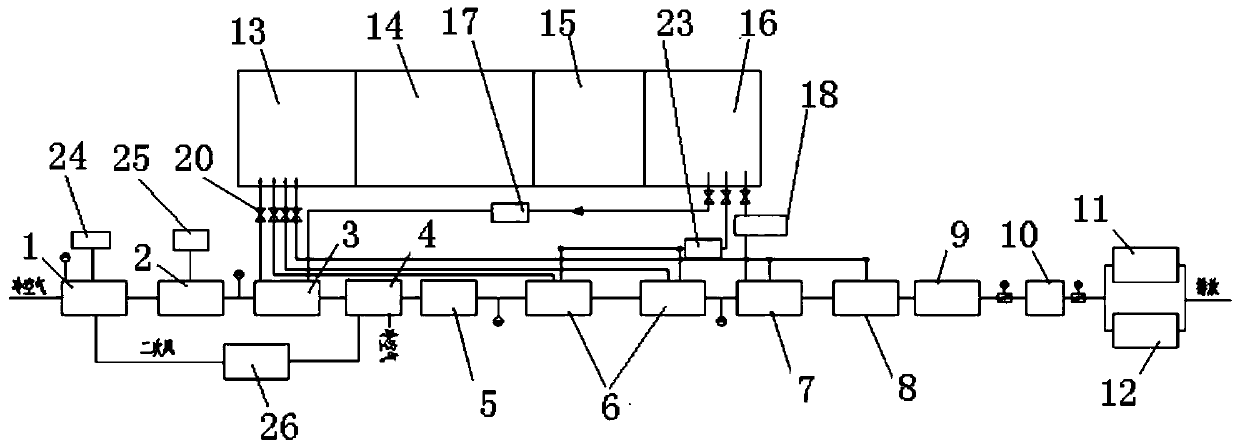

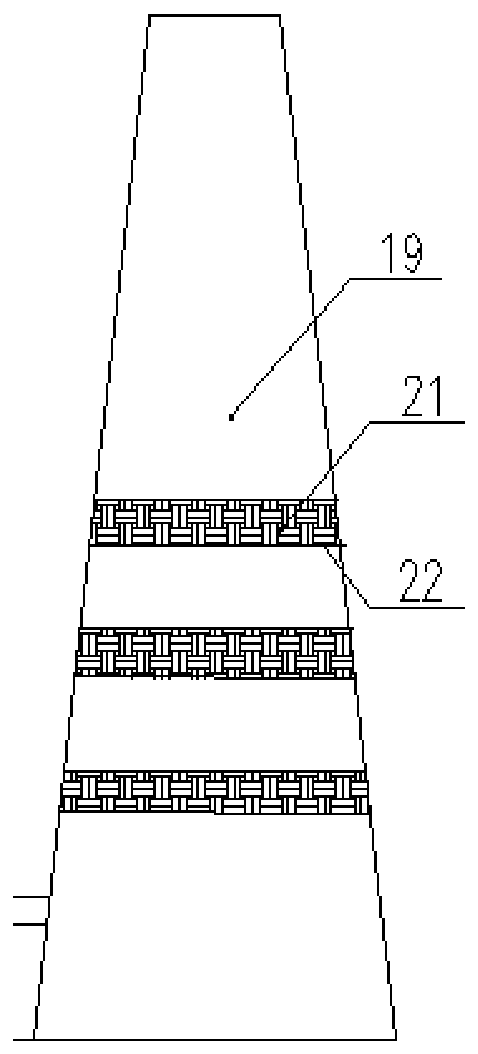

A small waste incineration tail gas treatment system and its treatment process

A technology of waste incineration and waste incinerator, which is applied in gas treatment, incinerator, combustion type, etc., can solve the problems of affecting the surrounding environmental quality, affecting the living environment of environmental safety and residents, and achieve the effect of improving efficiency and high purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The daily processing capacity is 12t, and the garbage is sent into the garbage incinerator manually after simple sorting. The whole set of equipment covers an area of 110 square meters, the actual temperature in the furnace is 900°C, and the combustion temperature of waste is 1100°C. SO 2 Concentration 310mg / m 3 , NO x Concentration 330mg / m 3 , particle concentration 250mg / m 3 . Dioxin concentration was not detected at 1m of the factory boundary, SO 2、 NO x Particulate matter was not detected.

[0051] The daily processing capacity is 5t, and the garbage is simply sorted and sent to the garbage incinerator through the conveyor. SO 2 Concentration 320mg / m 3 , NO x Concentration 360mg / m 3 , particle concentration 270mg / m 3 . Dioxin concentration was not detected at 1m of the factory boundary, SO 2、 NO x Particulate matter was not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com