Method for recycling lithium-ion battery positive electrode scraps

A technology of lithium-ion batteries and ion batteries, which is applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as unfavorable human health and inability to remove carbon, and achieve short process, low energy consumption, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

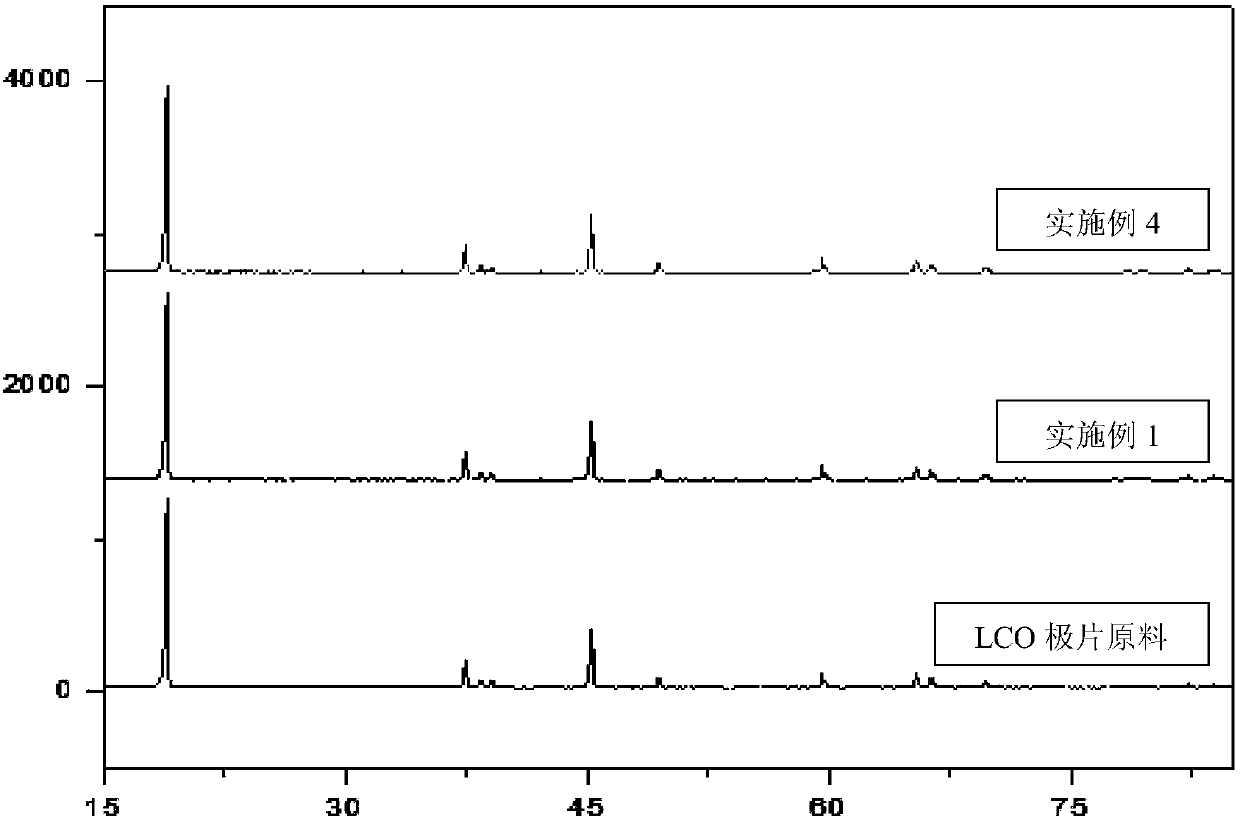

[0047]Take 50g of lithium cobaltate (LCO) positive electrode scraps and crush them with a pulverizer until the pieces are about 5mm in size. smash.

[0048] After filtering and drying the filter residue, sieve with a standard inspection sieve to obtain 8.0 g of positive electrode material powder collected under the sieve and aluminum particles remaining on the sieve.

[0049] Take 500mL of 2.0mol / L LiOH solution, wash and sieve the positive electrode material with this solution for 30min, then let it stand until the solution is clear, decant the upper layer and floating matter, filter the bottom slurry, wash the filter cake with water, filter and dry That is, 40.2 g of a qualified positive electrode material was obtained. The recycling process is shown in Figure 4 , the composition of the recovered positive electrode material and aluminum particles is shown in Table 1.

