Flushing and detecting system of triple valve, solvent valve and spray gun of automata

A detection system and automaton technology, applied in the testing of mechanical components, testing of machine/structural components, and detecting the appearance of fluid at leakage points, etc., can solve problems such as time-consuming, inability to detect, and affect production quality. Achieve the effect of avoiding time and strengthening the washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

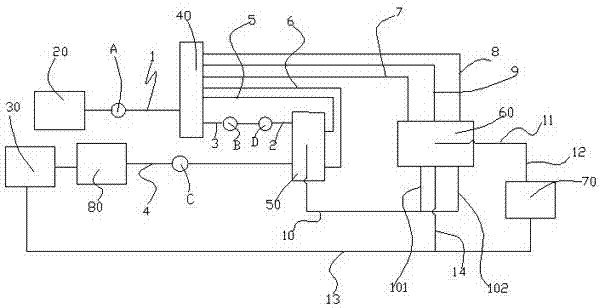

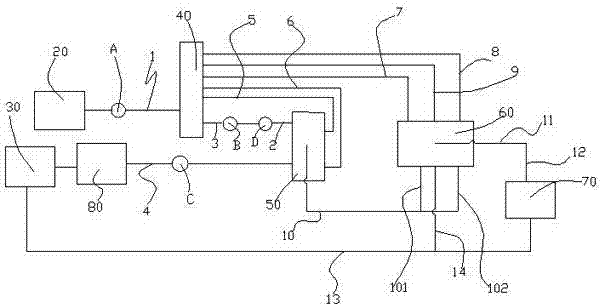

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Such as figure 1 Shown, the flushing and detection system of the automaton solvent valve of this embodiment, triple valve and spray gun include:

[0031] Compressed air supply device 20, this compressed air supply device can be any suitable device in the prior art;

[0032] The solvent supply device 30, in this embodiment, is a solvent pool for containing solvents, and a filter screen is arranged in the solvent pool to filter the returned solvent to realize recycling, and the placement position and structure of the filter screen can filter It is advisable to drop the dross and impurities in the backflow solvent. The solvent here is the solvent commonly used in the spraying process, such as the automatic color change solvent;

[0033] Diaphragm pump 80, which is connected to the solvent supply device 30, and is used to pump out the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com