Novel full-function double-drying high-position electric control washing machine (without any impeller, drum and dehydration drum)

The technology of washing machine and throwing bucket is applied in the field of full-function double-drying high-level electric-controlled new-type washing machine, which can solve the problems of single basic washing method, inability to adapt to washing needs, and long washing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

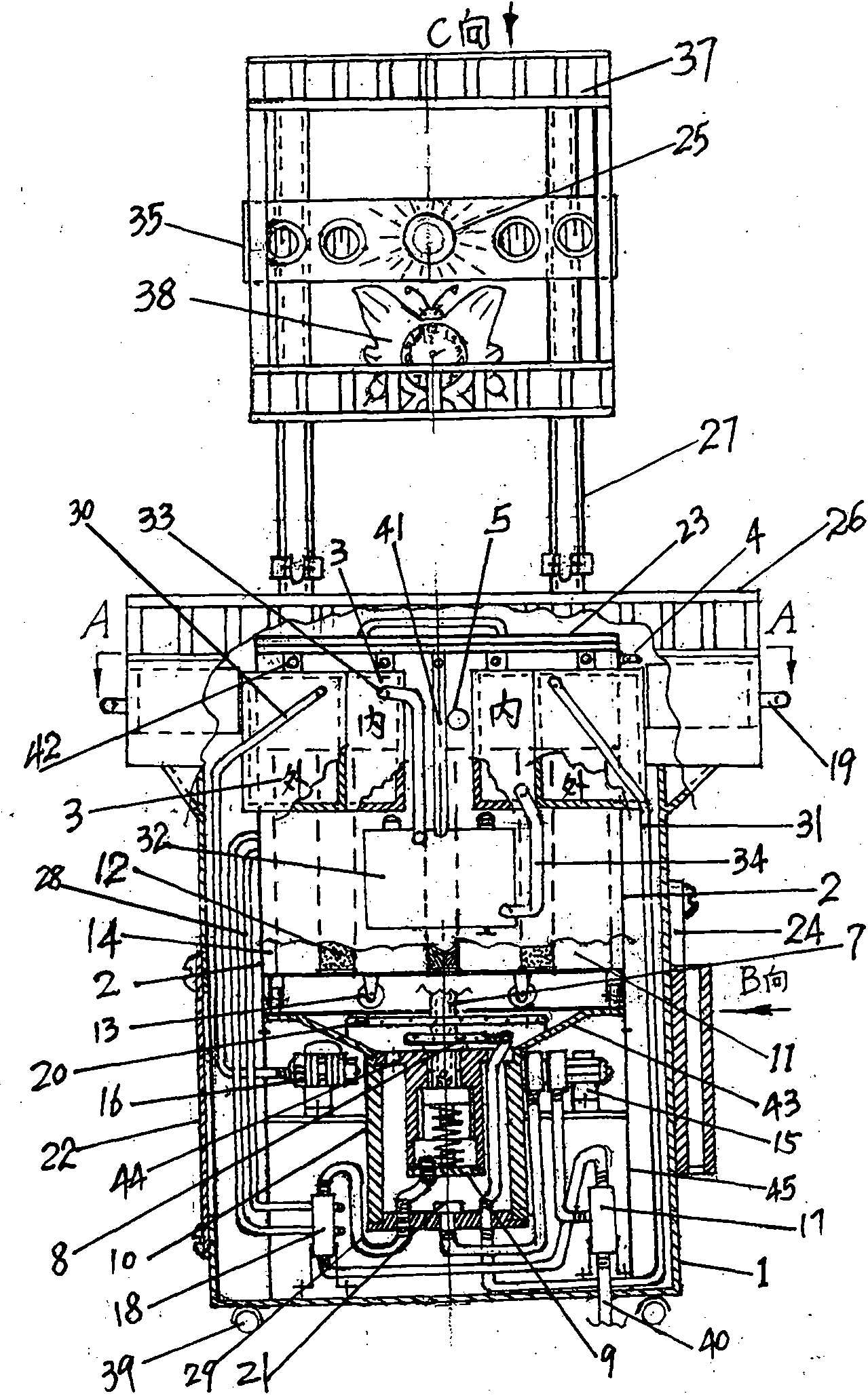

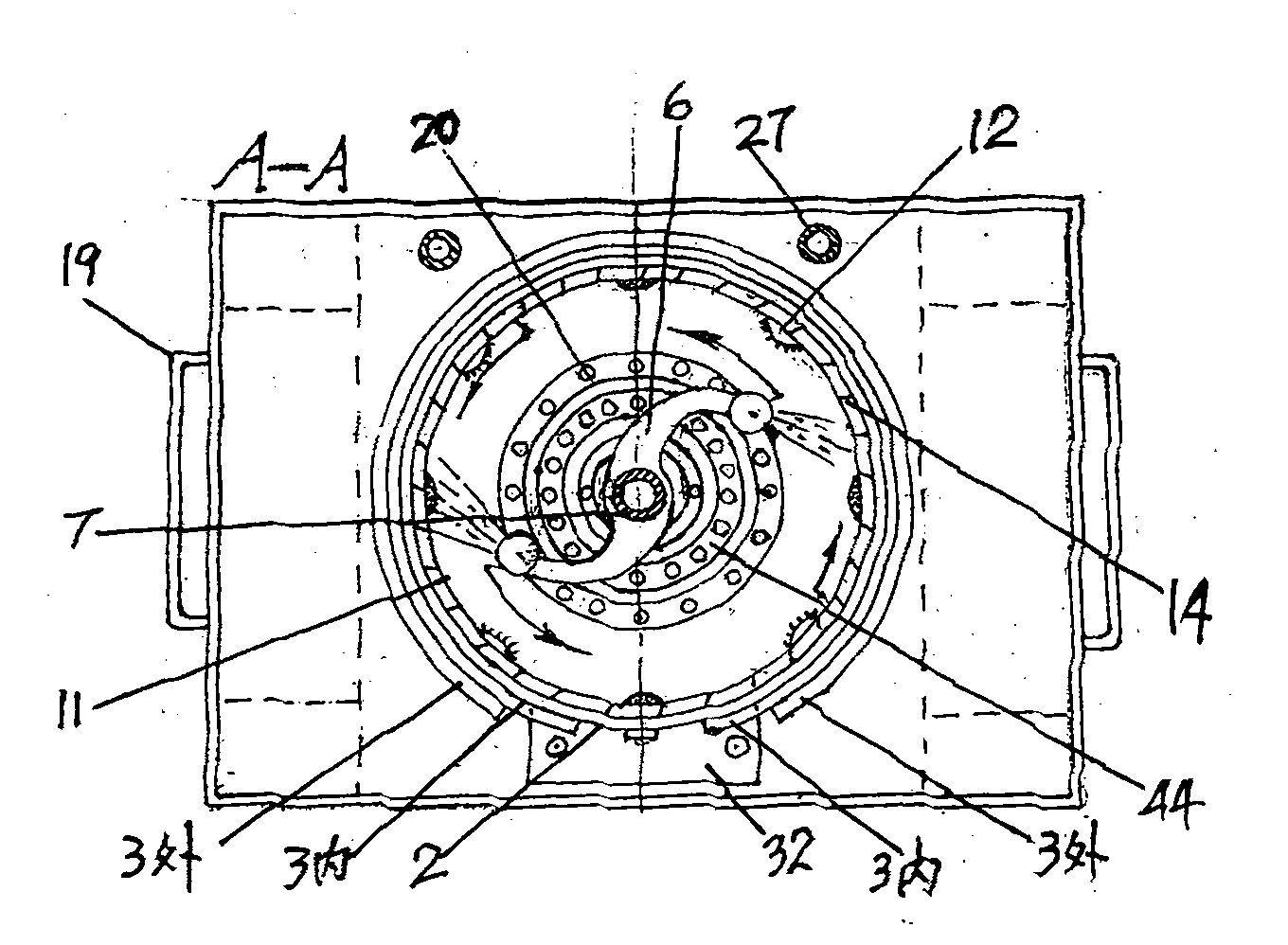

