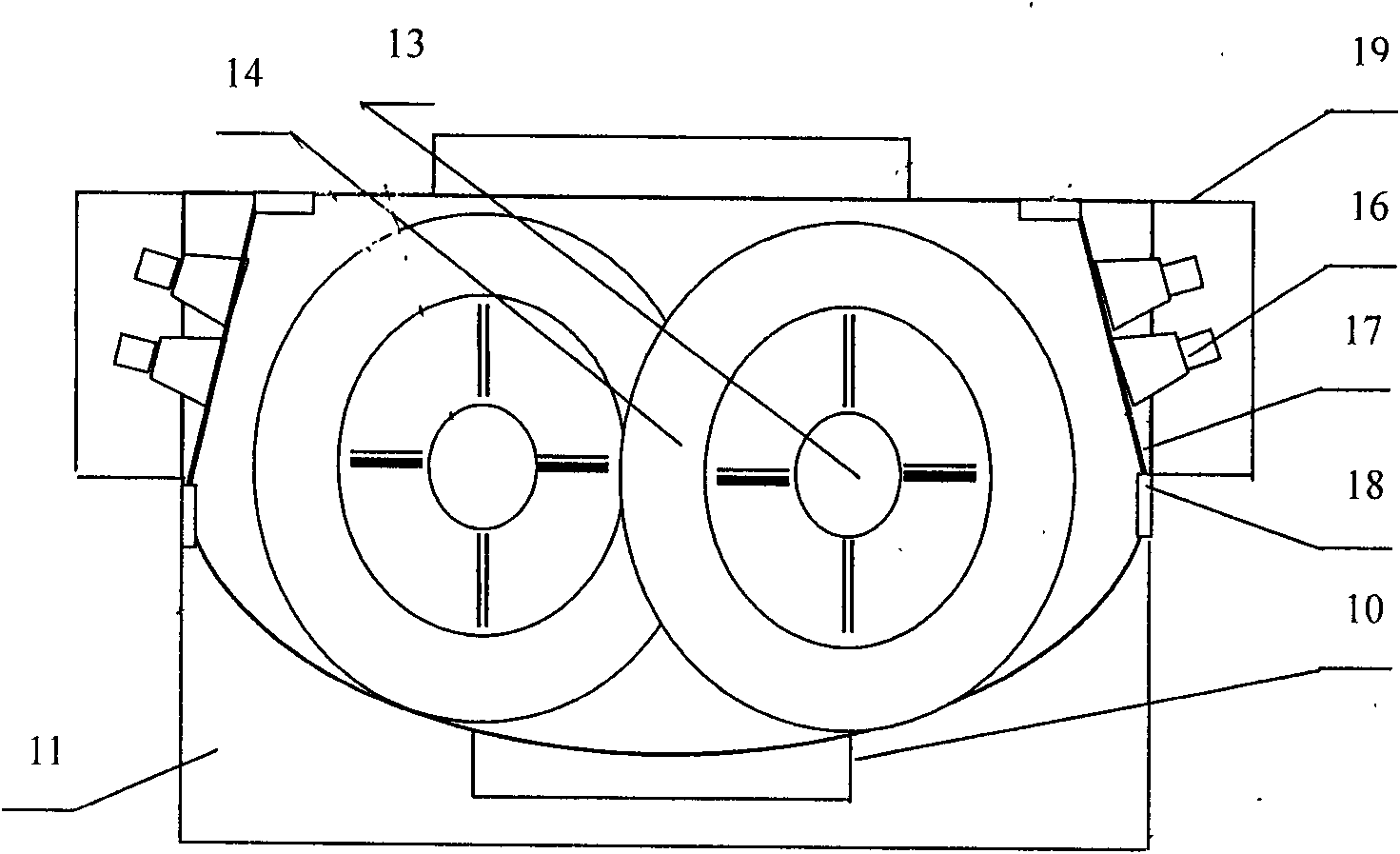

[0016] Example 1: Combination figure 1 , figure 2 , the present invention is a multi-stage combined continuous countercurrent ultrasonic extraction equipment, which is composed of a plurality of pipeline-type leaching cabins (1), belt-type double-spiral propellers (2) and embedded ultrasonic transducers, which are arranged side by side in a staggered manner. The box body (3) is composed of a belt-type double screw propeller (2) arranged inside the pipeline type leaching cabin (1), and an embedded ultrasonic transducer box body is arranged outside the side wall of the pipeline type leaching cabin (1). (3).

[0017] The present invention also has the following technical features:

[0018] The pipeline-type leaching chamber (1) comprises quick-opening cleaning ports (9) arranged at equal intervals at the upper part, a steam heating interlayer (10) at the lower part, a thermal insulation material (11) and a stainless steel skin (12) covered on the outer surface, The extraction...

Embodiment 2

[0022] Example 2: Combination Figure 1-Figure 3 , using four 12-meter-long pipeline-type leaching chambers (1) staggered side by side, with a total volume of 20M3, the interior is a belt-type double screw propeller (2); the side walls are equipped with 80 sets of embedded ultrasonic transducer boxes Body (3), the total sound power is 80KW. An extraction liquid buffer tank (4), a transfer pump (5) and a rotary drum filter (6) are arranged at the liquid outlet end of each pipeline-type bench-top extraction chamber (1), and a screw slag discharger (7) is arranged at the slag discharge end.

[0023] Combination working mode A: 4 pipeline extraction chambers (1) work independently and in parallel, with a countercurrent stroke of 12 meters, and the extraction time can be adjusted and controlled within 30-60MIN, which can complete the extraction and production tasks of tea drinks, tea polyphenols and other varieties. The processing capacity is about 30 tons.

[0024] Combination w...

Embodiment 3

[0026] Embodiment 3: a kind of multi-stage combined continuous countercurrent ultrasonic extraction equipment of the present invention focuses on solving the following technical obstacles that hinder the popularization and application of countercurrent ultrasonic extraction process:

[0027] ①Application flexibility: Usually, the extraction and production tasks of multiple varieties need to be completed in stages in the large-scale extraction base (workshop). In general, if a traditional extraction tank is used, it can be applied to the extraction production of all these varieties. Countercurrent extraction equipment has many superior properties, but a set of countercurrent extraction equipment with a fixed-length pipeline extraction tank can only adapt to the production process requirements of some varieties due to the limitation of "countercurrent stroke" and "extraction time". If a plurality of special equipment with different length specifications are configured for this r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com