Device for measuring tension of winch cable and measuring method thereof

The technology of a measuring device and a measuring method is applied in the field of steel wire rope measurement to achieve the effects of accurate measurement data, high practical reliability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

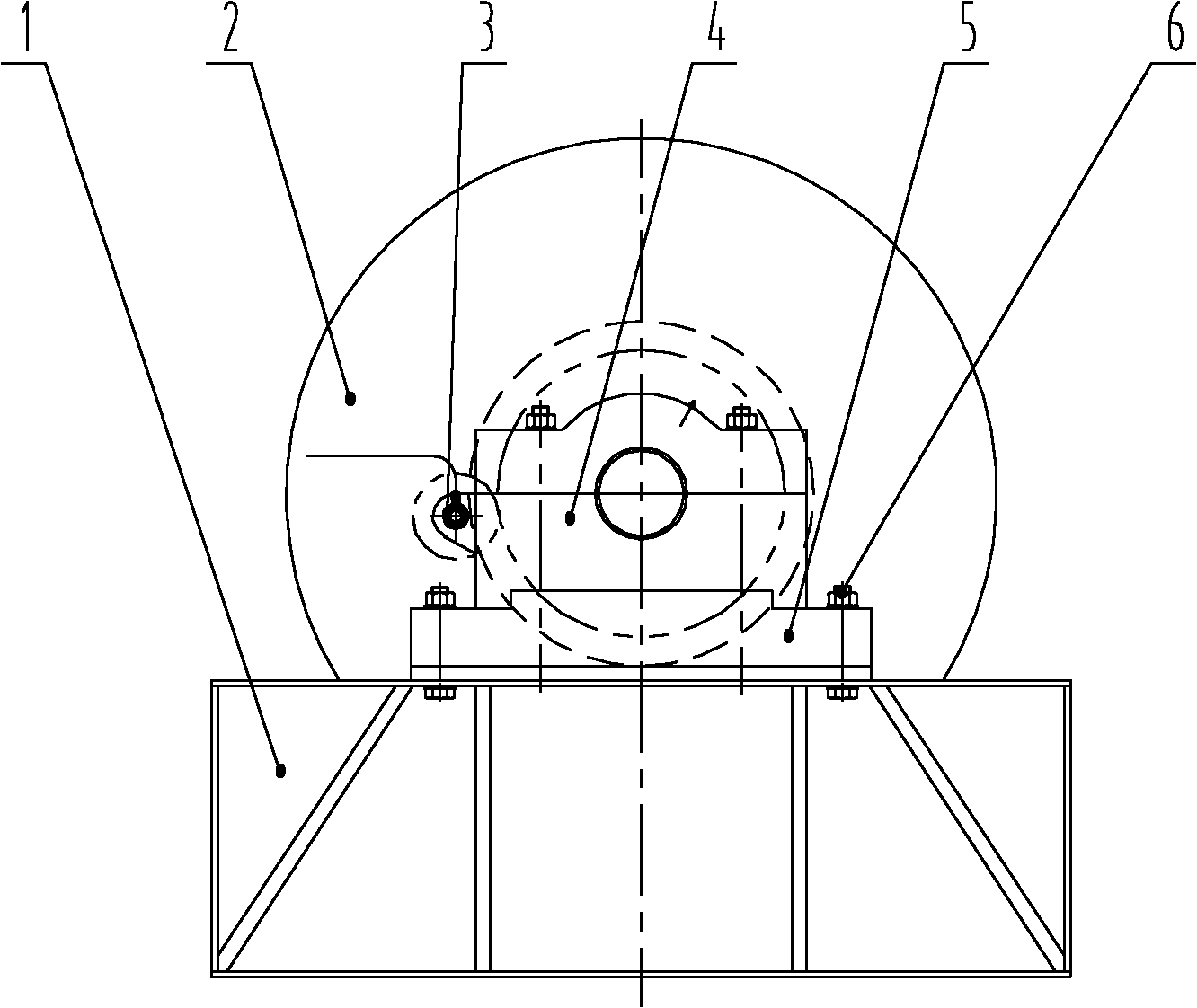

[0028] The winch wire rope tension measuring device includes a winch drum support 1, a wire rope drum 2 and a bearing seat 4, the drum support 1 is equipped with a bearing seat, the bearing seat 4 is equipped with a wire rope drum 2, and the bearing seat 4 is equipped with a wire rope force sensor 5 and wire rope speed sensor 3.

[0029] The wire rope speed measuring sensor 3 is a gear speed measuring method. The speed measuring sensor is equipped with a small gear, and a matching large gear is assembled on the reel shaft. The large gear and the reel shaft rotate synchronously. The speed measuring sensor 3 measures the angular velocity and the rotational speed of the pinion laps passed. The wire rope load cell is a load cell.