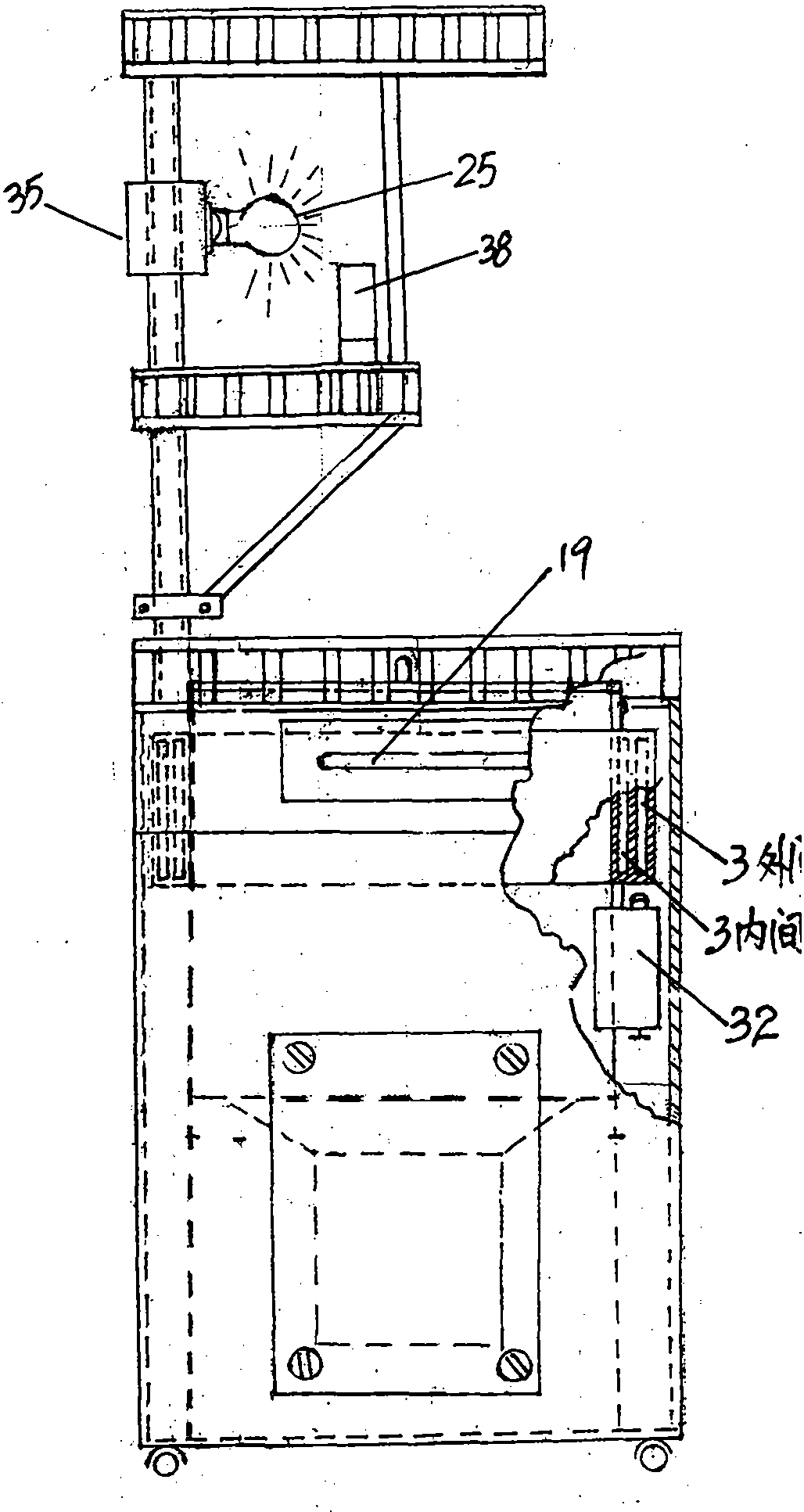

[0052] The overall structure of this new washing machine is relatively simple. Due to its small size, complete functions, high technical content, and wide range of clothing, it looks a bit complicated. The materials are mainly metal sheet parts and pipe fittings, and the processing methods are welding and stamping. , Cut sheet, roll sheet, fitter, car, 铇 and other common simple processes. No need for sophisticated difficult processes and rare special materials.

[0053] Here is a key reminder of the processing procedures (processes) of several main parts and components, and it must be clearly understood that the "washing tub (barrel)" mentioned here is the "dehydration jar (barrel)" and the "drying jar (barrel)". ", any one cylinder can support three cylinders, saving time, labor, materials and land.

[0054] When processing the laundry tub 2, select a stainless steel sheet of about 1.2-1.5, cut the sheet according to the design size, roll it into a tube on the sheet rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com