[0050] Table 1 Example 1 result

[0051]

Embodiment 2

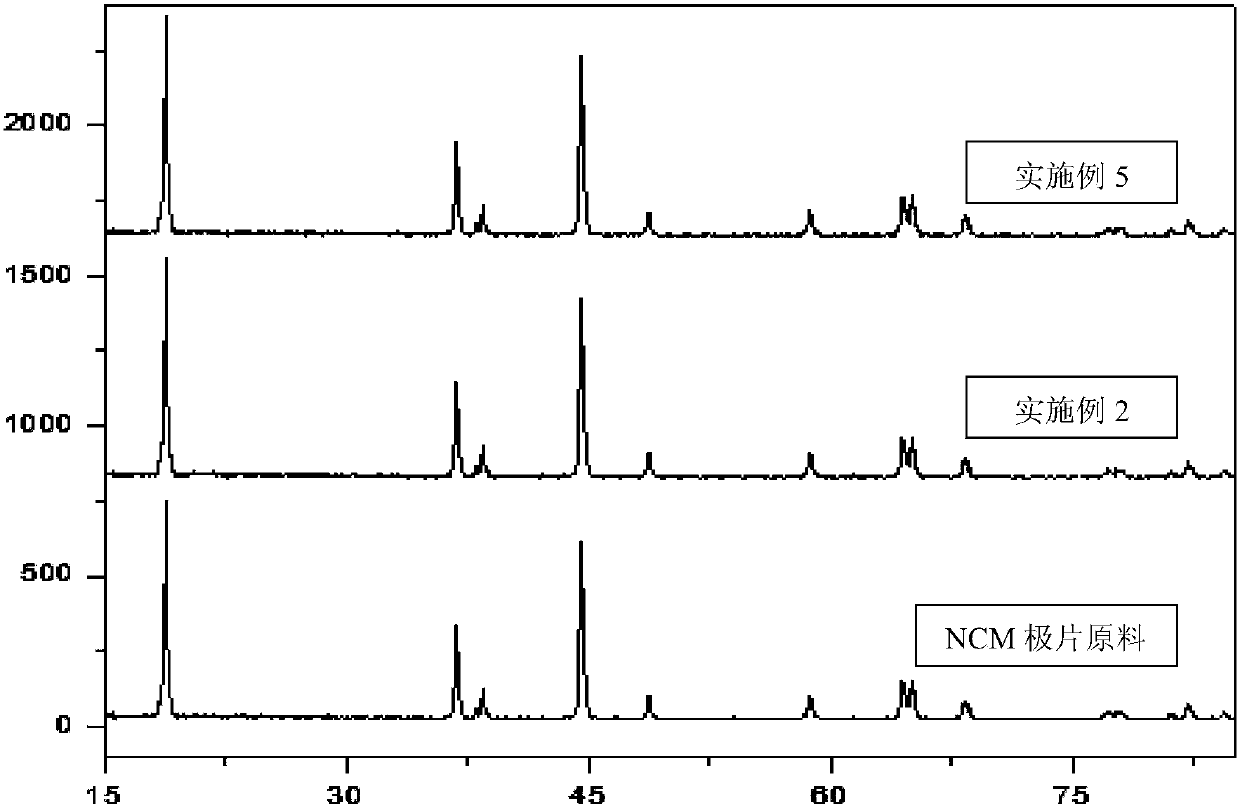

[0053] Take 50g of nickel-cobalt-manganese-manganate (NCM) positive electrode strip scraps and crush them with a pulverizer until the pieces are about 5mm in size, add ethanol to the pulverizer according to the ratio of alcohol to positive strip scraps at a mass ratio of 5:1, soak for 40min, and then fully smash.

[0054] After filtering and drying the filter residue, sieve with a standard inspection sieve to obtain 7.1 g of positive electrode material powder collected under the sieve and aluminum particles remaining on the sieve.

[0055] Take 500 mL of 1.5 mol / L NaOH solution, wash and sieve the positive electrode material with this solution for 30 minutes, then let it stand until the solution is clear, decant the upper layer and floating matter, filter the bottom slurry, wash the filter cake with water, filter and dry That is, 41.1 g of a qualified positive electrode material was obtained. The recycling process is shown in Figure 4 , the composition of the recovered posi...

