Half-bridge drive circuit

A half-bridge drive and half-bridge circuit technology, applied in electrical components, conversion equipment without intermediate conversion to AC, output power conversion devices, etc., can solve the problem that the driver 2 cannot start, the half-bridge circuit 1 cannot work normally, charging and other problems, to achieve the effect of a wide range of applicable working conditions, a small increase in cost and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

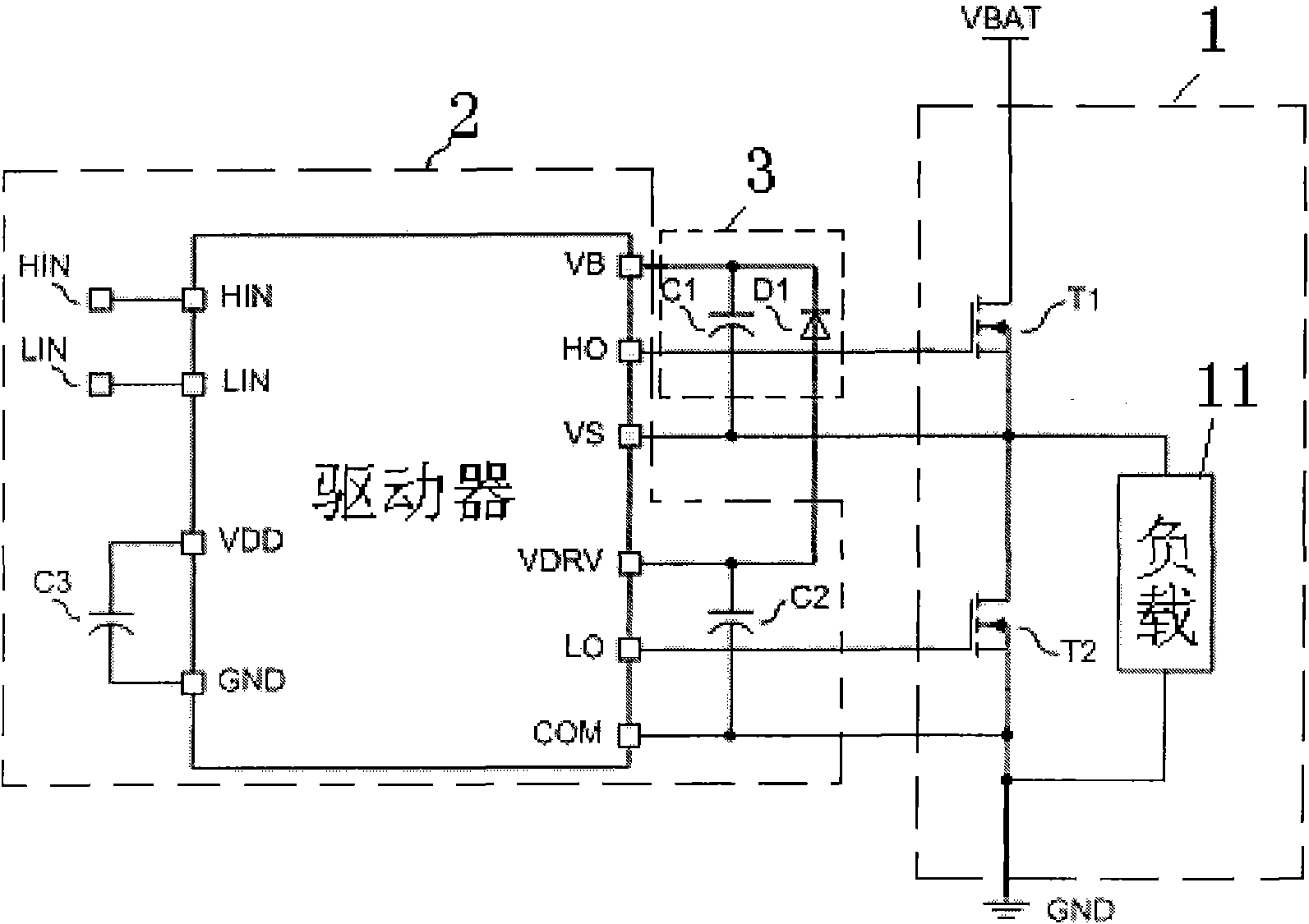

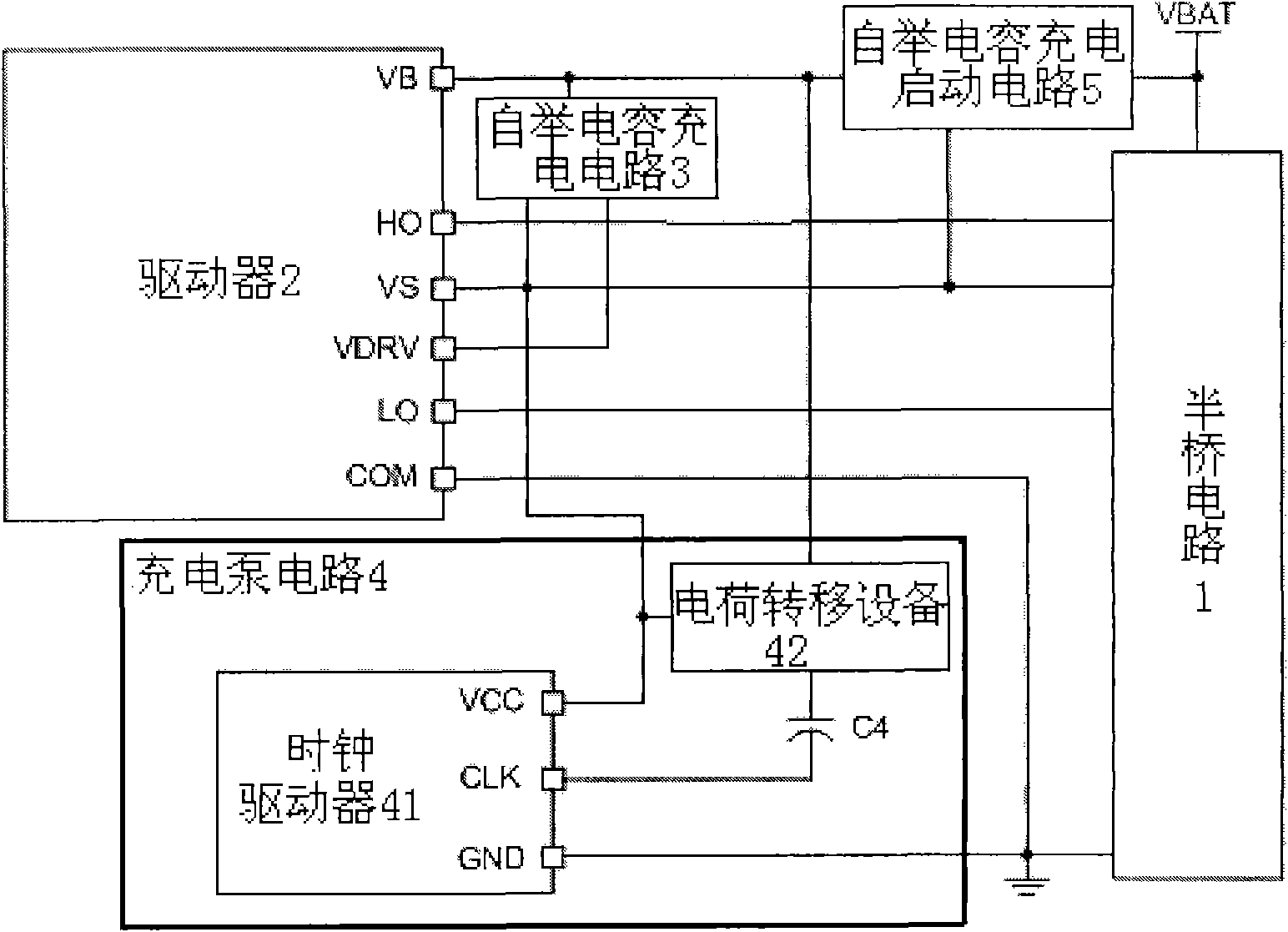

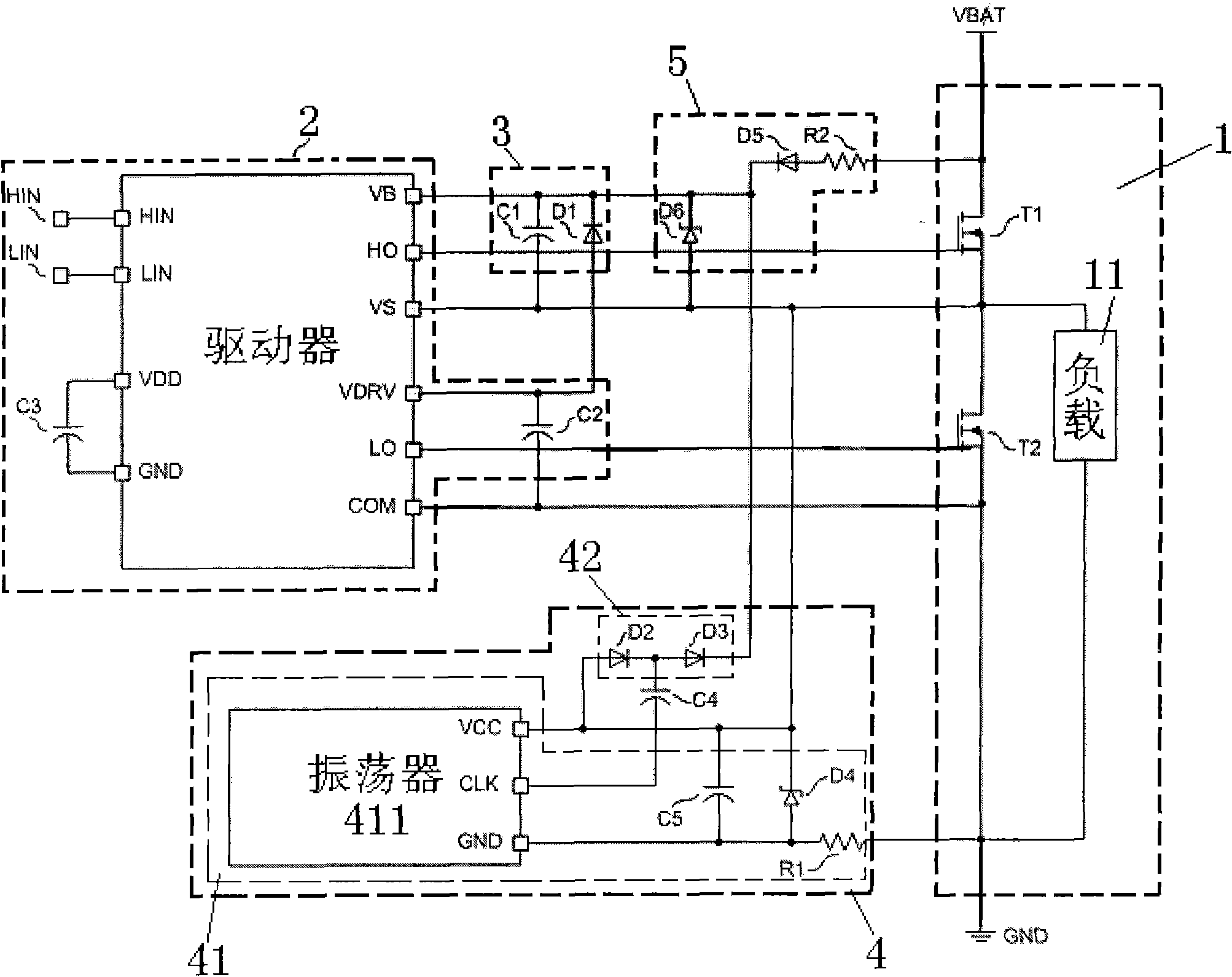

[0021] Such as figure 2 As shown, the half-bridge drive circuit provided by the present invention includes a half-bridge circuit 1 , a driver 2 , a bootstrap capacitor charging circuit 3 , a charge pump circuit 4 and a bootstrap capacitor charging startup circuit 5 . Among them, the connections and functions of the half-bridge circuit 1 , the driver 2 and the bootstrap capacitor charging circuit 3 are the same as those of the traditional half-bridge drive circuit, and will not be described in detail here. The charge pump circuit 4 is connected to the high-side driving floating power terminal (pin VB) and the high-side driving floating ground terminal (pin VS) on the driver 2 , and the ground of the charge pump circuit 4 is connected to the power ground of the half-bridge circuit 1 . The input end of the bootstrap capacitor charging startup circuit 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com