Integrated three-tube three-valve large transfusion soft bag and bottle packaging plastic double-color cover

An integrated, large-scale infusion technology, applied in the field of medical supplies, can solve the problems of multiple production processes, liquid medicine pollution, and high cost, and achieve the effects of reducing production costs, avoiding pollution, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

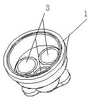

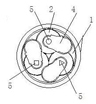

[0026] Such as figure 1 , 2 , 3, 4, and 5, the one-piece large infusion soft bag with three tubes and three valves, the plastic two-color cover for bottle packaging, including the cover 1, and the blind tube 2 protruding from the top surface of the cover 1, which is arranged on the blind tube 2 The inner valve plug 3 also includes a frangible handle 4 arranged on the top surface of the dead pipe 2 . Such as figure 1 , 3 , 5, the top surface of the cover 1 has three dead legs 2 provided with valve plugs 3 (such as Figure 4 , 5 As shown, one end of the blind pipe 2 is closed and the other end is open, and the opening direction is consistent with the opening direction of the cover), the cover 1 and the valve plug 3 are integral structures, and are connected as one by injection molding.

[0027] Such as figure 1 , 3 As shown, the easy-to-break handle 4 is arranged parallel to the top surface of the cover 1, and the easy-to-break handle 4 is provided with graphic marks 5 fo...

Embodiment 2

[0032] Such as Figure 7 , 8 , 9, the two ends of the dead leg 2 are closed, the valve plug 3 is located in the dead leg, and the opening 7 of the dead leg is located on one side of the dead leg 2, and its opening direction is parallel to the top surface of the cover. The easy-folding handle 4 is arranged perpendicular to the top surface of the cover 1 .

[0033] All the other implementations are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com