Integrated water-cooled motor base for new energy electric vehicle

A water-cooled motor, electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve the problems of small contact area between the spiral waterway and the base, limited capacity of the vehicle battery, low heat transfer efficiency, etc., to save welding materials and Welding labor, improved utilization, high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

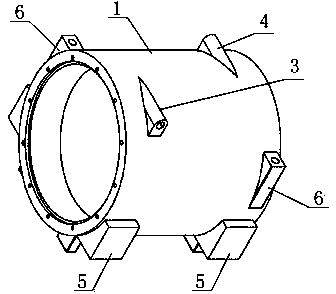

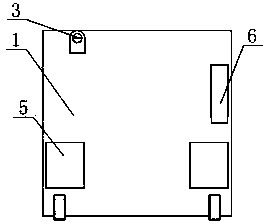

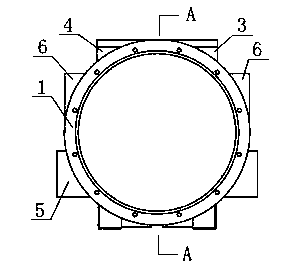

[0016] Such as Figure 1 to Figure 6 As shown, the integrated water-cooled motor base for a new energy electric vehicle includes a casing 1, and a spiral waterway 2 integrally formed with the casing 1 is arranged inside the casing 1, and the two ends of the outer surface of the casing 1 are respectively provided with A water inlet 3 and a water outlet 4, the flow channels in the water inlet 3 and the water outlet 4 are respectively tangent to the two ends of the spiral waterway 2. The one-piece structure enables the spiral waterway 2 and the inner shell of the machine base to be cast and formed at the same time, without welding, and directly enters the finishing process. Compared with the existing spiral waterway 2 welding manufacturing process, the welding process is canceled, and the welding materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com