Adaptive welding method for pipe-plate circumference welding and subsection parameter setting and arc welding equipment

A technology for setting parameters and arc welding equipment, applied in arc welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting welding quality, low welding qualification rate, poor forming effect, etc., to improve the welding seam Forming effect, improving welding qualification rate and saving welding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

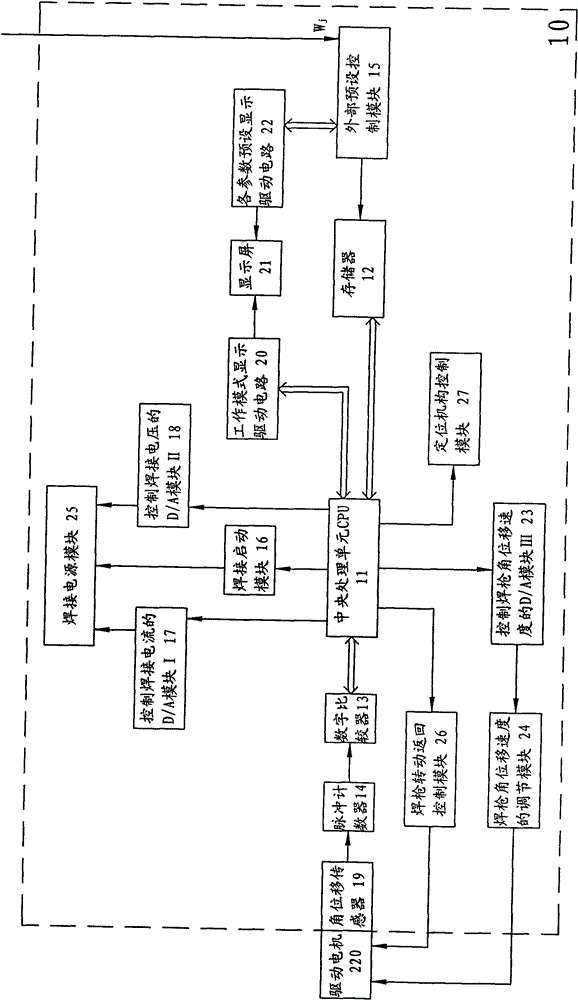

[0044] see figure 1 and figure 2 , the present invention relates to a kind of adaptive welding method for tube-plate circumferential welding, segmentally set parameters, comprising the following steps:

