Engineering wheel manufacturing process

A manufacturing process and wheel technology, applied in the field of engineering wheel manufacturing process, can solve the problems of being unsuitable for small batch or single-piece production, slow cost recovery, long processing cycle, etc., and achieve low processing cost, beautiful contour, and short processing cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

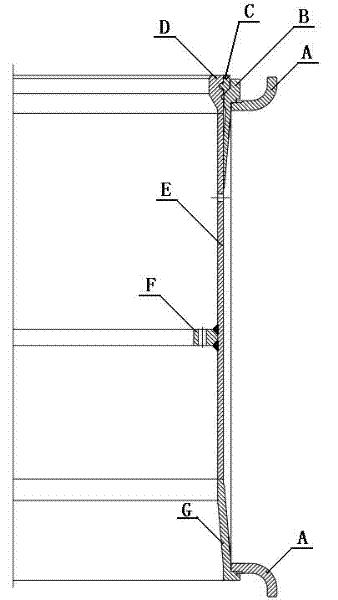

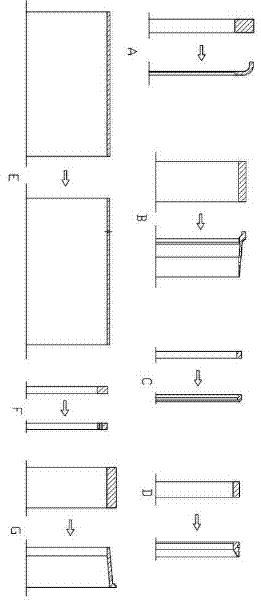

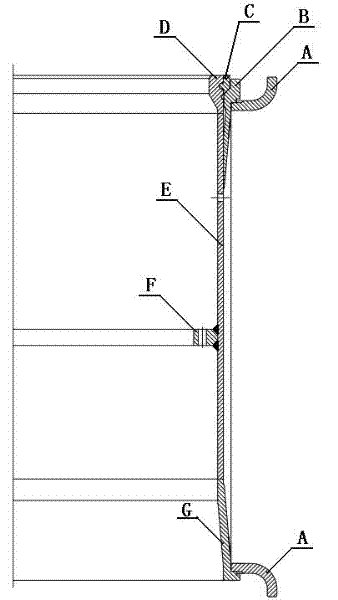

[0012] refer to figure 1 — figure 2 , an engineering wheel manufacturing process, the engineering wheel is divided into seven parts: rim A, movable seat ring B, movable retaining ring C, fixed retaining ring D, straight cylinder E, spoke plate F, fixed seat ring G, wherein the wheel Edge A is two symmetrical. The processing steps are carried out in the following order:

[0013] (1) Material preparation: Except for the straight tube E, which is welded by sheet metal rolling, the rest of the parts are forged; among them, the material of the welded part is 50#, the weld is double-sided groove welded, the welding line is even and full, and the weldment is tempered Stress relief treatment, welds need X-ray flaw detection, no welding defects such as pores, slag inclusions, undercuts, etc., the impact test and tensile test indicators at the welds must not be lower than the strength of the raw material; forgings are selected from Q345B, and no forging defects such as slag inclusions...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com