Embodiment 2

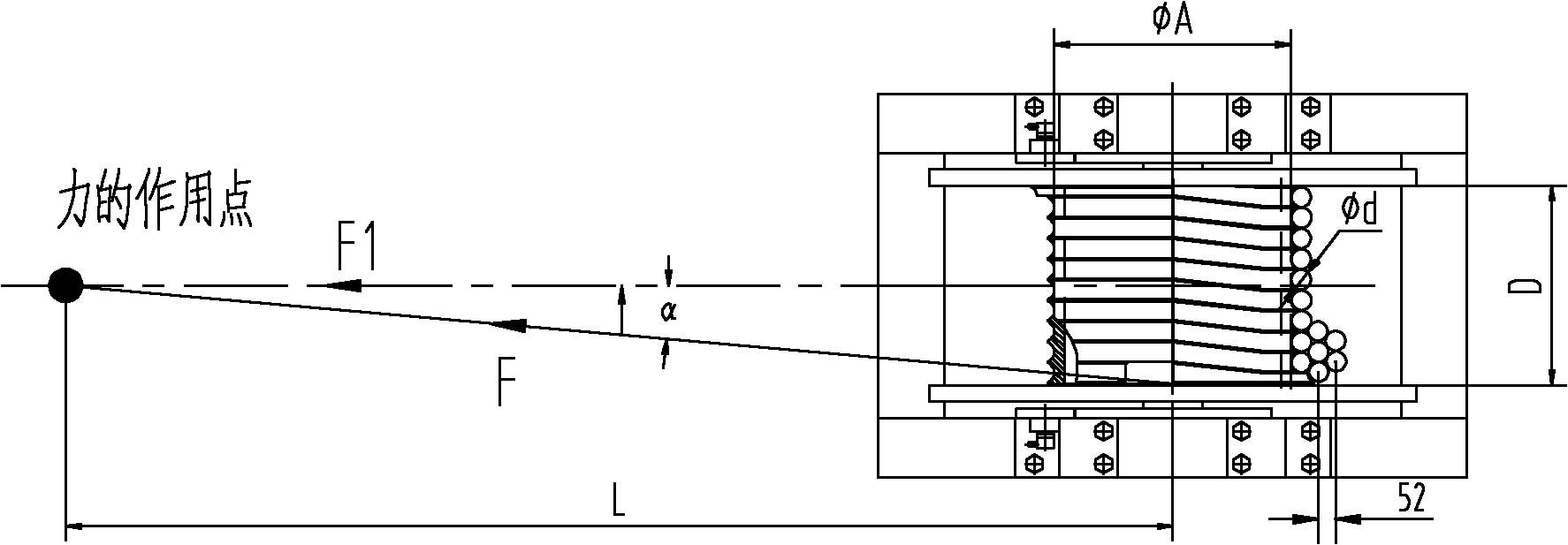

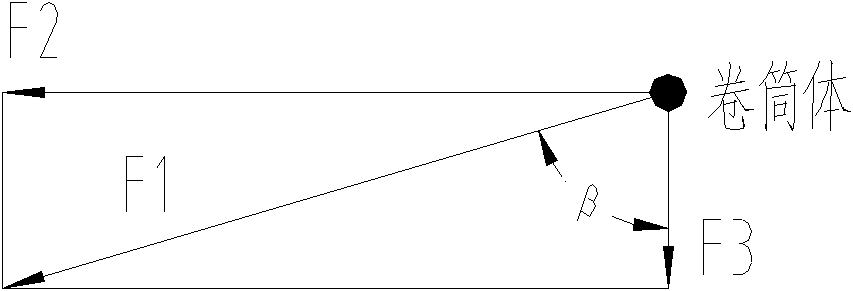

[0031] The measurement method of the wire rope tension measuring device of the winch, the steps of measuring the wire rope tension by the measuring device, measuring the force of the wire rope force sensor installed on the bearing housing, measuring the data of the wire rope speed sensor, and determining the length of the wire rope and its position on the wire rope drum , the wire rope force is calculated from the position of the wire rope on the wire rope drum to determine the tension of the wire rope.

[0032] Measuring the force of the wire rope load cell installed on the bearing housing is to measure the force of the load cell of the wire rope installed. The wire rope speed sensor is a gear speed measurement method. The speed sensor is equipped with a small gear, and a paired large gear is installed on the reel shaft. The large gear and the reel shaft rotate synchronously. The data measured by the wire rope speed sensor is measured by the small gear of the speed sensor. an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com