Environment-friendly blasting compaction method for treating soft foundation

A technology for blasting and silting, soft foundation treatment, applied in soil protection, coastline protection, infrastructure engineering, etc. Affect, reduce the effect of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

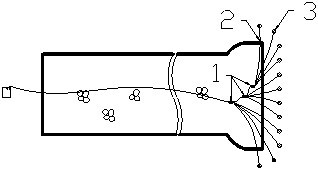

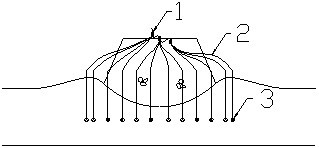

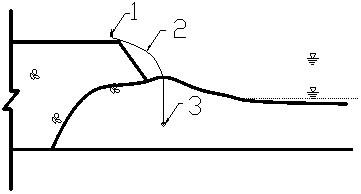

[0042] Embodiment 1: If the project is constructed in a shallow sea area, when the area affected by the blasting vibration is within the scope of the low tide mud bag, the combination of differential blasting and dew beach blasting is used for construction; the construction layout is as follows figure 1 , figure 2 , image 3 .

[0043] 1. Determination of explosive filling parameters. According to the geological exploration report, geotechnical calculation principles and design height of the embankment, the height of the dike body is determined after theoretical analysis and calculation. Under the premise that the embankment crest is not super high after water explosion, the height of the embankment should be as high as possible to achieve the effect of silting to the greatest extent; then, according to the calculated height value of the embankment and the designed section of the embankment, the width of the embankment is calculated. The volume of filling in the widened pa...

Embodiment 2

[0073] Example 2: The seawater in the explosive filling construction area of the project is relatively deep, or the project advances to the deep sea with the construction. When the low tide level, the area affected by the blasting vibration is within the seawater range, and the combination of differential blasting and air bubble curtain is used for construction; the construction layout is as follows Figure 4 , Figure 5 , Figure 6 .

[0074] 1. Determination of explosive filling parameters. According to the geological exploration report, geotechnical calculation principles and design height of the embankment, the height of the dike body is determined after theoretical analysis and calculation. Under the premise that the embankment crest is not super high after water explosion, the height of the embankment should be as high as possible to achieve the effect of silting to the greatest extent; then, according to the calculated height value of the embankment and the designed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com