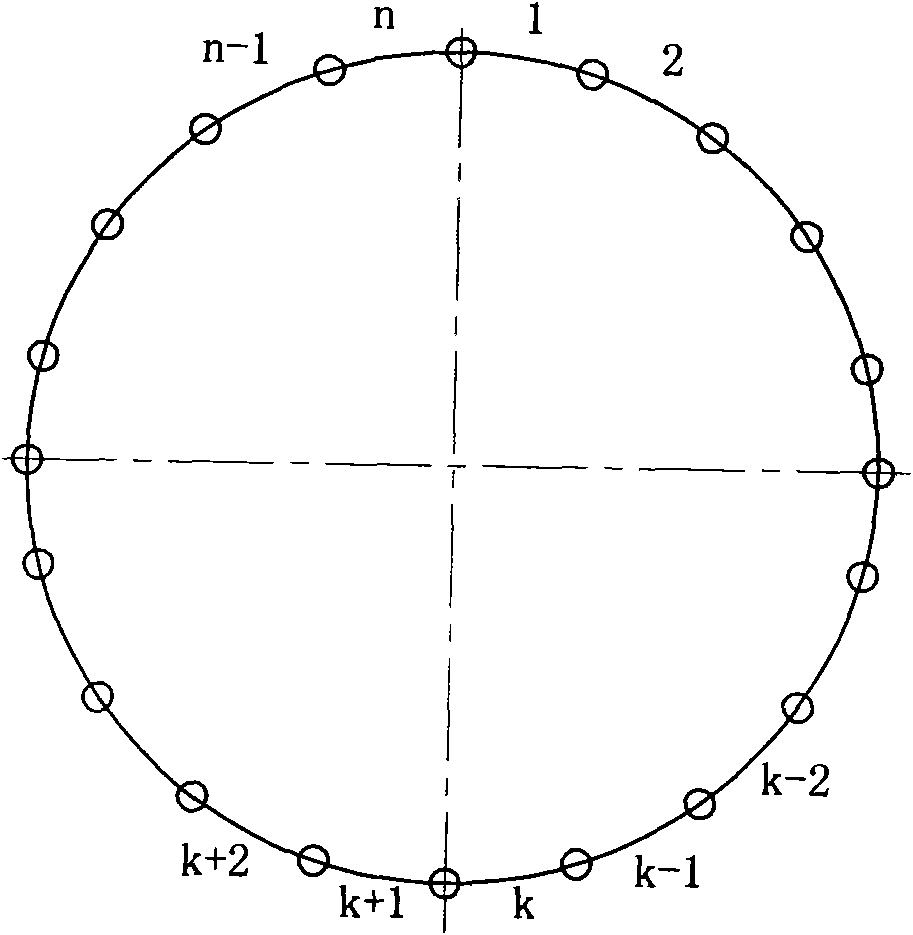

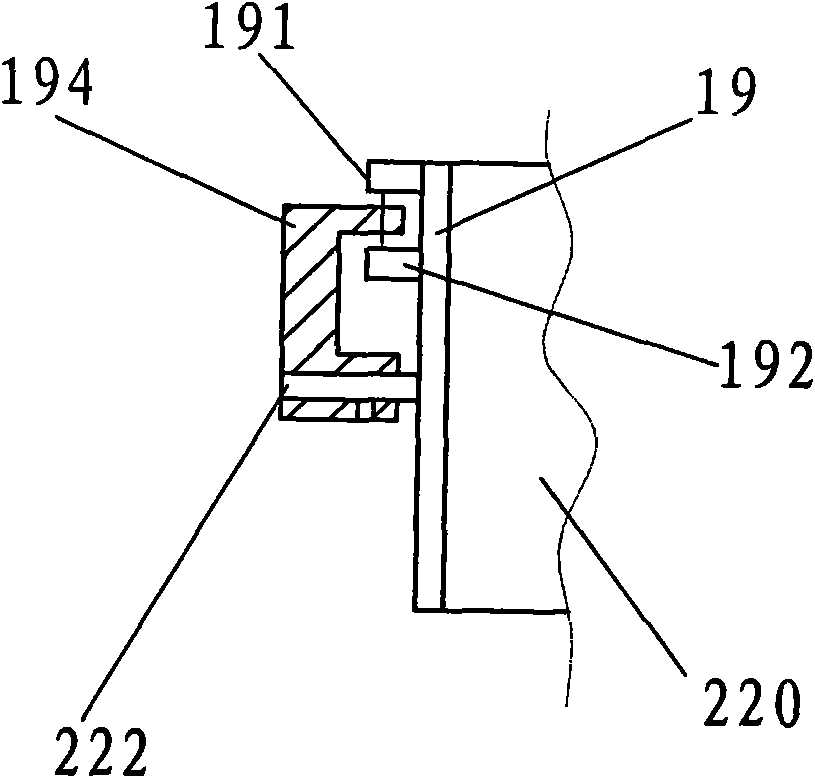

[0045] A. Divide the circumferential weld of the tube-plate to be welded into n arc segments, where n is an integer, and 20≥n≥2. There are different process requirements according to the different geometric positions of each arc segment, and each arc is preset. Section welding parameters W j ={I j , U j , β j}, j=1 to n, where I j , U j and beta j Respectively, the angular displacement of the welding torch rotation corresponding to the welding current, welding voltage and arc length of the arc section welding seam required by the welding process of the jth arc section on the circumferential weld seam;

[0046] B. Will implement the n sets of welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com