Electromagnetic shielding vapor sealing zipper and preparation method thereof

A sealing zipper and electromagnetic shielding technology, applied in the field of zipper, can solve the problems of poor anti-static property, poor electromagnetic shielding performance, poor fire resistance and flame retardancy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

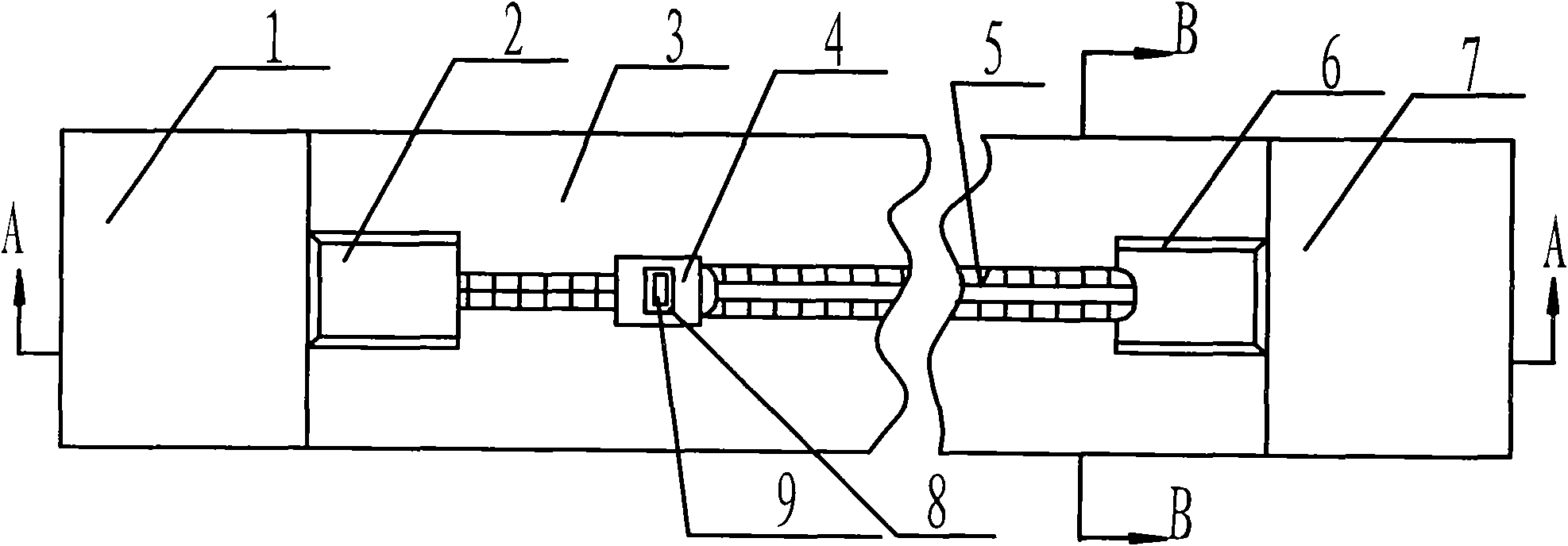

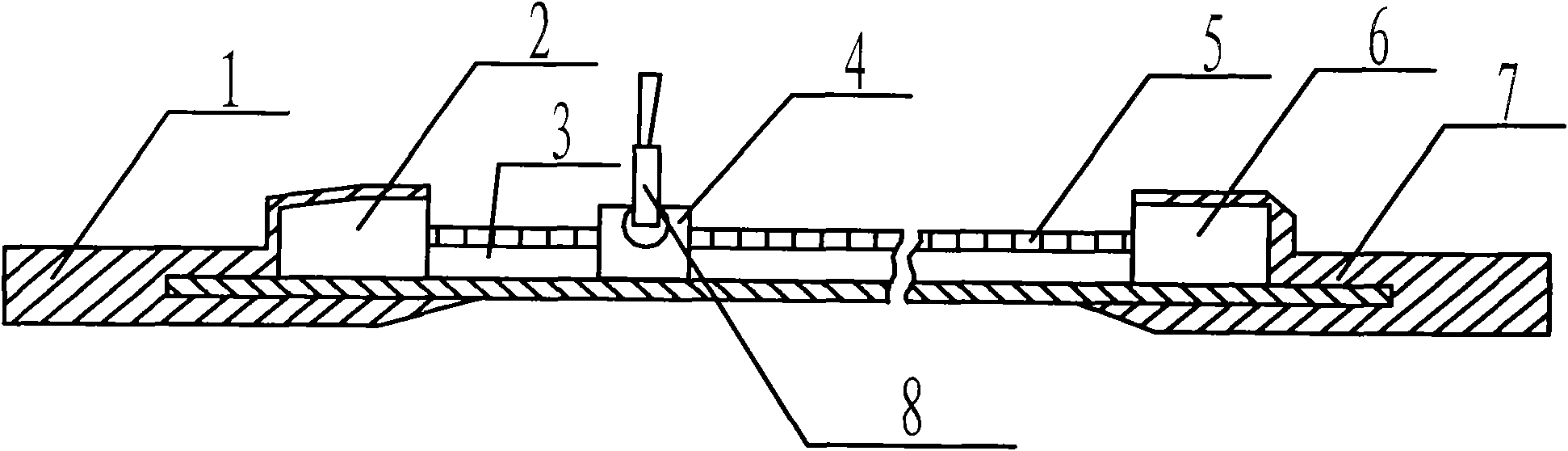

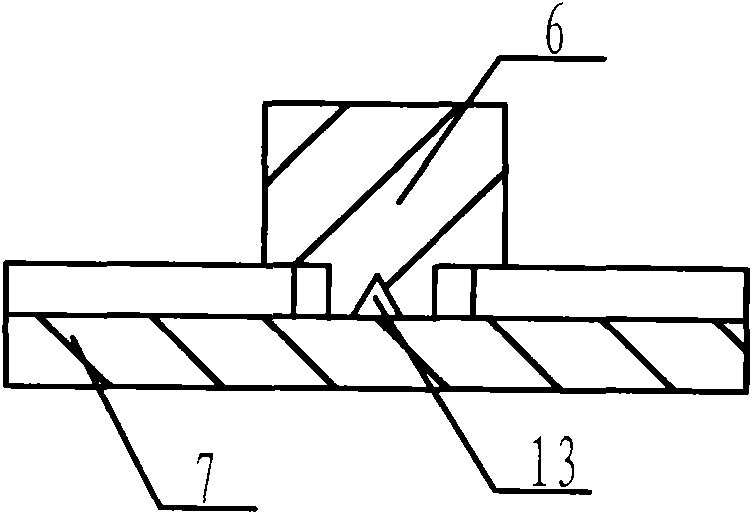

[0029] Embodiment 1: see figure 1 , 2 , 3 and 6, an electromagnetic shielding water-air-tight zipper, including a composite conductive base cloth 3, a chain 5, a copper alloy slider 4, an upper stop 2, a lower stop 6, an upper end 1 and a lower end 7; The chain 5 is composed of chain teeth fixed on the composite conductive base cloth 3 coupled with each other; the upper end of the chain 5 and the upper stop 2 are fixed on the upper head 1 by means of vulcanization molding, injection molding or casting molding; the chain 5 The lower end and the lower stop 6 are fixed on the lower head 7 by means of vulcanization molding, injection molding or pouring molding.

[0030] The composite conductive base cloth 3 is composed of a base cloth body, a front adhesive layer and a reverse adhesive layer; the surface of the front adhesive layer is set to a pitted surface, and the surface of the reverse adhesive layer is polished into a rough surface; the base cloth body is composed of 2- 5 l...

Embodiment 2

[0037] Example 2: see figure 1 , 4 , 5 and 6, an electromagnetic shielding water-air-tight zipper, including a composite conductive base cloth 3, a chain 5, a copper alloy slider 4, an upper stop 2, a lower stop 6, an upper end 1 and a lower end 7; The chain 5 is composed of chain teeth fixed on the composite conductive base cloth 3 coupled with each other; the upper end of the chain 5 and the upper stop 2 are fixed on the upper head 1 by means of vulcanization molding, injection molding or casting molding; the chain 5 The lower end and the lower stop 6 are fixed on the lower head 7 by means of vulcanization molding, injection molding or pouring molding.

[0038] The composite conductive base cloth 3 is composed of a base cloth body, a front adhesive layer and a reverse adhesive layer; the surface of the front adhesive layer is set to a pitted surface, and the surface of the reverse adhesive layer is polished into a rough surface; the base cloth body is composed of 2- 5 laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com