Embodiment 3

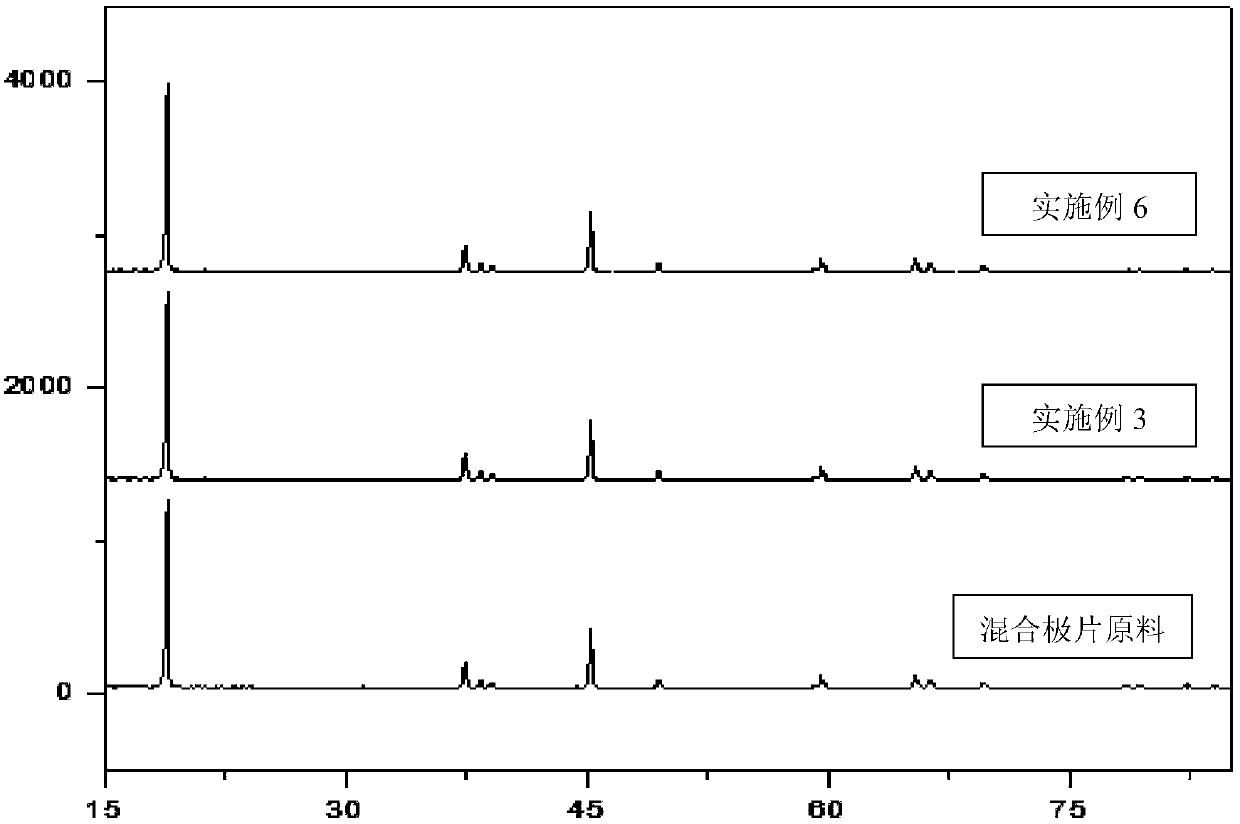

[0059] Take 50g of compound type (LCO:NCM=3:1) positive electrode scraps and crush them with a pulverizer until the pieces are about 5mm in size. Then fully pulverize.

[0060] After filtering and drying the filter residue, sieve with a standard inspection sieve to obtain 6.3g of positive electrode material powder collected under the sieve and aluminum particles left on the sieve.

[0061] Take 2.5mol / L of Na 2 CO 3 Solution 500mL, use this solution to wash the positive electrode material obtained by sieving for 30min, then let it stand until the solution is clear, decant the upper liquid and floating matter, filter the bottom slurry, wash the filter cake with water, filter and dry to obtain a qualified positive electrode material 42.5 g. The recycling process is shown in Figure 4 , the composition of the recovered positive electrode material and aluminum particles is shown in Table 3.

[0062] Table 3 Example 3 results

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com