Device technology configuration method for treating house refuses by using rotary cement kiln

A cement rotary kiln and domestic waste technology, applied in cement production, etc., can solve problems such as complex components, and achieve the effects of simple incineration process, low investment, and air pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

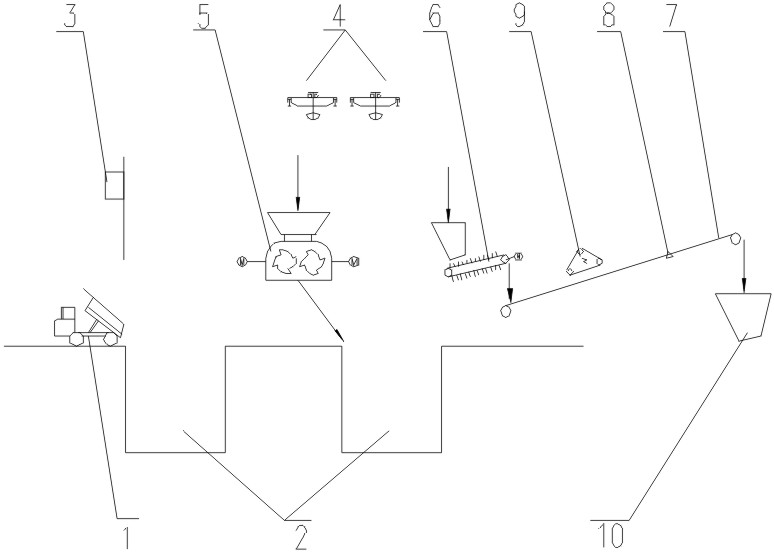

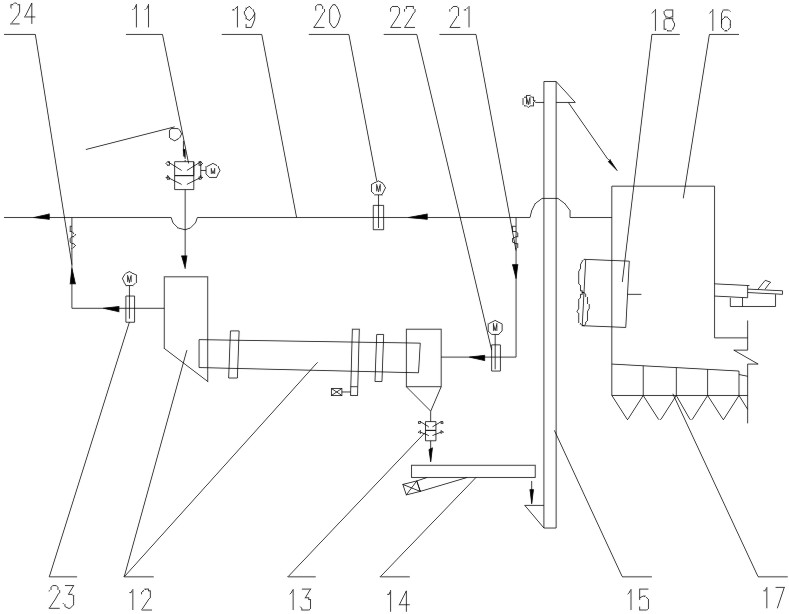

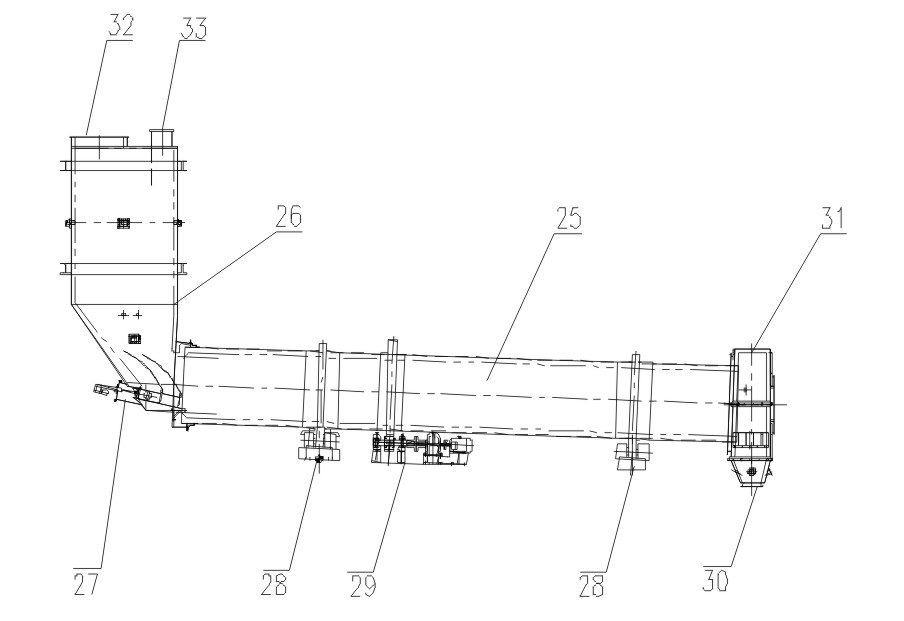

[0037] The equipment process configuration method of the present invention using cement rotary kiln to process household garbage includes a pretreatment equipment process configuration method and an incineration equipment process configuration method. The whole process of incineration is carried out for the treated domestic waste.

[0038] Due to the mixed collection of domestic waste in my country, the composition is complex, the size is different, the moisture is high, and the calorific value is low, which is not conducive to the incineration of domestic waste. Therefore, it is necessary to carry out the whole process of shredding and treatment of domestic waste before incineration, and the ultimate goal of the pretreatment equipment process configuration method is to carry out crushing and iron removal treatment on domestic waste.

[0039] combine figure 1 , the pretreatment equipment process configuration method is as follows:

[0040]After the domestic garbage is concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com